air suspension CHRYSLER VOYAGER 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 145 of 2339

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following:

(a) Disconnect the battery positive cable.

(b) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(c) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(d) Remove the screw securing the coolant filler

neck to the battery tray.

(e) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system.

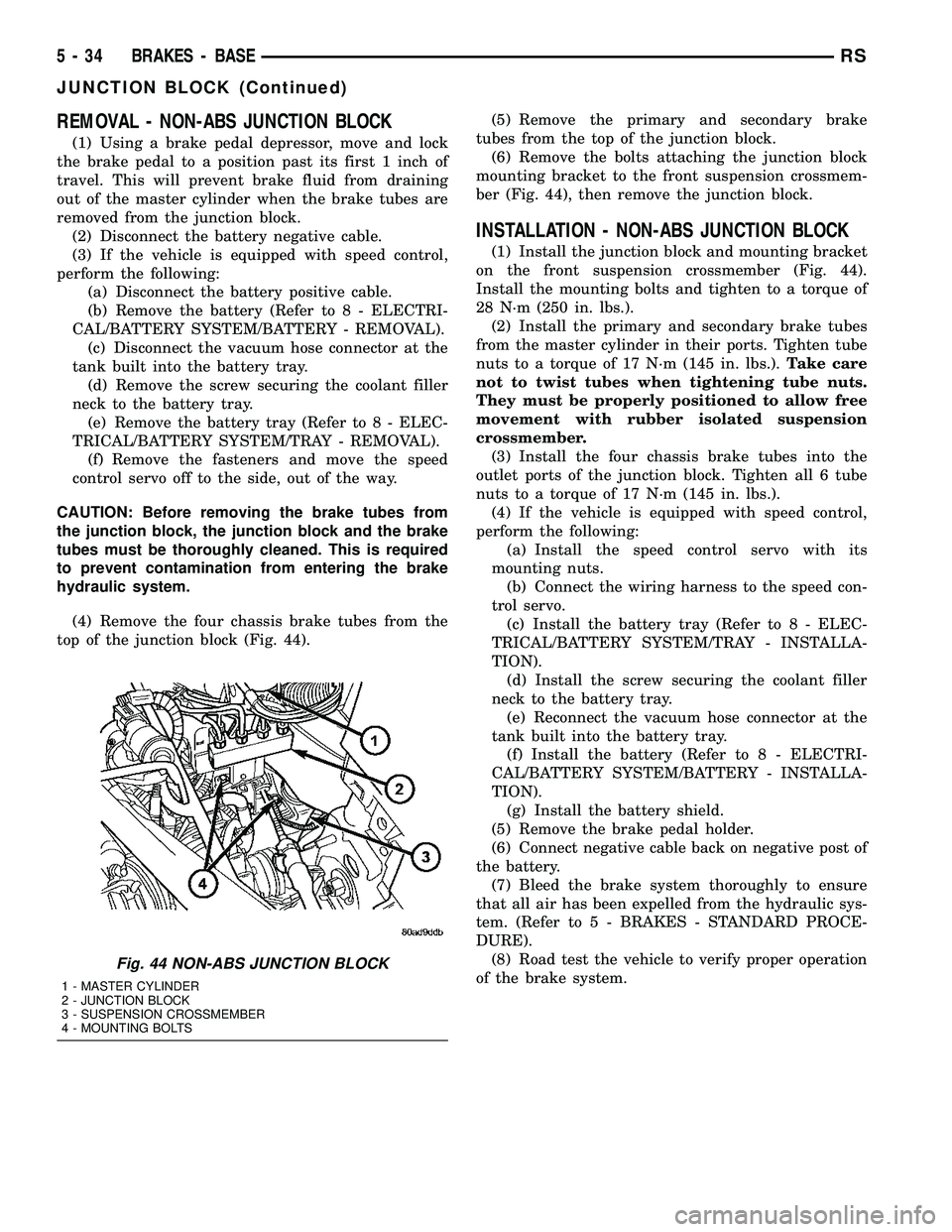

(4) Remove the four chassis brake tubes from the

top of the junction block (Fig. 44).(5) Remove the primary and secondary brake

tubes from the top of the junction block.

(6) Remove the bolts attaching the junction block

mounting bracket to the front suspension crossmem-

ber (Fig. 44), then remove the junction block.

INSTALLATION - NON-ABS JUNCTION BLOCK

(1) Install the junction block and mounting bracket

on the front suspension crossmember (Fig. 44).

Install the mounting bolts and tighten to a torque of

28 N´m (250 in. lbs.).

(2) Install the primary and secondary brake tubes

from the master cylinder in their ports. Tighten tube

nuts to a torque of 17 N´m (145 in. lbs.).Take care

not to twist tubes when tightening tube nuts.

They must be properly positioned to allow free

movement with rubber isolated suspension

crossmember.

(3) Install the four chassis brake tubes into the

outlet ports of the junction block. Tighten all 6 tube

nuts to a torque of 17 N´m (145 in. lbs.).

(4) If the vehicle is equipped with speed control,

perform the following:

(a) Install the speed control servo with its

mounting nuts.

(b) Connect the wiring harness to the speed con-

trol servo.

(c) Install the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - INSTALLA-

TION).

(d) Install the screw securing the coolant filler

neck to the battery tray.

(e) Reconnect the vacuum hose connector at the

tank built into the battery tray.

(f) Install the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - INSTALLA-

TION).

(g) Install the battery shield.

