windshield wipers CHRYSLER VOYAGER 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 558 of 2339

INSTALLATION

(1) Push filler neck and front washer hose through

the opening in the front fender side shield. Connect

the reservoir to the body mount by lowering the res-

ervoir down.

(2) Install the two reservoir mounting screws.

Torque screws to 8.5 - 11.3 N´m (75 - 100 in. lbs.).

(3) Connect the electrical body harness connectors

to the washer pump motor and the fluid level sensor.

Slide the red lock on the connector to the closed or

locked position.

(4) Assure that washer is properly routed to pre-

vent pinching and possible inoperative washers.

(5) Install the left right front wheelhouse splash

shield (Refer to 23 - BODY/EXTERIOR/WHEEL-

HOUSE SPLASH SHIELD - INSTALLATION).

(6) Install the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - INSTALLATION).

(7) lower vehicle from hoist or jack stands.

(8) Install the filler tube screw. Torque screw to 8.5

- 11.3 N´m (75 - 100 in. lbs.).

(9) Connect the washer hose to the hose clip

located on the front fender side shield.

(10) Connect the washer hose at the in-line con-

nector forward of the cowl grille.

(11) Install the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(12) Connect the battery negative cable.

(13) Verify system operation.

WIPER BLADES

REMOVAL

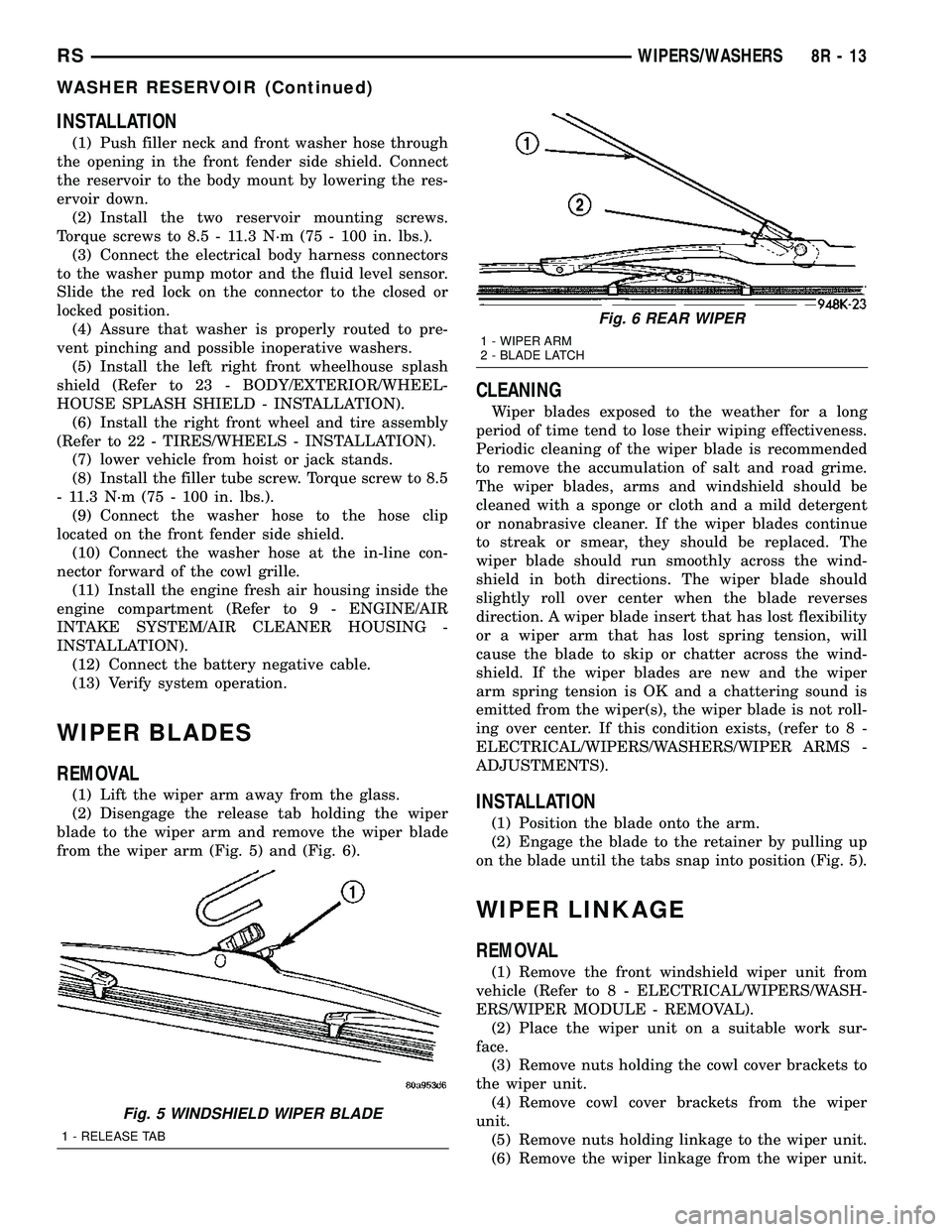

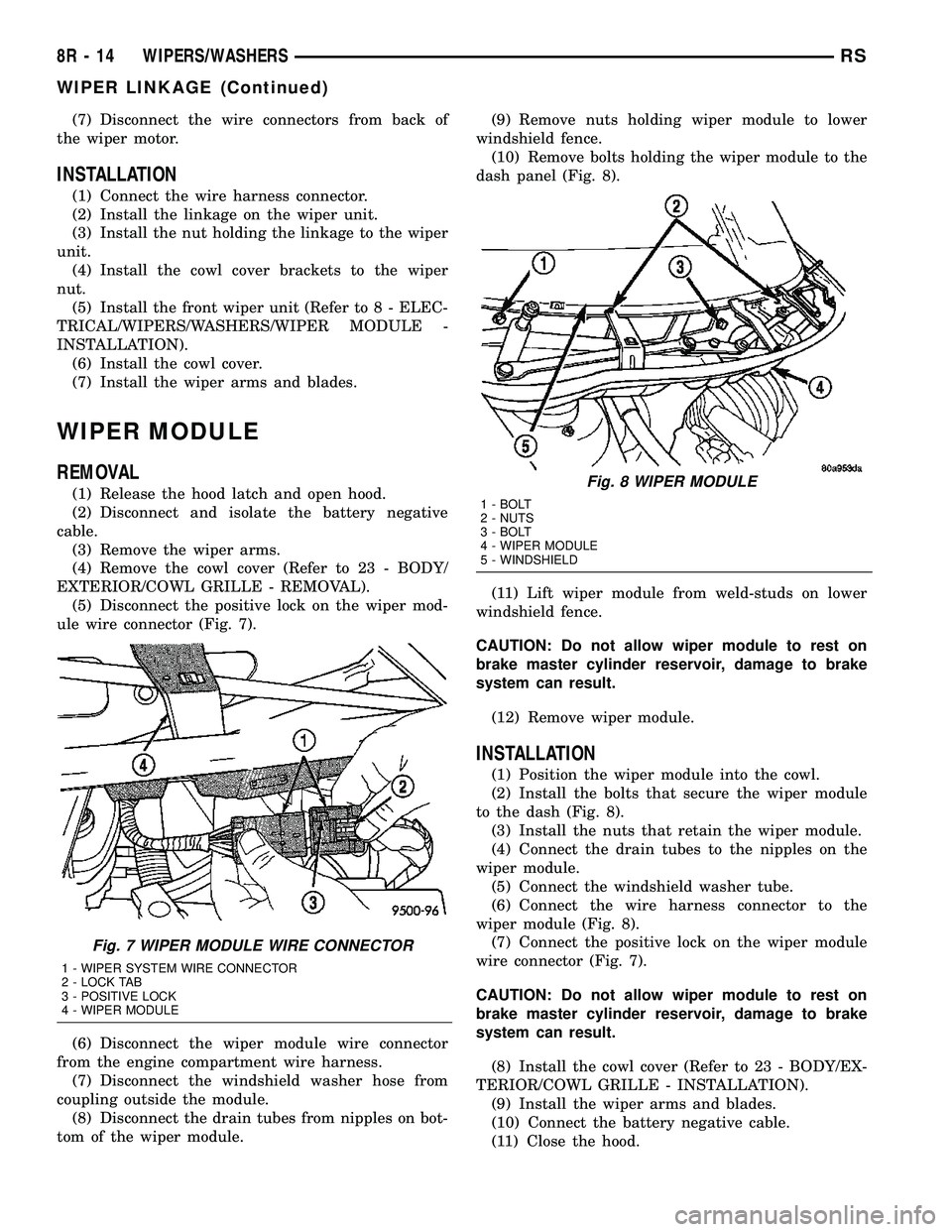

(1) Lift the wiper arm away from the glass.

(2) Disengage the release tab holding the wiper

blade to the wiper arm and remove the wiper blade

from the wiper arm (Fig. 5) and (Fig. 6).

