warning CHRYSLER VOYAGER 2004 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 505 of 2585

(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.

If the system is still inoperative proceed with check-

ing remaining components.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

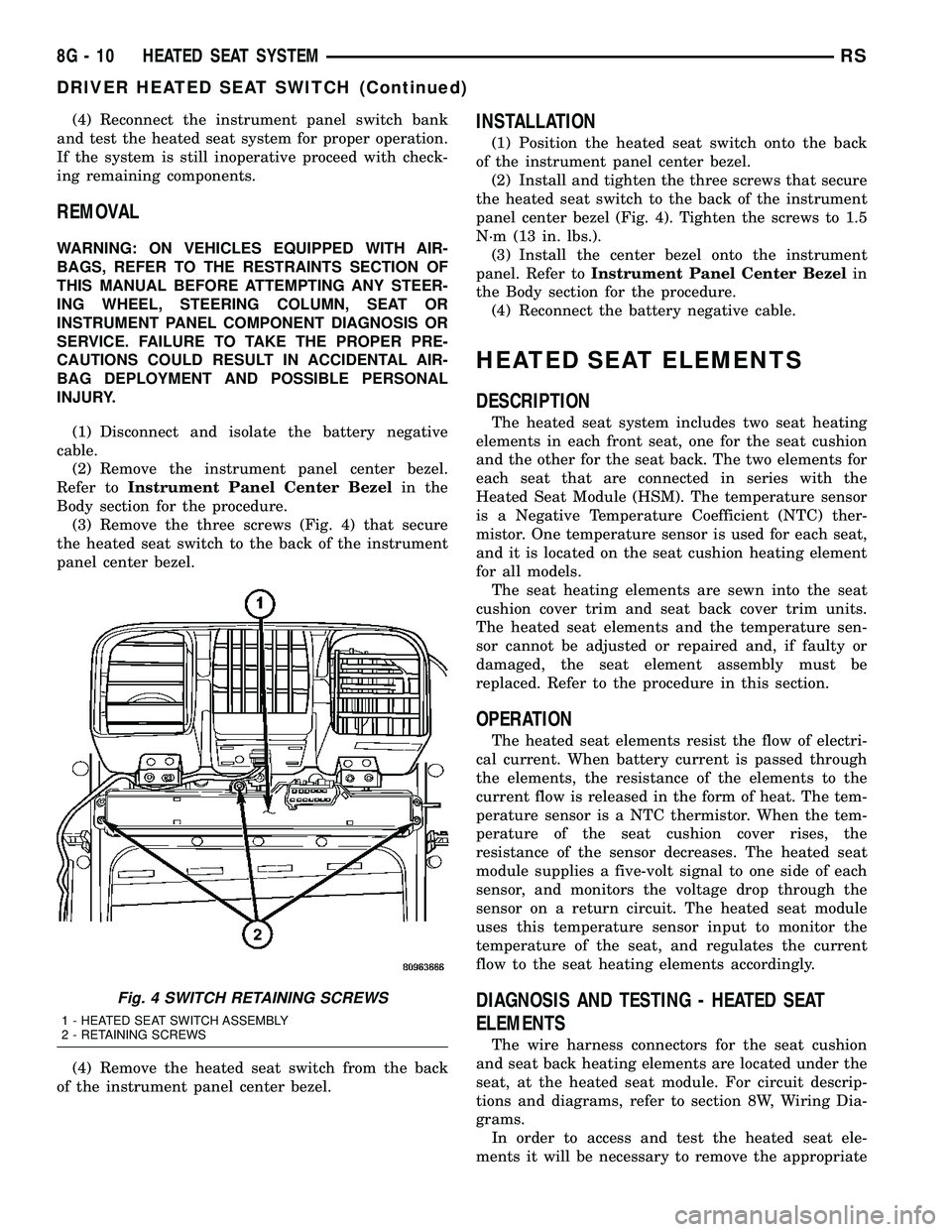

(3) Remove the three screws (Fig. 4) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrument

panel center bezel (Fig. 4). Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.

(4) Reconnect the battery negative cable.

HEATED SEAT ELEMENTS

DESCRIPTION

The heated seat system includes two seat heating

elements in each front seat, one for the seat cushion

and the other for the seat back. The two elements for

each seat that are connected in series with the

Heated Seat Module (HSM). The temperature sensor

is a Negative Temperature Coefficient (NTC) ther-

mistor. One temperature sensor is used for each seat,

and it is located on the seat cushion heating element

for all models.

The seat heating elements are sewn into the seat

cushion cover trim and seat back cover trim units.

The heated seat elements and the temperature sen-

sor cannot be adjusted or repaired and, if faulty or

damaged, the seat element assembly must be

replaced. Refer to the procedure in this section.

OPERATION

The heated seat elements resist the flow of electri-

cal current. When battery current is passed through

the elements, the resistance of the elements to the

current flow is released in the form of heat. The tem-

perature sensor is a NTC thermistor. When the tem-

perature of the seat cushion cover rises, the

resistance of the sensor decreases. The heated seat

module supplies a five-volt signal to one side of each

sensor, and monitors the voltage drop through the

sensor on a return circuit. The heated seat module

uses this temperature sensor input to monitor the

temperature of the seat, and regulates the current

flow to the seat heating elements accordingly.

