ad blue CHRYSLER VOYAGER 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1077 of 2339

PASSENGER DOOR COURTESY LAMP (LUXURY/EXPORT) - GRAY 3 WAY

CAV CIRCUIT FUNCTION

1 Z322 20BK/BR (LHD) GROUND

1 Z321 20BK/BR (RHD) GROUND

2- -

3 M21 14YL/BR (EXCEPT EXPORT) COURTESY LAMPS DRIVER

3 M21 20YL/BR (EXPORT) COURTESY LAMPS DRIVER

PASSENGER DOOR LOCK SWITCH - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1- -

2 G160 20VT/LG (LHD) RIGHT DOOR LOCK SWITCH MUX

2 G161 20VT/DG (RHD) LEFT DOOR LOCK SWITCH MUX

3 Z460 20BK/LG (LHD) GROUND

3 Z461 20BK/DG (RHD) GROUND

PASSENGER FOLDING MIRROR RELAY (EXPORT) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3- -

4 A108 20LG/RD FUSED B(+)

5 P164 18LG/DB PASSENGER FOLDING MIRROR RELAY INPUT

6 P162 18LG/DG PASSENGER FOLDING MIRROR RELAY CONTROL

7- -

8 P160 18TN/LG PASSENGER FOLDING MIRROR RELAY OUTPUT

9- -

PASSENGER HEATED SEAT BACK - LT. GREEN 2 WAY

CAV CIRCUIT FUNCTION

A S1 16DB (EXCEPT EXPORT) SEAT HEATER B(+) DRIVER

A S1 18WT (EXPORT) SEAT HEATER B(+) DRIVER

B Z848 16BK/OR (EXCEPT EXPORT) GROUND

B S2 18GY (EXPORT) SEAT HEATER GROUND

8W - 80 - 108 8W-80 CONNECTOR PIN-OUTSRS

Page 1090 of 2339

RADIATOR FAN RELAY (GAS)-4WAY

CAV CIRCUIT FUNCTION

1 A112 12OR/RD FUSED B(+)

2 N23 12DB/DG RADIATOR FAN RELAY OUTPUT

3 Z723 18BK/DG GROUND

4 N173 18DB/VT RAD FAN RELAY CONTROL

RADIATOR FAN RELAY NO. 1 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 N201 12DB/LG RADIATOR FAN RELAY NO. 1 OUTPUT

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5- -

6 N210 18DB/DG LOW SPEED RADIATOR FAN RELAY CONTROL

7- -

8 A201 12RD/LG FUSED B(+)

9- -

RADIATOR FAN RELAY NO. 2 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 N112 12DB/OR RADIATOR FAN RELAY NO. 2 AND NO. 3 COMMON

