belt CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1451 of 2339

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

(4) Install the power steering fluid pressure hose

fitting into the pressure port of the power steering

pump (Fig. 12). Tighten the pressure line to pump

fitting tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid supply hose on

the power steering pump supply fitting (Fig. 12).Be

sure hose clamp is properly reinstalled.

(6) Install the accessary drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(7) Install the splash shields below the engine

compartment.

(8) Lower the vehicle.

(9) Connect the negative (-) battery cable on the

negative battery post.

(10) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(11) Inspect for leaks.

SPECIAL TOOLS

POWER STEERING PUMP

FLUID

STANDARD PROCEDURE - POWER STEERING

FLUID LEVEL CHECKING

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT INJURY

FROM MOVING PARTS AND TO ENSURE ACCU-

RATE FLUID LEVEL READING.

The fluid level can be read on the exterior of the

power steering fluid reservoir. The fluid level should

be within the ªFILL RANGEº when the fluid is at

normal ambient temperature, approximately 21ÉC to

27ÉC (70ÉF to 80ÉF) (Fig. 17).

Before removing the power steering filler cap, wipe

the reservoir filler cap free of dirt and debris. Do not

overfill the power steering system.Use only

MopartATF+4 Automatic Transmission Fluid

(MS-9602) in the power steering system.For

additional information on Automatic Transmission

Fluid, (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION).

CAUTION: Use only MoparTATF+4 Automatic Trans-

mission Fluid (MS-9602). Use of other MoparT

power steering fluids (MS5931 and MS9933) should

be avoided to ensure peak performance of the

power steering system under all operating condi-

tions.

Installer C-4063B

Puller C-4333

Fig. 17 Power Steering Fluid Reservoir

19 - 44 PUMPRS

PUMP (Continued)

Page 1770 of 2339

TIRES

DESCRIPTION

DESCRIPTION - TIRE

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain, in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

²Operating vehicle with over or under inflated

tire pressures

Radial ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation. This will

help to achieve a greater tread-life potential.

TIRE IDENTIFICATION

Tire type, size, load index and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the Tire Identification

chart to decipher the code. For example purposes, the

tire size P225/60 R 16 97 T is used in the chart. An

All Season type tire will also have eitherM+S,M&

SorM-S(indicating mud and snow traction)

imprinted on the side wall. An Extra or Light Load

marking ªXLº or ªLLº may also be listed on the side-

wall. The absence of an ªXLº or ªLLº marking infers

a standard load tire.