(5) Remove the brake pedal holder.

(6) Connect negative cable back on negative post of

the battery.

(7) Bleed the brake system thoroughly to ensure

that all air has been expelled from the hydraulic sys-

tem. (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

(8) Road test the vehicle to verify proper operation

of the brake system.

Fig. 44 NON-ABS JUNCTION BLOCK

1 - MASTER CYLINDER

2 - JUNCTION BLOCK

3 - SUSPENSION CROSSMEMBER

4 - MOUNTING BOLTS

5 - 34 BRAKES - BASERS

JUNCTION BLOCK (Continued)

Page 164 of 2339

PROPORTIONING VALVE

DESCRIPTION - PROPORTIONING VALVE

(HEIGHT SENSING)

NOTE: Only vehicles without antilock brakes (ABS)

have a proportioning valve. Vehicles with ABS uti-

lize electronic brake distribution which is controlled

through the ABS integrated control unit.

Vehicles not equipped with ABS use a height sens-

ing proportioning valve. It is mounted to the body of

the vehicle above the rear axle (Fig. 80). It has an

actuator lever that attaches to the rear axle and

moves with the axle to help the valve sense the vehi-

cle height.

CAUTION: The height sensing proportioning valve

is not adjustable. No attempt should be made to

adjust it. It is replaced as a complete assembly.

CAUTION: The use of after-market load leveling or

load capacity increasing devices on this vehicle are

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-

propriate reduction in hydraulic pressure potentially

could result in increased stopping distance of the

vehicle.

OPERATION - PROPORTIONING VALVE

(HEIGHT SENSING)

Vehicles not equipped with ABS use a height sens-

ing proportioning valve.

The height sensing proportioning valve operates

similarly to a standard proportioning valve in the fol-

lowing way. As hydraulic pressure is applied to the

valve, full input hydraulic pressure is supplied to the

rear brakes up to a certain pressure point, called the

split point. Beyond the split point, the proportioning

valve reduces the amount of hydraulic pressure to

the rear brakes according to a given ratio. Thus, on

light brake applications, approximately equal

hydraulic pressure will be transmitted to both the

front and rear brakes. Upon heavier brake applica-

tions, the hydraulic pressure transmitted to the rear

brakes will be lower than the front brakes. This will

prevent premature rear wheel lockup and skid.

Here is how the height sensing proportioning valve

differs from a standard proportioning valve. As the

height of the rear suspension changes, the height

sensing portion of the proportioning valve changes

the split point of the proportioning valve. When the

height of the rear suspension is low, the proportion-

ing valve interprets this as extra load and the split

point of the proportioning valve is raised to a higher

pressure to allow for more rear braking. When the

height of the rear suspension is high, the proportion-

ing valve interprets this as a light load and the split

point of the proportioning valve is lowered to a lower

pressure and rear braking is reduced.

The height sensing proportioning valve regulates

the pressure by sensing the load condition of the

vehicle through the movement of the proportioning

valve actuator lever (Fig. 80). As the position of the

rear axle changes, depending on the load the vehicle

is carrying, the movement is transferred to the pro-

portioning valve. The proportioning valve adjusts the

hydraulic pressure accordingly.

The height sensing proportioning valve allows the

brake system to maintain the optimal front to rear

brake balance regardless of the vehicle load condi-

tion. Under a light load condition, hydraulic pressure

to the rear brakes is minimized. As the rear load con-

dition increases, so does the hydraulic pressure to

the rear brakes.

Fig. 80 HEIGHT SENSING PROPORTIONING VALVE

1 - PROPORTIONING VALVE

2 - ACTUATOR LEVER

3 - AXLE BRACKET

4 - REAR AXLE

RSBRAKES - BASE5-53

Page 172 of 2339

SUPPORT PLATE - DRUM

BRAKE

REMOVAL

(1) Using a brake pedal depressor, move and

secure brake pedal to a position past its first 1 inch

of travel. This will prevent brake fluid from draining

out of master cylinder when brake tube is remove

from wheel cylinder.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(3) Remove wheel and tire assembly.

(4) Disconnect brake tube from rear of wheel cylin-

der. Cap open ends

(5) Remove brake drum.

(6) Remove brake shoes from brake support plate.

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

BRAKE PADS/SHOES - REMOVAL).

(7) Remove the 2 bolts attaching the wheel cylin-

der to the brake support plate.

(8) Remove the wheel cylinder from the brake sup-

port plate.

(9) Disconnect the park brake cable from the park

brake actuation lever.

(10) Using a suitable tool such as a 14 mm box

wrench (Fig. 92) or an aircraft type hose clamp, com-

press the flared legs on park brake cable retainer.

Then pull the park brake cable out of brake support

plate.

(11) Remove the rear hub and bearing. (Refer to 2

- SUSPENSION/REAR/HUB / BEARING -

REMOVAL)(12) Remove the rear brake support plate from the

rear axle.

INSTALLATION

(1) Install the 4 hub and bearing to axle mounting

bolts into the mounting holes in the flange of the

rear axle.

(2) Install the rear brake support plate on the 4

mounting bolts installed in the flange of the rear axle

(Fig. 93).

(3) Install the rear hub and bearing (and connect

wheel speed sensor where applicable) stopping short

of installing the brake drum. (Refer to 2 - SUSPEN-

SION/REAR/HUB / BEARING - INSTALLATION)

(4) Install the rear park brake cable into its

mounting hole in the rear brake support plate.