DIAGNOSIS AND TESTING - HEATED SEAT

ELEMENTS

The wire harness connectors for the seat cushion

and seat back heating elements are located under the

seat, at the heated seat module. For circuit descrip-

tions and diagrams, refer to section 8W, Wiring Dia-

grams.

In order to access and test the heated seat ele-

ments it will be necessary to remove the appropriate

Fig. 4 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 10 HEATED SEAT SYSTEMRS

DRIVER HEATED SEAT SWITCH (Continued)

Page 508 of 2585

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS AND TESTING - PASSENGER

HEATED SEAT SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.

(3) Reconnect the negative battery cable and Turn

heated seat ON in the LO position. Using an Ohm-

meter, check the resistance between cavities 2 and 3

of the gray connector noted above. Resistance should

be about 3.5 kiloohms (3500 ohms). If not OK, check

resistance directly at switch, as noted below. If OK,

proceed. If NOT OK replace the switch or faulty wir-

ing.

(4) Turn heated seat ON in the HI position. Using

an Ohmmeter, check the resistance between cavities

2 and 3 of the gray connector noted above. Resistance

should be about 1.4 kiloohms (1400 ohms). If not OK,

check resistance directly at switch, as noted below. If

OK, proceed. If NOT OK replace the switch or faulty

wiring.

(5) With the system ON in the HI position, Check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

NOT OK, repair open or wiring short.

CHECKING SWITCH ONLY

(1) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL). Check for continuity between the

ground circuit cavity (#10) of the instrument panel

switch bank electrical connector and a good ground.There should be continuity. If OK, go to Step 2. If not

OK, repair the open ground circuit to ground as

required.

(2) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel switch bank con-

nector (#4). If OK, turn the ignition switch to the Off

position, and go to Step 3. If not OK, repair the open

fused ignition switch output (run) circuit as required.

