oil filter CHRYSLER VOYAGER 2004 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1895 of 2585

(27) Lower engine/transaxle assembly with screw

jack. (28) Obtain helper and/or transmission jack.

Secure transmission jack to transaxle assembly. (29) Remove upper mount bracket from transaxle

(Fig. 14). (30) Remove remaining transaxle bellhousing-to-

engine bolts. (31) Remove transaxle assembly from vehicle.

DISASSEMBLY

NOTE: If transaxle is being overhauled (clutch

and/or seal replacement) or replaced, it is neces-

sary to perform the PCM/TCM Quick Learn Proce-

dure. (Refer t o 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/POWERTRAIN/TRANSMIS-

SION CONTROL MODULE - STANDARD PROCE-

DURE)

NOTE: This procedure does not include final drive

(differential) disassembly.

(1) Remove input and output speed sensors.

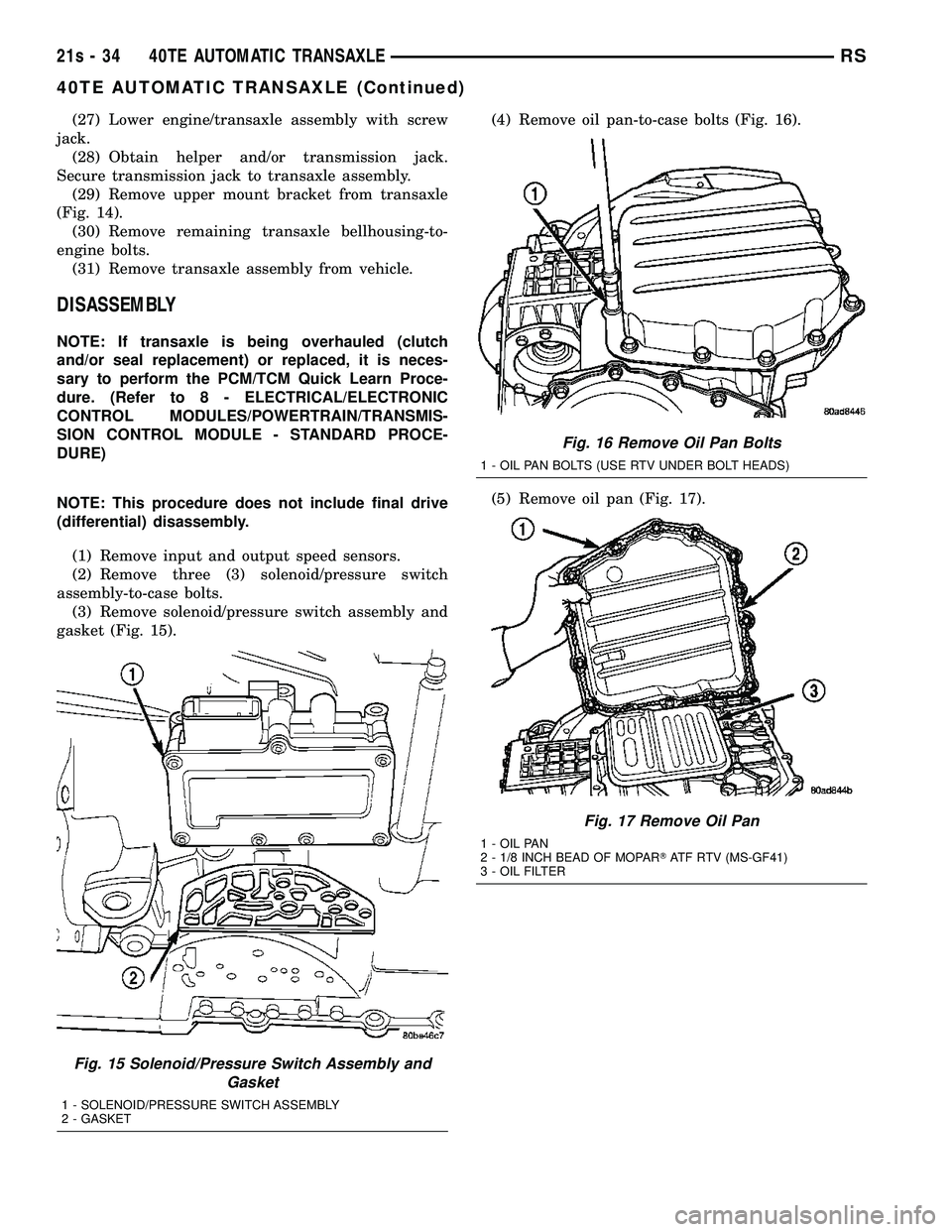

(2) Remove three (3) solenoid/pressure switch

assembly-to-case bolts. (3) Remove solenoid/pressure switch assembly and

gasket (Fig. 15). (4) Remove oil pan-to-case bolts (Fig. 16).

(5) Remove oil pan (Fig. 17).

