fuel fill door release CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 592 of 2585

Body Diagnostic Manual for a complete list of diag-

nostic routines.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). For a com-

plete power sliding door system wiring schematic,

refer to Wiring Diagrams. For power sliding door sys-

tem operation instructions, refer to the vehicle owner

manual.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the PCI Data Bus circuit (J1850) to the power sliding

door module. The power sliding door module then

signals the power sliding door latch to release the

door to the unlatched and movable position. The

motor then starts an open cycle.

During the door open cycle, if the power sliding

door module detects sufficient resistance to doortravel, such as an obstruction in the door's path, the

power sliding door module will immediately stop door

movement and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors and the door motor

speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a Diagnostic Scan Tool, such as the DRB IIIt, or with

a complete cycle of the door, using any one of the

command switches. Refer to Standard Procedures in

this section for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. See the power sliding door sys-

tem inhibitors noted below:

POWER SLIDING DOOR SYSTEM INHIBITORS

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The vehicles transmission must be inpark or

neutralin order for the power sliding door system to

start a cycle.

²The vehicles child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

²If multiple obstacles are detected during the

same power open or close cycle the power sliding

door may go into full manual mode.

²If severe Diagnostic Trouble Codes (DTC) are

stored in the power sliding door control module the

power sliding door may go into full manual mode.

²Due to the high pressure created in the passen-

ger compartment with the blower motor on high, the

power sliding door may not complete a power close

cycle unless a window is cracked, allowing the pres-

sure to escape. This situation will only be experi-

enced on some vehicles, or vehicles with brand new

side door weather seals installed. Refer to the Side

Door Adjustment procedure in the Standard Proce-

dures section of this group.

²The vehicles fuel tank filler door must be in the

closed position. Due to the sliding door interference

with the open fuel tank filler door, mechanical link-

age prevents the side door from opening and striking

Fig. 3 Power Side Door Fuse Location

RSPOWER SLIDING DOOR SYSTEM8N-21

POWER SLIDING DOOR SYSTEM (Continued)

Page 596 of 2585

CONDITION POSSIBLE CAUSES CORRECTION

Power loss during power

door operationWiring problems (system or

vehicle)Troubleshoot using electrical schematics.

Refer to wiring diagrams

Low battery voltage Charge battery

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of drive assembly Remove lower drive unit and check for no

drive condition

No latching in primary

and/or secondary positionsFailure of inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Failure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Door seal force too high Inspect seals for damage, mis-assembly,

foreign matter. Refer to Door adjustment in

the Body section of the service manual for

specifications

Failure of drive assembly Remove lower drive unit and check for no

drive condition

Failure of striker Striker misaligned or loose

Striker damaged

Replace striker if necessary

Latch will not fully release

from primary positionFailure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of fuel filler door lockout

mechanismCheck operation of fuel filler door lockout

mechanism. Refer to the Body section for

information

RSPOWER SLIDING DOOR SYSTEM8N-25

POWER SLIDING DOOR SYSTEM (Continued)

Page 1509 of 2585

FUEL DELIVERY

DESCRIPTION

The front wheel drive car uses a plastic fuel tank

located rear center of the vehicle.

The Fuel Delivery System consists of: the following

items:

²Electric fuel pump module

²Fuel filter

²Tubes/lines/hoses

²Fuel injectors

The in-tank fuel pump module contains the fuel

pump. The pump is serviced as part of the fuel pump

module. Refer to Fuel Pump Module.

The fuel filter is replaceable only as part of the

fuel pump module.

OPERATION

The fuel system provides fuel pressure by an

in-tank pump module. The Powertrain Control Mod-

ule (PCM) controls the operation of the fuel system

by providing battery voltage to the fuel pump

through the fuel pump relay. The PCM requires only

three inputs and a good ground to operate the fuel

pump relay. The three inputs are:

²Ignition voltage

²Crankshaft Position (CKP) sensor

²Camshaft Position (CMP) sensor

DIAGNOSIS AND TESTING - FUEL DELIVERY

SYSTEM

(Refer to Appropriate Diagnostic Information)

STANDARD PROCEDURE

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE PROCEDURE

(1) Remove Fuel Pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(2) Start and run engine until it stalls.

(3) Attempt restarting engine until it will no

longer run.

(4) Turn ignition key to OFF position.

(5) Return fuel pump relay to PDC.

(6) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRB IIItscan tool must be

used to erase a DTC.

STANDARD PROCEDURE - DRAINING FUEL

TANK

Two different procedures may be used to drain fuel

tank (lowering tank or using DRBIIItscan tool).The quickest draining procedure involves lowering

the fuel tank.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE. THIS MAY

RESULT IN PERSONAL INJURY OR DEATH.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRBIIItscan tool for fuel

pump activation procedures. Before disconnecting

fuel line at fuel rail, release fuel pressure. Refer to

the Fuel System Pressure Release Procedure in this

group for procedures. Disconnect the fuel line at the

fuel rail and remove the plastic retainer from the

fuel rail. Take plastic retainer and install it back into

the fuel line from body. Check the O-ring and make

sure that it is in place and not damaged. Attach end

of special test hose tool number 6539 at fuel line con-

nection from the body line. Position opposite end of

this hose tool to an approved gasoline draining sta-

tion. Activate fuel pump and drain tank until empty.

When done remove the special test hose tool number

6539 from the body line. Remove the plastic retainer

from the special test hose tool number 6539 and rein-

stall it into the fuel line from the body. Check the

O-ring and make sure that it is in place and not

damaged. Install the fuel line to the fuel rail.

If electric fuel pump is not operating, tank must be

lowered for fuel draining. Refer to following proce-

dures.

(1) Remove fuel filler cap.

(2) Perform the Fuel System Pressure Release pro-

cedure.

(3) Disconnect negative cable from battery.

(4) Raise vehicle and support.

(5) Certain models are equipped with a separate

grounding wire (strap) connecting the fuel fill tube

assembly to the body. Disconnect wire by removing

screw.

(6) Open fuel fill door and remove screws mount-

ing fuel filler tube assembly to body. Do not discon-

nect rubber fuel fill or vent hoses from tank at this

time.

(7) Place a transmission jack under center of fuel

tank. Apply a slight amount of pressure to fuel tank

with transmission jack.

(8) Remove fuel tank mounting straps.

(9)Lower the tank just enough so that the

filler tube fitting is the highest point of the fuel

tank.

(10) Remove filler tube from fuel tank. Tank will

be drained through this fitting.

14 - 2 FUEL DELIVERYRS

Page 2163 of 2585

FRONT FENDER

REMOVAL

(1) Remove headlamp housing. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - REMOVAL)

(2) Remove mud guard.

(3) Remove inner splash shield.

(4) Remove fender to fascia nuts.

(5) Remove outboard cowl grille/fender bracket

screw.

(6) Remove fender bolt to lower rocker panel.

(7) Remove fender bolt to lower cowl.

(8) Pull fascia away from fender.

(9) Remove bolts attaching fender to upper rail.

(10) Remove fender from vehicle (Fig. 8).

INSTALLATION

(1) Place fender in position on vehicle.

(2) From inside engine compartment, start the

center upper rail bolt. install all the bolts attaching

fender to upper rail and tighten.

(3) Install fender to lower cowl panel bolt.

(4) Install fender to rocker panel bolt.

(5) Place fascia into position.

(6) Install outboard cowl grille/fender bracket

screw.

(7) Install fender to fascia nuts.

(8) Install inner splash shield.

(9) Install mud guard.

(10) Install headlamp assembly. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - INSTALLATION)(11) Check fender for flush and gap.

FUEL FILL DOOR

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage latch release link from clip on fuel

fill blocker latch arm (Fig. 12).

(4) Open fuel fill door.

(5) Remove screws holding fuel fill neck to fuel

filler housing.

(6) Position fuel fill neck out of the way.

(7) Reaching inside fuel filler housing, release clips

holding housing to quarter panel (Fig. 9).

(8) Remove fuel fill door from vehicle.

(9) Disengage clip holding link to fuel fill door

(Fig. 13).

(10) Remove link from fuel fill door.

INSTALLATION

(1) Install spring to housing and door

(2) Snap door into housing.

(3) Insert lockout link into clip on fuel fill door.

(4) Engage clip to hold link to fuel fill door.

(5) Insert lockout link through grommet in panel

between inner and outer quarter panel.

(6) Close fuel fill door.

(7) Install fuel filler housing to outer quarter

panel.

(8) Verify that all clips on fuel filler housing are

fully engaged to outer quarter panel.