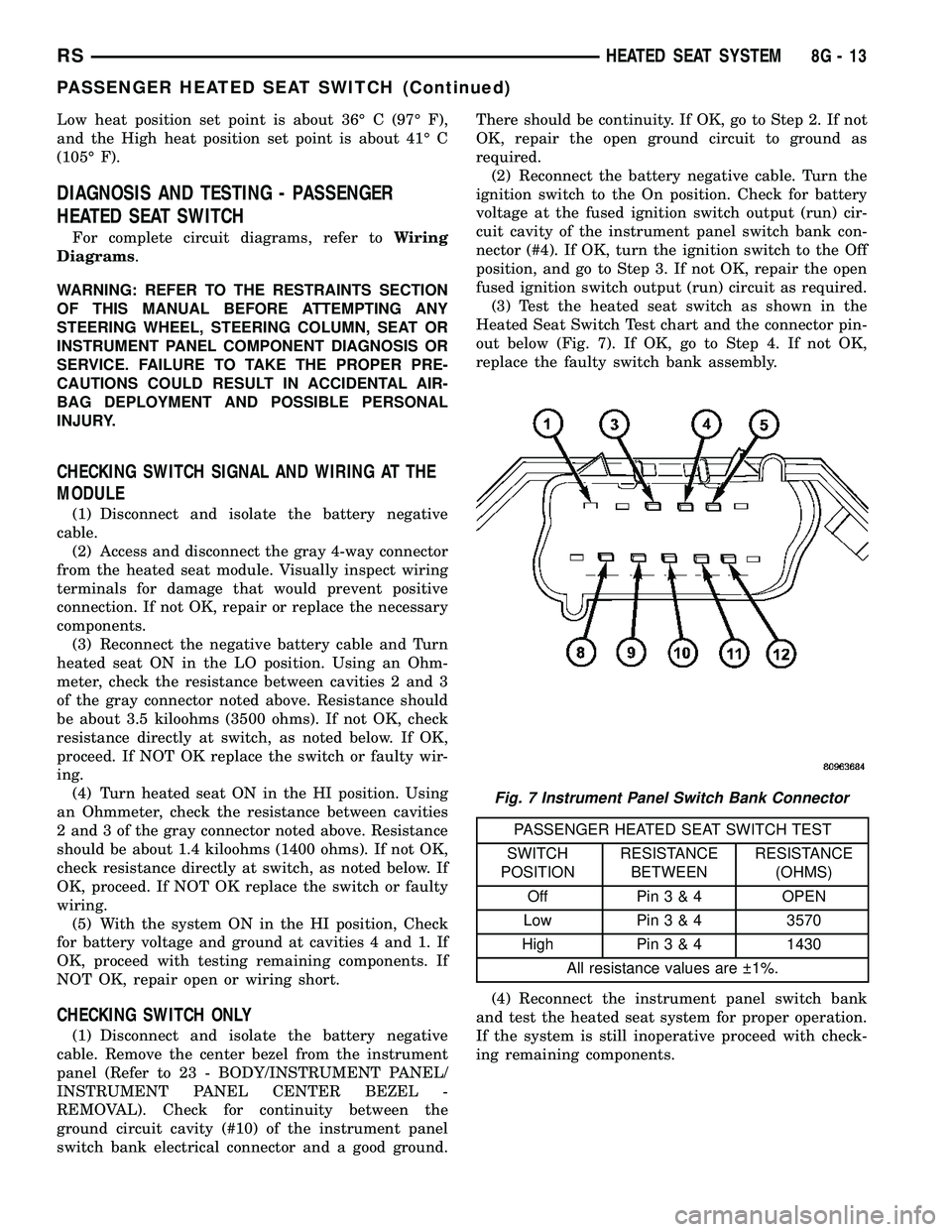

(3) Test the heated seat switch as shown in the

Heated Seat Switch Test chart and the connector pin-

out below (Fig. 7). If OK, go to Step 4. If not OK,

replace the faulty switch bank assembly.

PASSENGER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin3&4OPEN

Low Pin3&43570

High Pin3&41430

All resistance values are 1%.

(4) Reconnect the instrument panel switch bank

and test the heated seat system for proper operation.

If the system is still inoperative proceed with check-

ing remaining components.

Fig. 7 Instrument Panel Switch Bank Connector

RSHEATED SEAT SYSTEM8G-13

PASSENGER HEATED SEAT SWITCH (Continued)

Page 509 of 2585

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel.

Refer toInstrument Panel Center Bezelin the

Body section for the procedure.

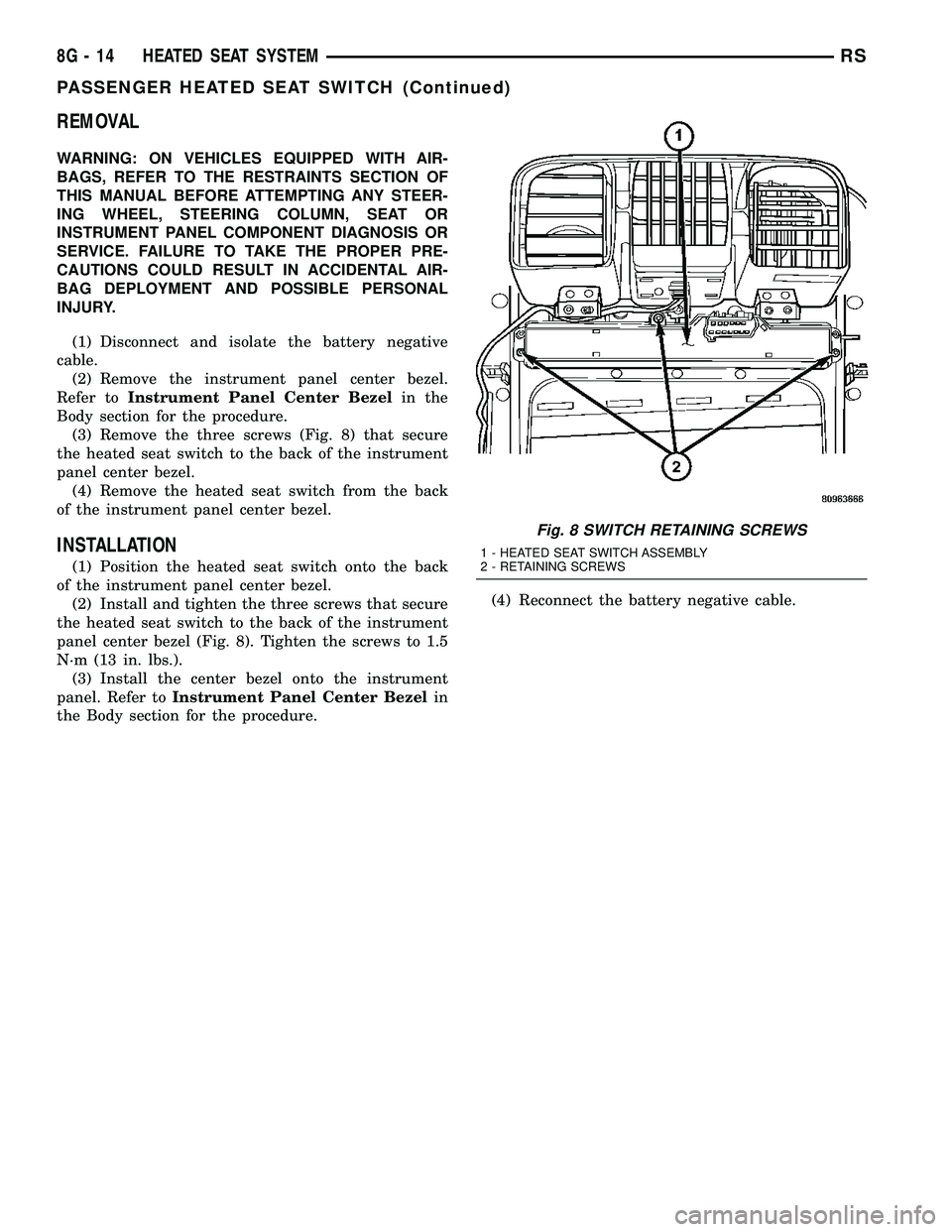

(3) Remove the three screws (Fig. 8) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws that secure

the heated seat switch to the back of the instrument

panel center bezel (Fig. 8). Tighten the screws to 1.5

N´m (13 in. lbs.).