Fig. 15 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 16 Remove Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 17 Remove Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF MOPAR TATF RTV (MS-GF41)

3 - OIL FILTER

21s - 34 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1896 of 2585

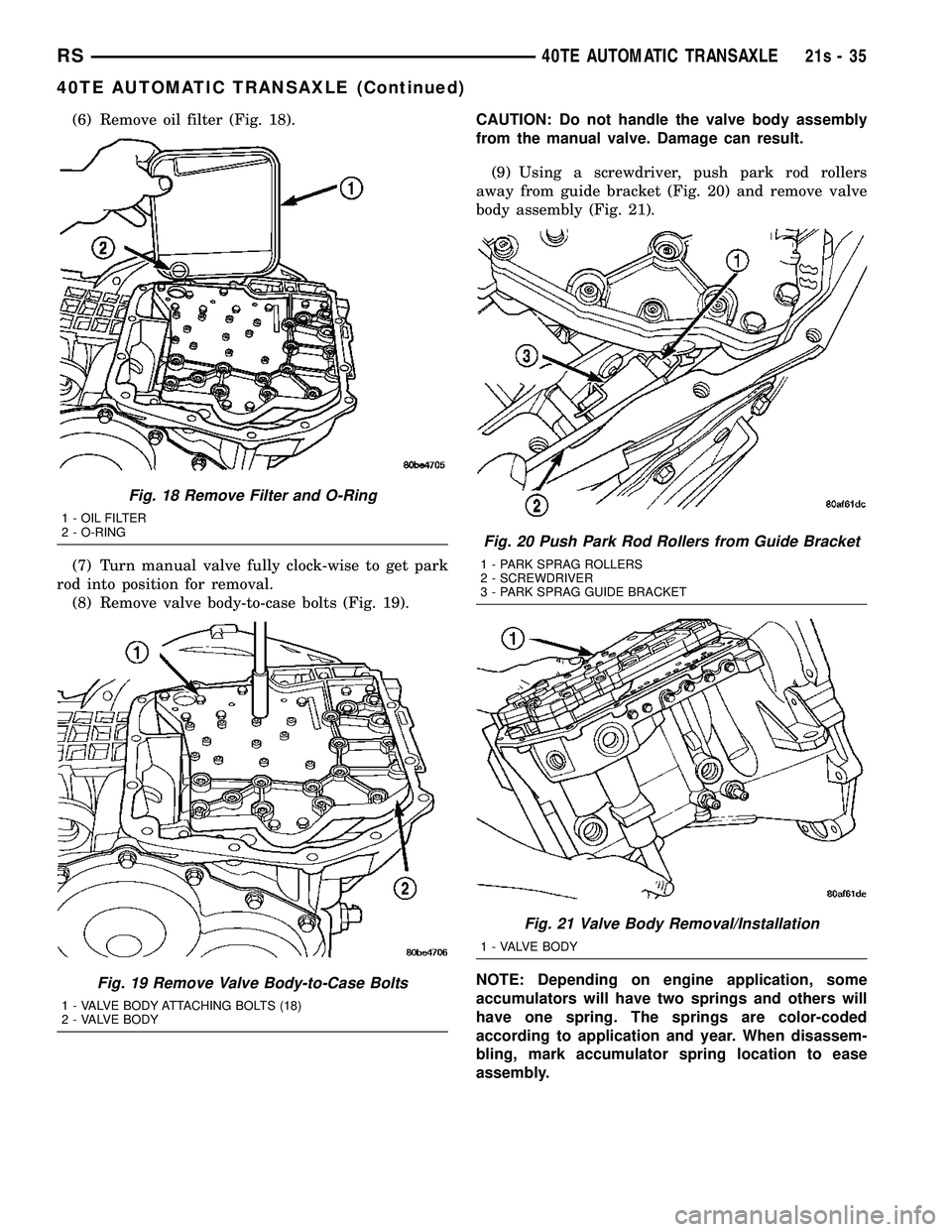

(6) Remove oil filter (Fig. 18).

(7) Turn manual valve fully clock-wise to get park

rod into position for removal. (8) Remove valve body-to-case bolts (Fig. 19). CAUTION: Do not handle the valve body assembly

from the manual valve. Damage can result.

(9) Using a screwdriver, push park rod rollers

away from guide bracket (Fig. 20) and remove valve

body assembly (Fig. 21).

NOTE: Depending on engine application, some

accumulators will have two springs and others will

have one spring. The springs are color-coded

according to application and year. When disassem-

bling, mark accumulator spring location to ease

assembly.

Fig. 18 Remove Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 19 Remove Valve Body-to-Case Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

Fig. 20 Push Park Rod Rollers from Guide Bracket

1 - PARK SPRAG ROLLERS

2 - SCREWDRIVER

3 - PARK SPRAG GUIDE BRACKET

Fig. 21 Valve Body Removal/Installation

1 - VALVE BODY

RS 40TE AUTOMATIC TRANSAXLE21s-35

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1933 of 2585

(65) Install oil filter and new o-ring (Fig. 155).

(66) Apply an 1/8º bead of MopartATF RTV (MS-

GF41) to oil pan and immediately install to case (Fig.

156).

(67) Install oil pan-to-case bolts and torque to 19

N´m (165 in. lbs.). (68) Install solenoid/pressure switch assembly and

gasket to case (Fig. 157). (69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 158).