CLEANING

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. The

wiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, (refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER ARMS -

ADJUSTMENTS).

INSTALLATION

(1) Position the blade onto the arm.

(2) Engage the blade to the retainer by pulling up

on the blade until the tabs snap into position (Fig. 5).

WIPER LINKAGE

REMOVAL

(1) Remove the front windshield wiper unit from

vehicle (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER MODULE - REMOVAL).

(2) Place the wiper unit on a suitable work sur-

face.

(3) Remove nuts holding the cowl cover brackets to

the wiper unit.

(4) Remove cowl cover brackets from the wiper

unit.

(5) Remove nuts holding linkage to the wiper unit.

(6) Remove the wiper linkage from the wiper unit.

Fig. 5 WINDSHIELD WIPER BLADE

1 - RELEASE TAB

Fig. 6 REAR WIPER

1 - WIPER ARM

2 - BLADE LATCH

RSWIPERS/WASHERS8R-13

WASHER RESERVOIR (Continued)

Page 559 of 2339

(7) Disconnect the wire connectors from back of

the wiper motor.

INSTALLATION

(1) Connect the wire harness connector.

(2) Install the linkage on the wiper unit.

(3) Install the nut holding the linkage to the wiper

unit.

(4) Install the cowl cover brackets to the wiper

nut.

(5) Install the front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(6) Install the cowl cover.

(7) Install the wiper arms and blades.

WIPER MODULE

REMOVAL

(1) Release the hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the wiper arms.

(4) Remove the cowl cover (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL).