(3) Install the center bezel onto the instrument

panel. Refer toInstrument Panel Center Bezelin

the Body section for the procedure.(4) Reconnect the battery negative cable.

Fig. 8 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 14 HEATED SEAT SYSTEMRS

PASSENGER HEATED SEAT SWITCH (Continued)

Page 510 of 2585

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 1

HORN

DIAGNOSIS AND TESTING - HORN..........3REMOVAL.............................4

INSTALLATION..........................5

HORN SWITCH

DESCRIPTION..........................5

HORN SYSTEM

DESCRIPTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, REFER TO ELECTRICAL, RESTRAINTS FOR

SAFETY PRECAUTIONS. DISCONNECT THE NEGA-

TIVE CABLE FROM THE BATTERY BEFORE SER-

VICING COMPONENTS INVOLVING THE AIRBAG

SYSTEM. ACCIDENTAL DEPLOYMENT OF AIRBAG

AND PERSONAL INJURY CAN RESULT.

The horn circuit consists of a horn switch, clock-

spring, horn relay, horns and Integrated Power Mod-

ule (IPM). The horn switch is a membrane switch

located in the airbag trim cover. The horns are

located forward of the left front wheel behind the

bumper fascia.

OPERATION

The horn relay plugs into the Integrated Power

Module (IPM) which is located in the engine com-

partment. For circuit information and component

locations, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

The horns will not function if the switch is

ªCLOSEDº for more than 30 seconds. Once the

switch is ªOPENº, a 20±30 second delay will occur

before the horns are functional again.

DIAGNOSIS AND TESTING - HORN SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Refer to Horn System Test below. If the horn does

not sound, check horn fuse located in the Integrated

Power Module (IPM). If the fuse is blown, replace

with the correct fuse. If the horns fail to sound and

the new fuse blows when depressing the horn switch,

a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble, or a defective horn switch allowed the horn to

burn out is responsible.

If the fuse is OK, test horn relay (Refer to 8 -

ELECTRICAL/HORN/HORN RELAY - DIAGNOSIS

AND TESTING).

If the relay is OK, test horn. Refer to Horn System

Test.

CAUTION: Continuous sounding of horn may

cause horn failure.

Should the horn sound continuously:

²Unplug the horn relay from IPM.

²Refer to (Refer to 8 - ELECTRICAL/HORN/

HORN RELAY - DIAGNOSIS AND TESTING).

Refer to the appropriate wiring information.

RSHORN8H-1

Page 526 of 2585

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS.........................2

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS...........................2REMOVAL.............................10

INSTALLATION.........................10

CLUSTER LENS

REMOVAL.............................10

INSTALLATION.........................10

INSTRUMENT CLUSTER

DESCRIPTION

The instrumentation gauges are contained in a

subdial assembly within the instrument cluster. The

individual gauges are not serviceable. If one of the

cluster gauges becomes faulty, the entire cluster

would require replacement.

The Mechanical Instrument Cluster (MIC) with a

tachometer is equipped with a electronic vacuum flu-

orescent transmission range indicator (PRND3L),

odometer, and trip odometer display.

The MIC without a tachometer is equipped with a

Light Emitting Diode (LED) transmission range indi-

cator (PRND3L) and a vacuum fluorescent odometer

display.

The MIC is equipped with the following warning

lamps.

²Lift Gate Ajar

²Low Fuel Level

²Low Windshield Washer Fluid Level

²Cruise

²Battery Voltage

²Fasten Seat Belt

²Door Ajar

²Coolant Temperature

²Anti-Lock Brake

²Brake

²Oil Pressure

²MIL (Malfunction Indicator Lamp)

²VTSS/SKIS Indicator

²Airbag

²Traction Control

²Autostick

The MIC without a tachometer also has the follow-

ing warning lamps:

²Turns Signals

²High Beam

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Lamp is located in the message

center. When moisture is found within the fuel sys-

tem, the sensor sends a message via the PCI data

bus to the instrument cluster. The MIC illuminates

the bulb in the message center, The sensor is located

underneath the vehicle, directly above the rear axle.

The sensor is housed within the fuel filter/water sep-

arator assembly cover. The sensor is not serviced sep-

arately. If found defective, the entire assembly cover

must be replaced.

OPERATION

Refer to the vehicle Owner's Manual for operation

instructions and conditions for the Instrument Clus-

ter Gauges.

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Sensor is a resistive type

switch. It is calibrated to sense the different resis-

tance between diesel fuel and water. When water

enters the fuel system, it is caught in the bottom of

the fuel filter/water separator assembly, where the

sensor is located. Water has less resistance than die-

sel fuel. The sensor then sends a PCI data bus mes-

sage to the instrument cluster to illuminate the

lamp.

If the lamp is inoperative, perform the self diag-

nostic test on the instrument cluster to check the

lamp operation before continuing diagnosis.

