engine overheat CHRYSLER VOYAGER 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1457 of 2339

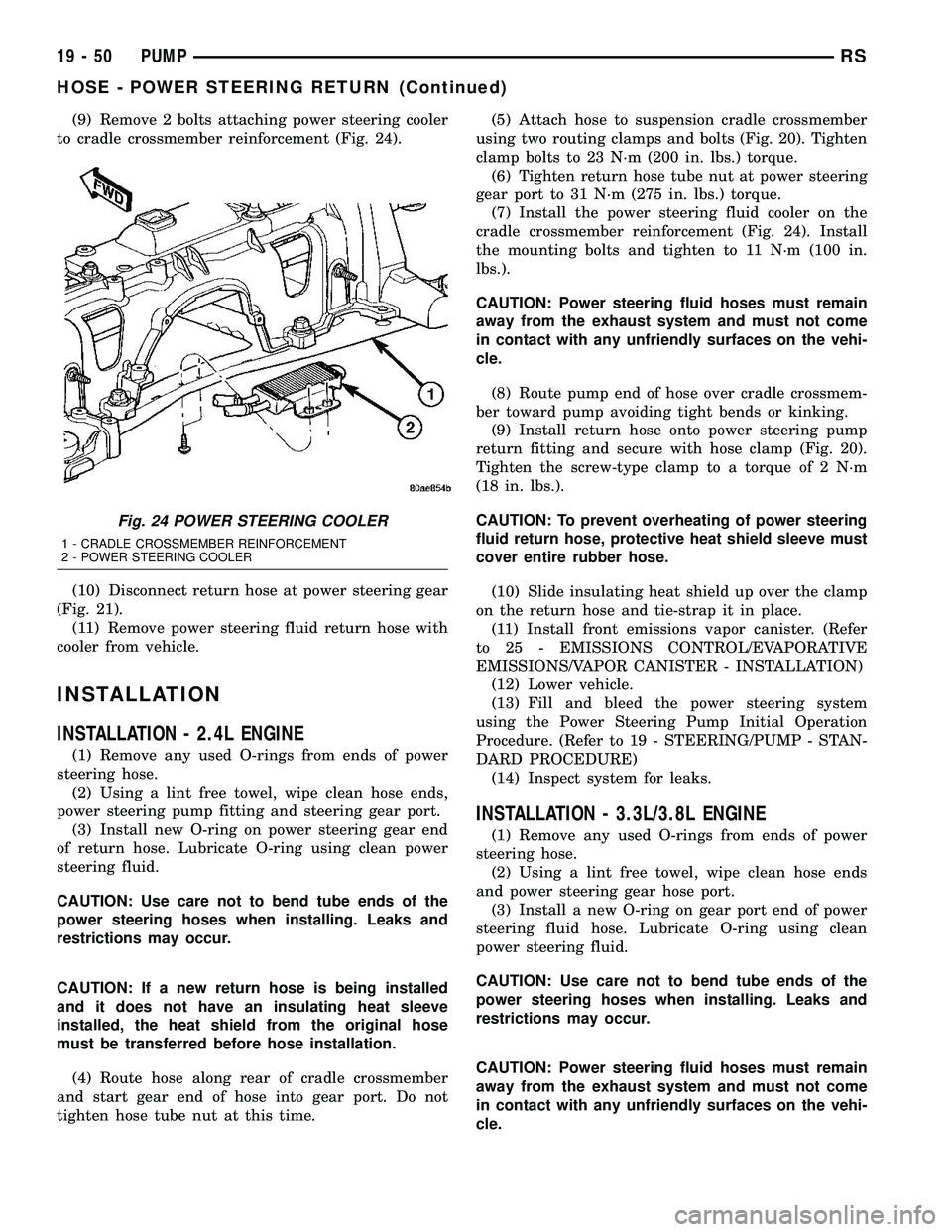

(9) Remove 2 bolts attaching power steering cooler

to cradle crossmember reinforcement (Fig. 24).

(10) Disconnect return hose at power steering gear

(Fig. 21).

(11) Remove power steering fluid return hose with

cooler from vehicle.