(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

Fig. 155 Install Oil Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 156 Install Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF MOPAR TATF RTV (MS-GF41)

3 - OIL FILTER

Fig. 157 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 158 Attaching Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

21s - 72 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1965 of 2585

STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

NOTE: Only fluids of the type labeled MoparTATF+4

should be used. A filter change should be made at

the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned

with a clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

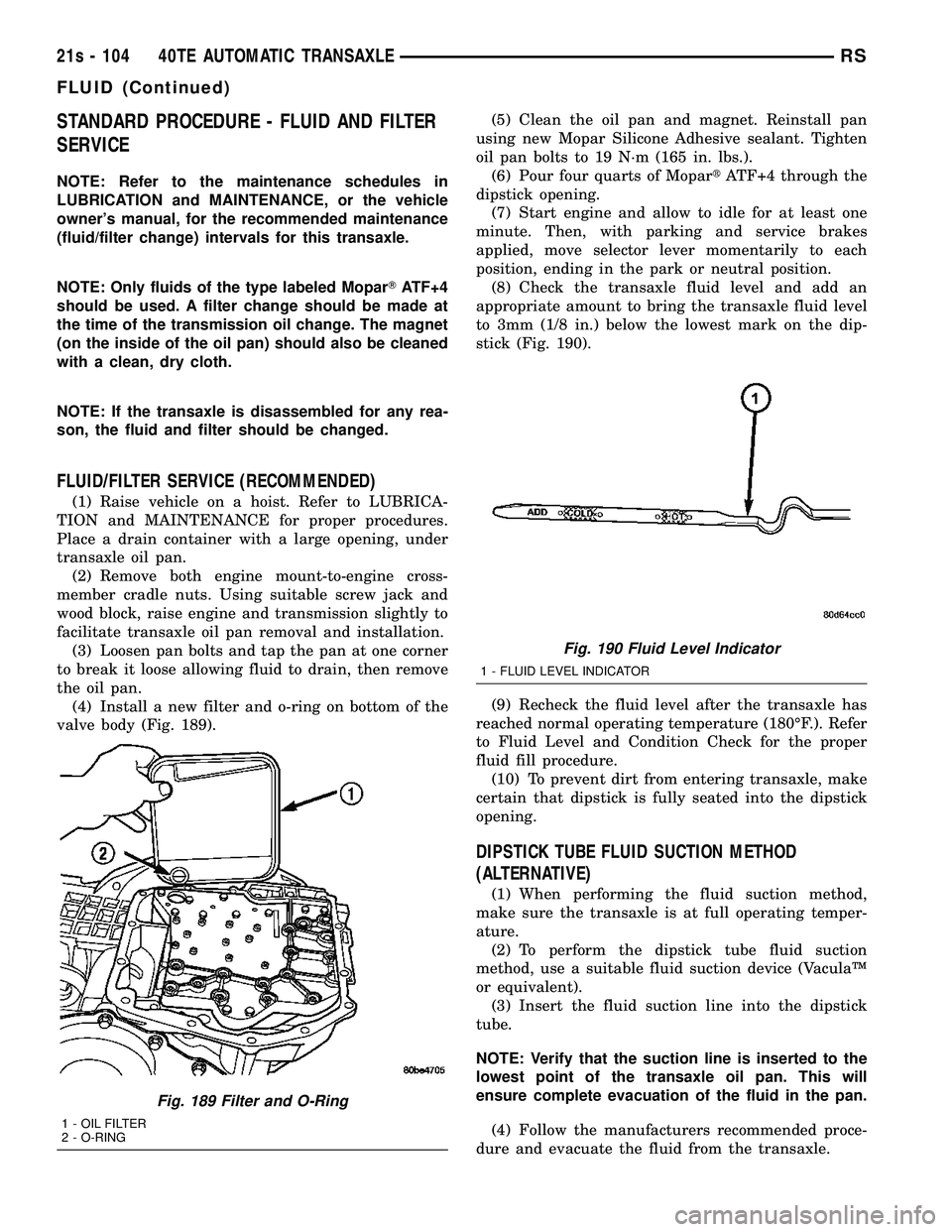

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Refer to LUBRICA-

TION and MAINTENANCE for proper procedures.

Place a drain container with a large opening, under

transaxle oil pan. (2) Remove both engine mount-to-engine cross-

member cradle nuts. Using suitable screw jack and

wood block, raise engine and transmission slightly to

facilitate transaxle oil pan removal and installation. (3) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan. (4) Install a new filter and o-ring on bottom of the

valve body (Fig. 189). (5) Clean the oil pan and magnet. Reinstall pan

using new Mopar Silicone Adhesive sealant. Tighten

oil pan bolts to 19 N´m (165 in. lbs.). (6) Pour four quarts of Mopar tATF+4 through the

dipstick opening. (7) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position. (8) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the lowest mark on the dip-

stick (Fig. 190).