RSINSTRUMENT CLUSTER8J-1

Page 527 of 2585

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic prob-

lems. Prior to any test, perform the Self-Diagnostic

Test. The self diagnostic system displays instrument

cluster stored fault codes in the odometer display,

sweeps the gauges to the calibration points, and bulb

checks the warning indicators. When the key is in the

ON position with the engine not running, the MIL will

remain illuminated for regulatory purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

400.0 EEPROM READ/WRITE FAILURE

400.1IMPROPER POWER DOWN

DETECTED

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS

CONDITIONS

Refer to the following tables for possible problems,

causes, and corrections.

²INSTRUMENT CLUSTER DIAGNOSIS

²SPEEDOMETER DIAGNOSIS

²TACHOMETER DIAGNOSIS

²FUEL GAUGE DIAGNOSIS

²TEMPERATURE GAUGE DIAGNOSIS

²ODOMETER DIAGNOSIS

²ELECTRONIC GEAR INDICATOR DISPLAY

DIAGNOSIS

NOTE: Always check the functionality of the cluster

by running the self test prior to troubleshooting.

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

Page 536 of 2585

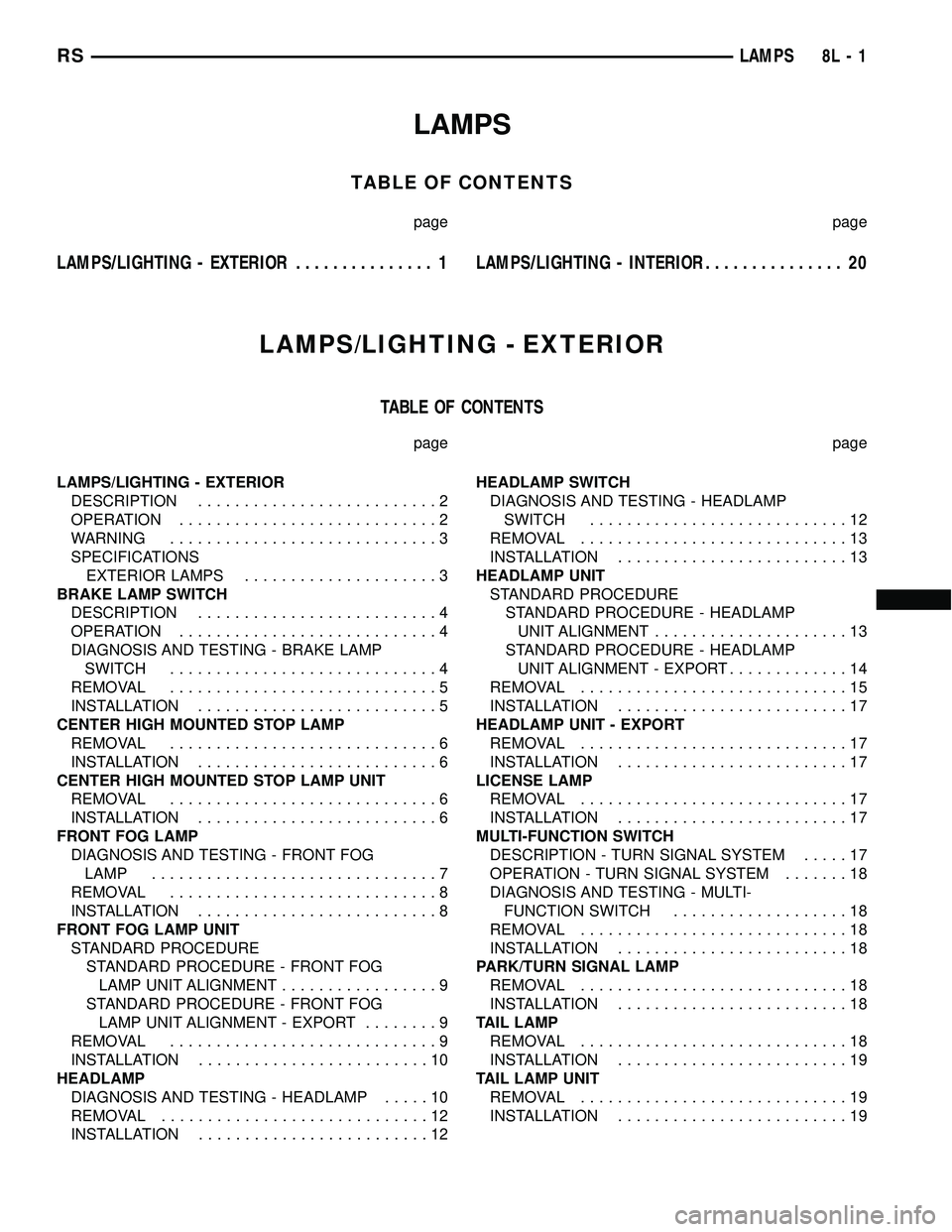

LAMPS

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR............... 1LAMPS/LIGHTING - INTERIOR............... 20

LAMPS/LIGHTING - EXTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION..........................2