INSTALLATION

INSTALLATION - 2.4L ENGINE

(1) Remove any used O-rings from ends of power

steering hose.

(2) Using a lint free towel, wipe clean hose ends,

power steering pump fitting and steering gear port.

(3) Install new O-ring on power steering gear end

of return hose. Lubricate O-ring using clean power

steering fluid.

CAUTION: Use care not to bend tube ends of the

power steering hoses when installing. Leaks and

restrictions may occur.

CAUTION: If a new return hose is being installed

and it does not have an insulating heat sleeve

installed, the heat shield from the original hose

must be transferred before hose installation.

(4) Route hose along rear of cradle crossmember

and start gear end of hose into gear port. Do not

tighten hose tube nut at this time.(5) Attach hose to suspension cradle crossmember

using two routing clamps and bolts (Fig. 20). Tighten

clamp bolts to 23 N┬┤m (200 in. lbs.) torque.

(6) Tighten return hose tube nut at power steering

gear port to 31 N┬┤m (275 in. lbs.) torque.

(7) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 24). Install

the mounting bolts and tighten to 11 N┬┤m (100 in.

lbs.).

CAUTION: Power steering fluid hoses must remain

away from the exhaust system and must not come

in contact with any unfriendly surfaces on the vehi-

cle.

(8) Route pump end of hose over cradle crossmem-

ber toward pump avoiding tight bends or kinking.

(9) Install return hose onto power steering pump

return fitting and secure with hose clamp (Fig. 20).

Tighten the screw-type clamp to a torque of 2 N┬┤m

(18 in. lbs.).

CAUTION: To prevent overheating of power steering

fluid return hose, protective heat shield sleeve must

cover entire rubber hose.

(10) Slide insulating heat shield up over the clamp

on the return hose and tie-strap it in place.

(11) Install front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - INSTALLATION)

(12) Lower vehicle.

(13) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(14) Inspect system for leaks.

INSTALLATION - 3.3L/3.8L ENGINE

(1) Remove any used O-rings from ends of power

steering hose.

(2) Using a lint free towel, wipe clean hose ends

and power steering gear hose port.

(3) Install a new O-ring on gear port end of power

steering fluid hose. Lubricate O-ring using clean

power steering fluid.

CAUTION: Use care not to bend tube ends of the

power steering hoses when installing. Leaks and

restrictions may occur.

CAUTION: Power steering fluid hoses must remain

away from the exhaust system and must not come

in contact with any unfriendly surfaces on the vehi-

cle.

Fig. 24 POWER STEERING COOLER

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

19 - 50 PUMPRS

HOSE - POWER STEERING RETURN (Continued)

Page 1543 of 2339

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK

NOTE: Only transmission fluid of the type labeled

Mopar ATF+4 (Automatic Transmission Fluid)

should be used in this transaxle.