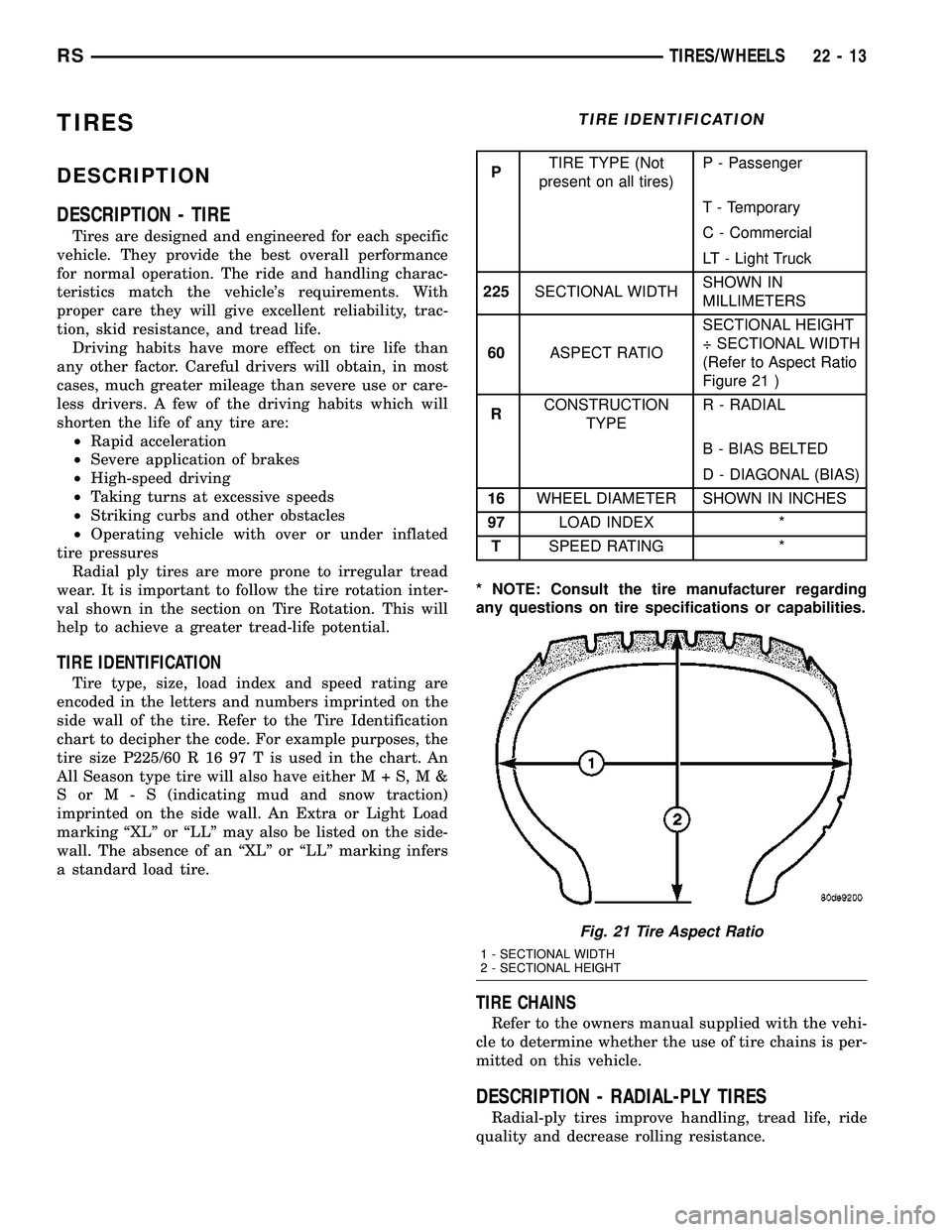

TIRE IDENTIFICATION

PTIRE TYPE (Not

present on all tires)P - Passenger

T - Temporary

C - Commercial

LT - Light Truck

225SECTIONAL WIDTHSHOWN IN

MILLIMETERS

60ASPECT RATIOSECTIONAL HEIGHT

÷ SECTIONAL WIDTH

(Refer to Aspect Ratio

Figure 21 )

RCONSTRUCTION

TYPER - RADIAL

B - BIAS BELTED

D - DIAGONAL (BIAS)

16WHEEL DIAMETER SHOWN IN INCHES

97LOAD INDEX *

TSPEED RATING *

* NOTE: Consult the tire manufacturer regarding

any questions on tire specifications or capabilities.

TIRE CHAINS

Refer to the owners manual supplied with the vehi-

cle to determine whether the use of tire chains is per-

mitted on this vehicle.

DESCRIPTION - RADIAL-PLY TIRES

Radial-ply tires improve handling, tread life, ride

quality and decrease rolling resistance.

Fig. 21 Tire Aspect Ratio

1 - SECTIONAL WIDTH

2 - SECTIONAL HEIGHT

RSTIRES/WHEELS22-13

Page 1789 of 2339

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightly

together and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-ing the glue. Once the new material is in place, it

may be necessary to use a soldering gun to melt

the newly applied material. Do not over heat the

affected area, damage to the exterior of the trim

panel may occur.

(4) Allow the repaired area to cool and verify the

repair.

(5) Install trim panel.