OUTPUT

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5- -

6 N122 18DB/YL HIGH SPEED RADIATOR FAN DUAL RELAY CONTROL

7- -

8 A112 12OR/RD FUSED B(+)

9- -

RS8W-80 CONNECTOR PIN-OUTS8W - 80 - 121

Page 1091 of 2339

RADIATOR FAN RELAY NO. 3 (DIESEL) - BLUE 9 WAY

CAV CIRCUIT FUNCTION

1- -

2 Z823 12BK/DG GROUND

3- -

4 K342 16BR/WT ECM/PCM RELAY OUTPUT

5 N112 12DB/OR RADIATOR FAN RELAY NO. 2 AND NO. 3 COMMON

OUTPUT

6 N122 18DB/YL HIGH SPEED RADIATOR FAN DUAL RELAY CONTROL

7- -

8 N202 12DB/OR RADIATOR FAN NO. 1 CONTROL

9- -

RADIO C1 - 22 WAY

CAV CIRCUIT FUNCTION

1 A114 16GY/RD FUSED B(+) (I.O.D.)

2 F306 18DB/PK FUSED ACCESSORY RELAY OUTPUT

3 E14 20OR/TN PANEL LAMPS DRIVER

4- -

5- -

6- -

7 X54 20GY (LOWLINE) RIGHT FRONT SPEAKER (+)

8 X56 20GY/BR (LOWLINE) RIGHT FRONT SPEAKER (-)

9 X55 20DG/BR (LOWLINE) LEFT FRONT SPEAKER (-)

10 X53 20DG (LOWLINE) LEFT FRONT SPEAKER (+)

11 Z514 16BK/LG GROUND

12 A114 16GY/RD FUSED B(+) (I.O.D.)

13 X60 20GY/YL (EXPORT) RADIO 12 VOLT OUTPUT

14 D25 20WT/VT PCI BUS

15 - -

16 - -

17 - -

18 X51 22DG/DB LEFT REAR SPEAKER (+)

19 X57 22DG/OR LEFT REAR SPEAKER (-)

20 X58 22GY/OR RIGHT REAR SPEAKER (-)

21 X52 22GY/DB RIGHT REAR SPEAKER (+)

22 Z515 16BK GROUND

8W - 80 - 122 8W-80 CONNECTOR PIN-OUTSRS

Page 1186 of 2339

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)

Page 1262 of 2339

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 3.3/3.8L9-85

ENGINE 3.3/3.8L (Continued)

Page 1284 of 2339

CYLINDER HEAD COVER -

LEFT

REMOVAL

(1) Disconnect spark plug wires from spark plugs.

(2) Disconnect crankcase vent hose from cylinder

head cover.

(3) Remove cylinder head cover bolts.

(4) Remove cylinder head cover and gasket.

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Inspect cylinder head cover surface for flatness.

Replace gasket as necessary.

(2) Assemble gasket to cylinder cover by inserting

the fasteners through each bolt hole on cover and

gasket (Fig. 25).

(3) Install the cylinder head cover and bolts (Fig.

26).

(4) Tighten cylinder head cover bolts to 12 N´m

(105 in. lbs.) (Fig. 26).

(5) Connect crankcase vent hose.

(6) Connect spark plug wires to spark plugs.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves have chrome plated valve stems with

four-bead lock grooves. The valve stem seals are

made of Viton rubber.

OPERATION

The two valves per cylinder are opened using

hydraulic lifters, push rods, and rocker arms.