(9) Place fuel fill neck in position.

Fig. 8 FENDER

1 - FASTENERS

2 - FENDER

3 - FASTENERS

Fig. 9 FUEL FILLER HOUSING AND DOOR

1 - FUEL FILLER HOUSING W/LATCH

2 - CLIP

3 - FUEL FILLER HOUSING DOOR

4 - CLIPS

5 - FIX CLIP

23 - 52 EXTERIORRS

Page 2164 of 2585

(10) Install screws to hold fuel fill neck to fuel

filler housing.

(11) Engage latch release link into clip on fuel fill

blocker latch arm.

(12) Verify fuel fill blocker latch operation.

(13) Install water shield patch to cover access hole

in C-pillar.

(14) Install left quarter trim panel.

FUEL FILL DOOR BLOCKER

LATCH

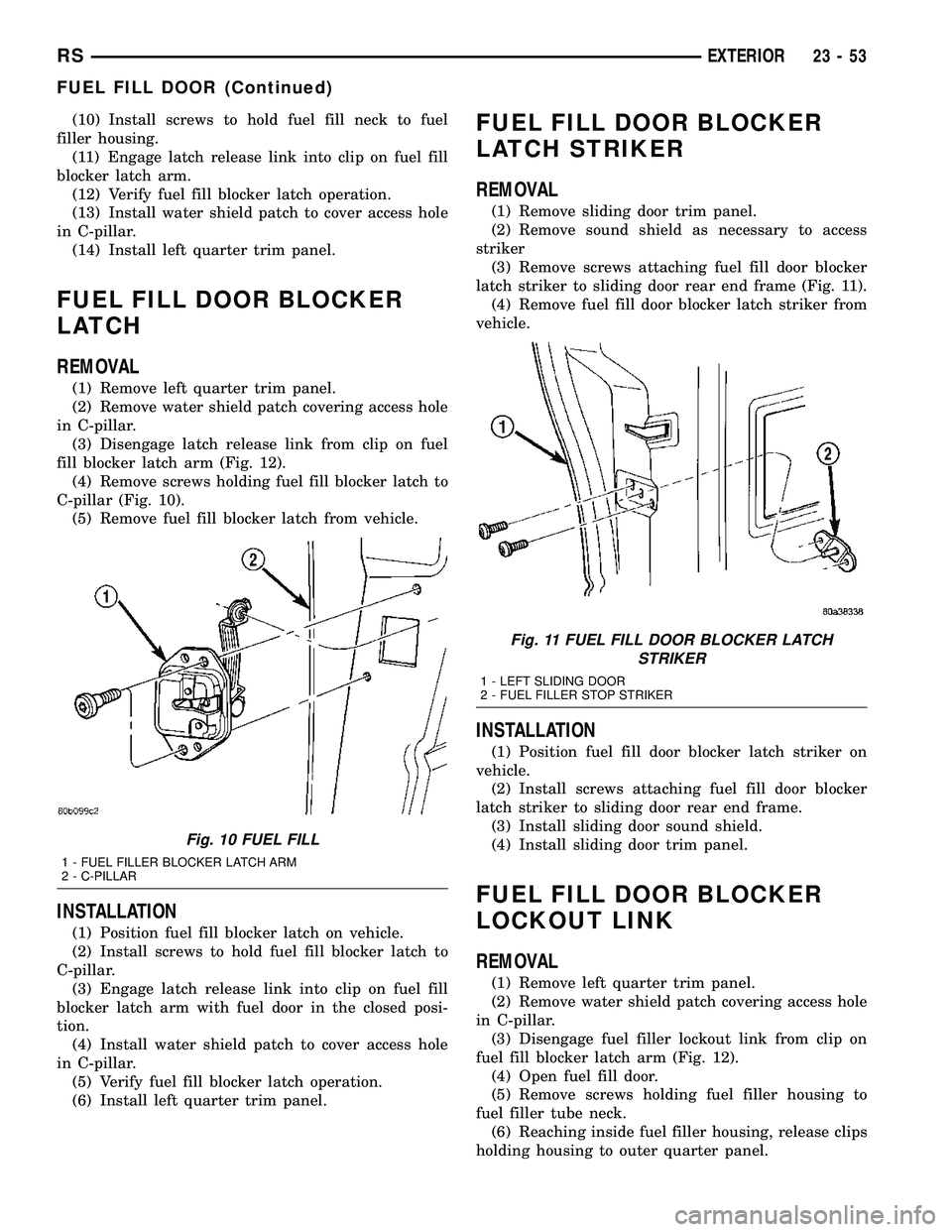

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage latch release link from clip on fuel

fill blocker latch arm (Fig. 12).

(4) Remove screws holding fuel fill blocker latch to

C-pillar (Fig. 10).

(5) Remove fuel fill blocker latch from vehicle.

INSTALLATION

(1) Position fuel fill blocker latch on vehicle.

(2) Install screws to hold fuel fill blocker latch to

C-pillar.

(3) Engage latch release link into clip on fuel fill

blocker latch arm with fuel door in the closed posi-

tion.

(4) Install water shield patch to cover access hole

in C-pillar.

(5) Verify fuel fill blocker latch operation.

(6) Install left quarter trim panel.

FUEL FILL DOOR BLOCKER

LATCH STRIKER

REMOVAL

(1) Remove sliding door trim panel.

(2) Remove sound shield as necessary to access

striker

(3) Remove screws attaching fuel fill door blocker

latch striker to sliding door rear end frame (Fig. 11).

(4) Remove fuel fill door blocker latch striker from

vehicle.

INSTALLATION

(1) Position fuel fill door blocker latch striker on

vehicle.

(2) Install screws attaching fuel fill door blocker

latch striker to sliding door rear end frame.

(3) Install sliding door sound shield.

(4) Install sliding door trim panel.

FUEL FILL DOOR BLOCKER

LOCKOUT LINK

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage fuel filler lockout link from clip on

fuel fill blocker latch arm (Fig. 12).

(4) Open fuel fill door.

(5) Remove screws holding fuel filler housing to

fuel filler tube neck.

(6) Reaching inside fuel filler housing, release clips

holding housing to outer quarter panel.

Fig. 10 FUEL FILL

1 - FUEL FILLER BLOCKER LATCH ARM

2 - C-PILLAR

Fig. 11 FUEL FILL DOOR BLOCKER LATCH

STRIKER

1 - LEFT SLIDING DOOR

2 - FUEL FILLER STOP STRIKER

RSEXTERIOR23-53

FUEL FILL DOOR (Continued)

Page 2165 of 2585

(7) Remove fuel filler housing and lockout link

from vehicle.

(8) Disengage clip holding link to fuel fill door

(Fig. 13).

(9) Remove link from fuel fill door.

INSTALLATION

(1) Insert link into clip on fuel fill door.

(2) Engage clip to hold link to fuel fill door.

(3) Insert lockout link through grommet in panel

between inner and outer quarter panel.

(4) Close fuel fill door.

(5) Install fuel filler housing to outer quarter

panel.(6) Verify that all clips on fuel filler housing are

fully engaged to outer quarter panel.

(7) Engage fuel filler lockout link into clip on fuel

fill blocker latch arm.

(8) Install water shield patch covering access hole

in C-pillar.

(9) Install left quarter trim panel.

GRILLE OPENING

REINFORCEMENT

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to cross-

member and position latch out of the way.

(3) Remove radiator sight shield.

(4) Remove engine air inlet resonator.

(5) Remove hood cable.

(6) Remove hood prop rod.

(7) Remove screw attaching coolant recovery bottle

to crossmember.

(8) Remove bolts attaching radiator isolators to

crossmember.

(9) Remove bolts attaching ends of crossmember to

radiator closure panel (Fig. 14).

(10) Lift crossmember upward and away from

radiator closure panel.

(11) Remove crossmember from vehicle.

INSTALLATION

(1) Place radiator closure panel crossmember in

position on vehicle.