SPECIFICATIONS

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

All seat belt anchor bolts 39 29 Ð

Armrest shoulder bolt 29 21 Ð

Bench seat riser bolts 48 35 Ð

Bench seat track nuts 48 35 Ð

Quad bucket seat track to cushion frame bolts 40 30 Ð

Bucket seat back pivot bolts 33 24 Ð

Center seat to seat track bolts 24 17 Ð

Child seat module screws (bench seats) 7 Ð 62

Child seat module screws (quad seats) 13.5 10 Ð

Crossmember to radiator closure panel bolts 28 21 Ð

Door check strap to door end frame 12 Ð 105

Door latch to door end frame bolts 10 Ð 89

Floor latch to seat cushion frame bolts 27 19 Ð

Fig. 14 COVER GAPS WITH MESH

1 - GROUND DOWN AREA

2 - PATCH

3 - MESH

Fig. 15 COVER MESH WITH ADHESIVE

1 - ADHESIVE

2 - MESH

3 - PATCH

4 - SPREADER

23 - 10 BODYRS

BODY (Continued)

Page 1790 of 2339

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front cover to seat track screws 4 Ð 32

Front door hinge to hinge pillar bolts 34 25 Ð

Front door hinge to door nuts and bolts 34 25 Ð

Front door latch striker bolts 28 21 Ð

Front/quad seat cushion bolts 28.5 21 Ð

Front seat belt retractor bolts 38 28 Ð

Front seat riser to floor nuts 60 44 Ð

Front seat track cover screws 4 Ð 35

Front seat riser to seat track nuts 81 60 Ð

Front seatback pivot bolts 54 40 Ð

Front seatback recliner nut 12 Ð 105

Front seatback assist strap screws 2.5 Ð 22

Grocery bag holder screws 2 Ð 17

Hinge to liftgate bolts 33 24 Ð

Hood latch to bolts 13.5 10 Ð

Hood latch striker bolts 13.5 10 Ð

Hood hinge to hood bolts 13.5 10 Ð

Liftgate exterior handle outer screws 20 15 Ð

Liftgate exterior handle inner bolts 40 30 Ð

Lifgate hinge to roof header bolts 33 24 Ð

Liftgate latch bolts 16 12 Ð

Liftgate latch striker bolts 28 21 Ð

Liftgate lift motor link to liftgate 28 21 Ð

Liftgate spoiler bolts 9 Ð 80

Lifgate stabilizer wedge striker to D-pillar bolts 3 Ð 30

Luggage rack crossbar fasteners 4 Ð 35

Lumbar support handle screw 1 Ð 9

Pivot bolt to the body half of hood hinge 28 21 Ð

Prop assembly to lifgate bolts 28 21 Ð

Rear door glass to regulator bolt 11 8 Ð

Rear door hinge to B-pillar bolt 28 20 Ð

Rear door hinge to door bolt 28 20 Ð

Rear door latch striker 28 20 Ð

Rear latch to sliding door end frame 28 20 Ð

Rear seat back to seat cushion bolt 27 19 Ð

Recliner to seat back frame 12 9 Ð

Seatback frame upper rail 8 Ð 71

Seatback hinge bolt 48 35 Ð

Seatback hinge cover screws 2.3 Ð 20

Shoulder belt turning loop onto height adjuster 39 29 Ð

Side view mirror bolts 10 Ð 85

Sliding door center hinge adjusting bolt 15 Ð 130

RSBODY23-11

BODY (Continued)