(5) Install the park brake cable on the park brake

actuation lever.

(6) Apply sealant such as Mopar Gasket-In-A-Tube

or equivalent around the wheel cylinder opening in

the brake support plate.

(7) Install wheel cylinder onto brake support.

Install and tighten the wheel cylinder to brake sup-

port plate attaching bolts to 8 N´m (75 in. lbs.)

torque.

(8) Install brake tube into wheel cylinder. Tighten

tube nut to a torque of 17 N´m (145 in. lbs.) torque.

(9) Install the rear brake shoes on the brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(10) Install brake drum.

(11) Install the wheel and tire assembly. Tighten

the wheel mounting nuts in proper sequence until all

nuts are torqued to half specification, then repeat the

Fig. 92 Removing Park Brake Cable From Brake

Support Plate

1 - PARK BRAKE CABLE

2 - CABLE RETAINER

3 - 14 mm BOX WRENCH

4 - BRAKE SUPPORT PLATE

Fig. 93 Brake Support Plate Mounted On Bearing

Attaching Bolts

1 - REAR BRAKE SUPPORT PLATE

2 - HUB/BEARING MOUNTING BOLTS

RSBRAKES - BASE5-61

Page 198 of 2339

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION

DESCRIPTION - ANTILOCK BRAKE

SYSTEM............................87

DESCRIPTION - ANTILOCK BRAKE

SYSTEM (EXPORT)....................87

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............88

DESCRIPTION - TRACTION CONTROL

SYSTEM............................88

OPERATION

OPERATION - ANTILOCK BRAKE SYSTEM . . 88

OPERATION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............89

OPERATION - TRACTION CONTROL

SYSTEM............................89

CAUTION.............................90

STANDARD PROCEDURE - ANTILOCK BRAKE

SYSTEM BLEEDING...................90

SPECIFICATIONS

ABS FASTENER TORQUE...............91

TONE WHEEL RUNOUT................91

WHEEL SPEED SENSOR AIR GAP........91

FRONT WHEEL SPEED SENSOR

REMOVAL.............................91

INSTALLATION.........................92

REAR WHEEL SPEED SENSOR - AWD

REMOVAL.............................92INSTALLATION.........................92

REAR WHEEL SPEED SENSOR - FWD

REMOVAL.............................93

INSTALLATION.........................93

TONE WHEEL

INSPECTION - TONE WHEEL..............94

TRACTION CONTROL SWITCH

DIAGNOSIS AND TESTING - TRACTION

CONTROL SWITCH....................94

REMOVAL.............................95

INSTALLATION.........................95

HYDRAULIC/MECHANICAL

OPERATION - HYDRAULIC CIRCUITS AND

VALVES .............................95

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION........................100

OPERATION..........................101

ICU (INTEGRATED CONTROL UNIT)

DESCRIPTION........................102

OPERATION..........................102

REMOVAL

REMOVAL - LHD.....................102

REMOVAL - RHD.....................104

DISASSEMBLY - ICU...................105

ASSEMBLY - ICU......................106

INSTALLATION

INSTALLATION - LHD.................106

INSTALLATION - RHD.................107

BRAKES - ABS

DESCRIPTION

DESCRIPTION - ANTILOCK BRAKE SYSTEM

This section covers the physical and operational

descriptions and the on-car service procedures for the

Mark 20e Antilock Brake System and the Mark 20e

Antilock Brake System with traction control.

The purpose of the antilock brake system (ABS) is

to prevent wheel lockup under braking conditions on

virtually any type of road surface. Antilock braking is

desirable because a vehicle that is stopped without

locking the wheels retains directional stability and

some steering capability. This allows the driver to

retain greater control of the vehicle during braking.

DESCRIPTION - ANTILOCK BRAKE SYSTEM

(EXPORT)

Four-wheel disc antilock brakes are standard on all

models. The Mark 20e antilock brake system is used

on all models. Depending on whether the vehicle is a

left-hand drive (LHD) or right-hand drive (RHD)

model, the integrated control unit (ICU) is located in

one of two locations. On LHD models, the ICU is

mounted above the front suspension cradle/cross-

member below the master cylinder. On RHD models,

the ICU is located behind the front suspension cra-

dle/crossmember on the left side of the vehicle.