(9) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.). Refer

to Fluid Level and Condition Check for the proper

fluid fill procedure. (10) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

DIPSTICK TUBE FLUID SUCTION METHOD

(ALTERNATIVE)

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature. (2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (VaculaŸ

or equivalent). (3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

Fig. 189 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 190 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21s - 104 40TE AUTOMATIC TRANSAXLERS

FLUID (Continued)

Page 2014 of 2585

SOLENOID SWITCH VALVE

The solenoid switch valve controls line pressure

from the LR/CC solenoid. In one position, it allows

the low/reverse clutch to be pressurized. In the other,

it directs line pressure to the converter control and

converter clutch valves.

MANUAL VALVE

The manual valve is operated by the mechanical

shift linkage. Its primary responsibility is to send

line pressure to the appropriate hydraulic circuits

and solenoids. The valve has three operating ranges

or positions.

CONVERTER CLUTCH SWITCH VALVE

The main responsibility of the converter clutch

switch valve is to control hydraulic pressure applied

to the front (off) side of the converter clutch piston.

Line pressure from the regulator valve is fed to the

torque converter regulator valve, where it passes

through the valve, and is slightly regulated. The

pressure is then directed to the converter clutch

switch valve and to the front side of the converter

clutch piston. This pressure pushes the piston back

and disengages the converter clutch.

CONVERTER CLUTCH CONTROL VALVE

The converter clutch control valve controls the

back (on) side of the torque converter clutch. When

the PCM/TCM energizes or modulates the LR/CC

solenoid to apply the converter clutch piston, both

the converter clutch control valve and the converter

control valve move, allowing pressure to be applied to

the back side of the clutch.

T/C REGULATOR VALVE

The torque converter regulator valve slightly regu-

lates the flow of fluid to the torque converter.

LOW/REVERSE SWITCH VALVE

The low/reverse clutch is applied from different

sources, depending on whether low (1st) gear or

reverse is selected. The low/reverse switch valve

alternates positions depending on from which direc-

tion fluid pressure is applied. By design, when the

valve is shifted by fluid pressure from one channel,

the opposing channel is blocked. The switch valve

alienates the possibility of a sticking ball check, thus

providing consistent application of the low/reverse

clutch under all operating conditions.