FLUID LEVEL CHECK

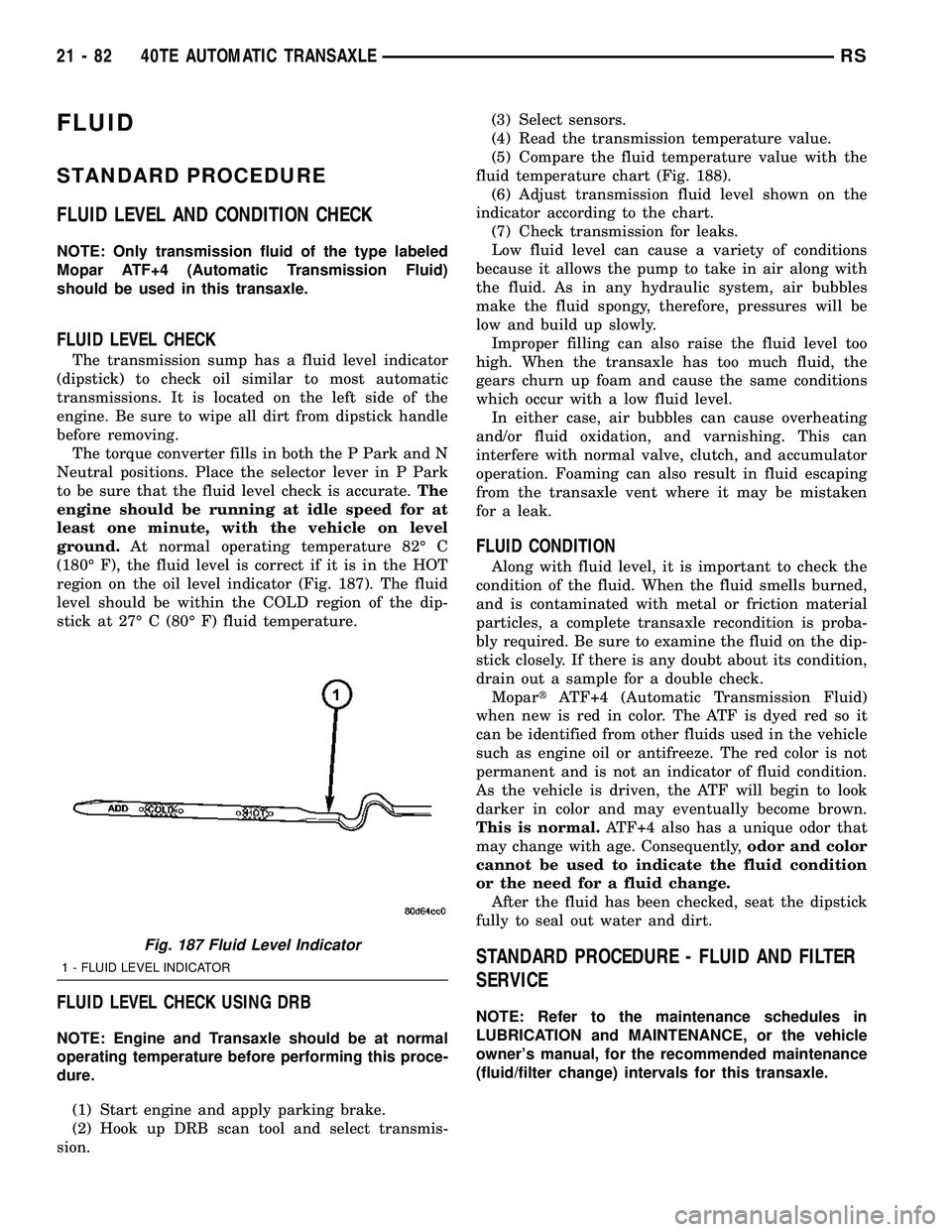

The transmission sump has a fluid level indicator

(dipstick) to check oil similar to most automatic

transmissions. It is located on the left side of the

engine. Be sure to wipe all dirt from dipstick handle

before removing.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground.At normal operating temperature 82É C

(180É F), the fluid level is correct if it is in the HOT

region on the oil level indicator (Fig. 187). The fluid

level should be within the COLD region of the dip-

stick at 27É C (80É F) fluid temperature.

FLUID LEVEL CHECK USING DRB

NOTE: Engine and Transaxle should be at normal

operating temperature before performing this proce-

dure.

(1) Start engine and apply parking brake.

(2) Hook up DRB scan tool and select transmis-

sion.(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 188).

(6) Adjust transmission fluid level shown on the

indicator according to the chart.

(7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.

FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

stick closely. If there is any doubt about its condition,

drain out a sample for a double check.

MopartATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.ATF+4 also has a unique odor that

may change with age. Consequently,odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

Fig. 187 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21 - 82 40TE AUTOMATIC TRANSAXLERS

Page 1592 of 2339

OPERATION

The Transmission Range Sensor (TRS) (Fig. 307)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combina-

tion of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM

interprets this information and determines the

appropriate transaxle gear position and shift sched-

ule.