OPERATION............................2

WARNING.............................3

SPECIFICATIONS

EXTERIOR LAMPS.....................3

BRAKE LAMP SWITCH

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING - BRAKE LAMP

SWITCH.............................4

REMOVAL.............................5

INSTALLATION..........................5

CENTER HIGH MOUNTED STOP LAMP

REMOVAL.............................6

INSTALLATION..........................6

CENTER HIGH MOUNTED STOP LAMP UNIT

REMOVAL.............................6

INSTALLATION..........................6

FRONT FOG LAMP

DIAGNOSIS AND TESTING - FRONT FOG

LAMP...............................7

REMOVAL.............................8

INSTALLATION..........................8

FRONT FOG LAMP UNIT

STANDARD PROCEDURE

STANDARD PROCEDURE - FRONT FOG

LAMP UNIT ALIGNMENT.................9

STANDARD PROCEDURE - FRONT FOG

LAMP UNIT ALIGNMENT - EXPORT........9

REMOVAL.............................9

INSTALLATION.........................10

HEADLAMP

DIAGNOSIS AND TESTING - HEADLAMP.....10

REMOVAL.............................12

INSTALLATION.........................12HEADLAMP SWITCH

DIAGNOSIS AND TESTING - HEADLAMP

SWITCH............................12

REMOVAL.............................13

INSTALLATION.........................13

HEADLAMP UNIT

STANDARD PROCEDURE

STANDARD PROCEDURE - HEADLAMP

UNIT ALIGNMENT.....................13

STANDARD PROCEDURE - HEADLAMP

UNIT ALIGNMENT - EXPORT.............14

REMOVAL.............................15

INSTALLATION.........................17

HEADLAMP UNIT - EXPORT

REMOVAL.............................17

INSTALLATION.........................17

LICENSE LAMP

REMOVAL.............................17

INSTALLATION.........................17

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM.....17

OPERATION - TURN SIGNAL SYSTEM.......18

DIAGNOSIS AND TESTING - MULTI-

FUNCTION SWITCH...................18

REMOVAL.............................18

INSTALLATION.........................18

PARK/TURN SIGNAL LAMP

REMOVAL.............................18

INSTALLATION.........................18

TAIL LAMP

REMOVAL.............................18

INSTALLATION.........................19

TAIL LAMP UNIT

REMOVAL.............................19

INSTALLATION.........................19

RSLAMPS8L-1

Page 538 of 2585

DAYTIME RUNNING LAMPS

Power is reduced using pulse-width modulation to

the high beams, where by the power is switched on

and off rapidly instead of remaining on continuously.

The duration and interval of the power pulses is pro-

grammed into the FCM. Daytime running lamps are

functional when 450 rpm's are reached.

HEADLAMP SYSTEM

The headlamp system will default to headlamps

ON position when ignition switch is ON and when an

open or short circuit failure occurs on the headlamp

switch input or PCI data bus communication between

the BCM and the FCM fails. The system will return

to normal operation when the open or short is

repaired. A fault will be reported by the BCM when a

failure occurs on the dimmer or headlamp switch

input.

If the exterior lamps are ON and the headlamp

switch is in any position other than OFF or AUTO

and with the ignition switch OFF (LOCK) after 3

minutes the BCM sends a message via PCI bus to

the FCM informing the FCM to turn off the head-

lamps, park lamps and fog lamps. This feature pre-

vents the vehicle battery from being discharged when

the vehicle lights have been left ON.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is activated by

turning the headlamps ON (high or low beam) while

the engine is running, turning the ignition switch

OFF, and then turning the headlamp switch OFF

within 45 seconds. The system will not activate if

more than 45 seconds elapse between ignition switch

OFF and headlamp switch OFF. The BCM will allow

the headlamps to remain ON for 90 seconds (config-

urable) before they automatically turn off (If the key

is in the ignition during the headlamp time delay

mode, then both the headlamps and park lamps

(including panel dimming) will be ON). Refer to the

Owner's Manual for more information.

If the headlamp switch is in the Auto Headlamp

Position, the headlamps are ON due to the night sig-

nal from the CMTC and the ignition switch is in any

position other than run/start, the BCM shall enter a

90 second (configurable) Auto Headlamps time delay

mode. If the key is in the ignition during the head-

lamp time delay mode, then both the headlamps and

park lamps (including panel dimming) will be ON. If

the key is not in the ignition, then only the head-

lamps will be ON. The BCM will allow the head-

lamps to remain ON for 90 seconds before they

automatically turn OFF. Refer to the Owner's Man-

ual for more information.

OPTICAL HORN/HIGH BEAMS

When the multi-function switch is pulled to the

first detent (optical horn) signal, the headlamps are

ON, key-in the ignition the BCM shall send a mes-

sage via PCI bus to the FCM to turn on the head-

lamps drivers to illuminate all four filaments (Low

and High beams). When the multi-function switch is

pulled to the second detent (high beam) signal and

the headlamps are ON, the BCM shall send a mes-

sage via PCI bus to the FCM to turn on the head-

lamps drivers. The High Beams are illuminated and

the Low Beams and Fog Lamps (if ON) are extin-

guished. If the headlamps were in the high beam

configuration when power was removed from the

headlamps, the headlamps will be configured as low

beam the next time they are activated.