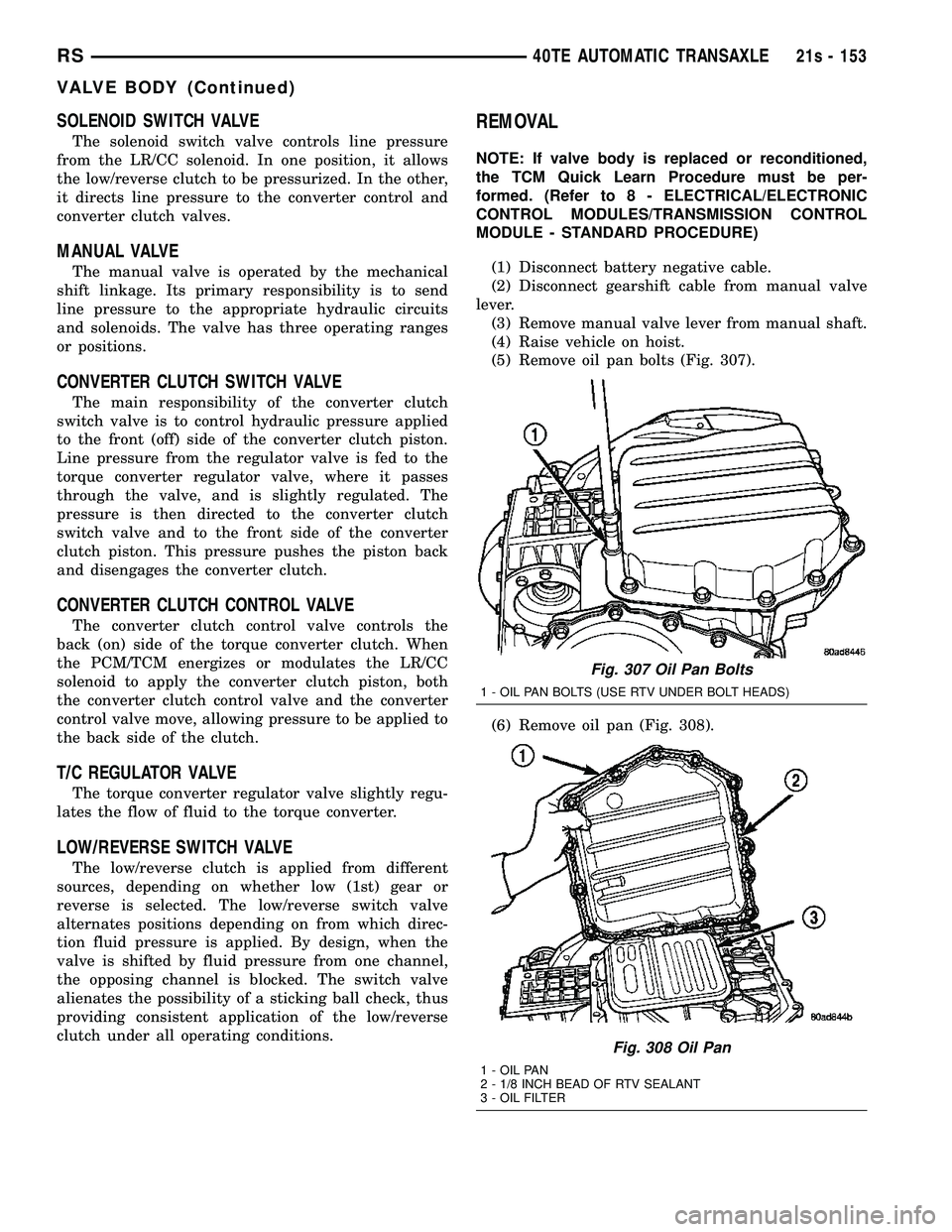

REMOVAL

NOTE: If valve body is replaced or reconditioned,

the TCM Quick Learn Procedure must be per-

formed. (Refer t o 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

(1) Disconnect battery negative cable.

(2) Disconnect gearshift cable from manual valve

lever. (3) Remove manual valve lever from manual shaft.

(4) Raise vehicle on hoist.

(5) Remove oil pan bolts (Fig. 307).

(6) Remove oil pan (Fig. 308).

Fig. 307 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 308 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

RS 40TE AUTOMATIC TRANSAXLE21s - 153

VALVE BODY (Continued)

Page 2015 of 2585

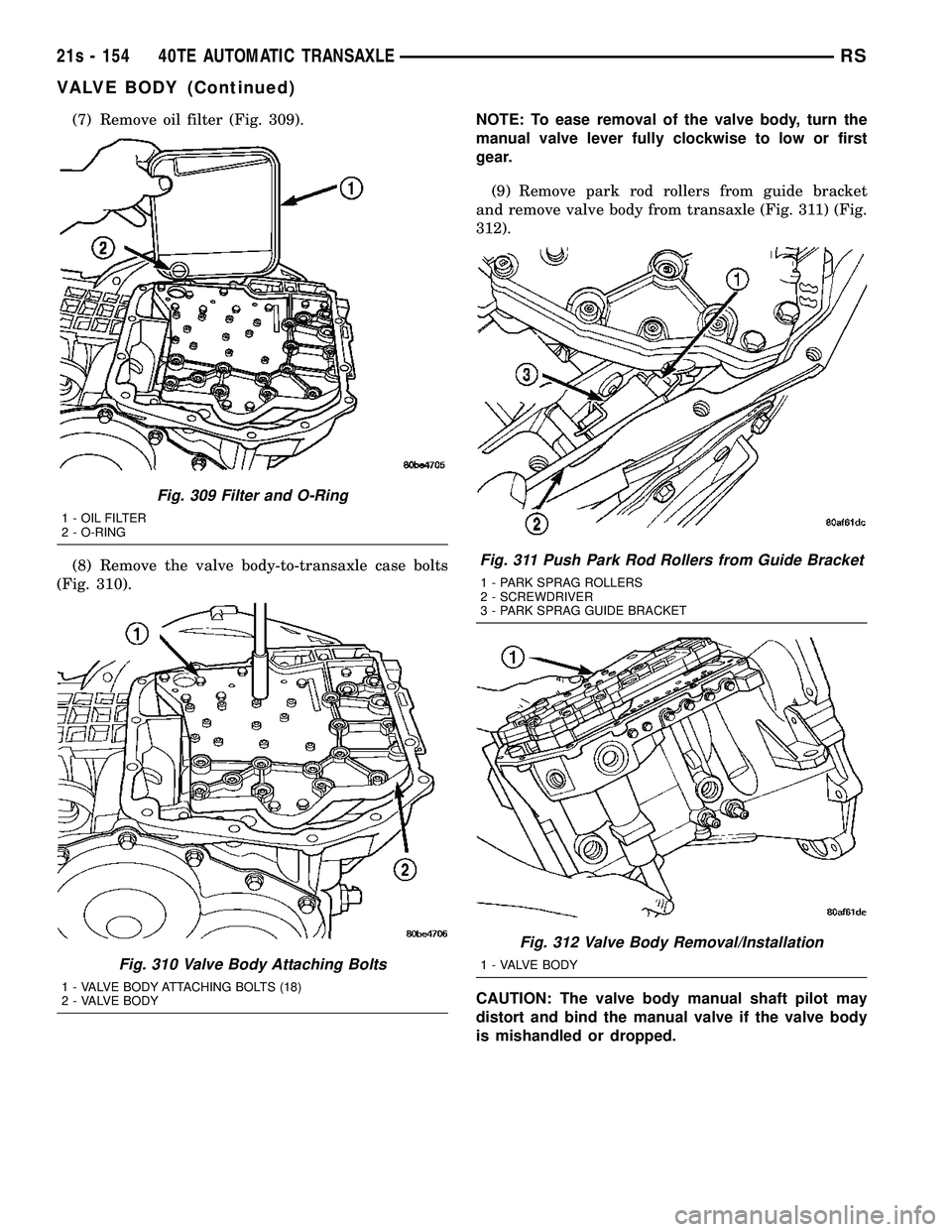

(7) Remove oil filter (Fig. 309).