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

Fig. 12 FUEL FILLER LOCKOUT LINK AT LATCH

ARM

1 - FUEL FILLER LOCKOUT LINK

2 - C-PILLAR

3 - FUEL FILLER BLOCKER LATCH ARM

4 - PLASTIC LINK CLIP

5 - INNER QUARTER PANEL

Fig. 13 FUEL FILLER LOCKOUT LINK

1 - FUEL FILLER LOCKOUT LINK

2 - FUEL FILLER OPENING

3 - QUARTER PANELFig. 14 RADIATOR CLOSURE PANEL

CROSSMEMBER

1 - RADIATOR CLOSURE PANEL CROSSMEMBER

2 - FRONT FASCIA

23 - 54 EXTERIORRS

FUEL FILL DOOR BLOCKER LOCKOUT LINK (Continued)

Page 2547 of 2585

BLEEDING - STANDARD PROCEDURE,

BASE BRAKE......................5-7,5s-7

BLEEDING - STANDARD PROCEDURE,

MASTER CYLINDER...............5-35,5s-34

BLEND DOOR ACTUATOR -

DESCRIPTION..................24-23,24-35

BLEND DOOR ACTUATOR -

INSTALLATION..................24-23,24-36

BLEND DOOR ACTUATOR - OPERATION . . 24-23,

24-35

BLEND DOOR ACTUATOR - REMOVAL....24-23,

24-36

BLOCK - CLEANING, ENGINE.......9-112,9-36

BLOCK - DESCRIPTION, BLOWER

MOTOR RESISTOR...................24-26

BLOCK - DESCRIPTION, ENGINE.....9-112,9-35

BLOCK - DESCRIPTION, NON-ABS

JUNCTION......................5-33,5s-32

BLOCK - DIAGNOSIS AND TESTING,

BLOWER MOTOR RESISTOR............24-26

BLOCK - DIAGNOSIS AND TESTING,

REAR BLOWER MOTOR RESISTOR......24-38

BLOCK - INSPECTION, ENGINE......9-112,9-36

BLOCK - INSTALLATION, BLOWER

MOTOR RESISTOR...................24-27

BLOCK - INSTALLATION, NON-ABS

JUNCTION......................5-33,5s-32

BLOCK - OPERATION, BLOWER MOTOR

RESISTOR..........................24-26

BLOCK - OPERATION, NON-ABS

JUNCTION......................5-33,5s-32

BLOCK - REMOVAL, BLOWER MOTOR

RESISTOR...........................24-26

BLOCK - REMOVAL, NON-ABS JUNCTION . . 5-33,

5s-32

BLOCK HEATER - DESCRIPTION, ENGINE . . . 7-20

BLOCK HEATER - INSTALLATION,

ENGINE.............................7-20

BLOCK HEATER - OPERATION, ENGINE....7-20

BLOCK HEATER - REMOVAL, ENGINE......7-20

BLOCK HEATER TESTING - DIAGNOSIS

AND TESTING, ENGINE.................7-20

BLOCKER LATCH - INSTALLATION, FUEL

FILL DOOR.........................23-53

BLOCKER LATCH - REMOVAL, FUEL FILL

DOOR.............................23-53

BLOCKER LATCH STRIKER -

INSTALLATION, FUEL FILL DOOR........23-53

BLOCKER LATCH STRIKER - REMOVAL,

FUEL FILL DOOR.....................23-53

BLOCKER LOCKOUT LINK -

INSTALLATION, FUEL FILL DOOR........23-54

BLOCKER LOCKOUT LINK - REMOVAL,

FUEL FILL DOOR.....................23-53

BLOWER MOTOR - DESCRIPTION . . 24-46,24-57

BLOWER MOTOR - DESCRIPTION,

POWER MODULE....................24-31

BLOWER MOTOR - DESCRIPTION,

POWER MODULE - REAR..............24-41

BLOWER MOTOR - DIAGNOSIS AND

TESTING...........................24-47

BLOWER MOTOR - DIAGNOSIS AND

TESTING, REAR......................24-58

BLOWER MOTOR - INSTALLATION . . 24-49,24-58

BLOWER MOTOR - INSTALLATION,

POWER MODULE....................24-32

BLOWER MOTOR - INSTALLATION,

POWER MODULE - REAR..............24-42

BLOWER MOTOR - OPERATION....24-46,24-57

BLOWER MOTOR - OPERATION, POWER

MODULE...........................24-31

BLOWER MOTOR - OPERATION, POWER

MODULE - REAR.....................24-41

BLOWER MOTOR - REMOVAL......24-47,24-58

BLOWER MOTOR - REMOVAL, POWER

MODULE...........................24-31

BLOWER MOTOR - REMOVAL, POWER

MODULE - REAR.....................24-41

BLOWER MOTOR RELAY - DESCRIPTION

. 24-24,

24-37

BLOWER MOTOR RELAY -

INSTALLATION

..................24-25,24-38

BLOWER MOTOR RELAY - OPERATION

. . . 24-24,

24-37

BLOWER MOTOR RELAY - REMOVAL

....24-25,

24-38

BLOWER MOTOR RESISTOR -

DESCRIPTION

.......................24-38BLOWER MOTOR RESISTOR -

INSTALLATION.......................24-39

BLOWER MOTOR RESISTOR -

OPERATION.........................24-38

BLOWER MOTOR RESISTOR - REMOVAL . . 24-39

BLOWER MOTOR RESISTOR BLOCK -

DESCRIPTION.......................24-26

BLOWER MOTOR RESISTOR BLOCK -

DIAGNOSIS AND TESTING.............24-26

BLOWER MOTOR RESISTOR BLOCK -

DIAGNOSIS AND TESTING, REAR........24-38

BLOWER MOTOR RESISTOR BLOCK -

INSTALLATION.......................24-27

BLOWER MOTOR RESISTOR BLOCK -

OPERATION.........................24-26

BLOWER MOTOR RESISTOR BLOCK -

REMOVAL..........................24-26

BODY - ASSEMBLY, VALVE.....21-257,21s-159,

21s-212

BODY - DESCRIPTION, THROTTLE.......14-35

BODY - DESCRIPTION, VALVE . . . 21-250,21s-152

BODY - DISASSEMBLY, VALVE . . 21-252,21s-155,

21s-208

BODY - INSTALLATION, THROTTLE.......14-35

BODY - INSTALLATION, VALVE . . 21-262,21s-164,

21s-217

BODY - OPERATION, THROTTLE.........14-35

BODY - OPERATION, VALVE....21-250,21s-152

BODY - REMOVAL, THROTTLE..........14-35

BODY - REMOVAL, VALVE.....21-251,21s-153,

21s-206

BODY AND CABLE - DESCRIPTION,

ANTENNA...........................8A-4

BODY AND CABLE - DIAGNOSIS AND

TESTING, ANTENNA...................8A-4

BODY AND CABLE - INSTALLATION,

ANTENNA...........................8A-6

BODY AND CABLE - OPERATION,

ANTENNA...........................8A-4

BODY AND CABLE - REMOVAL,

ANTENNA...........................8A-5

BODY CODE PLATE - DESCRIPTION.....Intro.-1

BODY CONTROL MODULE -

DESCRIPTION........................8s-1

BODY CONTROL MODULE -

DESCRIPTION........................8E-3

BODY CONTROL MODULE -

INSTALLATION........................8s-3

BODY CONTROL MODULE -

INSTALLATION........................8E-5

BODY CONTROL MODULE - OPERATION . . . 8s-1

BODY CONTROL MODULE - OPERATION . . . 8E-3

BODY CONTROL MODULE - REMOVAL.....8s-3

BODY CONTROL MODULE - REMOVAL.....8E-4

BODY LUBRICATION, SPECIFICATIONS....23-12

BODY OPENING DIMENSIONS -

SPECIFICATIONS....................23-127

BODY PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC.................23-3