RSBRAKES - ABS5-87

Page 1361 of 2339

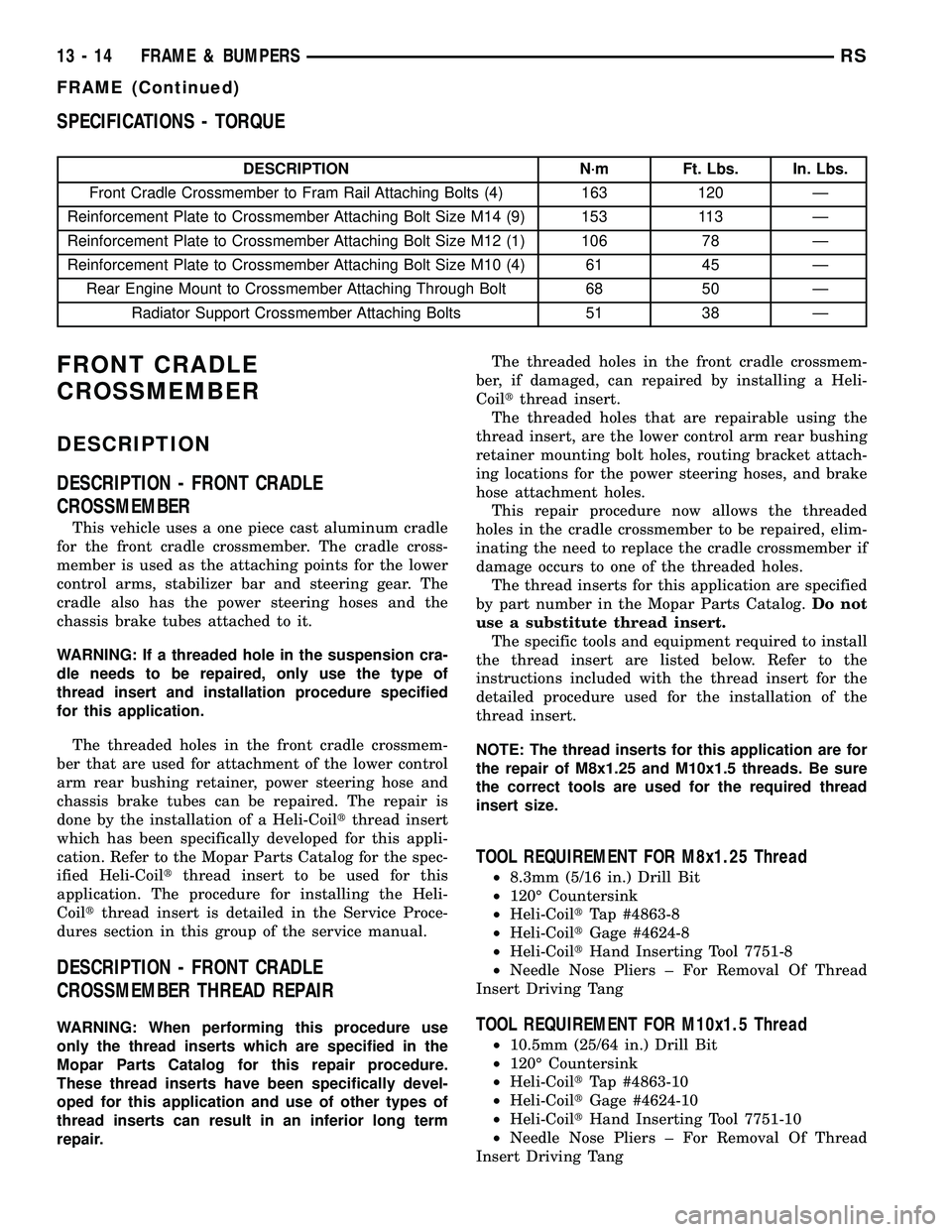

SPECIFICATIONS - TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front Cradle Crossmember to Fram Rail Attaching Bolts (4) 163 120 Ð

Reinforcement Plate to Crossmember Attaching Bolt Size M14 (9) 153 113 Ð

Reinforcement Plate to Crossmember Attaching Bolt Size M12 (1) 106 78 Ð

Reinforcement Plate to Crossmember Attaching Bolt Size M10 (4) 61 45 Ð

Rear Engine Mount to Crossmember Attaching Through Bolt 68 50 Ð

Radiator Support Crossmember Attaching Bolts 51 38 Ð

FRONT CRADLE

CROSSMEMBER

DESCRIPTION

DESCRIPTION - FRONT CRADLE

CROSSMEMBER

This vehicle uses a one piece cast aluminum cradle

for the front cradle crossmember. The cradle cross-

member is used as the attaching points for the lower

control arms, stabilizer bar and steering gear. The

cradle also has the power steering hoses and the

chassis brake tubes attached to it.

WARNING: If a threaded hole in the suspension cra-

dle needs to be repaired, only use the type of

thread insert and installation procedure specified

for this application.

The threaded holes in the front cradle crossmem-

ber that are used for attachment of the lower control

arm rear bushing retainer, power steering hose and

chassis brake tubes can be repaired. The repair is

done by the installation of a Heli-Coiltthread insert

which has been specifically developed for this appli-

cation. Refer to the Mopar Parts Catalog for the spec-

ified Heli-Coiltthread insert to be used for this

application. The procedure for installing the Heli-

Coiltthread insert is detailed in the Service Proce-

dures section in this group of the service manual.

DESCRIPTION - FRONT CRADLE

CROSSMEMBER THREAD REPAIR

WARNING: When performing this procedure use

only the thread inserts which are specified in the

Mopar Parts Catalog for this repair procedure.

These thread inserts have been specifically devel-

oped for this application and use of other types of

thread inserts can result in an inferior long term

repair.The threaded holes in the front cradle crossmem-

ber, if damaged, can repaired by installing a Heli-

Coiltthread insert.

The threaded holes that are repairable using the

thread insert, are the lower control arm rear bushing

retainer mounting bolt holes, routing bracket attach-

ing locations for the power steering hoses, and brake

hose attachment holes.

This repair procedure now allows the threaded

holes in the cradle crossmember to be repaired, elim-

inating the need to replace the cradle crossmember if

damage occurs to one of the threaded holes.

The thread inserts for this application are specified

by part number in the Mopar Parts Catalog.Do not

use a substitute thread insert.

The specific tools and equipment required to install

the thread insert are listed below. Refer to the

instructions included with the thread insert for the

detailed procedure used for the installation of the

thread insert.

NOTE: The thread inserts for this application are for

the repair of M8x1.25 and M10x1.5 threads. Be sure

the correct tools are used for the required thread

insert size.