(8) Remove the valve body-to-transaxle case bolts

(Fig. 310). NOTE: To ease removal of the valve body, turn the

manual valve lever fully clockwise to low or first

gear.

(9) Remove park rod rollers from guide bracket

and remove valve body from transaxle (Fig. 311) (Fig.

312).

CAUTION: The valve body manual shaft pilot may

distort and bind the manual valve if the valve body

is mishandled or dropped.

Fig. 309 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

Fig. 310 Valve Body Attaching Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

Fig. 311 Push Park Rod Rollers from Guide Bracket

1 - PARK SPRAG ROLLERS

2 - SCREWDRIVER

3 - PARK SPRAG GUIDE BRACKET

Fig. 312 Valve Body Removal/Installation

1 - VALVE BODY

21s - 154 40TE AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

Page 2025 of 2585

(16) Install manual shaft seal (Fig. 343).

INSTALLATION

NOTE: If valve body assembly is being replaced or

reconditioned, it is necessary to perform the TCM

Quick Learn Procedure. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Install valve body assembly to transaxle (Fig.

344). Install and torque valve body-to-transaxle case

bolts (Fig. 345) to 12 N´m (105 in. lbs.). (2) Install transaxle oil filter (Fig. 346). Inspect

the o-ring and replace if necessary.

Fig. 343 Manual Shaft Seal

1 - SEAL

2 - MANUAL SHAFT

Fig. 344 Valve Body Removal/Installation

1 - VALVE BODY

Fig. 345 Valve Body Attaching Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

Fig. 346 Filter and O-Ring

1 - OIL FILTER

2 - O-RING

21s - 164 40TE AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

Page 2026 of 2585

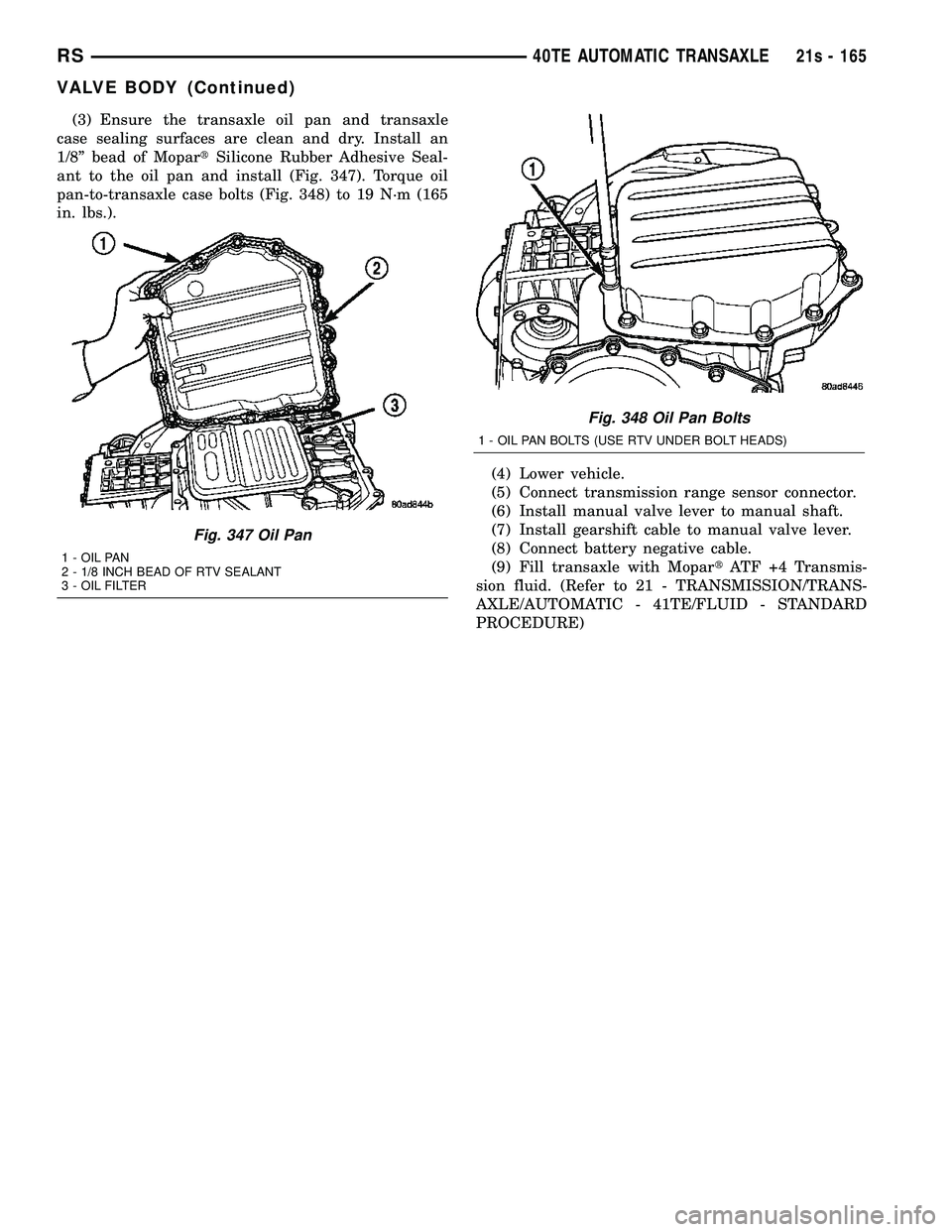

(3) Ensure the transaxle oil pan and transaxle

case sealing surfaces are clean and dry. Install an

1/8º bead of Mopar tSilicone Rubber Adhesive Seal-

ant to the oil pan and install (Fig. 347). Torque oil

pan-to-transaxle case bolts (Fig. 348) to 19 N´m (165

in. lbs.).