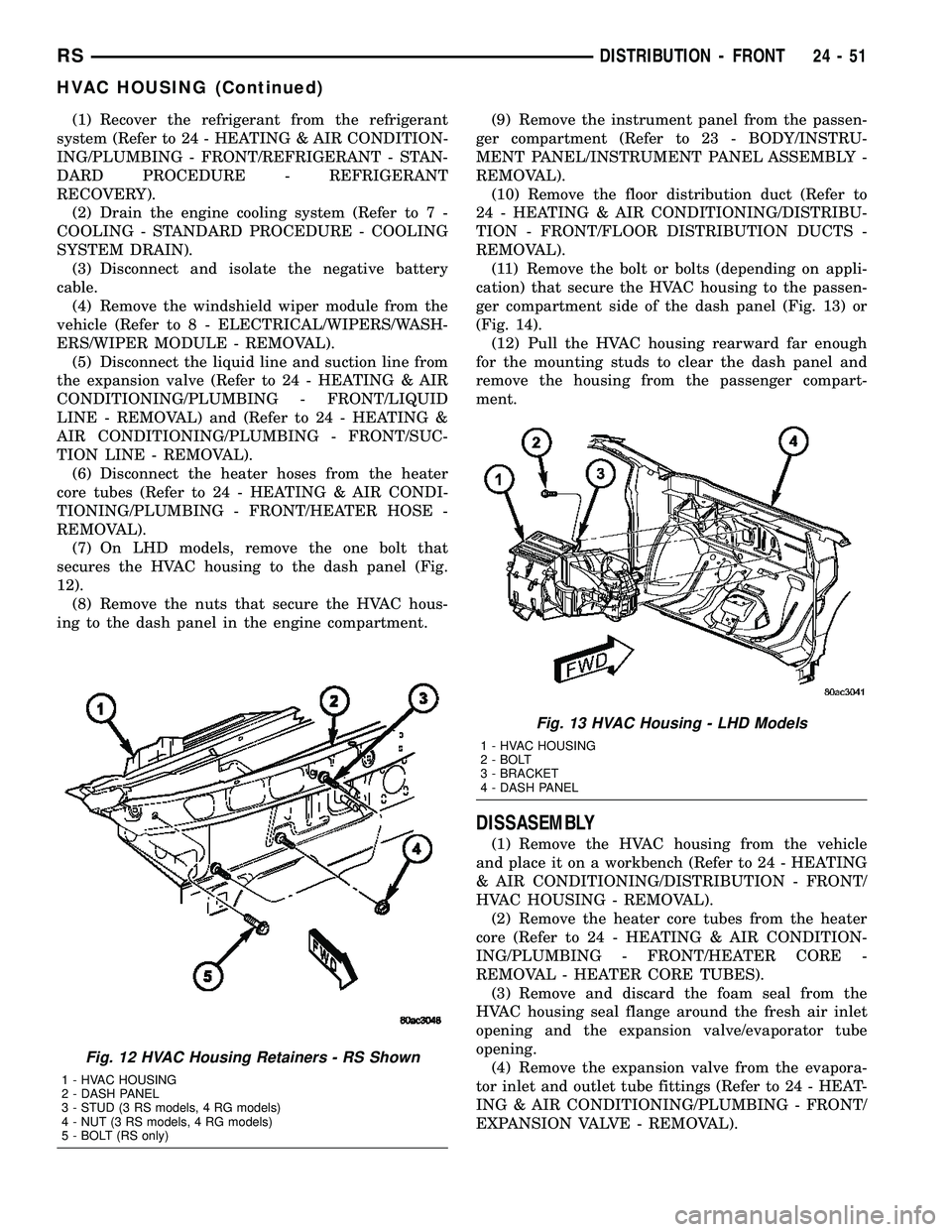

(5) Disconnect the positive lock on the wiper mod-

ule wire connector (Fig. 7).

(6) Disconnect the wiper module wire connector

from the engine compartment wire harness.

(7) Disconnect the windshield washer hose from

coupling outside the module.

(8) Disconnect the drain tubes from nipples on bot-

tom of the wiper module.(9) Remove nuts holding wiper module to lower

windshield fence.

(10) Remove bolts holding the wiper module to the

dash panel (Fig. 8).

(11) Lift wiper module from weld-studs on lower

windshield fence.

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.

(12) Remove wiper module.

INSTALLATION

(1) Position the wiper module into the cowl.

(2) Install the bolts that secure the wiper module

to the dash (Fig. 8).

(3) Install the nuts that retain the wiper module.

(4) Connect the drain tubes to the nipples on the

wiper module.

(5) Connect the windshield washer tube.

(6) Connect the wire harness connector to the

wiper module (Fig. 8).

(7) Connect the positive lock on the wiper module

wire connector (Fig. 7).

CAUTION: Do not allow wiper module to rest on

brake master cylinder reservoir, damage to brake

system can result.

(8) Install the cowl cover (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION).

(9) Install the wiper arms and blades.

(10) Connect the battery negative cable.

(11) Close the hood.

Fig. 7 WIPER MODULE WIRE CONNECTOR

1 - WIPER SYSTEM WIRE CONNECTOR

2 - LOCK TAB

3 - POSITIVE LOCK

4 - WIPER MODULE

Fig. 8 WIPER MODULE

1 - BOLT

2 - NUTS

3 - BOLT

4 - WIPER MODULE

5 - WINDSHIELD

8R - 14 WIPERS/WASHERSRS

WIPER LINKAGE (Continued)

Page 1829 of 2339

COWL GRILLE

REMOVAL

(1) Remove wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL)

(2) Remove four (4) screws securing cowl cover to

wiper module (Fig. 6).

(3) Disengage quarter turn fasteners at outboard

ends of cowl grill from body.

(4) Release hood latch and open hood.

CAUTION: To prevent hood scratching of cowl grille

before removal, cover outboard exterior ends of

cowl grille with masking tape or equivalent method.

NOTE: Do not over bend cowl grille during removal.

Bend cowl grille just enough to clear top of wiper

pivot shaft and bottom rear corner of hood.

(5) Remove cowl grill by raising above driver side

wiper pivot shaft and swinging away towards engine

compartment. The cowl grille will need to be bent onoutboard end to clear simultaneously top of wiper

pivot shaft and bottom corner of hood.

(6) Close hood. Do not latch. Remove outboard

screws. (Fig. 7).

(7) Disconnect washer hose in line connector.

(8) Disconnect washer hose and grommet from

hole in wiper module and pull out.

(9) Remove cowl grille by raising over opposite

wiper pivot shaft and removing away from vehicle.