Page 1792 of 2339

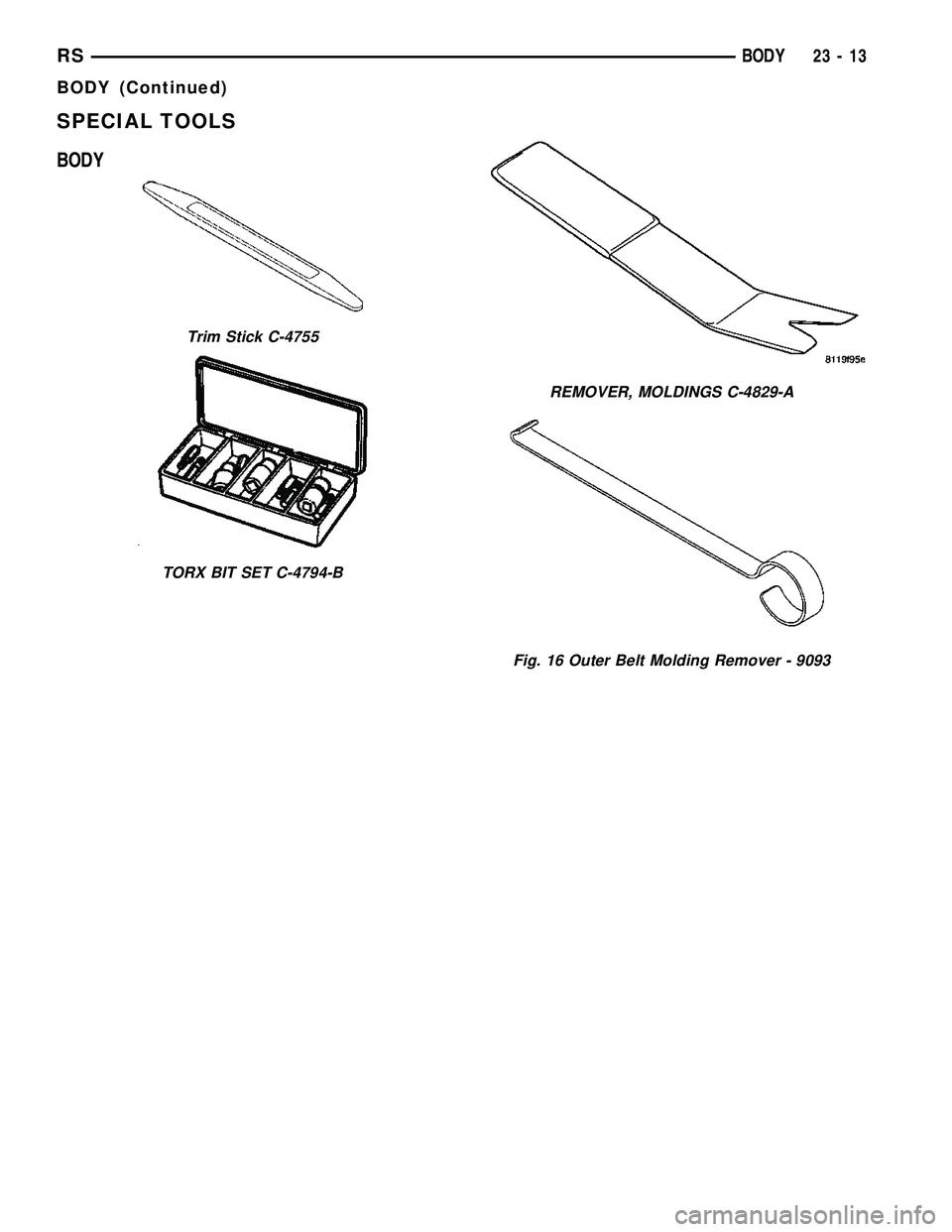

SPECIAL TOOLS

BODY

Trim Stick C-4755

TORX BIT SET C-4794-B

REMOVER, MOLDINGS C-4829-A

Fig. 16 Outer Belt Molding Remover - 9093

RSBODY23-13

BODY (Continued)

Page 1793 of 2339

DOOR - FRONT

TABLE OF CONTENTS

page page

APPLIQUE

REMOVAL.............................14

INSTALLATION.........................14

CHECK STRAP

REMOVAL.............................15

INSTALLATION.........................15

DOOR

REMOVAL.............................15

INSTALLATION.........................15

DOOR GLASS

REMOVAL.............................16

INSTALLATION.........................17

FRAME CLOSEOUT MOLDING

REMOVAL ± A-PILLAR-HEADER, OR B-PILLAR . 17

INSTALLATION ± A-PILLAR-HEADER, OR

B-PILLAR............................17

HINGE

REMOVAL.............................17

INSTALLATION.........................18

LATCH

REMOVAL.............................18

INSTALLATION.........................18

LATCH STRIKER

REMOVAL.............................19INSTALLATION.........................19

LOCK CYLINDER

REMOVAL.............................19

INSTALLATION.........................19

TRIM PANEL

REMOVAL.............................20

INSTALLATION.........................20

WATERSHIELD

REMOVAL.............................21

INSTALLATION.........................21

WINDOW CRANK

REMOVAL.............................21

INSTALLATION.........................21

EXTERIOR HANDLE

REMOVAL.............................21

INSTALLATION.........................22

WINDOW REGULATOR - POWER

REMOVAL.............................22

INSTALLATION.........................22

WINDOW REGULATOR - MANUAL

REMOVAL.............................22

INSTALLATION.........................23

APPLIQUE

REMOVAL

(1) Roll door glass down.