(4) Lower vehicle.

(5) Connect transmission range sensor connector.

(6) Install manual valve lever to manual shaft.

(7) Install gearshift cable to manual valve lever.

(8) Connect battery negative cable.

(9) Fill transaxle with MopartATF +4 Transmis-

sion fluid. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE/FLUID - STANDARD

PROCEDURE)

Fig. 348 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 347 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

RS 40TE AUTOMATIC TRANSAXLE21s - 165

VALVE BODY (Continued)

Page 2028 of 2585

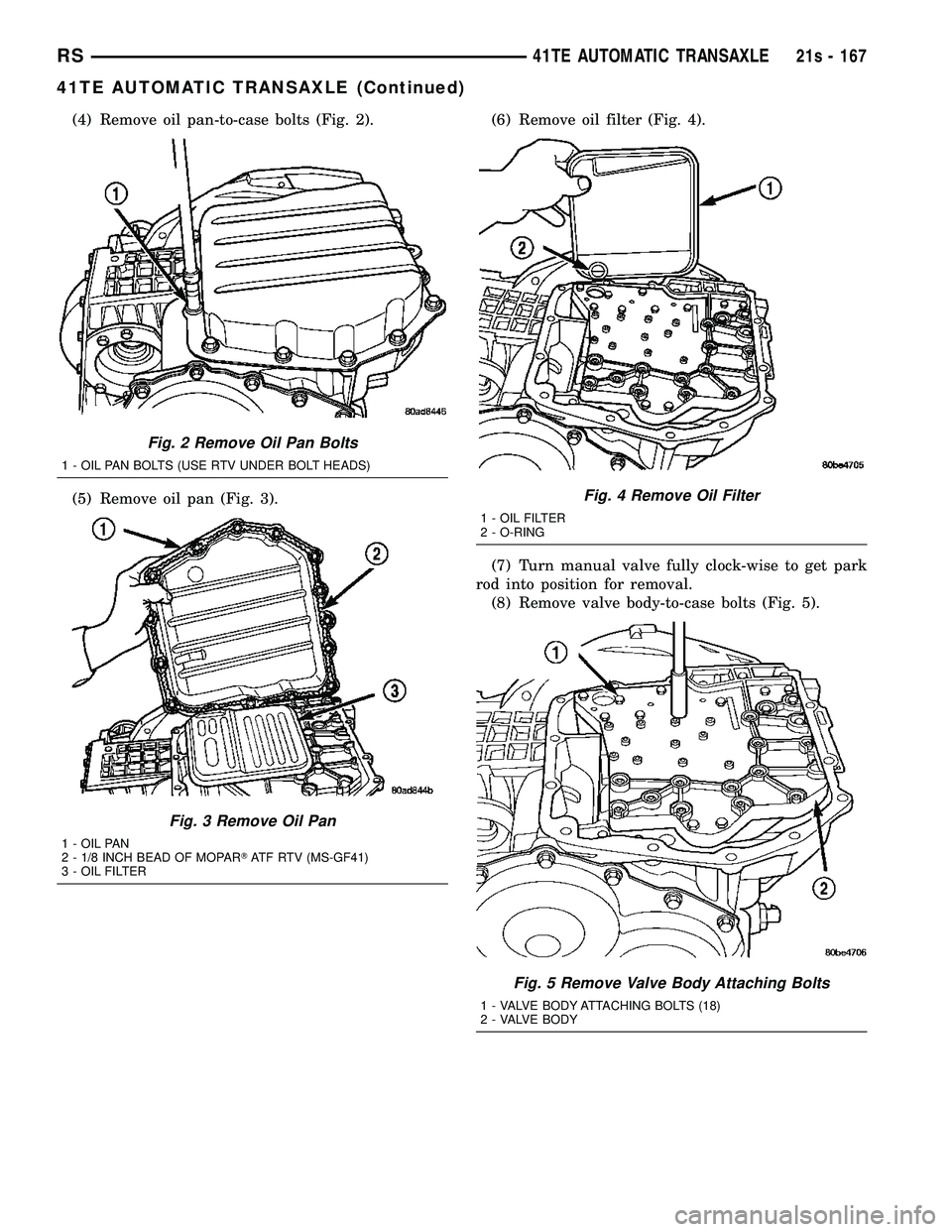

(4) Remove oil pan-to-case bolts (Fig. 2).

(5) Remove oil pan (Fig. 3).(6) Remove oil filter (Fig. 4).