(10) Remove cowl cover from vehicle.

INSTALLATION

(1) Reverse removal procedure.

(2) When installing cowl cover over wiper module,

make sure fore aft locator on the underside of cowl

grill seat into the locator grooves on top of wiper

module.

(3) Start all cowl grille mounting screws by hand

before torquing to specifications.

(4) Assure washer hose is properly routed and not

pinched.

(5) Center cowl grille to body and windshield.

(6) Assure ªarrowº indicator head of quarter turn

fasteners is pointing toward windshield.

Fig. 5 BODY SIDE MOLDINGS WITH APPLIQUE - TYPICAL

1 - FRONT ROCKER PANEL APPLIQUE

2 - FRONT DOOR MOLDING

3 - SLIDING DOOR MOLDING4 - REAR ROCKER PANEL APPLIQUE

5 - LIFTGATE MOLDING

6 - POP-RIVET

23 - 50 EXTERIORRS

BODY SIDE MOLDINGS (Continued)

Page 1830 of 2339

(7) Tighten screw to 1.2 N´m (11 in. lbs.) torque.

(8) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

(9) Check for proper spray pattern from washer

nozzles.

EXTERIOR NAME PLATES -

TAPE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) Using a nonmetallic prying device, such as a

plastic or wood trim stick gently pry up at corners

and remove.

(4) Clean off all traces of adhesive or double sided

tape from the panel with a general purpose adhesive

remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Align badgeing to reference points.

(3) Install and press securely to full adhesive con-

tact

(4) Clean away any reference points.

EXTERIOR NAME PLATES -

ADHESIVE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) With your fingernail lift up and peel away

badgeing/tape from panel, using a heat gun as you

go.

(4) Clean off all traces of adhesive from the pan-

el(s) with a general purpose adhesive remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Remove paper carrier and align badgeing/tape

to reference points or adjacent panel.

(3) Install and press securely, using a plastic

spreader to eliminate all air bubbles.

(4) Remove top protective carrier.

(5) Clean away any reference points.

FRONT FENDER

REMOVAL

(1) Remove headlamp housing. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - REMOVAL)

(2) Remove mirror bezel

(3) Remove mud guard.

(4) Remove inner splash shield.

(5) Remove fender to fascia nuts.

Fig. 6 COWL COVER

1 - COWL COVER

2 - WIPER PIVOT

3 - WASHER HOSES

4 - HOOD

Fig. 7 COWL COVER RETAINERS

1 - SCREW

2 - WINDSHIELD

3 - COWL COVER

4 - FRONT FENDER

RSEXTERIOR23-51

COWL GRILLE (Continued)

Page 1942 of 2339

(16) Apply 150 mm (6 in.) lengths of 50 mm (2 in.)

masking tape spaced 250 mm (10 in.) apart to hold

molding in place until urethane cures.

(17) Install A-pillar trim panels.

(18) Install cowl cover and wipers.

(19) Install inside rear view mirror.

(20) After urethane has cured, remove tape strips

and water test windshield to verify repair.SLIDING DOOR GLASS

REMOVAL

The temperature of the vehicle should be at least

21É C (70É F) before removing the stationary quarter/

sliding door glass. Butyl sealer becomes more pliable

at high temperatures.

(1) Remove interior trim as necessary to gain

access attaching locations on back of glass.

(2) Remove nuts holding stationary glass to fence.

(3)

Using razor knife, cut butyl sealer holding glass

to fence from between the mounting studs (Fig. 4).

(4) Push glass from opening.

INSTALLATION

The temperature of the vehicle should be at least

21É C (70É F) before removing the stationary quarter/

sliding door glass. Butyl sealer becomes more pliable

at high temperatures.

The stationary glass fence should be cleaned of all

old butyl sealer.

(1) Applya6mm(0.25 in.) butyl tape around

perimeter of glass assembly encapsulation track.

Ensure that the butyl tape is wrapped around the

mounting studs.

(2) Place the glass into the opening and insert

mounting studs through holes in fence.

(3) Install nuts to hold stationary glass to fence.

CAUTION: Tighten nuts to 3.4 N´m (30 in. lbs.)

torque in the sequence indicated. Do not over

torque, or glass breakage may result (Fig. 4).

(4) Water test before installing interior trim.

(5) Install interior trim. (Refer to 23 - BODY/

DOORS - SLIDING/TRIM PANEL - INSTALLATION)

(6) Verify alignment and flushness.

Fig. 2 WORK SURFACE SET UP AND MOLDING

INSTALLATION

1 - WINDSHIELD AND MOLDINGS

2 - BLOCKS

Fig. 3 LOWER WINDSHIELD INTO POSITION

1 - WINDSHIELD

2 - COMPRESSION SPACERS

Fig. 4 SLIDING DOOR STATIONARY GLASS

1 - NUMBERS INDICATE THE TIGHTENING SEQUENCE

2-6mmBEAD OF BUTYL TAPE

3 - BODY SIDE/SLIDING DOOR GLASS

RSSTATIONARY GLASS23 - 163

WINDSHIELD (Continued)

Page 2178 of 2339

The evaporator temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

OPERATION

The evaporator temperature sensor monitors the

temperature of the conditioned air once it passes

through the A/C evaporator. The evaporator temper-

ature sensor will change its internal resistance in

response to the air temperatures it monitors and is

connected to the A/C-heater control through sensor

ground and signal circuits. As the conditioned air

temperature increases, the resistance of the evapora-

tor temperature sensor decreases and the voltage

monitored by the A/C-heater control decreases. The

external location of the evaporator temperature sen-

sor allows the sensor to be removed or installed with-

out disturbing the refrigerant in the A/C system.