BODY SEALING LOCATIONS -

SPECIFICATIONS....................23-130

BODY SIDE MOLDINGS - INSTALLATION . . 23-46

BODY SIDE MOLDINGS - REMOVAL......23-45

BODY, SPECIAL TOOLS................23-13

BOLSTER - INSTALLATION, QUARTER

TRIM..............................23-79

BOLSTER - REMOVAL, QUARTER TRIM . . . 23-79

BOOSTER - DESCRIPTION, POWER

BRAKE.........................5-40,5s-43

BOOSTER - DIAGNOSIS AND TESTING,

POWER BRAKE..................5-41,5s-44

BOOSTER - OPERATION, POWER BRAKE . . 5-41,

5s-44

BOOT - INNER - INSTALLATION, CV........3-6

BOOT - INNER - REMOVAL, CV...........3-6

BOOT - INNER/OUTER - INSTALLATION,

CV .................................3-17

BOOT - INNER/OUTER - REMOVAL, CV....3-15

BOOT - INSTALLATION, GEARSHIFT......21-73

BOOT - OUTER - INSTALLATION, CV......3-10

BOOT - OUTER - REMOVAL, CV..........3-10

BOOT - REMOVAL, GEARSHIFT

..........21-72

BORE FITTING - STANDARD

PROCEDURE, PISTON TO CYLINDER

......9-42

BORE HONING - STANDARD

PROCEDURE, CYLINDER

...........9-112,9-35

BOX - INSTALLATION, GLOVE

...........23-64

BOX - REMOVAL, GLOVE

..............23-64BOX LAMP SWITCH - INSTALLATION,

GLOVE.............................8L-22

BOX LAMP SWITCH - REMOVAL, GLOVE . . 8L-22

BOX LATCH - INSTALLATION, GLOVE.....23-64

BOX LATCH - REMOVAL, GLOVE.........23-64

BOX LATCH STRIKER - INSTALLATION,

GLOVE.............................23-64

BOX LATCH STRIKER - REMOVAL,

GLOVE.............................23-64

B-PILLAR - INSTALLATION, A-PILLAR-

HEADER, OR........................23-17

B-PILLAR - REMOVAL, A-PILLAR-

HEADER, OR........................23-17

B-PILLAR LOWER TRIM - INSTALLATION . . 23-75

B-PILLAR LOWER TRIM - REMOVAL.....23-74

B-PILLAR SWITCH - DESCRIPTION, LEFT . 8N-32

B-PILLAR SWITCH - DESCRIPTION,

RIGHT.............................8N-32

B-PILLAR SWITCH - INSTALLATION,

LEFT..............................8N-32

B-PILLAR SWITCH - INSTALLATION,

RIGHT.............................8N-32

B-PILLAR SWITCH - OPERATION, LEFT . . . 8N-32

B-PILLAR SWITCH - OPERATION, RIGHT . . 8N-32

B-PILLAR SWITCH - REMOVAL, LEFT....8N-32

B-PILLAR SWITCH - REMOVAL, RIGHT . . . 8N-32

B-PILLAR UPPER TRIM - INSTALLATION . . 23-75

B-PILLAR UPPER TRIM - REMOVAL......23-75

BRACKET - 2.4L ENGINE -

INSTALLATION, A/C COMPRESSOR

MOUNTING.........................24-76

BRACKET - 2.4L ENGINE - REMOVAL,

A/C COMPRESSOR MOUNTING..........24-75

BRACKET - DESCRIPTION, TRANSVERSE . . 8N-18

BRACKET - INSTALLATION, TRANSVERSE . 8N-18

BRACKET - OPERATION, TRANSVERSE . . . 8N-18

BRACKET - REMOVAL, TRANSVERSE.....8N-18

BRACKET ASSEMBLY - INSTALLATION,

FLOOR CONSOLE TRAY................23-83

BRACKET ASSEMBLY - REMOVAL,

FLOOR CONSOLE TRAY................23-83

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK...........................8E-5

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK...........................8E-6

BRAKE - INSTALLATION, LEVER -

PARKING.......................5-65,5s-67

BRAKE - INSTALLATION, SHOES -

PARKING.......................5-72,5s-75

BRAKE - INSTALLATION, SUPPORT

PLATE - DRUM..................5-56,5s-58

BRAKE - OPERATION, CONTROLLER

ANTILOCK...........................8E-5

BRAKE - REMOVAL, CONTROLLER

ANTILOCK...........................8E-6

BRAKE - REMOVAL, LEVER - PARKING....5-64,

5s-67

BRAKE - REMOVAL, SHOES - PARKING . . . 5-67,

5s-69

BRAKE - REMOVAL, SUPPORT PLATE -

DRUM

.........................5-56,5s-58

BRAKE AUTOMATIC ADJUSTER -

DIAGNOSIS AND TESTING, DRUM

. . . 5-13,5s-13

BRAKE AUTOMATIC ADJUSTER TENSION

RELEASE - STANDARD PROCEDURE,

PARKING

.......................5-58,5s-61

BRAKE AUTOMATIC ADJUSTER TENSION

RESET - STANDARD PROCEDURE,

PARKING

.......................5-59,5s-61

BRAKE BLEEDING - STANDARD

PROCEDURE, BASE

.................5-7,5s-7

BRAKE BOOSTER - DESCRIPTION,

POWER

........................5-40,5s-43

BRAKE BOOSTER - DIAGNOSIS AND

TESTING, POWER

................5-41,5s-44

BRAKE BOOSTER - OPERATION, POWER

. . 5-41,

5s-44

BRAKE CABLE (FRONT) - INSTALLATION,

PARKING

.......................5-63,5s-65

BRAKE CABLE (FRONT) - REMOVAL,

PARKING

.......................5-59,5s-62

BRAKE CABLE (INTERMEDIATE) -

INSTALLATION, PARKING

..........5-63,5s-66

BRAKE CABLE (INTERMEDIATE) -

REMOVAL, PARKING

..............5-60,5s-62

BRAKE CABLE (LEFT REAR) -

INSTALLATION, PARKING

..........5-64,5s-66

4 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2558 of 2585

FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES) -

INSTALLATION.......................5s-15

FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES) -

REMOVAL..........................5s-14

FRONT DISC BRAKE SHOES (DISC/DISC

BRAKES) - INSTALLATION...............5-16

FRONT DISC BRAKE SHOES (DISC/DISC

BRAKES) - REMOVAL..................5-14

FRONT DISC BRAKE SHOES (DISC/

DRUM BRAKES) - INSTALLATION.........5-17

FRONT DISC BRAKE SHOES (DISC/

DRUM BRAKES) - REMOVAL............5-15

FRONT DISC BRAKE SHOES (TRW

BRAKES) - INSTALLATION..............5s-16

FRONT DISC BRAKE SHOES (TRW

BRAKES) - REMOVAL.................5s-14

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION.......23-113

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL...........23-113

FRONT DOOR INNER BELT MOLDING -

INSTALLATION......................23-115

FRONT DOOR INNER BELT MOLDING -

REMOVAL.........................23-115

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION......................23-113