(2) Remove outer door belt molding.

(3) Disengage clips holding front edge of applique

to door frame.

(4) Remove applique from vehicle (Fig. 1).

INSTALLATION

(1) Position applique on vehicle.

(2) Hook rear edge of applique over rear edge of

door frame and seat applique bottom edge on sheet

metal.

(3) Engage clips to hold front edge of applique to

door frame.

(4) Install outer door belt molding.

23 - 14 DOOR - FRONTRS

Page 1795 of 2339

(2) Position door to vehicle. Verify net pierce nub-

bin is engaged if reusing original hinges. Applies to

body half of hinge only.

(3) Steady door on lifting device and install bolts

attaching upper hinge to door end frame. Tighten

bolts to 34 N´m (25 ft. lbs.) torque.

(4) Install bolts attaching lower hinge to door end

frame. Tighten bolts to 34 N´m (25 ft. lbs.) torque.

Align door to achieve equal spacing to surrounding

body panels. Panels should be flush across all gaps.

(5) Install bolts attaching door check strap to

A-pillar. Tighten bolts to 12 N´m (105 in. lbs.) torque.

(6) Connect door harness into body wiring harness.

(7) Connect positive lock slide on the side of the

wire connectors.

(8) Connect clips attaching door harness wire con-

nector to inner fender brace.

(9) Install front wheelhouse splash shield.

(10) Verify door operation and alignment. Adjust

as necessary.

DOOR GLASS

REMOVAL

(1) Remove watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - REMOVAL)

(2) Remove inner belt molding.(Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - REMOVAL)

Fig. 3 FRONT DOOR WIRE CONNECTORS

1 - LOCK TAB

2 - POSITIVE LOCK

3 - BODY HARNESS CONNECTOR

4 - FRONT FENDER

5 - DOOR HARNESS CONNECTOR

6 - BODY HARNESS

Fig. 4 FRONT DOOR - HINGE PIN REMOVAL

1 - FRONT DOOR

2 - CLIP

3 - A-PILLAR

4 - HINGE PIN

5 - CLIP

6 - DOOR CHECK STRAP

Fig. 5 FRONT DOOR - HINGE BOLT REMOVAL

1 - FRONT DOOR

2 - UPPER HINGE

3 - CHECK STRAP

4 - LOWER HINGE

23 - 16 DOOR - FRONTRS

DOOR (Continued)