NOTE: For RG - Export vehicles, the low beams and

front fog lamps will remain ON when high beams

are activated.

WARNING

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY OR DEATH CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

CAUTION: Do not use bulbs other than those listed

in the Bulb Application Table. Damage to lamp can

result. Do not touch halogen bulbs with fingers or

other oily surfaces. Bulb life will be reduced.

SPECIFICATIONS

EXTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

BACK-UP 3057

CHMSL 921

FRONT SIDE MARKER/PARK/

TURN3157A

RSLAMPS/LIGHTING - EXTERIOR8L-3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 555 of 2585

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS.....................20

CENTER CONSOLE LAMP

REMOVAL.............................21

INSTALLATION.........................21

CENTER CONSOLE LAMP SWITCH

REMOVAL.............................21

INSTALLATION.........................21

CLUSTER ILLUMINATION LAMPS

REMOVAL.............................21

INSTALLATION.........................21

COURTESY LAMP

REMOVAL.............................21

INSTALLATION.........................21DOME/CARGO LAMP

REMOVAL.............................22

INSTALLATION.........................22

GLOVE BOX LAMP SWITCH

REMOVAL.............................22

INSTALLATION.........................22

LIFTGATE LAMP

REMOVAL.............................22

INSTALLATION.........................22

READING LAMP

REMOVAL.............................23

INSTALLATION.........................23

VANITY LAMP

REMOVAL.............................24

INSTALLATION.........................24

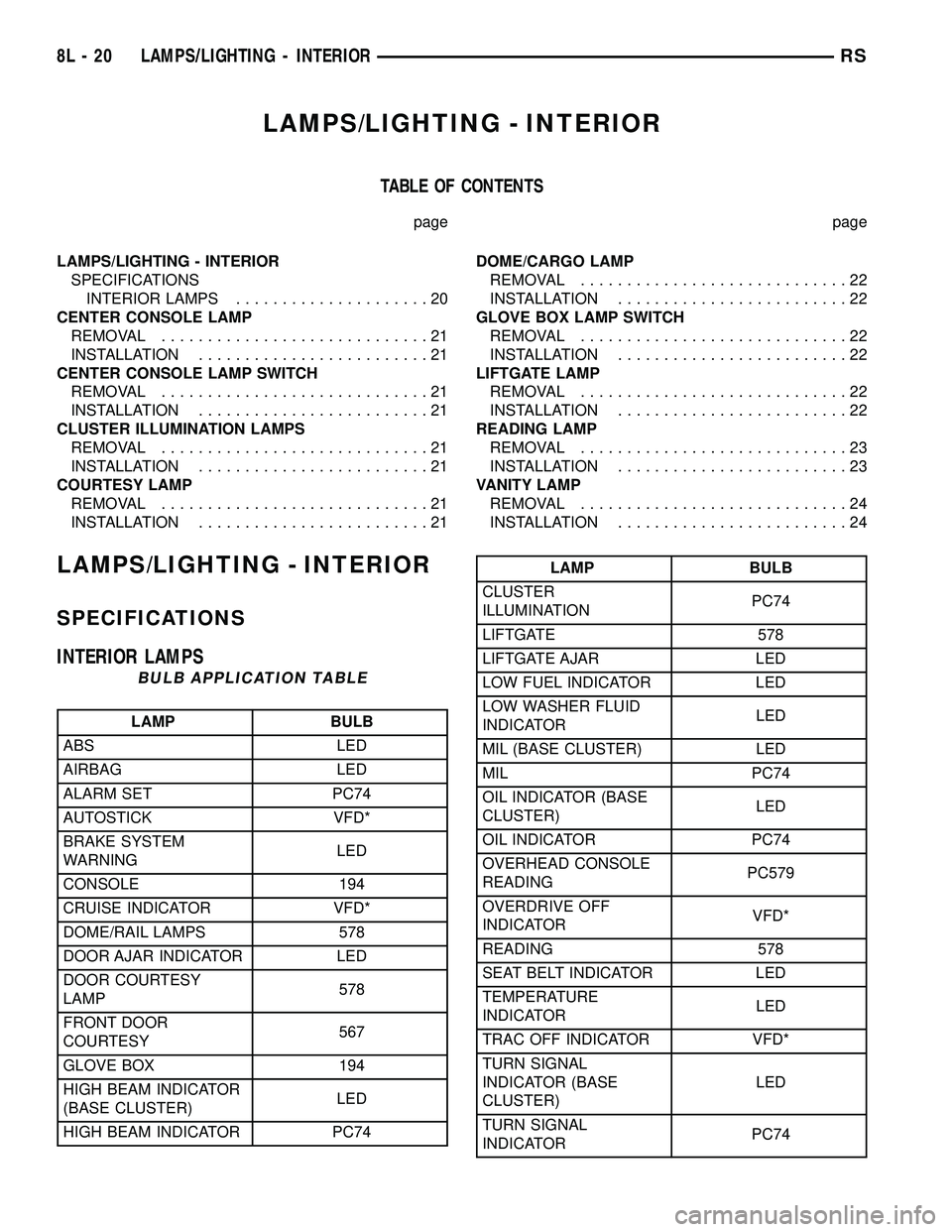

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

ABS LED

AIRBAG LED

ALARM SET PC74

AUTOSTICK VFD*

BRAKE SYSTEM

WARNINGLED

CONSOLE 194

CRUISE INDICATOR VFD*

DOME/RAIL LAMPS 578

DOOR AJAR INDICATOR LED

DOOR COURTESY

LAMP578

FRONT DOOR

COURTESY567

GLOVE BOX 194

HIGH BEAM INDICATOR

(BASE CLUSTER)LED

HIGH BEAM INDICATOR PC74

LAMP BULB

CLUSTER

ILLUMINATIONPC74

LIFTGATE 578

LIFTGATE AJAR LED

LOW FUEL INDICATOR LED

LOW WASHER FLUID

INDICATORLED

MIL (BASE CLUSTER) LED

MIL PC74

OIL INDICATOR (BASE

CLUSTER)LED

OIL INDICATOR PC74

OVERHEAD CONSOLE

READINGPC579

OVERDRIVE OFF

INDICATORVFD*

READING 578

SEAT BELT INDICATOR LED

TEMPERATURE

INDICATORLED

TRAC OFF INDICATOR VFD*

TURN SIGNAL

INDICATOR (BASE

CLUSTER)LED

TURN SIGNAL

INDICATORPC74

8L - 20 LAMPS/LIGHTING - INTERIORRS

Page 567 of 2585

PROGRAMMABLE FEATURES

NOTE: Tire pressure monitoring (TPM) system infor-

mation is not covered in this section of the service

manual. Refer to the tires/wheels section of this

manual for detailed tire pressure monitoring system

information.

²LANGUAGE?- The options include English,

Francaise, Deutsch, Italiana, or Espanol. The default

is English. All EVIC display nomenclature, including

the trip computer functions, warning messages and

the programmable features appear in the selected

language.

²DISPLAY U.S. OR METRIC?- The options

include U.S. and M. The default is U.S. This feature

toggles the trip computer temperature, fuel economy

and odometer display readings between U.S. and

metric units of measure. It also changes the odome-

ter display in the instrument cluster.