FRONT DOOR OUTER BELT MOLDING -

REMOVAL.........................23-113

FRONT DOOR WEATHERSTRIP -

INSTALLATION......................23-114

FRONT DOOR WEATHERSTRIP -

REMOVAL.........................23-114

FRONT FASCIA - INSTALLATION..........13-1

FRONT FASCIA - REMOVAL..............13-1

FRONT FENDER - INSTALLATION........23-52

FRONT FENDER - REMOVAL............23-52

FRONT FOG LAMP - DIAGNOSIS AND

TESTING............................8L-7

FRONT FOG LAMP - INSTALLATION.......8L-8

FRONT FOG LAMP - REMOVAL...........8L-8

FRONT FOG LAMP UNIT ALIGNMENT -

EXPORT - STANDARD PROCEDURE.......8L-9

FRONT FOG LAMP UNIT ALIGNMENT -

STANDARD PROCEDURE................8L-9

FRONT INBOARD - INSTALLATION, SEAT

BELT BUCKLE.......................8O-12

FRONT INBOARD - REMOVAL, SEAT

BELT BUCKLE.......................8O-12

FRONT MOUNT - INSTALLATION....9-131,9-49

FRONT MOUNT - REMOVAL........9-131,9-49

FRONT SEAT - INSTALLATION...........23-91

FRONT SEAT - REMOVAL..............23-91

FRONT SEAT BACK - INSTALLATION......23-92

FRONT SEAT BACK - REMOVAL.........23-92

FRONT SEAT CUSHION SIDE COVER -

INSTALLATION.......................23-94

FRONT SEAT CUSHION SIDE COVER -

REMOVAL..........................23-94

FRONT SEAT RISER - MANUAL TRACK -

INSTALLATION.......................23-95

FRONT SEAT RISER - MANUAL TRACK -

REMOVAL..........................23-94

FRONT SEAT TRACK - REAR COVER -

INSTALLATION.......................23-96

FRONT SEAT TRACK - REAR COVER -

REMOVAL..........................23-96

FRONT SEAT TRACK MANUAL

ADJUSTER - INSTALLATION............23-95

FRONT SEAT TRACK MANUAL

ADJUSTER - REMOVAL................23-95

FRONT SEAT TRACK POWER ADJUSTER

- INSTALLATION.....................23-95

FRONT SEAT TRACK POWER ADJUSTER

- REMOVAL.........................23-95

FRONT SEATBACK ASSIST STRAP -

INSTALLATION.......................23-92

FRONT SEATBACK ASSIST STRAP -

REMOVAL..........................23-92

FRONT SEATBACK COVER -

INSTALLATION.......................23-93

FRONT SEATBACK COVER - REMOVAL

....23-93

FRONT SEATBACK PANEL -

INSTALLATION

.......................23-93

FRONT SEATBACK PANEL - REMOVAL

....23-92

FRONT SUSPENSION - DESCRIPTION

......2-2

FRONT SUSPENSION - OPERATION

........2-2FRONT SUSPENSION FASTENER

TORQUE, SPECIFICATIONS...............2-3

FRONT SUSPENSION, SPECIAL TOOLS.....2-3

FRONT WASHER PUMP MOTOR -

INSTALLATION.......................8R-8

FRONT WASHER PUMP MOTOR -

REMOVAL...........................8R-8

FRONT WHEEL SPEED SENSOR -

INSTALLATION........................5-80

FRONT WHEEL SPEED SENSOR -

REMOVAL...........................5-79

FRONT WHEELHOUSE SPLASH SHIELD -

INSTALLATION.......................23-55

FRONT WHEELHOUSE SPLASH SHIELD -

REMOVAL..........................23-55

FRONT WIPER ARM ALIGNMENT -

STANDARD PROCEDURE...............8R-8

FRONT WIPER ARMS - INSTALLATION....8R-9

FRONT WIPER ARMS - REMOVAL........8R-9

FRONT WIPER MOTOR - INSTALLATION . . . 8R-9

FRONT WIPER MOTOR - REMOVAL.......8R-9

FRONT WIPER SYSTEM - DIAGNOSIS

AND TESTING........................8R-2

FRONT WIPER/WASHER SWITCH -

DIAGNOSIS AND TESTING..............8R-2

FRONT/QUAD SEAT CUSHION -

INSTALLATION.......................23-93

FRONT/QUAD SEAT CUSHION -

REMOVAL..........................23-93

FRONT-WHEEL-DRIVE - INSTALLATION....2-36

FRONT-WHEEL-DRIVE - REMOVAL........2-36

FUEL CORRECTION OR ADAPTIVE

MEMORIES, OPERATION...............14-20

FUEL DELIVERY - DESCRIPTION..........14-2

FUEL DELIVERY - OPERATION...........14-2

FUEL DELIVERY SYSTEM - DIAGNOSIS

AND TESTING........................14-2

FUEL DOSING PUMP - DESCRIPTION....24-115

FUEL DOSING PUMP - INSTALLATION . . . 24-116

FUEL DOSING PUMP - OPERATION.....24-115

FUEL DOSING PUMP - REMOVAL.......24-115

FUEL ENGINE OIL - DESCRIPTION,

FLEXIBLE.............................0-3

FUEL FILL DOOR - INSTALLATION.......23-52

FUEL FILL DOOR - REMOVAL...........23-52

FUEL FILL DOOR BLOCKER LATCH -

INSTALLATION.......................23-53

FUEL FILL DOOR BLOCKER LATCH -

REMOVAL..........................23-53

FUEL FILL DOOR BLOCKER LATCH

STRIKER - INSTALLATION..............23-53

FUEL FILL DOOR BLOCKER LATCH

STRIKER - REMOVAL.................23-53

FUEL FILL DOOR BLOCKER LOCKOUT

LINK - INSTALLATION.................23-54

FUEL FILL DOOR BLOCKER LOCKOUT

LINK - REMOVAL.....................23-53

FUEL FILLER CAP - DESCRIPTION.......25-12

FUEL FILLER CAP - OPERATION.........25-12

FUEL INJECTOR - DESCRIPTION.........14-26

FUEL INJECTOR - OPERATION..........14-26

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION..........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-5

FUEL LINE - INSTALLATION...........24-118

FUEL LINE - REMOVAL...............24-117

FUEL LINES/HOSES AND CLAMPS -

DESCRIPTION........................14-6

FUEL PRESSURE REGULATOR -

INSTALLATION........................14-7

FUEL PRESSURE REGULATOR -

OPERATION..........................14-7

FUEL PRESSURE REGULATOR -

REMOVAL...........................14-7

FUEL PUMP - DESCRIPTION.............14-8

FUEL PUMP - OPERATION..............14-8

FUEL PUMP MODULE - DESCRIPTION.....14-8

FUEL PUMP MODULE - INSTALLATION....14-9

FUEL PUMP MODULE - OPERATION

.......14-8

FUEL PUMP MODULE - REMOVAL

........14-8

FUEL PUMP RELAY - DESCRIPTION

......14-28

FUEL PUMP RELAY - OPERATION

........14-28

FUEL REQUIREMENTS - DESCRIPTION

......0-4FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-6

FUEL, SPECIAL TOOLS............14-23,14-4

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE - STANDARD

PROCEDURE.........................14-2

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-3

FUEL TANK - DESCRIPTION............14-10

FUEL TANK - INSTALLATION............14-12

FUEL TANK - OPERATION..............14-11

FUEL TANK - REMOVAL...............14-11

FUEL TANK - STANDARD PROCEDURE,

DRAINING...........................14-2

FUEL TANK FILLER TUBE -

INSTALLATION.......................14-13

FUEL TANK FILLER TUBE - REMOVAL....14-12

FULL OPEN SWITCH - DESCRIPTION....8N-12,

8N-31

FULL OPEN SWITCH - INSTALLATION....8N-13

FULL OPEN SWITCH - OPERATION . 8N-12,8N-31

FULL OPEN SWITCH - REMOVAL........8N-13

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD...........8W-97-3

FUSE - OPERATION, IOD.............8W-97-3

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON......8W-01-10

FWD - INSTALLATION..................2-45

FWD - INSTALLATION, REAR WHEEL

SPEED SENSOR.......................5-81

FWD - INSTALLATION, SPRING...........2-42

FWD - REMOVAL......................2-45

FWD - REMOVAL, REAR WHEEL SPEED

SENSOR............................5-81

FWD - REMOVAL, SPRING..............2-41

GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE AND OIL . 9-10,9-86

GAP AND FLUSH MEASUREMENTS -

SPECIFICATIONS....................23-124

GAP, SPECIFICATIONS - WHEEL SPEED

SENSOR AIR.........................5-79

GAS - INSTALLATION, MODULAR

CLUTCH ASSY - 2.4L..................6-11

GAS - REMOVAL, MODULAR CLUTCH

ASSY - 2.4L..........................6-11

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD.............9-24,9-99,9s-16

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE....9-11,9-85

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE.......9-11,9-84

GASOLINE ENGINES - DIAGNOSIS AND

TESTING, SYSTEM CHARGE LEVEL

TEST..............................24-67

GEAR - DESCRIPTION.................19-26

GEAR - INSTALLATION, LHD............19-32

GEAR - INSTALLATION, RHD............19-33

GEAR & LINK ROD - DESCRIPTION, LIFT . 8N-16

GEAR & LINK ROD - INSTALLATION,

LIFT...............................8N-16

GEAR & LINK ROD - OPERATION, LIFT . . . 8N-16

GEAR & LINK ROD - REMOVAL, LIFT.....8N-16

GEAR - OPERATION...................19-27

GEAR - REMOVAL, LHD...............19-27

GEAR - REMOVAL, RHD...............19-31

GEAR END PLAY - ADJUSTMENT,

DIFFERENTIAL SIDE..................21-70

GEAR SHIFT CABLE - INSTALLATION....21-205

GEAR SHIFT CABLE - REMOVAL . 21-204,21s-105

GEAR SHIFT LEVER - INSTALLATION.....19-21

GEAR SHIFT LEVER - REMOVAL.........19-21

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-34

GEARSHIFT BOOT - INSTALLATION......21-73

GEARSHIFT BOOT - REMOVAL..........21-72

GEARSHIFT CABLE - CROSSOVER -

INSTALLATION.......................21-76

GEARSHIFT CABLE - CROSSOVER -

REMOVAL..........................21-73

GEARSHIFT CABLE - SELECTOR -

INSTALLATION

.......................21-84

GEARSHIFT CABLE - SELECTOR -

REMOVAL

..........................21-81

GEARSHIFT CABLE ADJUSTMENT,

ADJUSTMENTS

.....................21-206

GEARSHIFT KNOB - INSTALLATION

......21-87

GEARSHIFT KNOB - REMOVAL

..........21-87

RSINDEX15

Description Group-Page Description Group-Page Description Group-Page

Page 2562 of 2585

KEY REMOTE ENTRY MODULE -

INSTALLATION, SENTRY................8Q-6

KEY REMOTE ENTRY MODULE -

OPERATION, SENTRY..................8Q-4

KEY REMOTE ENTRY MODULE -

REMOVAL, SENTRY...................8Q-5

KEY REMOTE ENTRY SYSTEM -

DIAGNOSIS AND TESTING, SENTRY.......8Q-3

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE...............8N-43

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE...............8N-43

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE..............8N-44

KEYLESS ENTRY MODULE - OPERATION,

REMOTE...........................8N-43

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE...........................8N-44