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 308)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-dicted fluid temperature which is calculated from a

combination of inputs:

┬▓Battery (ambient) temperature

┬▓Engine coolant temperature

┬▓In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

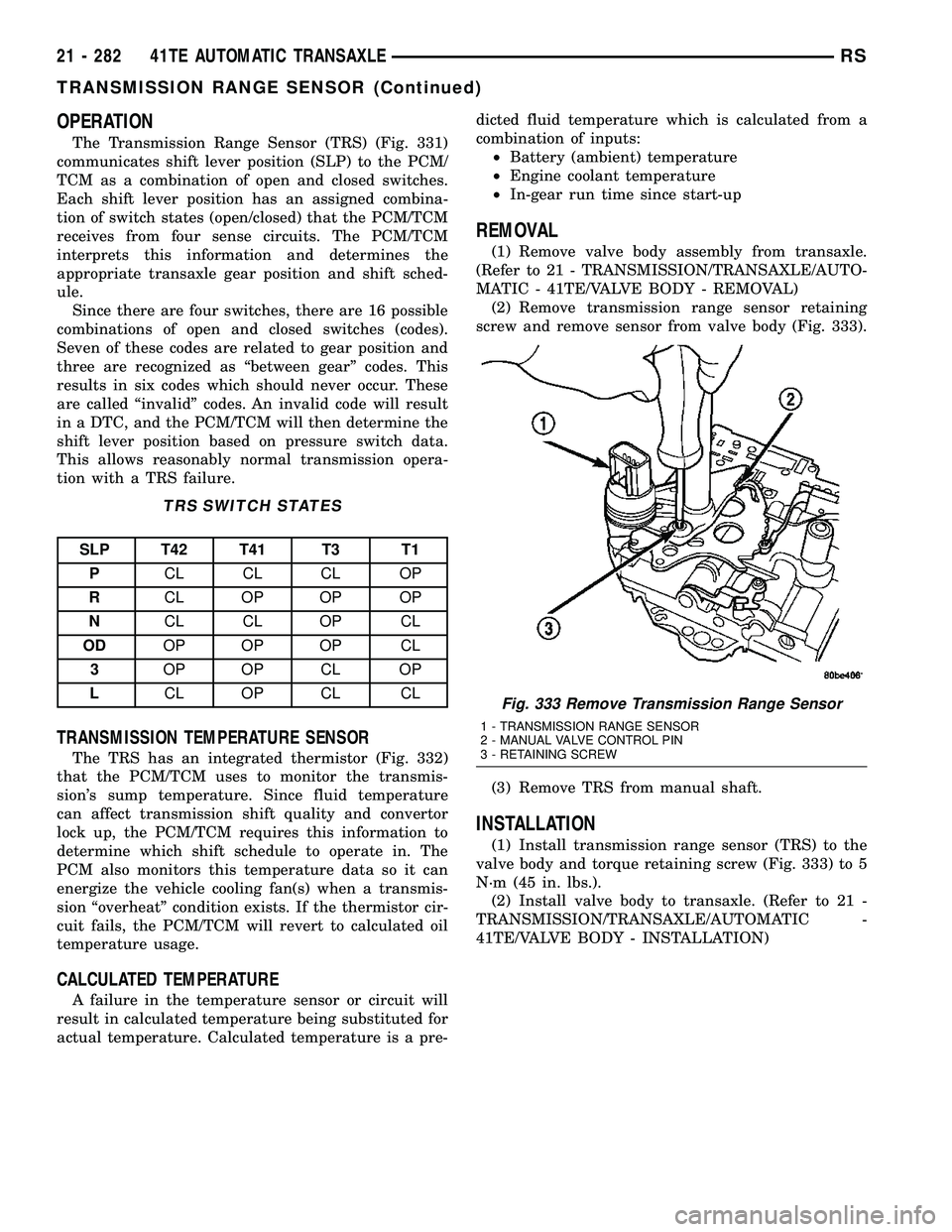

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 309).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 309) to 5

N┬┤m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

Fig. 309 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

RS40TE AUTOMATIC TRANSAXLE21 - 131

TRANSMISSION RANGE SENSOR (Continued)

Page 1691 of 2339

CAUTION: Do not damage the transaxle case and/or

differential retainer sealing surface.