TOOL REQUIREMENT FOR M8x1.25 Thread

²8.3mm (5/16 in.) Drill Bit

²120É Countersink

²Heli-CoiltTap #4863-8

²Heli-CoiltGage #4624-8

²Heli-CoiltHand Inserting Tool 7751-8

²Needle Nose Pliers ± For Removal Of Thread

Insert Driving Tang

TOOL REQUIREMENT FOR M10x1.5 Thread

²10.5mm (25/64 in.) Drill Bit

²120É Countersink

²Heli-CoiltTap #4863-10

²Heli-CoiltGage #4624-10

²Heli-CoiltHand Inserting Tool 7751-10

²Needle Nose Pliers ± For Removal Of Thread

Insert Driving Tang

13 - 14 FRAME & BUMPERSRS

FRAME (Continued)

Page 1362 of 2339

REMOVAL

The front cradle crossmember must be installed in

the design location to achieve proper front end sus-

pension alignment. If the cradle crossmember is

removed without applying reference marks on the

frame rails, align the cradle crossmember according

to the dimensions provided in this group.

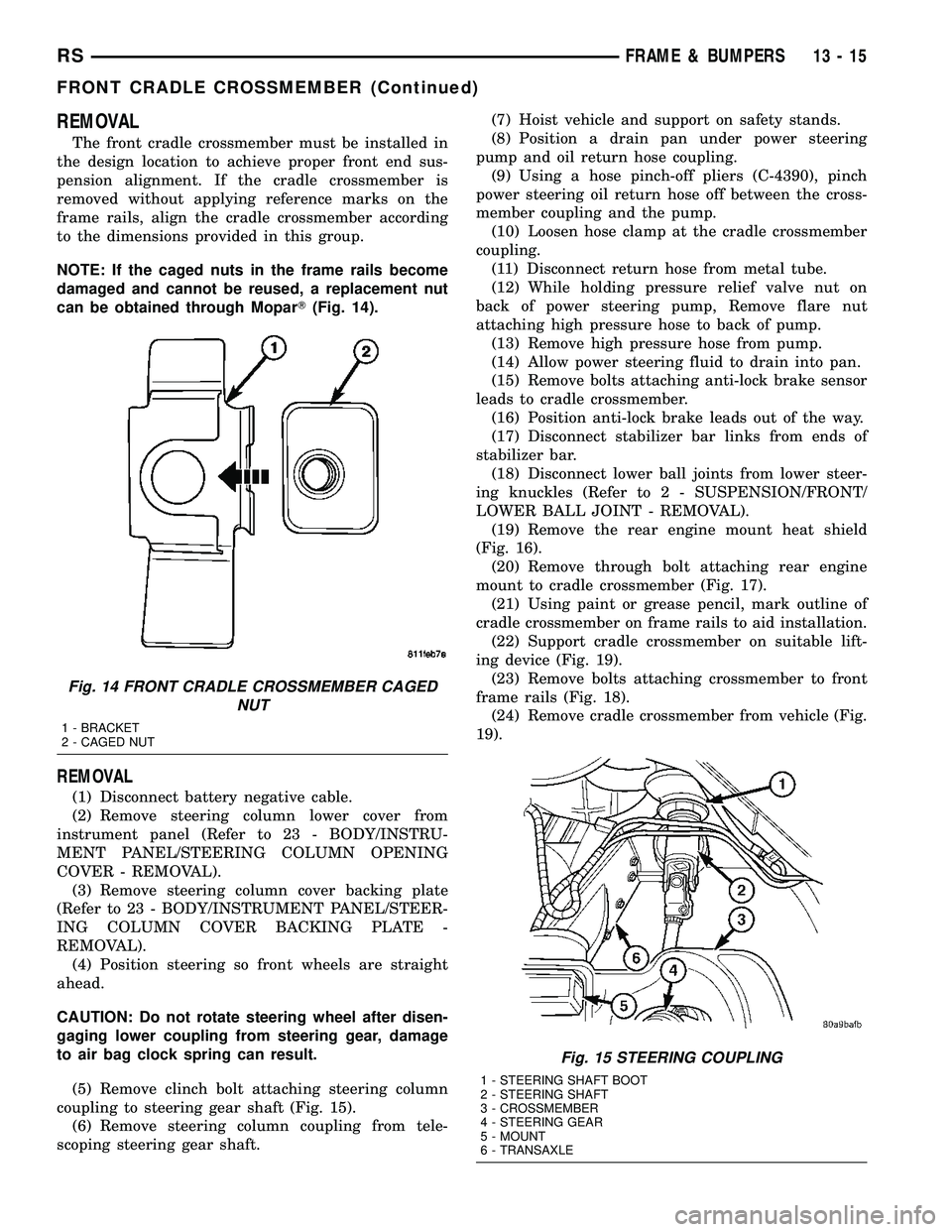

NOTE: If the caged nuts in the frame rails become

damaged and cannot be reused, a replacement nut

can be obtained through MoparT(Fig. 14).

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove steering column lower cover from

instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/STEERING COLUMN OPENING

COVER - REMOVAL).

(3) Remove steering column cover backing plate

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN COVER BACKING PLATE -

REMOVAL).

(4) Position steering so front wheels are straight

ahead.

CAUTION: Do not rotate steering wheel after disen-

gaging lower coupling from steering gear, damage

to air bag clock spring can result.

(5) Remove clinch bolt attaching steering column

coupling to steering gear shaft (Fig. 15).