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING.........8N-42,8N-5

KEYLESS ENTRY TRANSMITTER

PROGRAMMING - STANDARD

PROCEDURE, REMOTE.................8N-5

KEY/LOCK CYLINDER - DESCRIPTION....19-20

KEY/LOCK CYLINDER - INSTALLATION....19-20

KEY/LOCK CYLINDER - OPERATION......19-20

KEY/LOCK CYLINDER - REMOVAL.......19-20

KNOB - INSTALLATION, GEARSHIFT......21-87

KNOB - INSTALLATION, SEAT BELT

HEIGHT ADJUSTER...................8O-14

KNOB - REMOVAL, GEARSHIFT..........21-87

KNOB - REMOVAL, SEAT BELT HEIGHT

ADJUSTER.........................8O-14

KNOCK SENSOR - DESCRIPTION..........8I-8

KNOCK SENSOR - OPERATION...........8I-8

KNUCKLE - DESCRIPTION................2-6

KNUCKLE - INSPECTION, STEERING........2-9

KNUCKLE - INSTALLATION, STEERING......2-9

KNUCKLE - OPERATION.................2-7

KNUCKLE - REMOVAL, STEERING.........2-7

LABEL - DESCRIPTION, E-MARK......Intro.-11

LABEL - DESCRIPTION, VECI.........Intro.-11

LABEL - DESCRIPTION, VEHICLE

CERTIFICATION....................Intro.-11

LABEL - DESCRIPTION, VEHICLE

EMISSION CONTROL INFORMATION.......25-1

LAMP - DESCRIPTION, VTSS/SKIS

INDICATOR..........................8Q-7

LAMP - DIAGNOSIS AND TESTING,

FRONT FOG..........................8L-7

LAMP - INSTALLATION, CENTER

CONSOLE...........................8L-21

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - INSTALLATION, COURTESY......8L-21

LAMP - INSTALLATION, DOME/CARGO....8L-22

LAMP - INSTALLATION, FRONT FOG.......8L-8

LAMP - INSTALLATION, LICENSE........8L-17

LAMP - INSTALLATION, LIFTGATE.......8L-22

LAMP - INSTALLATION, PARK/TURN

SIGNAL............................8L-18

LAMP - INSTALLATION, READING........8L-23

LAMP - INSTALLATION, TAIL...........8L-19

LAMP - INSTALLATION, VANITY.........8L-24

LAMP - OPERATION, VTSS/SKIS

INDICATOR..........................8Q-8

LAMP - REMOVAL, CENTER CONSOLE....8L-21

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - REMOVAL, COURTESY..........8L-21

LAMP - REMOVAL, DOME/CARGO.......8L-22

LAMP - REMOVAL, FRONT FOG..........8L-8

LAMP - REMOVAL, LICENSE............8L-17

LAMP - REMOVAL, LIFTGATE...........8L-22

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-18

LAMP - REMOVAL, READING...........8L-23

LAMP - REMOVAL, TAIL...............8L-18

LAMP - REMOVAL, VANITY.............8L-24

LAMP REPLACEMENT - STANDARD

PROCEDURE, MODULE................8M-3

LAMP REPLACEMENT - STANDARD

PROCEDURE, READING/COURTESY

.......8M-3

LAMP SWITCH - DESCRIPTION, BRAKE

....8L-4

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE

......................8L-4

LAMP SWITCH - INSTALLATION,

BACK-UP

...........................21-62

LAMP SWITCH - INSTALLATION, BRAKE

. . . 8L-5LAMP SWITCH - INSTALLATION, CENTER

CONSOLE...........................8L-21

LAMP SWITCH - INSTALLATION, GLOVE

BOX ...............................8L-22

LAMP SWITCH - OPERATION, BRAKE......8L-4

LAMP SWITCH - REMOVAL, BACK-UP....21-62

LAMP SWITCH - REMOVAL, BRAKE.......8L-5

LAMP SWITCH - REMOVAL, CENTER

CONSOLE...........................8L-21

LAMP SWITCH - REMOVAL, GLOVE BOX . . 8L-22

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP.................8L-6

LAMP UNIT - INSTALLATION, TAIL.......8L-19

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP UNIT - REMOVAL, TAIL...........8L-19

LAMP UNIT ALIGNMENT - EXPORT -

STANDARD PROCEDURE, FRONT FOG.....8L-9

LAMP UNIT ALIGNMENT - STANDARD

PROCEDURE, FRONT FOG...............8L-9

LAMPS - INSTALLATION, CLUSTER

ILLUMINATION......................8L-21

LAMPS - REMOVAL, CLUSTER

ILLUMINATION......................8L-21

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-3

LAMPS, SPECIFICATIONS - INTERIOR....8L-20

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-2

LAMPS/LIGHTING - EXTERIOR -

WARNING...........................8L-3

LASH ADJUSTER NOISE DIAGNOSIS -

DIAGNOSIS AND TESTING, HYDRAULIC....9-34

LASH ADJUSTERS - INSTALLATION,

HYDRAULIC..........................9-34

LASH ADJUSTERS - REMOVAL,

HYDRAULIC..........................9-34

LATCH - DESCRIPTION...........8N-13,8N-29

LATCH - INSTALLATION.....23-18,23-41,23-61

LATCH - INSTALLATION..........8N-14,8N-29

LATCH - INSTALLATION, FUEL FILL

DOOR BLOCKER.....................23-53

LATCH - INSTALLATION, GLOVE BOX.....23-64

LATCH - INSTALLATION, HOLD OPEN.....23-25

LATCH / LOCK ASSEMBLY -

INSTALLATION.......................23-27

LATCH / LOCK ASSEMBLY - REMOVAL....23-26

LATCH - OPERATION............8N-13,8N-29

LATCH - REMOVAL.........23-18,23-41,23-61

LATCH - REMOVAL..............8N-13,8N-29

LATCH - REMOVAL, FUEL FILL DOOR

BLOCKER...........................23-53

LATCH - REMOVAL, GLOVE BOX.........23-64

LATCH - REMOVAL, HOLD OPEN........23-25

LATCH ACTUATOR - DESCRIPTION......8N-14

LATCH ACTUATOR - INSTALLATION......8N-14

LATCH ACTUATOR - OPERATION........8N-14

LATCH ACTUATOR - REMOVAL..........8N-14

LATCH CABLE - INSTALLATION, HOLD

OPEN..............................23-38

LATCH CABLE - REMOVAL, HOLD OPEN . . . 23-38

LATCH HANDLE - INSTALLATION, INSIDE . . 23-34

LATCH HANDLE - REMOVAL, INSIDE.....23-34

LATCH LOCKING LINK - INSTALLATION,

SEAT RISER........................23-106

LATCH LOCKING LINK - REMOVAL, SEAT

RISER

............................23-106

LATCH RELEASE CABLE - INSTALLATION

. . 23-62

LATCH RELEASE CABLE - REMOVAL

.....23-61

LATCH STRIKER - INSTALLATION

. . 23-19,23-41,

23-62

LATCH STRIKER - INSTALLATION, FUEL

FILL DOOR BLOCKER

.................23-53

LATCH STRIKER - INSTALLATION, GLOVE

BOX

...............................23-64

LATCH STRIKER - INSTALLATION, HOLD

OPEN

..............................23-26

LATCH STRIKER - INSTALLATION, REAR

. . 23-29

LATCH STRIKER - REMOVAL

. 23-19,23-41,23-62

LATCH STRIKER - REMOVAL, FUEL FILL

DOOR BLOCKER

.....................23-53

LATCH STRIKER - REMOVAL, GLOVE

BOX

...............................23-64

LATCH STRIKER - REMOVAL, HOLD

OPEN

..............................23-26

LATCH STRIKER - REMOVAL, REAR

......23-29LEAD - DIAGNOSIS AND TESTING,

TIRE/VEHICLE..................22-14,22s-6

LEAF SPRING FRONT BUSHING -

INSTALLATION........................2-30

LEAF SPRING FRONT BUSHING -

REMOVAL...........................2-29

LEAK DETECTION ASSY - INSTALLATION,

NATURAL VAC.......................25-13

LEAK DETECTION ASSY - REMOVAL,

NATURAL VAC.......................25-13

LEAK DETECTION PUMP - INSTALLATION . 25-13

LEAK DETECTION PUMP - REMOVAL.....25-13

LEAK DIAGNOSIS, DIAGNOSIS AND

TESTING - FLUID......................21-3

LEAK INSPECTION - DIAGNOSIS AND

TESTING, ENGINE OIL...............9-8,9-82

LEAK REPAIRING - STANDARD

PROCEDURE, TIRE..............22-17,22s-9

LEAK TEST - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-2

LEAKAGE - DIAGNOSIS AND TESTING,

TORQUE CONVERTER HOUSING FLUID . . 21-123,

21s-31

LEAKAGE TEST - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION

PRESSURE.......................9-83,9-9

LEAKS - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD...............9-145,9-58