(9) Using the end play measurement that was

determined, add 0.18mm (0.007 inch). This should

give you between 5-18 inch pounds of bearing pre-

load. Refer to the Differential Bearing Shim Chart to

determine which shim to use.

(10) Remove the differential bearing retainer.

Remove the bearing cup.

(11) Install the oil baffle. Install the proper shim

combination under the bearing cup.

(12) Install the differential bearing retainer. Seal

the retainer to the housing with MopartSilicone

Rubber Adhesive Sealant. Torque bolts to 28 N┬┤m

(250 in. lbs.).

(13) Using Miller Special Tool L-4436-A and an

inch-pound torque wrench, check the turning torque

of the differential (Fig. 204). The turning torque

should be between 5-18 inch-pounds.

NOTE: If turning torque is too high install a 0.05mm

(0.002 inch) thicker shim. If the turning torque is too

low, install a 0.05mm (0.002 inch) thinner shim.

Repeat until 5-18 inch-pounds of turning torque is

obtained.

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK

NOTE: Only transmission fluid of the type labeled

Mopar ATF+4 (Automatic Transmission Fluid)

should be used in this transaxle.

FLUID LEVEL CHECK

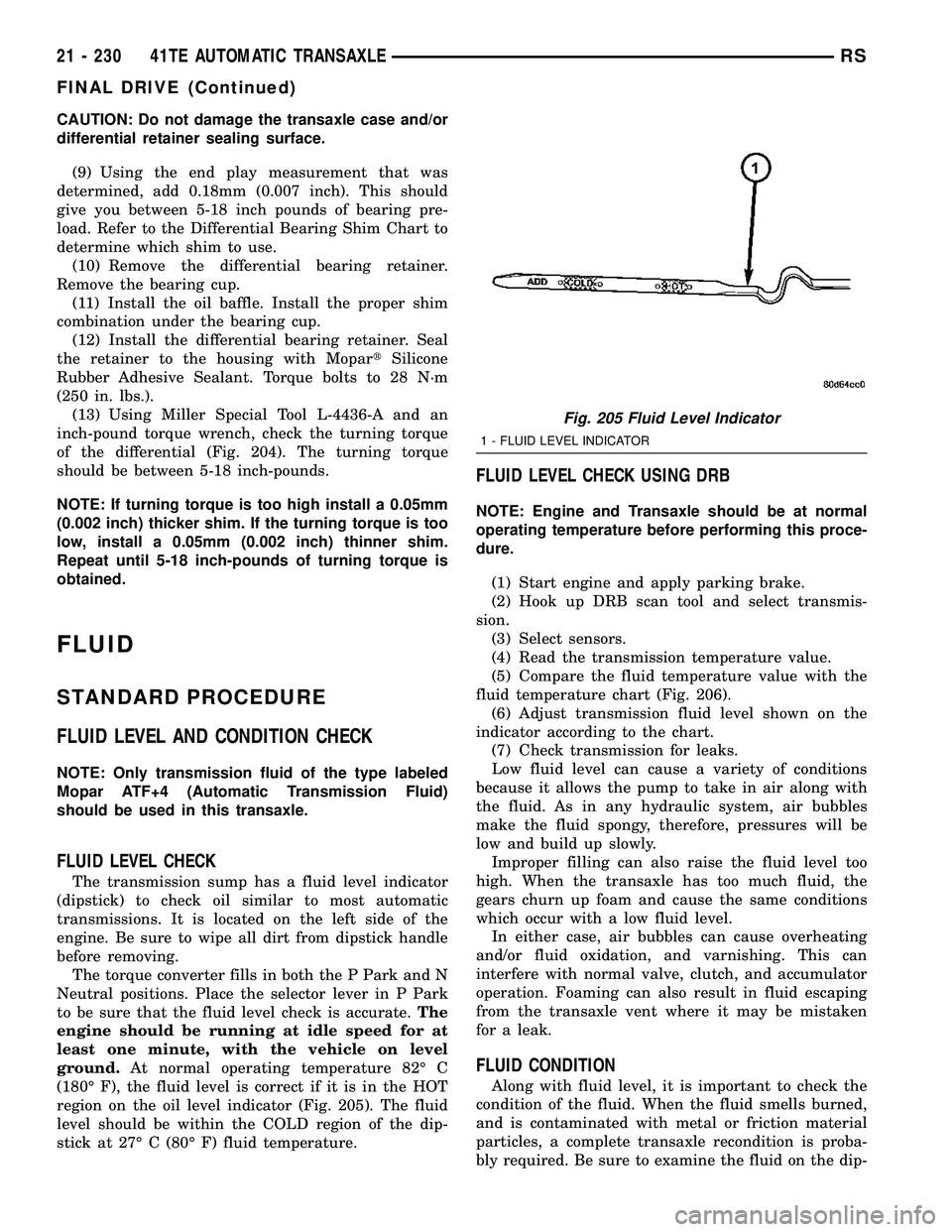

The transmission sump has a fluid level indicator

(dipstick) to check oil similar to most automatic

transmissions. It is located on the left side of the

engine. Be sure to wipe all dirt from dipstick handle

before removing.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground.At normal operating temperature 82É C

(180É F), the fluid level is correct if it is in the HOT

region on the oil level indicator (Fig. 205). The fluid

level should be within the COLD region of the dip-

stick at 27É C (80É F) fluid temperature.

FLUID LEVEL CHECK USING DRB

NOTE: Engine and Transaxle should be at normal

operating temperature before performing this proce-

dure.

(1) Start engine and apply parking brake.

(2) Hook up DRB scan tool and select transmis-

sion.