²SERVICE INTV. =- The options include from

1000 to 12000 kilometers in 1000 kilometer incre-

ments (2000 to 7500 miles in 500 mile increments).

The default is 12000 kilometers (7500 miles). The

selected distance becomes the interval at which the

Perform Service warning message will be displayed

by the EVIC. If a new distance is selected, a second

programmable feature appears,RESET SERVICE

DISTANCE?- The options include No and Yes. The

default is Yes. When Yes is selected, the accumulated

distance since the last previous Perform Service

warning message will be reset to zero because the

service interval has been changed. When No is

selected, the distance until the next Perform Service

warning message is reduced by the accumulated dis-

tance since the last previous message.

²USE FACTORY SETTINGS?- The options

include Yes and No. The default is Yes. When yes is

selected all the programmable features will return to

there defaults and the rest of the programmable fea-

tures will not be displayed. If No is selected the rest

of the programmable features will be displayed at

there default values. This feature will automatically

return to the Yes default under two conditions. First,

if no programmable features are changed from there

defaults. Second, if all the programmable features

equal there defaults.

²AUTO DOOR LOCKS?- The options include

Yes and No. The default is Yes. When Yes is selected,

all doors and the liftgate lock automatically when

vehicle speed reaches 25 kilometers-per-hour (15

miles-per-hour). If YES is selected, a second program-

mable feature appears,AUTO UNLOCK ON EXIT?

- The options again include Yes and No. The default

is No. When Yes is selected, following each Auto Door

Lock event all doors and the liftgate will automati-

cally unlock when the driver door is opened, if thevehicle is stopped and the transmission gear selector

is in Park or Neutral. The Auto Door Unlock event

will only occur once following each Auto Door Lock

event.

²REMOTE UNLOCK- The options include

Driver Door 1st and All Doors. The default is Driver

Door 1st. When Diver Door 1st is selected, only the

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE trans-

mitter must be depressed twice to unlock all doors.

When All Doors is selected, all doors unlock when the

Unlock button of the RKE transmitter is depressed

once.

²REMOTE LINKED TO MEMORY?- This pro-

grammable feature only applies to vehicles equipped

with the optional memory / heated system. The

options include Yes and No. The default is No. When

Yes is selected, the memory system will recall the

Driver 1 or Driver 2 memory settings assigned to the

RKE transmitter being used to unlock the vehicle.

When No is selected, the memory system will only

recall memory settings when the Driver 1 or Driver 2

push buttons of the memory switch on the driver side

front door trim panel are depressed.

²SOUND HORN ON LOCK?- The options

include Yes and No. The default is No. When Yes is

selected, a short horn chirp will provide an audible

confirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.

²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²HEADLAMPS ON WITH WIPERS?- This pro-

grammable feature only applies to vehicles equipped

8M - 8 MESSAGE SYSTEMSRS

ELECTRONIC VEHICLE INFO CENTER (Continued)