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-66

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-1

LEARN CYCLE - STANDARD

PROCEDURE, POWER DOOR.............8N-28

LEARN CYCLE - STANDARD

PROCEDURE, POWER LIFTGATE..........8N-9

LEARN PROCEDURE - STANDARD

PROCEDURE, QUICK.............8E-16,8E-23

LEFT - CLEANING, EXHAUST MANIFOLD . . 9-152

LEFT - INSPECTION, EXHAUST

MANIFOLD..........................9-152

LEFT - INSTALLATION, CYLINDER HEAD

COVER.............................9-103

LEFT - INSTALLATION, EXHAUST

MANIFOLD..........................9-152

LEFT - REMOVAL, CYLINDER HEAD

COVER.............................9-103

LEFT - REMOVAL, EXHAUST MANIFOLD . . . 9-152

LEFT B-PILLAR SWITCH - DESCRIPTION . . 8N-32

LEFT B-PILLAR SWITCH - INSTALLATION . 8N-32

LEFT B-PILLAR SWITCH - OPERATION....8N-32

LEFT B-PILLAR SWITCH - REMOVAL.....8N-32

LEFT D-PILLAR TRIM PANEL -

INSTALLATION.......................23-78

LEFT D-PILLAR TRIM PANEL - REMOVAL . 23-78

LEFT MOUNT - INSTALLATION......9-133,9-50

LEFT MOUNT - REMOVAL..........9-133,9-49

LEFT OUTBOARD - INSTALLATION, SEAT

BELT & RETRACTOR - SECOND ROW....8O-17

LEFT OUTBOARD - REMOVAL, SEAT

BELT & RETRACTOR - SECOND ROW....8O-17

LEFT QUARTER TRIM PANEL -

INSTALLATION.......................23-80

LEFT QUARTER TRIM PANEL - REMOVAL

. 23-80

LENS - INSTALLATION, CLUSTER

........8J-10

LENS - REMOVAL, CLUSTER

............8J-10

LEVEL - STANDARD PROCEDURE,

CHECKING BATTERY ELECTROLYTE

......8F-14

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL

...................24-93

LEVEL AND CONDITION CHECK,

STANDARD PROCEDURE - FLUID

......21-201,

21s-102

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT

.................7-5

LEVEL CHECK - STANDARD

PROCEDURE, ENGINE OIL

..............9-137

LEVEL CHECK - STANDARD

PROCEDURE, FLUID

..................21-71

LEVEL CHECK, STANDARD PROCEDURE

- ENGINE OIL

........................9-53

LEVEL CHECKING - STANDARD

PROCEDURE, BRAKE FLUID

........5-32,5s-31

LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING FLUID

. . . 19-44

LEVEL INSPECTION - STANDARD

PROCEDURE, FLUID

...................21-4

RSINDEX19

Description Group-Page Description Group-Page Description Group-Page

Page 2563 of 2585

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL...................14-5

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL..................14-5

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL.....................14-5

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL......................14-5

LEVEL SWITCH - DESCRIPTION, BRAKE

FLUID..........................5-10,5s-9

LEVEL SWITCH - INSTALLATION, BRAKE

FLUID..........................5-11,5s-10

LEVEL SWITCH - INSTALLATION,

WASHER FLUID.....................8R-12

LEVEL SWITCH - OPERATION, BRAKE

FLUID..........................5-10,5s-9

LEVEL SWITCH - REMOVAL, BRAKE

FLUID..........................5-11,5s-10

LEVEL SWITCH - REMOVAL, WASHER

FLUID.............................8R-12

LEVEL TEST - 2.5L DIESEL - DIAGNOSIS

AND TESTING, SYSTEM CHARGE........24-68

LEVEL TEST - GASOLINE ENGINES -

DIAGNOSIS AND TESTING, SYSTEM

CHARGE............................24-67

LEVER - INSTALLATION, GEAR SHIFT.....19-21

LEVER - PARKING BRAKE -

INSTALLATION...................5-65,5s-67

LEVER - PARKING BRAKE - REMOVAL....5-64,

5s-67

LEVER - REMOVAL, GEAR SHIFT........19-21

LEVER AND BEARING - INSTALLATION,

CLUTCH RELEASE......................6-7

LEVER AND BEARING - REMOVAL,

CLUTCH RELEASE......................6-6

LEVER AND FRONT CABLE -

INSTALLATION, PARKING BRAKE....5-66,5s-69

LEVER AND FRONT CABLE - REMOVAL,

PARKING BRAKE.................5-65,5s-68

LHD - INSTALLATION.....5-38,5-46,5-94,5s-37,

5s-49

LHD - INSTALLATION, MASTER

CYLINDER...........................6-10

LHD - REMOVAL....5-36,5-42,5-90,5s-35,5s-45

LHD - REMOVAL, MASTER CYLINDER......6-9

LHD GEAR - INSTALLATION............19-32

LHD GEAR - REMOVAL................19-27

LICENSE LAMP - INSTALLATION.........8L-17

LICENSE LAMP - REMOVAL............8L-17

LIFT GEAR & LINK ROD - DESCRIPTION . . 8N-16

LIFT GEAR & LINK ROD - INSTALLATION . 8N-16

LIFT GEAR & LINK ROD - OPERATION....8N-16

LIFT GEAR & LINK ROD - REMOVAL.....8N-16

LIFTERS - DIAGNOSIS AND TESTING,

HYDRAULIC.........................9-113

LIFTERS (CAM IN BLOCK) -

DESCRIPTION, HYDRAULIC.............9-113

LIFTERS (CAM IN BLOCK) -

INSTALLATION, HYDRAULIC............9-114

LIFTERS (CAM IN BLOCK) - REMOVAL,

HYDRAULIC.........................9-114

LIFTGATE - INSTALLATION.............23-42

LIFTGATE - REMOVAL.................23-42

LIFTGATE ADJUSTMENT - STANDARD

PROCEDURE.........................8N-9

LIFTGATE CONTROL MODULE -

DESCRIPTION, POWER................8E-10

LIFTGATE CONTROL MODULE -

INSTALLATION, POWER...............8E-11

LIFTGATE CONTROL MODULE -

OPERATION, POWER..................8E-11

LIFTGATE CONTROL MODULE -

REMOVAL, POWER...................8E-11

LIFTGATE LAMP - INSTALLATION

........8L-22

LIFTGATE LAMP - REMOVAL

............8L-22

LIFTGATE LEARN CYCLE - STANDARD

PROCEDURE, POWER

..................8N-9

LIFTGATE MOTOR - DESCRIPTION

.......8N-15

LIFTGATE MOTOR - INSTALLATION

......8N-15

LIFTGATE MOTOR - OPERATION

.........8N-15

LIFTGATE MOTOR - REMOVAL

..........8N-15

LIFTGATE SIDE - INSTALLATION

.........23-44

LIFTGATE SIDE - REMOVAL

............23-44

LIFTGATE SILL PLATE - INSTALLATION

. . . 23-79

LIFTGATE SILL PLATE - REMOVAL

.......23-79

LIFTGATE SPOILER - INSTALLATION

......23-42

LIFTGATE SPOILER - REMOVAL

.........23-42LIFTGATE SYSTEM - DESCRIPTION,

POWER.............................8N-2

LIFTGATE SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................8N-4