STANDARD PROCEDURE - REFACING VALVES

AND VALVE SEATS

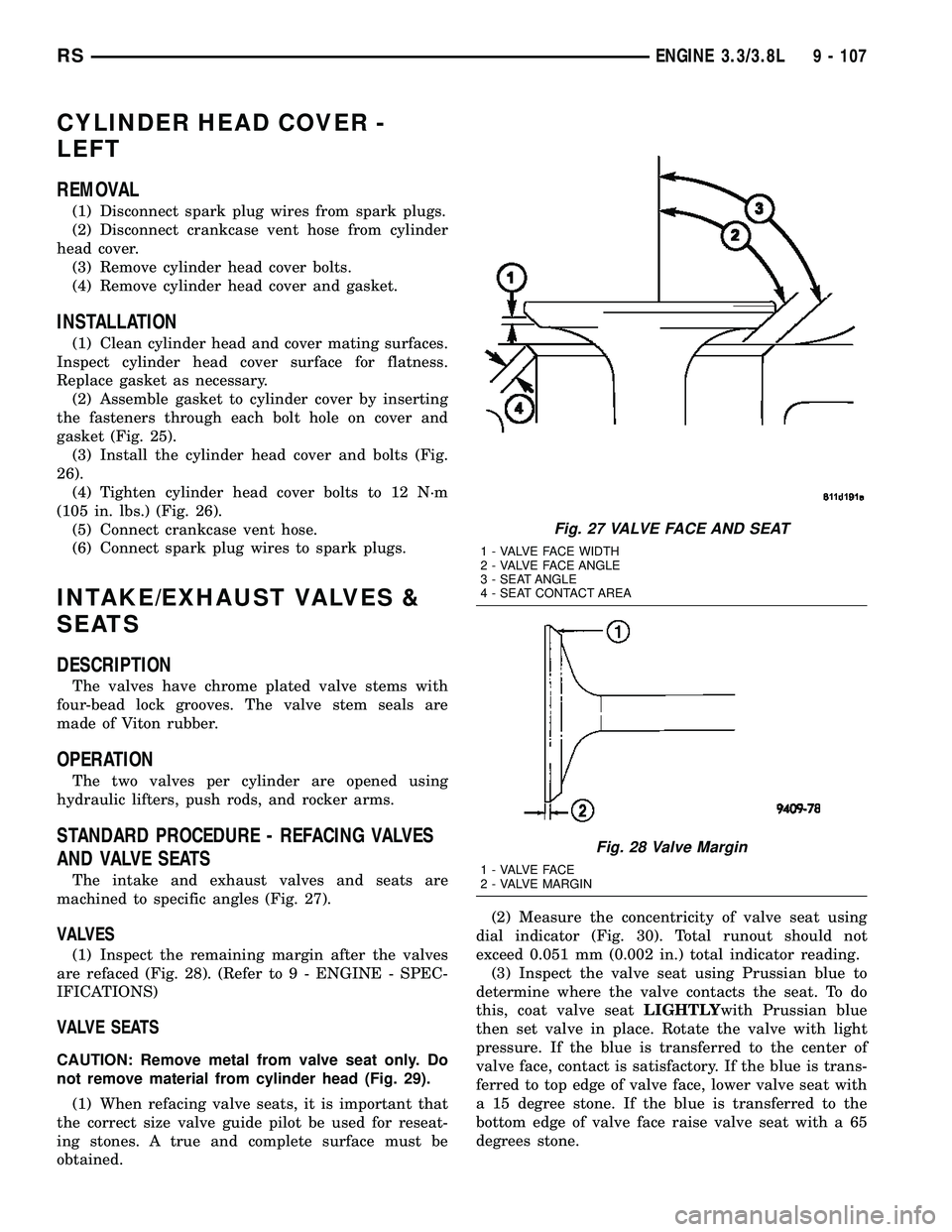

The intake and exhaust valves and seats are

machined to specific angles (Fig. 27).

VALVES

(1) Inspect the remaining margin after the valves

are refaced (Fig. 28). (Refer to 9 - ENGINE - SPEC-

IFICATIONS)

VALVE SEATS

CAUTION: Remove metal from valve seat only. Do

not remove material from cylinder head (Fig. 29).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.(2) Measure the concentricity of valve seat using

dial indicator (Fig. 30). Total runout should not

exceed 0.051 mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat using Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of valve face, lower valve seat with

a 15 degree stone. If the blue is transferred to the

bottom edge of valve face raise valve seat with a 65

degrees stone.

Fig. 27 VALVE FACE AND SEAT

1 - VALVE FACE WIDTH

2 - VALVE FACE ANGLE

3 - SEAT ANGLE

4 - SEAT CONTACT AREA

Fig. 28 Valve Margin

1 - VALVE FACE

2 - VALVE MARGIN

RSENGINE 3.3/3.8L9 - 107

Page 1817 of 2339

of the handle bracket and then unhook swedged

cable end from the handle link.

(6) Open the side door and remove the latch

assembly. Refer to the Power Side Doors section for

the procedure.

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(7) Trace the inside handle cable along its routing

path and disconnect from its retaining clips.

(8) Disconnect the inside handle cable from the

latch assembly. Gently pry cable sleeve retainer out

of the latch mounting bracket and then unhook

swedged cable end from the latch link.

(9) Remove the inside handle cable from the side

door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Match the replacement cable up against the old

cable to verify the correct part.

(2) Position the inside handle cable on the side

door.

(3) Connect the inside handle cable on the handle

assembly. Hook the swedged cable end on the handle

link and gently push the cable sleeve retainer in the

handle bracket.

(4) Install the inside handle assembly on the side

door. (Refer to 23 - BODY/DOORS - SLIDING/IN-

SIDE LATCH HANDLE - INSTALLATION)

NOTE: The inside handle cable is marked with blue

tape and must be attached to the latch at the center

(just above the lower cable). This position is

marked with a ªBº on the latch.

(5) Connect the inside handle cable on the latch

assembly. Hook the swedged cable end on the latch

link and gently push the cable sleeve retainer in the

latch bracket.

(6) Trace the inside handle cable along its routing

path and install on its retaining clips and position

foam insulators. Use previously made schematic as a

guide or remove the opposite side door trim panel

and use that door as a guide.

CAUTION: Be certain replacement cable is routed

and retained correctly and foam insulators are

properly positioned.(7) Install the latch assembly. Refer to the Power

Side Doors section for the procedure.

(8) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(9) Install the appropriate side door trim panel on

the vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(10) Connect the negative battery cable.