(6) Remove steering column coupling from tele-

scoping steering gear shaft.(7) Hoist vehicle and support on safety stands.

(8) Position a drain pan under power steering

pump and oil return hose coupling.

(9) Using a hose pinch-off pliers (C-4390), pinch

power steering oil return hose off between the cross-

member coupling and the pump.

(10) Loosen hose clamp at the cradle crossmember

coupling.

(11) Disconnect return hose from metal tube.

(12) While holding pressure relief valve nut on

back of power steering pump, Remove flare nut

attaching high pressure hose to back of pump.

(13) Remove high pressure hose from pump.

(14) Allow power steering fluid to drain into pan.

(15) Remove bolts attaching anti-lock brake sensor

leads to cradle crossmember.

(16) Position anti-lock brake leads out of the way.

(17) Disconnect stabilizer bar links from ends of

stabilizer bar.

(18) Disconnect lower ball joints from lower steer-

ing knuckles (Refer to 2 - SUSPENSION/FRONT/

LOWER BALL JOINT - REMOVAL).

(19) Remove the rear engine mount heat shield

(Fig. 16).

(20) Remove through bolt attaching rear engine

mount to cradle crossmember (Fig. 17).

(21) Using paint or grease pencil, mark outline of

cradle crossmember on frame rails to aid installation.

(22) Support cradle crossmember on suitable lift-

ing device (Fig. 19).

(23) Remove bolts attaching crossmember to front

frame rails (Fig. 18).

(24) Remove cradle crossmember from vehicle (Fig.

19).

Fig. 14 FRONT CRADLE CROSSMEMBER CAGED

NUT

1 - BRACKET

2 - CAGED NUT

Fig. 15 STEERING COUPLING

1 - STEERING SHAFT BOOT

2 - STEERING SHAFT

3 - CROSSMEMBER

4 - STEERING GEAR

5 - MOUNT

6 - TRANSAXLE

RSFRAME & BUMPERS13-15

FRONT CRADLE CROSSMEMBER (Continued)

Page 1410 of 2339

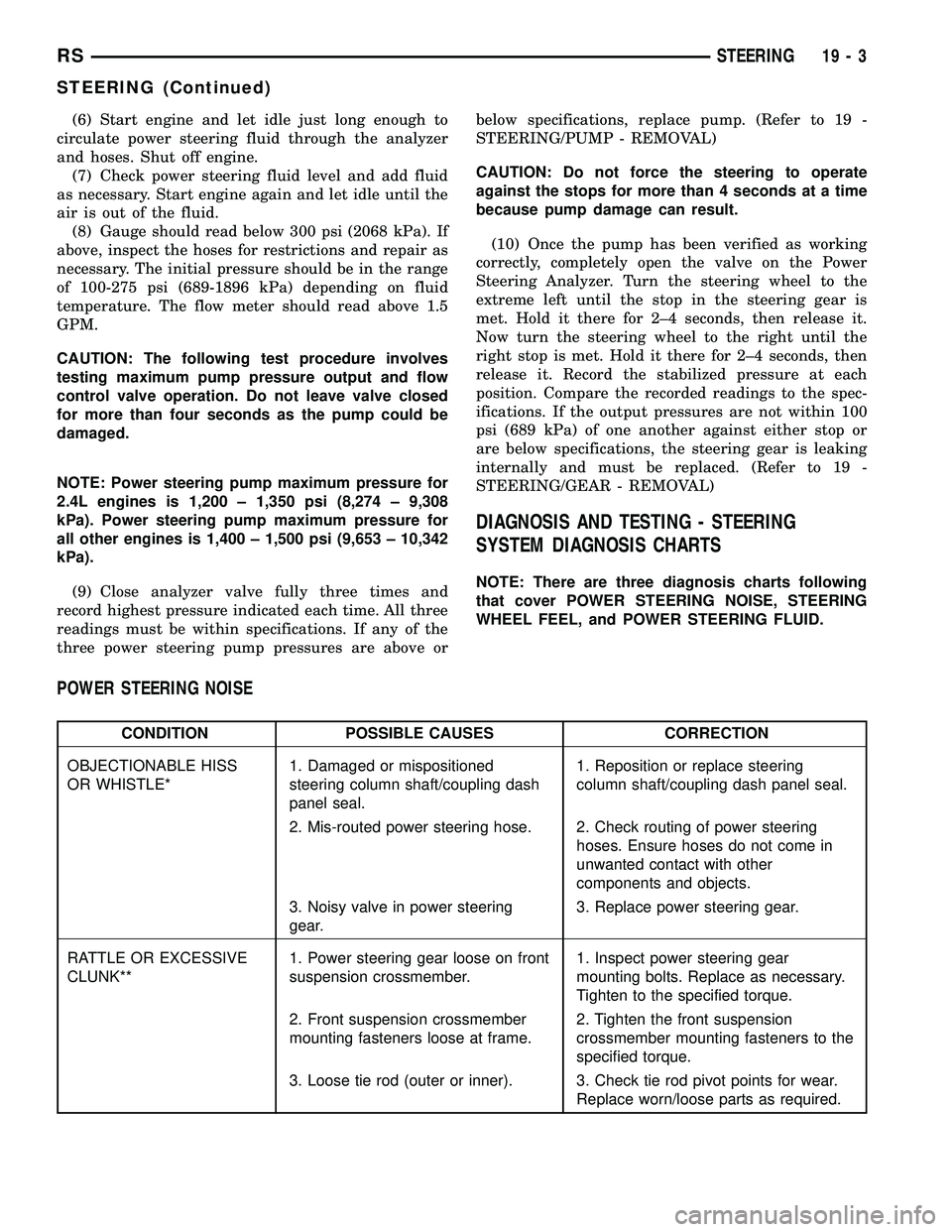

(6) Start engine and let idle just long enough to

circulate power steering fluid through the analyzer

and hoses. Shut off engine.