LIFTGATE SYSTEM - OPERATION,

POWER.............................8N-3

LIMITS - DESCRIPTION, HIGH AND LOW . . . 25-8

LINE - DESCRIPTION, REFRIGERANT.....24-65

LINE - INSTALLATION, A/C DISCHARGE . . . 24-80

LINE - INSTALLATION, FUEL...........24-118

LINE - INSTALLATION, LIQUID....24-105,24-90

LINE - INSTALLATION, SUCTION . . . 24-107,24-95

LINE - REMOVAL, A/C DISCHARGE.......24-79

LINE - REMOVAL, FUEL...............24-117

LINE - REMOVAL, LIQUID........24-104,24-88

LINE - REMOVAL, SUCTION......24-106,24-94

LINE AND TERMINAL REPAIR -

STANDARD PROCEDURE, GRID..........8G-4

LINE EXTENSION - INSTALLATION, REAR

A/C EVAPORATOR....................24-99

LINE EXTENSION - REMOVAL, A/C

EVAPORATOR.......................24-98

LINES - DESCRIPTION, OIL COOLER.....9-138

LINES - DESCRIPTION, UNDERBODY....24-107

LINES - INSTALLATION, OIL COOLER.....9-138

LINES - INSTALLATION, REAR HEATER . . 24-111

LINES - INSTALLATION, TRANSMISSION

OIL COOLER.........................7-38

LINES - INSTALLATION, UNDERBODY

REFRIGERANT......................24-111

LINES - OPERATION, OIL COOLER.......9-138

LINES - OPERATION, REFRIGERANT......24-65

LINES - OPERATION, UNDERBODY......24-107

LINES - REMOVAL, OIL COOLER........9-138

LINES - REMOVAL, TRANSMISSION OIL

COOLER.............................7-38

LINES - REMOVAL, UNDERBODY

REFRIGERANT......................24-110

LINES/HOSES AND CLAMPS -

DESCRIPTION, FUEL...................14-6

LINING - INSPECTION, REAR DRUM

BRAKE SHOE....................5-22,5s-21

LINK - DESCRIPTION, TRD............21-249

LINK - INSTALLATION, FUEL FILL DOOR

BLOCKER LOCKOUT..................23-54

LINK - INSTALLATION, SEAT RISER

LATCH LOCKING....................23-106

LINK - OPERATION, TRD..............21-249

LINK - REMOVAL, FUEL FILL DOOR

BLOCKER LOCKOUT..................23-53

LINK - REMOVAL, SEAT RISER LATCH

LOCKING..........................23-106

LINK CONNECTOR - DESCRIPTION, DATA . . 8E-6

LINK CONNECTOR - OPERATION, DATA....8E-7

LINK ROD - DESCRIPTION, LIFT GEAR . . . 8N-16

LINK ROD - INSTALLATION, LIFT GEAR . . . 8N-16

LINK ROD - OPERATION, LIFT GEAR.....8N-16

LINK ROD - REMOVAL, LIFT GEAR.......8N-16

LINKAGE - INSTALLATION, WIPER.......8R-14

LINKAGE - REMOVAL, WIPER...........8R-14

LIQUID LINE - INSTALLATION.....24-105,24-90

LIQUID LINE - REMOVAL........24-104,24-88

LOADS - STANDARD PROCEDURE,

TESTING FOR A SHORT TO GROUND

ON FUSES POWERING SEVERAL.....8W-01-10

LOCATION - DESCRIPTION, CONNECTOR/

GROUND/SPLICE...................8W-91-1

LOCATIONS - DESCRIPTION, FLUID

FILL/CHECK...........................0-7

LOCATIONS - SPECIFICATIONS, BODY

SEALING..........................23-130

LOCATIONS - SPECIFICATIONS,

STRUCTURAL ADHESIVE..............23-156

LOCATIONS - SPECIFICATIONS, WELD . . . 23-166

LOCK ASSEMBLY - INSTALLATION,

LATCH .............................23-27

LOCK ASSEMBLY - REMOVAL, LATCH....23-26

LOCK CYLINDER - INSTALLATION . . 23-19,23-42

LOCK CYLINDER - REMOVAL......23-19,23-42

LOCK CYLINDER HOUSING -

INSTALLATION

.......................19-19

LOCK CYLINDER HOUSING - REMOVAL

. . . 19-17

LOCK MOTOR - DIAGNOSIS AND

TESTING, DOOR

.................8N-4,8N-41

LOCK MOTOR - INSTALLATION, SLIDING

DOOR

.........................8N-44,8N-6

LOCK MOTOR - REMOVAL, SLIDING

DOOR

.........................8N-44,8N-6LOCK SWITCH - DESCRIPTION, DOOR

CYLINDER..........................8N-40

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR.................8N-4,8N-41

LOCK SWITCH - DIAGNOSIS AND

TESTING, DOOR CYLINDER............8N-40

LOCK SWITCH - EXPORT -

DESCRIPTION, DOOR CYLINDER.........8N-3

LOCK SWITCH - EXPORT - DIAGNOSIS

AND TESTING, DOOR CYLINDER.........8N-3

LOCK SWITCH - EXPORT -

INSTALLATION, DOOR CYLINDER.........8N-4

LOCK SWITCH - EXPORT - OPERATION,

DOOR CYLINDER.....................8N-3

LOCK SWITCH - EXPORT - REMOVAL,

DOOR CYLINDER.....................8N-3

LOCK SWITCH - INSTALLATION, DOOR....8N-4,

8N-42

LOCK SWITCH - INSTALLATION, DOOR

CYLINDER..........................8N-41

LOCK SWITCH - OPERATION, DOOR

CYLINDER..........................8N-40

LOCK SWITCH - REMOVAL, DOOR . . 8N-4,8N-42

LOCK SWITCH - REMOVAL, DOOR

CYLINDER..........................8N-41

LOCKED ENGINE - STANDARD

PROCEDURE, HYDROSTATIC.........9-10,9-85

LOCKING LINK - INSTALLATION, SEAT

RISER LATCH......................23-106

LOCKING LINK - REMOVAL, SEAT RISER

LATCH ............................23-106

LOCK/LATCH - INSTALLATION, UNDER

SEAT STORAGE BIN.................23-105

LOCK/LATCH - REMOVAL, UNDER SEAT

STORAGE BIN......................23-105

LOCKOUT LINK - INSTALLATION, FUEL

FILL DOOR BLOCKER.................23-54

LOCKOUT LINK - REMOVAL, FUEL FILL

DOOR BLOCKER.....................23-53

LOCKS - DESCRIPTION, POWER....8N-1,8N-38

LOCKS - OPERATION, POWER......8N-2,8N-39

LOUVER - INSTALLATION, REAR HVAC . . . 23-81

LOUVER - REMOVAL, REAR HVAC.......23-81

LOW LIMITS - DESCRIPTION, HIGH.......25-8

LOWER - CLEANING, INTAKE MANIFOLD . . 9-148

LOWER - INSPECTION, INTAKE

MANIFOLD......................9-148,9-60

LOWER - INSTALLATION, INTAKE

MANIFOLD...........................9-60

LOWER - INSTALLATION, SHROUD.......19-22

LOWER - REMOVAL, INTAKE MANIFOLD . . . 9-60

LOWER - REMOVAL, SHROUD..........19-21

LOWER BALL JOINT - DESCRIPTION......2-10

LOWER BALL JOINT - DIAGNOSIS AND

TESTING............................2-10

LOWER BALL JOINT - OPERATION........2-10

LOWER CONSOLE - INSTALLATION......23-69

LOWER CONSOLE - REMOVAL..........23-69

LOWER CONTROL ARM - DESCRIPTION . . . 2-12

LOWER CONTROL ARM - INSPECTION.....2-14

LOWER CONTROL ARM - INSTALLATION . . . 2-16

LOWER CONTROL ARM - OPERATION.....2-12

LOWER CONTROL ARM - REMOVAL......2-12

LOWER CONTROL ARM (REAR BUSHING

- HYDRO) - ASSEMBLY.................2-14

LOWER CONTROL ARM (REAR BUSHING

- HYDRO) - DISASSEMBLY..............2-14

LOWER CONTROL ARM (REAR BUSHING

- STANDARD) - ASSEMBLY..............2-14

LOWER CONTROL ARM (REAR BUSHING

- STANDARD) - DISASSEMBLY...........2-13

LOWER DRIVE UNIT - DESCRIPTION.....8N-32

LOWER DRIVE UNIT - INSTALLATION....8N-33

LOWER DRIVE UNIT - OPERATION.......8N-32

LOWER DRIVE UNIT - REMOVAL........8N-33

LOWER DRIVE UNIT TRACK & RACK -

DESCRIPTION.......................8N-34

LOWER DRIVE UNIT TRACK & RACK -

INSTALLATION......................8N-34

LOWER DRIVE UNIT TRACK & RACK -

OPERATION

.........................8N-34

LOWER DRIVE UNIT TRACK & RACK -

REMOVAL

..........................8N-34

LOWER EXTENSION TRIM -

INSTALLATION, A-PILLAR

..............23-74

LOWER EXTENSION TRIM - REMOVAL,

A-PILLAR

...........................23-74

LOWER HINGE - INSTALLATION

.........23-28

20 INDEXRS

Description Group-Page Description Group-Page Description Group-Page