(7) Turn manual valve fully clock-wise to get park

rod into position for removal. (8) Remove valve body-to-case bolts (Fig. 5).

Fig. 2 Remove Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 3 Remove Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF MOPAR TATF RTV (MS-GF41)

3 - OIL FILTER

Fig. 4 Remove Oil Filter

1 - OIL FILTER

2 - O-RING

Fig. 5 Remove Valve Body Attaching Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

RS 41TE AUTOMATIC TRANSAXLE21s - 167

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2066 of 2585

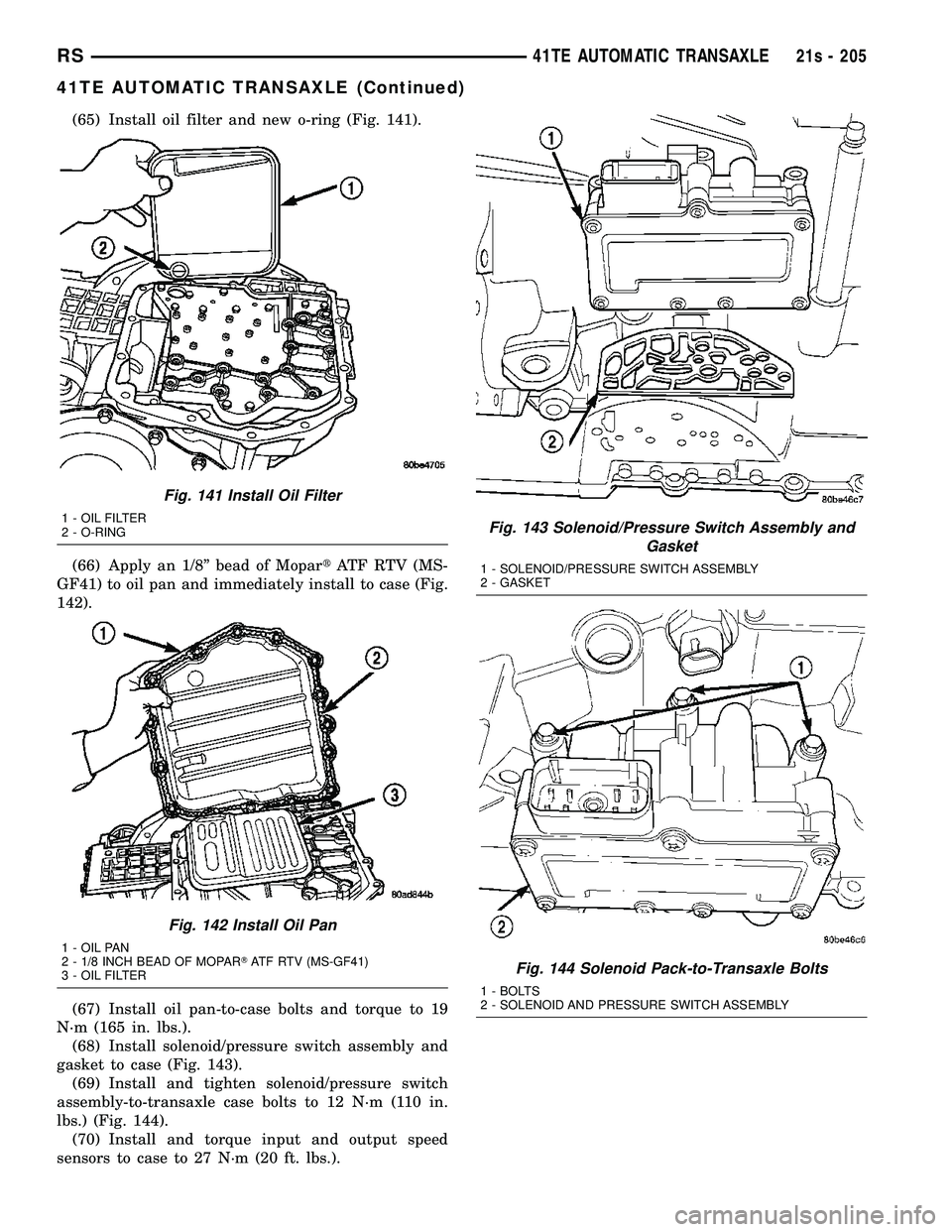

(65) Install oil filter and new o-ring (Fig. 141).

(66) Apply an 1/8º bead of MopartATF RTV (MS-

GF41) to oil pan and immediately install to case (Fig.

142).

(67) Install oil pan-to-case bolts and torque to 19

N´m (165 in. lbs.). (68) Install solenoid/pressure switch assembly and

gasket to case (Fig. 143). (69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 144). (70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

Fig. 141 Install Oil Filter

1 - OIL FILTER

2 - O-RING

Fig. 142 Install Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF MOPAR TATF RTV (MS-GF41)

3 - OIL FILTER

Fig. 143 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 144 Solenoid Pack-to-Transaxle Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

RS 41TE AUTOMATIC TRANSAXLE21s - 205

41TE AUTOMATIC TRANSAXLE (Continued)