The A/C-heater control uses this monitored voltage

reading as an indication of the evaporator tempera-

ture. The A/C-heater control is programmed to

respond to this input by sending electronic messages

to the powertrain control module (PCM) over the con-

troller area network (CAN) data bus. The PCM then

cycles the A/C compressor clutch as necessary to opti-

mize A/C system performance and to protect the A/C

system from evaporator freezing.

The evaporator temperature sensor cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

The evaporator temperature sensor is diagnosed

using the DRBIIItscan tool. Refer to Body Diagnos-

tic Procedures.

REMOVAL

RG MODELS

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the air cleaner housing from the right

side of the engine compartment.

(3) Remove the windshield wiper assembly from

the vehicle (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL).

(4) Remove the temperature sensor retainer from

the expansion valve (Fig. 17).

(5) Pull the evaporator temperature sensor away

from the expansion valve far enough to access the

red release ring on the wiring connector. Push the

red ring toward the connector to release the lock and

disconnect the wire harness connector from the tem-

perature sensor.

(6) Remove the evaporator temperature sensor

from the engine compartment.

RS MODELS

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the instrument panel from the vehicle

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - REMOVAL).

(3) Disconnect the wire harness connector from the

evaporator temperature sensor located on the top of

the HVAC housing (Fig. 18).

(4) Remove the evaporator temperature sensor

from the HVAC housing.

INSTALLATION

RG MODELS

NOTE: Any grease removed with the evaporator

temperature sensor must be replaced. Failure to do

so could result in poor A/C performance.

(1) Position the evaporator temperature sensor

into the right rear corner of the engine compartment.

(2) Reconnect the wire harness connector to the

evaporator temperature sensor.

(3) Position the evaporator temperature sensor

onto the top of the expansion valve with the sensor

probe inserted into the well in the expansion valve.

(4) Install the temperature sensor retainer.

(5) Install the window wiper module (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION).

(6) Reinstall the air cleaner housing into the right

side of the engine compartment.

(7) Reconnect the battery negative cable.

Fig. 17 Evaporator Temperature Sensor - RG Models

1 - RIGHT FRONT STRUT TOWER

2 - EVAPORATOR TEMPERATURE SENSOR

3 - EXPANSION VALVE

4 - DASH PANEL

5 - RETAINER

RSCONTROLS - FRONT24-27

EVAPORATOR TEMPERATURE SENSOR (Continued)

Page 2202 of 2339

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(3) Disconnect and isolate the negative battery

cable.

(4) Remove the windshield wiper module from the

vehicle (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER MODULE - REMOVAL).

(5) Disconnect the liquid line and suction line from

the expansion valve (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - FRONT/LIQUID

LINE - REMOVAL) and (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - FRONT/SUC-

TION LINE - REMOVAL).

(6) Disconnect the heater hoses from the heater

core tubes (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/HEATER HOSE -

REMOVAL).