HOLD OPEN LATCH CABLE

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the appropriate side door trim panel

from the vehicle. (Refer to 23 - BODY/DOORS -

SLIDING/TRIM PANEL - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

(4) Open the side door and remove the latch

assembly. (Refer to 8 - ELECTRICAL/POWER

DOORS/LATCH - REMOVAL)

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(5) Trace the hold open latch cable along its rout-

ing path and disconnect from its retaining clips.

(6) Disconnect the hold open latch cable from the

latch assembly. Gently pry cable sleeve retainer out

of the latch mounting bracket and then unhook

swedged cable end from the latch link.

(7) Remove the hold open latch from the side door.

(Refer to 23 - BODY/DOORS - SLIDING/HOLD

OPEN LATCH - REMOVAL)

(8) Disconnect the hold open latch cable from the

hold open latch. Gently pry cable sleeve retainer out

of the handle bracket and then unhook swedged

cable end from the latch link.

(9) Remove the hold open latch cable from the side

door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

23 - 38 DOORS - SLIDINGRS

INSIDE HANDLE CABLE (Continued)

Page 1879 of 2339

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS - COLOR CODE CHARTS . . 100

BASE COAT/CLEARCOAT FINISH

DESCRIPTION........................101

PAINT CODE

DESCRIPTION........................101PAINTED TOUCH-UP

DESCRIPTION........................101

FINESSE SANDING/BUFFING & POLISHING

DESCRIPTION........................101

PAINT

SPECIFICATIONS - COLOR CODE CHARTS

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER

COLOR CODEEXTERIOR COLOR DAIMLERCHRYSLER

COLOR CODE

BRIGHT SILVER

METALLIC CLEAR

COATWS2 LIGHT KHAKI

METALLIC CLEAR

COATAJC

BRILLIANT BLACK

CRYSTAL PEARL

COATAXR LINEN GOLD PEARL

COATCYG

BUTANE BLUE

METALLIC CLEAR

COATABE MAGNESIUM PEARL

COATBPK

DARK KHAKI

METALLIC CLEAR

COATBJT MIDNIGHT BLUE

PEARL COATBB8

DEEP BERYL GREEN

PEARL COATCGV PATRIOT BLUE

PEARL COATWB7

DEEP LAVA RED

PEARL COATZMQ SATIN JADE PEARL

COATAP4

DEEP MOLTEN RED

PEARL COATBR8 SHALE GREEN

METALLIC CLEAR

COATWS2

GRAPHITE METALLIC

CLEAR COATZDR STONE WHITE CLEAR

COATSW1

INFERNO RED TINTED

PEARL COATWEL

23 - 100 PAINTRS

Page 2221 of 2339

MANIFOLD GAUGE SET

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 3). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

²LOW PRESSURE GAUGE HOSE- The low

pressure hose (Blue with Black stripe) attaches to

the low side service port. This service port is located

on the suction line near the A/C compressor.

²HIGH PRESSURE GAUGE HOSE- The high

pressure hose (Red with Black stripe) attaches to the

high side service port. This service port is located on

the liquid line fitting at the reciever/drier.

²RECOVERY/RECYCLING/EVACUATION/

CHARGING HOSE- The center manifold hose (Yel-

low, or White, with Black stripe) is used to recover,

evacuate, and charge the refrigerant system. When

the low or high pressure valves on the manifold

gauge set are opened, the refrigerant in the system

will escape through this hose.

REFRIGERANT SYSTEM RECOVERY

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to recover the refrigerant from an R-134a refrig-

erant system. Refer to the operating instructions sup-

plied by the equipment manufacturer for the proper

care and use of this equipment.

REFRIGERANT SYSTEM EVACUATE

NOTE: Special effort must be used to prevent mois-

ture from entering the A/C system oil. Moisture in

the oil is very difficult to remove and will cause a

reliability problem with the compressor.

Fig. 2 Refrigerant Recovery/Recycling Station -

Typical

1 - R-134a REFRIGERANT STATION

Fig. 3 Manifold Gauge Set - Typical

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/BLACK STRIPE)

4 - HIGH PRESSURE HOSE (RED W/BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

24 - 70 PLUMBING - FRONTRS

PLUMBING - FRONT (Continued)