(7) Check power steering fluid level and add fluid

as necessary. Start engine again and let idle until the

air is out of the fluid.

(8) Gauge should read below 300 psi (2068 kPa). If

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the range

of 100-275 psi (689-1896 kPa) depending on fluid

temperature. The flow meter should read above 1.5

GPM.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than four seconds as the pump could be

damaged.

NOTE: Power steering pump maximum pressure for

2.4L engines is 1,200 ± 1,350 psi (8,274 ± 9,308

kPa). Power steering pump maximum pressure for

all other engines is 1,400 ± 1,500 psi (9,653 ± 10,342

kPa).

(9) Close analyzer valve fully three times and

record highest pressure indicated each time. All three

readings must be within specifications. If any of the

three power steering pump pressures are above orbelow specifications, replace pump. (Refer to 19 -

STEERING/PUMP - REMOVAL)

CAUTION: Do not force the steering to operate

against the stops for more than 4 seconds at a time

because pump damage can result.

(10) Once the pump has been verified as working

correctly, completely open the valve on the Power

Steering Analyzer. Turn the steering wheel to the

extreme left until the stop in the steering gear is

met. Hold it there for 2±4 seconds, then release it.

Now turn the steering wheel to the right until the

right stop is met. Hold it there for 2±4 seconds, then

release it. Record the stabilized pressure at each

position. Compare the recorded readings to the spec-

ifications. If the output pressures are not within 100

psi (689 kPa) of one another against either stop or

are below specifications, the steering gear is leaking

internally and must be replaced. (Refer to 19 -

STEERING/GEAR - REMOVAL)

DIAGNOSIS AND TESTING - STEERING

SYSTEM DIAGNOSIS CHARTS

NOTE: There are three diagnosis charts following

that cover POWER STEERING NOISE, STEERING

WHEEL FEEL, and POWER STEERING FLUID.

POWER STEERING NOISE

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONABLE HISS

OR WHISTLE*1. Damaged or mispositioned

steering column shaft/coupling dash

panel seal.1. Reposition or replace steering

column shaft/coupling dash panel seal.

2. Mis-routed power steering hose. 2. Check routing of power steering

hoses. Ensure hoses do not come in

unwanted contact with other

components and objects.

3. Noisy valve in power steering

gear.3. Replace power steering gear.

RATTLE OR EXCESSIVE

CLUNK**1. Power steering gear loose on front

suspension crossmember.1. Inspect power steering gear

mounting bolts. Replace as necessary.

Tighten to the specified torque.

2. Front suspension crossmember

mounting fasteners loose at frame.2. Tighten the front suspension

crossmember mounting fasteners to the

specified torque.

3. Loose tie rod (outer or inner). 3. Check tie rod pivot points for wear.

Replace worn/loose parts as required.

RSSTEERING19-3

STEERING (Continued)

Page 1411 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

4. Loose lower control arm mounting

bolts at front suspension

crossmember.4. Tighten control arm mounting bolts to

the specified torques.

5. Lower control arm pivot bushing

worn.5. Replace lower control arm pivot

bushing.

6. Loose strut assembly mounting

fasteners at tower or knuckle.6. Tighten strut assembly fasteners to

the specified torque.

7. Power steering fluid hose touching

the body of the vehicle.7. Adjust hose to proper position by

loosening, repositioning, and tightening

attachments to specified torque. Do not

bend tubing.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

9. Stabilizer bar link ball joints worn. 9. Replace stabilizer bar link.

10. Lug nuts loose. 10. Tighten lug nuts to specifications.

11. Excessive Wheel bearing

free-play.11. Verify correct halfshaft hub nut

torque. Replace hub and bearing if

torque is okay.

12. Internal power steering gear

noise.12. Replace power steering gear.

POPPING NOISE 1. Worn outer tie rod. 1. Check ball joint for free-play;

Replace outer tie rod.

2. Loose inner tie rod. 2. Replace power steering gear.

CHIRP OR SQUEAL

(POWER STEERING

PUMP)1. Loose power steering pump drive

belt.1. Check and adjust power steering

pump drive belt to specifications or

replace automatic tensioner where

applicable. Replace belt if worn or

glazed.

2. Malfuctioning belt auto-tensioner 2. Replace belt auto-tensioner.

WHINE, GROWL, MOAN

OR GROAN (POWER

STEERING PUMP)***1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level and check for leaks (make

sure all air is bled from the system

fluid).

2. Power steering hose touching

vehicle body or frame.2. Adjust hose to proper position by

loosening, repositioning, and tightening

fitting to specified torque. Do not bend

tubing. Replace hose if damaged.

3. Extremely low ambient

temperature.3. Some noise can be expected, but will

go away as vehicle warms. Replace

pump if noise is excessive.

4. Extreme wear of power steering

pump internal components.4. Replace power steering pump and

flush system as necessary.

19 - 4 STEERINGRS

STEERING (Continued)

Page 1458 of 2339

(4) Route hose (with cooler attached) up toward

reservoir avoiding tight bends or kinking.