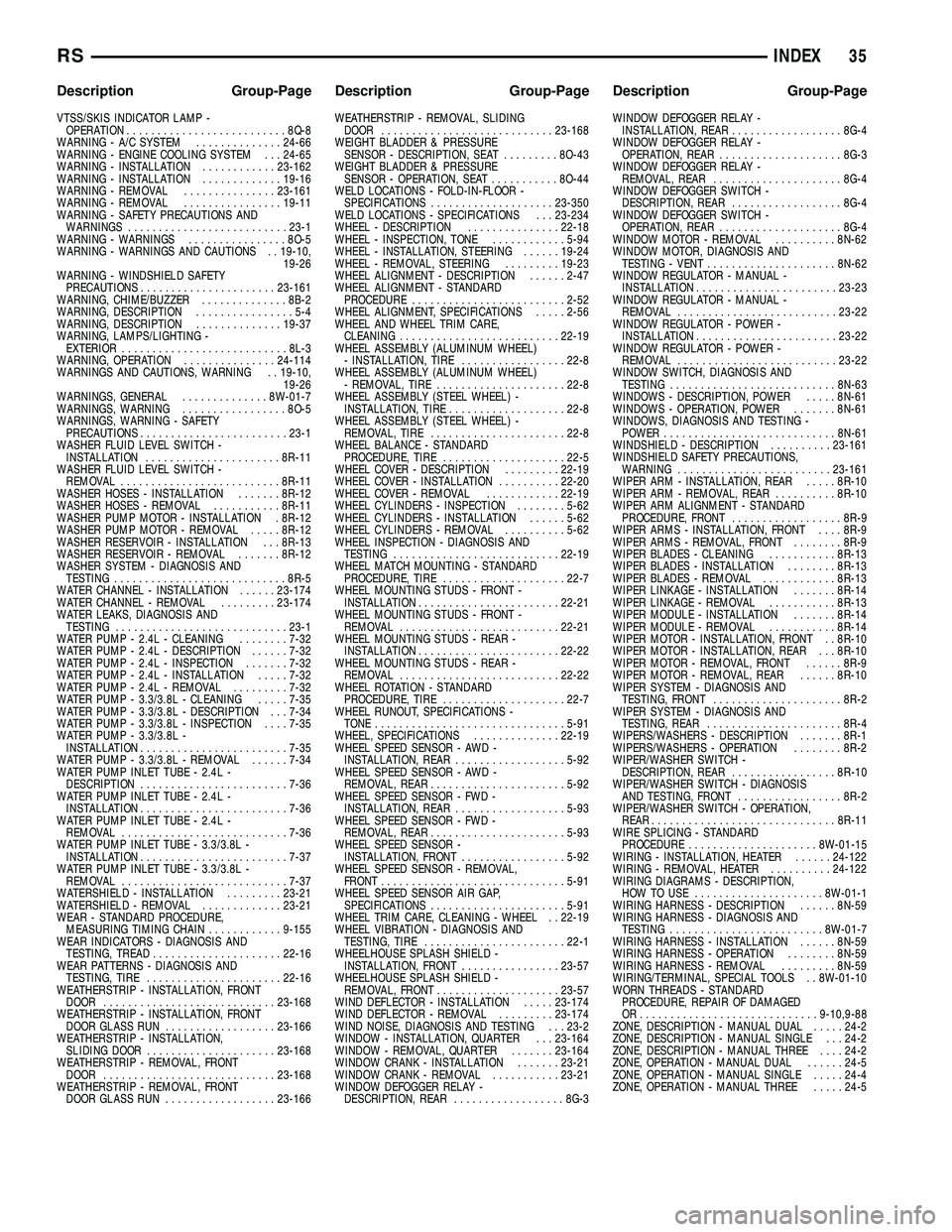

(7) On LHD models, remove the one bolt that

secures the HVAC housing to the dash panel (Fig.

12).

(8) Remove the nuts that secure the HVAC hous-

ing to the dash panel in the engine compartment.(9) Remove the instrument panel from the passen-

ger compartment (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL ASSEMBLY -

REMOVAL).

(10) Remove the floor distribution duct (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION - FRONT/FLOOR DISTRIBUTION DUCTS -

REMOVAL).

(11) Remove the bolt or bolts (depending on appli-

cation) that secure the HVAC housing to the passen-

ger compartment side of the dash panel (Fig. 13) or

(Fig. 14).

(12) Pull the HVAC housing rearward far enough

for the mounting studs to clear the dash panel and

remove the housing from the passenger compart-

ment.

DISSASEMBLY

(1) Remove the HVAC housing from the vehicle

and place it on a workbench (Refer to 24 - HEATING

& AIR CONDITIONING/DISTRIBUTION - FRONT/

HVAC HOUSING - REMOVAL).

(2) Remove the heater core tubes from the heater

core (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/HEATER CORE -

REMOVAL - HEATER CORE TUBES).

(3) Remove and discard the foam seal from the

HVAC housing seal flange around the fresh air inlet

opening and the expansion valve/evaporator tube

opening.

(4) Remove the expansion valve from the evapora-

tor inlet and outlet tube fittings (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - FRONT/

EXPANSION VALVE - REMOVAL).

Fig. 12 HVAC Housing Retainers - RS Shown

1 - HVAC HOUSING

2 - DASH PANEL

3 - STUD (3 RS models, 4 RG models)

4 - NUT (3 RS models, 4 RG models)

5 - BOLT (RS only)

Fig. 13 HVAC Housing - LHD Models

1 - HVAC HOUSING

2 - BOLT

3 - BRACKET

4 - DASH PANEL

RSDISTRIBUTION - FRONT24-51

HVAC HOUSING (Continued)

Page 2205 of 2339

(7) Reconnect the heater hoses to the heater core

tubes (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/HEATER HOSE -

INSTALLATION).

(8) Reconnect the suction line and liquid line to

the expansion valve (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - FRONT/SUCTION

LINE - INSTALLATION) and (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - FRONT/

LIQUID LINE - INSTALLATION).

(9) Install the windshield wiper module (Refer to 8

- ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION).

(10) Reconnect the negative battery cable.

(11) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

(12) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(13) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

INSTRUMENT PANEL

DEMISTER DUCTS

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - REMOVAL).

(3) Place the instrument panel face down on a

suitable work surface. Be certain to take the proper

precautions to protect the face of the instrument

panel from cosmetic damage.

(4) Remove the fasteners that secure the demister

ducts to the instrument panel armature.

(5) Disengage the demister ducts from the demis-

ter outlets.

(6) Remove the demister ducts from the instru-

ment panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the demister ducts to the instrument

panel.

(2) Engage the demister ducts to the demister out-

lets.

(3) Install the fasteners that secure the demister

ducts to the instrument panel armature.

(4) Reinstall the instrument panel into the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - INSTALLA-

TION).

(5) Reconnect the battery negative cable.

24 - 54 DISTRIBUTION - FRONTRS

HVAC HOUSING (Continued)