Page 1796 of 2339

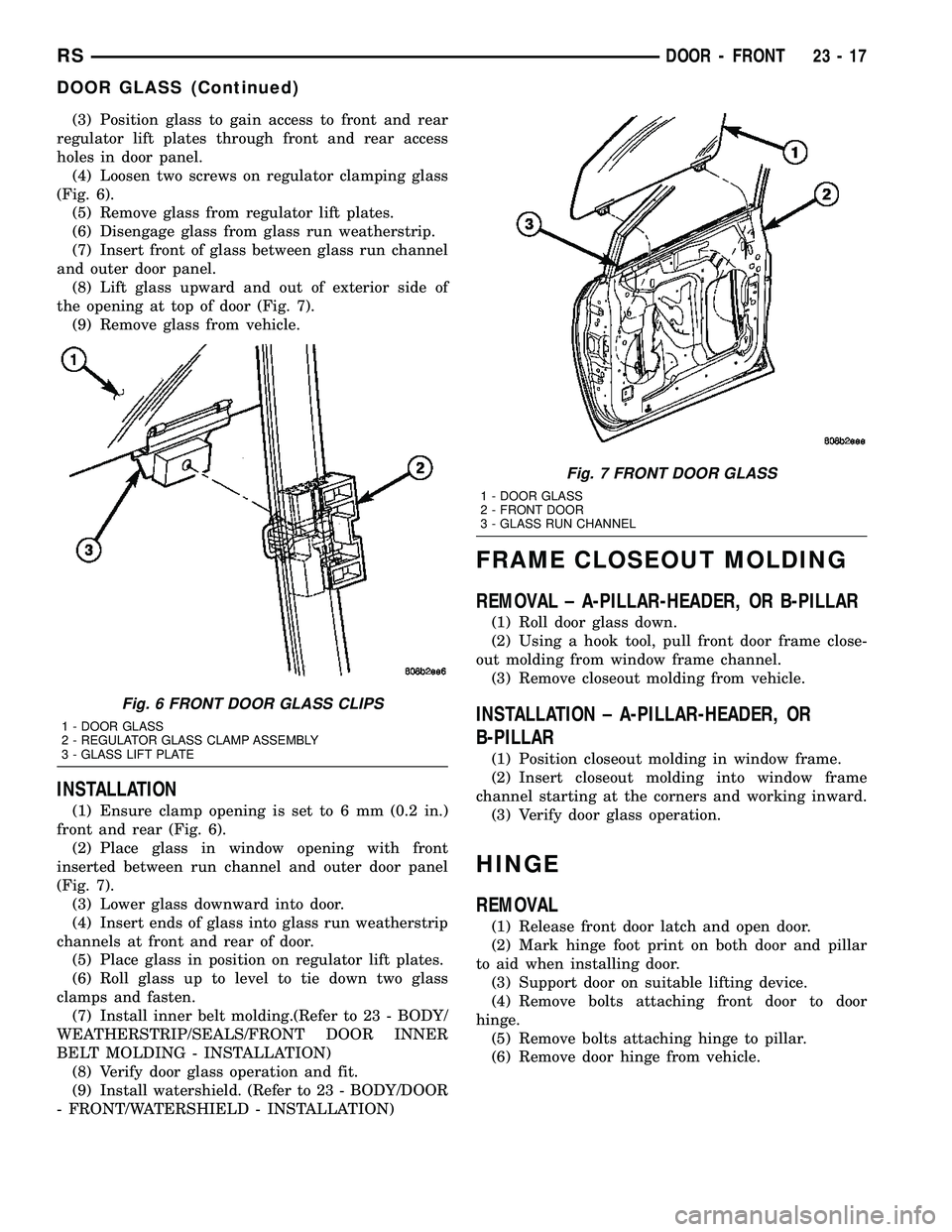

(3) Position glass to gain access to front and rear

regulator lift plates through front and rear access

holes in door panel.

(4) Loosen two screws on regulator clamping glass

(Fig. 6).

(5) Remove glass from regulator lift plates.

(6) Disengage glass from glass run weatherstrip.

(7) Insert front of glass between glass run channel

and outer door panel.

(8) Lift glass upward and out of exterior side of

the opening at top of door (Fig. 7).

(9) Remove glass from vehicle.

INSTALLATION

(1) Ensure clamp opening is set to 6 mm (0.2 in.)

front and rear (Fig. 6).

(2) Place glass in window opening with front

inserted between run channel and outer door panel

(Fig. 7).

(3) Lower glass downward into door.

(4) Insert ends of glass into glass run weatherstrip

channels at front and rear of door.

(5) Place glass in position on regulator lift plates.

(6) Roll glass up to level to tie down two glass

clamps and fasten.

(7) Install inner belt molding.(Refer to 23 - BODY/

WEATHERSTRIP/SEALS/FRONT DOOR INNER

BELT MOLDING - INSTALLATION)

(8) Verify door glass operation and fit.

(9) Install watershield. (Refer to 23 - BODY/DOOR

- FRONT/WATERSHIELD - INSTALLATION)

FRAME CLOSEOUT MOLDING

REMOVAL ± A-PILLAR-HEADER, OR B-PILLAR

(1) Roll door glass down.

(2) Using a hook tool, pull front door frame close-

out molding from window frame channel.

(3) Remove closeout molding from vehicle.

INSTALLATION ± A-PILLAR-HEADER, OR

B-PILLAR

(1) Position closeout molding in window frame.