(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 206).

(6) Adjust transmission fluid level shown on the

indicator according to the chart.

(7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.

FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

Fig. 205 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21 - 230 41TE AUTOMATIC TRANSAXLERS

FINAL DRIVE (Continued)

Page 1743 of 2339

OPERATION

The Transmission Range Sensor (TRS) (Fig. 331)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combina-

tion of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM

interprets this information and determines the

appropriate transaxle gear position and shift sched-

ule.

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the PCM/TCM will then determine the

shift lever position based on pressure switch data.

This allows reasonably normal transmission opera-

tion with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

The TRS has an integrated thermistor (Fig. 332)

that the PCM/TCM uses to monitor the transmis-

sion's sump temperature. Since fluid temperature

can affect transmission shift quality and convertor

lock up, the PCM/TCM requires this information to

determine which shift schedule to operate in. The

PCM also monitors this temperature data so it can

energize the vehicle cooling fan(s) when a transmis-

sion ªoverheatº condition exists. If the thermistor cir-

cuit fails, the PCM/TCM will revert to calculated oil

temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-dicted fluid temperature which is calculated from a

combination of inputs:

┬▓Battery (ambient) temperature

┬▓Engine coolant temperature

┬▓In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 333).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 333) to 5

N┬┤m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

Fig. 333 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

21 - 282 41TE AUTOMATIC TRANSAXLERS

TRANSMISSION RANGE SENSOR (Continued)