(5) Start steering gear end of hose into gear port.

Do not tighten hose tube nut at this time.

(6) Attach return hose tubes to suspension cradle

crossmember using routing clamp and bolt (Fig. 21).

Tighten clamp bolt to 23 N´m (200 in. lbs.) torque.

(7) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 24). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.). When installing mounting bolts, include pres-

sure hose routing clamp.

(8) Tighten hose tube nut at power steering gear

port to 31 N´m (275 in. lbs.) torque.

(9) Install front emissions vapor canister. (Refer to

25 - EMISSIONS CONTROL/EVAPORATIVE EMIS-

SIONS/VAPOR CANISTER - INSTALLATION)

(10) Lower vehicle.

(11) Install return hose tube into retainer on ABS

bracket (Fig. 21). Close the bracket.

(12) Install return hose onto reservoir (Fig. 22).

Slide the hose clamp into position on fluid reservoir

and attach it.Be sure hose clamp in installed

past bead on fluid reservoir fitting.

(13) Fill and bleed power steering system using

the Power Steering Pump Initial Operation Proce-

dure. (Refer to 19 - STEERING/PUMP - STANDARD

PROCEDURE)

(14) Inspect system for leaks.

HOSE - POWER STEERING

SUPPLY

REMOVAL

REMOVAL - 2.4L ENGINE

(1) Remove filler cap from power steering fluid res-

ervoir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove hose clamp securing supply hose to

power steering pump, then remove supply hose from

pump fitting.

(5) Lower vehicle.

(6) Remove hose clamp attaching power steering

fluid supply hose to power steering fluid reservoir,

then remove supply hose.

(7) Remove the power steering fluid supply hose

from the vehicle.

REMOVAL - 3.3L/3.8L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Place an oil drain pan under vehicle to catch

any draining power steering fluid.

(4) Remove clamp attaching supply hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 22).

(5) Pull upward on hose routing clip releasing it

from bracket on cylinder head cover (Fig. 22).

NOTE: It may be necessary to remove air cleaner

housing to gain greater access to supply hose at

power steering pump. (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL)

(6) Remove clamp attaching supply hose to power

steering pump. Disconnect hose from pump and

remove from vehicle (Fig. 22).

INSTALLATION

INSTALLATION - 2.4L ENGINE

(1) Install and correctly route power steering fluid

supply hose from remote fluid reservoir to power

steering pump.

(2) Install fluid supply hose onto power steering

fluid reservoir. Install hose clamp.Be sure hose

clamp is installed past bead on fluid reservoir

fitting.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Install power steering fluid supply hose on

power steering pump supply fitting. Install hose

clamp.Be sure hose clamp is installed past bead

on pump fitting.

(5) Lower vehicle.

(6) Fill and bleed power steering system using

Power Steering Pump Initial Operation Procedure.

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE)

(7) Inspect system for leaks.

RSPUMP19-51

HOSE - POWER STEERING RETURN (Continued)

Page 1836 of 2339

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

(3) Align with paint breaks around bolt heads.

(4) Install bolts attaching ends of crossmember to

radiator closure panel (Fig. 16). Tighten bolts to 19

N´m (14 ft. lbs.) torque.

(5) Install bolts attaching radiator isolators to

crossmember.

(6) Install screw attaching coolant recovery bottle

to crossmember.

(7) Install bolt attaching air cleaner housing to

crossmember.

(8) Install engine air inlet resonator.

(9) Install hood prop rod.

(10) Align hood latch by placing latch over net

pierce tabs. If alignment is required, flatten tabs.

(11) Install bolts attaching hood latch to cross-

member and clip cable. Tighten bolts to 13.5 N´m (10

ft. lbs.) torque.

(12) Install radiator sight shield.

(13) Verify hood latch operation and hood align-

ment.

FRONT WHEELHOUSE

SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE).

(2) Remove front wheel.

(3) Remove push pin fasteners attaching splash

shield to frame rail forward of suspension.

(4) Remove push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(5) Remove screws attaching wheelhouse splash

shield to front fender and front bumper fascia.

(6) Remove splash shield from vehicle (Fig. 17).

INSTALLATION

(1) Place splash shield in position on vehicle (Fig.

17).

(2) Install push pin fasteners attaching splash

shield to frame rail forward of suspension.

(3) Install push pin fasteners attaching splash

shield to frame rail rearward of suspension.

(4) Install screws attaching wheelhouse splash

shield to front fender.

(5) Install front wheel.

(6) Lower vehicle.

LUGGAGE RACK RISER

REMOVAL

(1) Remove two fasteners from the front riser.

Gently pull up on the luggage rack side rail and

detach the riser snap to remove riser from the rail

(Fig. 18).

(2) Repeat for the opposite side, if necessary.

(3) Remove front riser(s) from vehicle (Fig. 19).

Fig. 17 FRONT WHEELHOUSE SPLASH SHIELD

1 - FRONT FENDER WHEELHOUSE SPLASH SHIELD

2 - PUSH PIN FASTENERS

3 - ACCESSORY DRIVE SPLASH SHIELD

4 - SCREWS

Fig. 18 LUGGAGE RACK RISER COVER

1 - FRONT RISER COVER

2 - LOCK TABS

3 - LUGGAGE RACK SIDE RAIL

4 - FRONT RISER

RSEXTERIOR23-57

UPPER RADIATOR CROSSMEMBER (Continued)