Page 2336 of 2339

VTSS/SKIS INDICATOR LAMP -OPERATION .......................... 8Q-8

WARNING - A/C SYSTEM ..............24-66

WARNING - ENGINE COOLING SYSTEM . . . 24-65

WARNING - INSTALLATION ............23-162

WARNING - INSTALLATION .............19-16

WARNING - REMOVAL ...............23-161

WARNING - REMOVAL ................19-11

WARNING - SAFETY PRECAUTIONS AND WARNINGS .......................... 23-1

WARNING - WARNINGS ................8O-5

WARNING - WARNINGS AND CAUTIONS . . 19-10, 19-26

WARNING - WINDSHIELD SAFETY PRECAUTIONS ...................... 23-161

WARNING, CHIME/BUZZER ..............8B-2

WARNING, DESCRIPTION ................5-4

WARNING, DESCRIPTION ..............19-37

WARNING, LAMPS/LIGHTING - EXTERIOR ........................... 8L-3

WARNING, OPERATION ...............24-114

WARNINGS AND CAUTIONS, WARNING . . 19-10, 19-26

WARNINGS, GENERAL ..............8W-01-7

WARNINGS, WARNING .................8O-5

WARNINGS, WARNING - SAFETY PRECAUTIONS ........................ 23-1

WASHER FLUID LEVEL SWITCH - INSTALLATION ...................... 8R-11

WASHER FLUID LEVEL SWITCH - REMOVAL .......................... 8R-11

WASHER HOSES - INSTALLATION .......8R-12

WASHER HOSES - REMOVAL ...........8R-11

WASHER PUMP MOTOR - INSTALLATION . 8R-12

WASHER PUMP MOTOR - REMOVAL .....8R-12

WASHER RESERVOIR - INSTALLATION . . . 8R-13

WASHER RESERVOIR - REMOVAL .......8R-12

WASHER SYSTEM - DIAGNOSIS AND TESTING ............................ 8R-5

WATER CHANNEL - INSTALLATION ......23-174

WATER CHANNEL - REMOVAL .........23-174

WATER LEAKS, DIAGNOSIS AND TESTING ............................ 23-1

WATER PUMP - 2.4L - CLEANING ........7-32

WATER PUMP - 2.4L - DESCRIPTION ......7-32

WATER PUMP - 2.4L - INSPECTION .......7-32

WATER PUMP - 2.4L - INSTALLATION .....7-32

WATER PUMP - 2.4L - REMOVAL .........7-32

WATER PUMP - 3.3/3.8L - CLEANING .....7-35

WATER PUMP - 3.3/3.8L - DESCRIPTION . . . 7-34

WATER PUMP - 3.3/3.8L - INSPECTION ....7-35

WATER PUMP - 3.3/3.8L - INSTALLATION ........................ 7-35

WATER PUMP - 3.3/3.8L - REMOVAL ......7-34

WATER PUMP INLET TUBE - 2.4L - DESCRIPTION ........................ 7-36

WATER PUMP INLET TUBE - 2.4L - INSTALLATION ........................ 7-36

WATER PUMP INLET TUBE - 2.4L - REMOVAL ........................... 7-36

WATER PUMP INLET TUBE - 3.3/3.8L - INSTALLATION ........................ 7-37

WATER PUMP INLET TUBE - 3.3/3.8L - REMOVAL ........................... 7-37

WATERSHIELD - INSTALLATION .........23-21

WATERSHIELD - REMOVAL .............23-21

WEAR - STANDARD PROCEDURE, MEASURING TIMING CHAIN ............9-155

WEAR INDICATORS - DIAGNOSIS AND TESTING, TREAD ..................... 22-16

WEAR PATTERNS - DIAGNOSIS AND TESTING, TIRE ...................... 22-16

WEATHERSTRIP - INSTALLATION, FRONT DOOR ............................ 23-168

WEATHERSTRIP - INSTALLATION, FRONT DOOR GLASS RUN .................. 23-166

WEATHERSTRIP - INSTALLATION, SLIDING DOOR ..................... 23-168

WEATHERSTRIP - REMOVAL, FRONT DOOR ............................ 23-168

WEATHERSTRIP - REMOVAL, FRONT DOOR GLASS RUN .................. 23-166WEATHERSTRIP - REMOVAL, SLIDING

DOOR ............................ 23-168

WEIGHT BLADDER & PRESSURE SENSOR - DESCRIPTION, SEAT .........8O-43

WEIGHT BLADDER & PRESSURE SENSOR - OPERATION, SEAT ...........8O-44

WELD LOCATIONS - FOLD-IN-FLOOR - SPECIFICATIONS .................... 23-350

WELD LOCATIONS - SPECIFICATIONS . . . 23-234

WHEEL - DESCRIPTION ...............22-18

WHEEL - INSPECTION, TONE ............5-94

WHEEL - INSTALLATION, STEERING ......19-24

WHEEL - REMOVAL, STEERING .........19-23

WHEEL ALIGNMENT - DESCRIPTION ......2-47

WHEEL ALIGNMENT - STANDARD PROCEDURE ......................... 2-52

WHEEL ALIGNMENT, SPECIFICATIONS .....2-56

WHEEL AND WHEEL TRIM CARE, CLEANING .......................... 22-19

WHEEL ASSEMBLY (ALUMINUM WHEEL) - INSTALLATION, TIRE .................22-8

WHEEL ASSEMBLY (ALUMINUM WHEEL) - REMOVAL, TIRE ..................... 22-8

WHEEL ASSEMBLY (STEEL WHEEL) - INSTALLATION, TIRE ................... 22-8

WHEEL ASSEMBLY (STEEL WHEEL) - REMOVAL, TIRE ...................... 22-8

WHEEL BALANCE - STANDARD PROCEDURE, TIRE .................... 22-5

WHEEL COVER - DESCRIPTION .........22-19

WHEEL COVER - INSTALLATION ..........22-20

WHEEL COVER - REMOVAL ............22-19

WHEEL CYLINDERS - INSPECTION ........5-62

WHEEL CYLINDERS - INSTALLATION ......5-62

WHEEL CYLINDERS - REMOVAL ..........5-62

WHEEL INSPECTION - DIAGNOSIS AND TESTING ........................... 22-19

WHEEL MATCH MOUNTING - STANDARD PROCEDURE, TIRE .................... 22-7

WHEEL MOUNTING STUDS - FRONT - INSTALLATION ....................... 22-21