Page 2160 of 2339

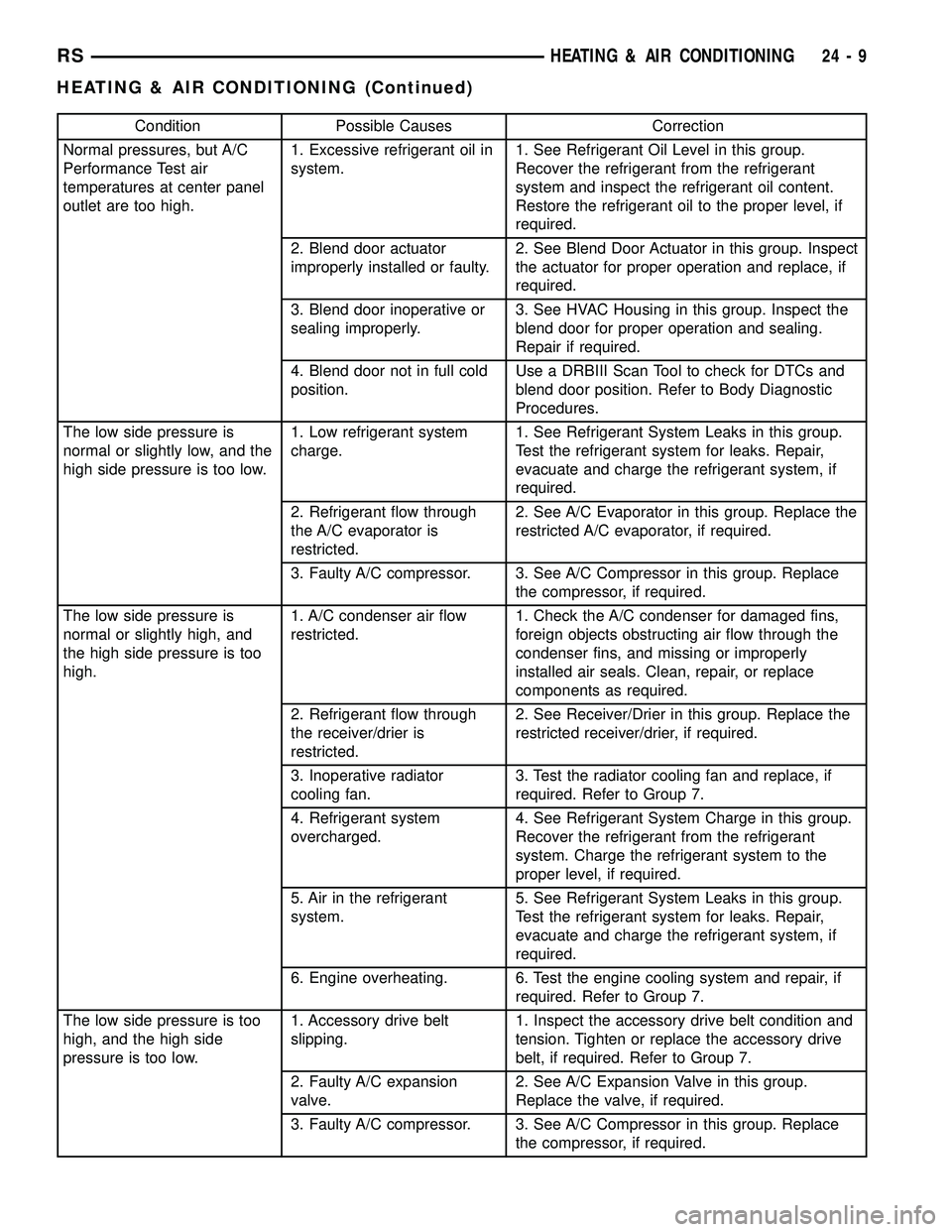

Condition Possible Causes Correction

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil Level in this group.

Recover the refrigerant from the refrigerant

system and inspect the refrigerant oil content.

Restore the refrigerant oil to the proper level, if

required.

2. Blend door actuator

improperly installed or faulty.2. See Blend Door Actuator in this group. Inspect

the actuator for proper operation and replace, if

required.

3. Blend door inoperative or

sealing improperly.3. See HVAC Housing in this group. Inspect the

blend door for proper operation and sealing.

Repair if required.

4. Blend door not in full cold

position.Use a DRBIII Scan Tool to check for DTCs and

blend door position. Refer to Body Diagnostic

Procedures.

The low side pressure is

normal or slightly low, and the

high side pressure is too low.1. Low refrigerant system

charge.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

2. Refrigerant flow through

the A/C evaporator is

restricted.2. See A/C Evaporator in this group. Replace the

restricted A/C evaporator, if required.

3. Faulty A/C compressor. 3. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. A/C condenser air flow

restricted.1. Check the A/C condenser for damaged fins,

foreign objects obstructing air flow through the

condenser fins, and missing or improperly

installed air seals. Clean, repair, or replace

components as required.

2. Refrigerant flow through

the receiver/drier is

restricted.2. See Receiver/Drier in this group. Replace the

restricted receiver/drier, if required.