(2) Insert closeout molding into window frame

channel starting at the corners and working inward.

(3) Verify door glass operation.

HINGE

REMOVAL

(1) Release front door latch and open door.

(2) Mark hinge foot print on both door and pillar

to aid when installing door.

(3) Support door on suitable lifting device.

(4) Remove bolts attaching front door to door

hinge.

(5) Remove bolts attaching hinge to pillar.

(6) Remove door hinge from vehicle.

Fig. 6 FRONT DOOR GLASS CLIPS

1 - DOOR GLASS

2 - REGULATOR GLASS CLAMP ASSEMBLY

3 - GLASS LIFT PLATE

Fig. 7 FRONT DOOR GLASS

1 - DOOR GLASS

2 - FRONT DOOR

3 - GLASS RUN CHANNEL

RSDOOR - FRONT23-17

DOOR GLASS (Continued)

Page 1799 of 2339

TRIM PANEL

REMOVAL

(1) Remove the plug and remove screw attaching

door pull cup to inner door panel.

(2) Remove switch bezel and disconnect power win-

dow/memory switch.

(3) Remove screws attaching trim panel to door

from below map pocket.

(4) If equipped, remove window crank. (Refer to 23

- BODY/DOOR - FRONT/WINDOW CRANK -

REMOVAL)

(5) Remove screw holding door trim to door panel

from behind inside latch release handle.

(6) Disengage clips attaching door trim to door

frame around perimeter of panel.

(7) Lift trim panel upward to disengage flange

from inner belt molding at top of door.

(8) Tilt top of trim panel away from door to gain

access to latch linkage.

(9) Disengage clip attaching linkage rod to inside

latch release handle (Fig. 12).

(10) Separate linkage rod from latch handle.

(11) Disconnect the power door switch, courtesy

lamp electrical connectors.

(12) Remove front door trim panel from vehicle.

INSTALLATION

(1) Hold top of trim panel away from door to gain

access to latch linkage.

(2) Place linkage rod in position on latch handle.

(3) Engage clip to hold linkage rod to inside latch

release handle.

Fig. 11 OUTSIDE DOOR HANDLE

1 - CLIP

2 - LOCK CYLINDER

3 - KEY CYLINDER TO LATCH LINK

4 - OUTSIDE HANDLE TO LATCH LINK5 - LOCK KNOB LINK

6 - FRONT DOOR

7 - KEY POSITION SWITCH

8 - OUTSIDE HANDLE

Fig. 12 INSIDE DOOR HANDLE LINKAGE

1 - DOOR LATCH HANDLE

2 - DOOR TRIM

3 - LATCH LINKAGE

4 - CLIP

5 - MEMORY SEAT SWITCH

23 - 20 DOOR - FRONTRS

LOCK CYLINDER (Continued)

Page 1800 of 2339

(4) Place front door trim panel in position on door.

(5) Install trim panel into inner belt molding at

top of door.

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

(11) Install screws to attach accessary switch

panel to door trim.

(12) Install screw cover into switch panel.

(13) If equipped, install window crank.

(14) If equipped, install screws to attach trim

panel to door inside map pocket.

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

(19) Install switch bezel.

WATERSHIELD

REMOVAL

(1) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Remove the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the water dam. Replace as necessary.

(2) Place the shield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Install the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - INSTALLATION)

(4) Install door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

WINDOW CRANK

REMOVAL

(1) Using a window crank removal tool, disengage

clip attaching window crank to regulator shaft (Fig.

13).

NOTE: Wrap a shop towel around the window crank

to catch the clip when it springs out.

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Place the clip on to the window crank handle.

(2) Position window crank to regulator shaft.

(3) Push window crank onto regulator shaft to

engage retaining clip.

EXTERIOR HANDLE

REMOVAL

(1) Roll door glass up.

(2) Remove the watershield as necessary to gain

access to the outside door handle. (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL)

(3) Through access hole at rear of inner door

panel, disconnect Vehicle Theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch (Fig. 11).

(6) Remove latch linkage from latch.

Fig. 13 WINDOW CRANK - TYPICAL

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

RSDOOR - FRONT23-21

TRIM PANEL (Continued)