WHEEL MOUNTING STUDS - FRONT - REMOVAL .......................... 22-21

WHEEL MOUNTING STUDS - REAR - INSTALLATION ....................... 22-22

WHEEL MOUNTING STUDS - REAR - REMOVAL .......................... 22-22

WHEEL ROTATION - STANDARD PROCEDURE, TIRE .................... 22-7

WHEEL RUNOUT, SPECIFICATIONS - TONE ............................... 5-91

WHEEL, SPECIFICATIONS ..............22-19

WHEEL SPEED SENSOR - AWD - INSTALLATION, REAR .................. 5-92

WHEEL SPEED SENSOR - AWD - REMOVAL, REAR ...................... 5-92

WHEEL SPEED SENSOR - FWD - INSTALLATION, REAR .................. 5-93

WHEEL SPEED SENSOR - FWD - REMOVAL, REAR ...................... 5-93

WHEEL SPEED SENSOR - INSTALLATION, FRONT .................5-92

WHEEL SPEED SENSOR - REMOVAL, FRONT .............................. 5-91

WHEEL SPEED SENSOR AIR GAP, SPECIFICATIONS ...................... 5-91

WHEEL TRIM CARE, CLEANING - WHEEL . . 22-19

WHEEL VIBRATION - DIAGNOSIS AND TESTING, TIRE ....................... 22-1

WHEELHOUSE SPLASH SHIELD - INSTALLATION, FRONT ................23-57

WHEELHOUSE SPLASH SHIELD - REMOVAL, FRONT .................... 23-57

WIND DEFLECTOR - INSTALLATION .....23-174

WIND DEFLECTOR - REMOVAL .........23-174

WIND NOISE, DIAGNOSIS AND TESTING . . . 23-2

WINDOW - INSTALLATION, QUARTER . . . 23-164

WINDOW - REMOVAL, QUARTER .......23-164

WINDOW CRANK - INSTALLATION .......23-21

WINDOW CRANK - REMOVAL ...........23-21

WINDOW DEFOGGER RELAY - DESCRIPTION, REAR .................. 8G-3WINDOW DEFOGGER RELAY -

INSTALLATION, REAR .................. 8G-4

WINDOW DEFOGGER RELAY - OPERATION, REAR .................... 8G-3

WINDOW DEFOGGER RELAY - REMOVAL, REAR ..................... 8G-4

WINDOW DEFOGGER SWITCH - DESCRIPTION, REAR .................. 8G-4

WINDOW DEFOGGER SWITCH - OPERATION, REAR .................... 8G-4

WINDOW MOTOR - REMOVAL ..........8N-62

WINDOW MOTOR, DIAGNOSIS AND TESTING - VENT ..................... 8N-62

WINDOW REGULATOR - MANUAL - INSTALLATION ....................... 23-23

WINDOW REGULATOR - MANUAL - REMOVAL .......................... 23-22

WINDOW REGULATOR - POWER - INSTALLATION ....................... 23-22

WINDOW REGULATOR - POWER - REMOVAL .......................... 23-22

WINDOW SWITCH, DIAGNOSIS AND TESTING ........................... 8N-63

WINDOWS - DESCRIPTION, POWER .....8N-61

WINDOWS - OPERATION, POWER .......8N-61

WINDOWS, DIAGNOSIS AND TESTING - POWER ............................ 8N-61

WINDSHIELD - DESCRIPTION ..........23-161

WINDSHIELD SAFETY PRECAUTIONS, WARNING ......................... 23-161

WIPER ARM - INSTALLATION, REAR .....8R-10

WIPER ARM - REMOVAL, REAR ..........8R-10

WIPER ARM ALIGNMENT - STANDARD PROCEDURE, FRONT .................. 8R-9

WIPER ARMS - INSTALLATION, FRONT ....8R-9

WIPER ARMS - REMOVAL, FRONT ........8R-9

WIPER BLADES - CLEANING ...........8R-13

WIPER BLADES - INSTALLATION ........8R-13

WIPER BLADES - REMOVAL ............8R-13

WIPER LINKAGE - INSTALLATION .......8R-14

WIPER LINKAGE - REMOVAL ...........8R-13

WIPER MODULE - INSTALLATION .......8R-14

WIPER MODULE - REMOVAL ...........8R-14

WIPER MOTOR - INSTALLATION, FRONT . . 8R-10

WIPER MOTOR - INSTALLATION, REAR . . . 8R-10

WIPER MOTOR - REMOVAL, FRONT ......8R-9

WIPER MOTOR - REMOVAL, REAR ......8R-10

WIPER SYSTEM - DIAGNOSIS AND TESTING, FRONT ..................... 8R-2

WIPER SYSTEM - DIAGNOSIS AND TESTING, REAR ...................... 8R-4

WIPERS/WASHERS - DESCRIPTION .......8R-1

WIPERS/WASHERS - OPERATION ........8R-2

WIPER/WASHER SWITCH - DESCRIPTION, REAR .................8R-10

WIPER/WASHER SWITCH - DIAGNOSIS AND TESTING, FRONT .................8R-2

WIPER/WASHER SWITCH - OPERATION, REAR .............................. 8R-11

WIRE SPLICING - STANDARD PROCEDURE .....................8W -01-15

WIRING - INSTALLATION, HEATER ......24-122

WIRING - REMOVAL, HEATER ..........24-122

WIRING DIAGRAMS - DESCRIPTION, HOW TO USE .....................8W -01-1

WIRING HARNESS - DESCRIPTION ......8N-59

WIRING HARNESS - DIAGNOSIS AND TESTING .........................8W -01-7

WIRING HARNESS - INSTALLATION ......8N-59

WIRING HARNESS - OPERATION ........8N-59

WIRING HARNESS - REMOVAL .........8N-59

WIRING/TERMINAL, SPECIAL TOOLS . . 8W-01-10

WORN THREADS - STANDARD PROCEDURE, REPAIR OF DAMAGED

OR............................. 9-10,9-88

ZONE, DESCRIPTION - MANUAL DUAL .....24-2

ZONE, DESCRIPTION - MANUAL SINGLE . . . 24-2

ZONE, DESCRIPTION - MANUAL THREE ....24-2

ZONE, OPERATION - MANUAL DUAL ......24-5

ZONE, OPERATION - MANUAL SINGLE .....24-4

ZONE, OPERATION - MANUAL THREE .....24-5

RS INDEX35

Description Group-Page Description Group-Page Description Group-Page