3. Inoperative radiator

cooling fan.3. Test the radiator cooling fan and replace, if

required. Refer to Group 7.

4. Refrigerant system

overcharged.4. See Refrigerant System Charge in this group.

Recover the refrigerant from the refrigerant

system. Charge the refrigerant system to the

proper level, if required.

5. Air in the refrigerant

system.5. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

6. Engine overheating. 6. Test the engine cooling system and repair, if

required. Refer to Group 7.

The low side pressure is too

high, and the high side

pressure is too low.1. Accessory drive belt

slipping.1. Inspect the accessory drive belt condition and

tension. Tighten or replace the accessory drive

belt, if required. Refer to Group 7.

2. Faulty A/C expansion

valve.2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Faulty A/C compressor. 3. See A/C Compressor in this group. Replace

the compressor, if required.

RSHEATING & AIR CONDITIONING24-9

HEATING & AIR CONDITIONING (Continued)

Page 2253 of 2339

(5) Install the rear evaporator line extension onto

the expansion valve (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - REAR/EVAPORA-

TOR - INSTALLATION - EVAPORATOR LINE

EXTENSION).

(6) Install the foam insulator wrap over the rear

expansion valve.

(7) Install the rear HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - INSTALLATION).

(8) Run the HVAC Cooldown Test to verify proper

operation.

HEATER CORE

DESCRIPTION

The rear heater core is located near the front of

the rear HVAC housing, behind the right rear wheel

house. It is a heat exchanger made of rows of tubes

and fins. One end of the core is fitted with a molded

plastic tank that includes integral heater core inlet

and outlet nipples. The rear heater core can be ser-

viced without removing the rear HVAC housing from

the vehicle.

OPERATION

Engine coolant is circulated through underbody

heater hoses to the rear heater core at all times. As

the coolant flows through the rear heater core, heat

removed from the engine is transferred to the heater

core fins and tubes. Air directed through the heater

core picks up the heat from the heater core fins. The

rear blend door allows control of the rear heater out-

put air temperature by controlling how much of the

air flowing through the rear HVAC housing is

directed through the heater core.

The rear heater core cannot be repaired and, if

faulty or damaged, it must be replaced.

STANDARD PROCEDURE

REAR HEATER CORE FILLING

In its final installed position, the rear heater core

is positioned higher than the radiator fill cap. There-

fore, when the cooling system is drained and refilled,

gravity will not refill the heater core with coolant to

the proper level. This may result in two problems:1.

Insufficient coolant level in the engine cooling sys-

tem, which may result in engine overheating.2.Air

entrapped within the rear heater core, which may

result in insufficient rear heater performance. There

are two methods that may be employed to prevent

these problems:1.Pre-filling of the rear heater core.

2.Thermal cycling of the engine cooling system. Fol-lowing are descriptions of both prevention methods,

as well as a method to verify rear heater perfor-

mance.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING

FRONT - WARNING - HEATER PLUMBING).

PRE-FILLING

If the rear heater core or the rear HVAC housing

have been removed from the vehicle for service, the

rear heater core may be pre-filled with the proper

engine coolant mixture prior to reconnecting the

heater hoses to the heater core hose fittings.

(1) The heater core should be installed in the rear

HVAC housing, and the rear HVAC housing should

be installed in the vehicle.

(2) Take the proper precautions to protect the car-

peting below the rear heater core from spilled engine

coolant and have absorbent toweling readily avail-

able to mop up any spills.

(3) Insert the small end of an appropriate funnel

into the upper hose fitting of the heater core (Fig. 4).

(4) Carefully pour the proper pre-mixed engine

coolant solution into the rear heater core through a

funnel until coolant begins to appear at the lower

hose fitting of the heater core.

(5) Use absorbent toweling to clean up any engine

coolant spills from the preceding operation.

(6) Reconnect the heater hoses to the rear heater

core (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - REAR/HEATER HOSE - INSTAL-

LATION).

Fig. 4 Pre-Filling Heater Core - Typical

1 - REAR HEATER CORE

24 - 102 PLUMBING - REARRS

A/C EXPANSION VALVE (Continued)