belt CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2014 of 2339

DESCRIPTION FIGURE

FUEL TANK SUPPORT AND TIRE STOWAGE - SHORT WHEEL BASE ONLY 119

INNER SIDE SILLS - SHORT WHEEL BASE ONLY 120

REAR SEAT REINFORCEMENTS - SHORT WHEEL BASE ONLY 121

CENTER CONSOLE REINFORCEMENT - SHORT WHEEL BASE ONLY 122

WHEELHOUSES - SHORT WHEEL BASE ONLY 123

FRONT SEAT CROSS MEMBER - SHORT WHEELBASE, ALL WHEEL DRIVE ONLY 124

FLOOR PAN SIDE RAIL - LONG WHEEL BASE ONLY 125

INNER BODY SIDE SILL REINFORCEMENTS 126

TOE BOARD CROSS MEMBER 127

FRONT SIDE RAIL - SHORT WHEEL BASE ONLY 128

DASH PANEL REINFORCEMENT 129

LOWER COWL PLENUM 130

UPPER COWL PLENUM SUPPORT 131

UPPER DASH PANEL 132

COWL SIDE PANELS 133

INSTRUMENT PANEL ATTACHMENT TAPPING PLATES 134

INSTRUMENT PANEL, DASH PANEL, ACM MODULE AND ACCELERATOR PEDAL 135

STRUT TOWER BRACKET AND COWL PLENUM 136

FRONT SIDE RAILS TO LOWER DASH PANEL 137

INNER BODY SIDE SILL TO LOWER DASH PANEL 138

FRONT HINGE TAPPING PLATE 139

FRONT HINGE PILLAR 140

INNER WINDSHIELD FRAME 141

WINDSHIELD FRAME 142

FENDER BRACKET 143

INNER B-PILLAR 144

STRIKER LATCH AND TAPPING PLATES 145

RIGHT REAR INNER QUARTER PANEL - LONG WHEEL BASE ONLY 146

RIGHT REAR INNER QUARTER PANEL/OUTER WHEELHOUSE - LONG WHEEL BASE

ONLY147

RIGHT REAR BODY SIDE APERTURE - LONG WHEEL BASE ONLY 148

STRIKER LATCH REINFORCEMENT - LONG WHEEL BASE ONLY 149

BELT TAPPING PLATE - LONG WHEEL BASE ONLY 150

C-PILLAR REINFORCEMENT - LONG WHEEL BASE ONLY 151

OUTER WHEELHOUSE - LONG WHEEL BASE ONLY 152

C AND D-PILLAR INNER REINFORCEMENTS - LONG WHEEL BASE ONLY 153

LEFT REAR INNER QUARTER PANEL - LONG WHEEL BASE ONLY 154

OUTER WHEELHOUSE EXTENSION - LONG WHEEL BASE ONLY 155

TAIL LAMP - LONG WHEEL BASE ONLY 156

SLIDING DOOR LATCH - LONG WHEEL BASE ONLY 157

ROOF BOW EXTENSION - LONG WHEEL BASE ONLY 158

RIGHT REAR INNER QUARTER PANEL - SHORT WHEEL BASE ONLY 159

RSBODY STRUCTURE23 - 235

WELD LOCATIONS (Continued)

Page 2016 of 2339

DESCRIPTION FIGURE

UPPER COWL PLENUM AND REINFORCEMENT - RIGHT HAND DRIVE 201

COWL SIDE PANEL AND DASH PANEL - RIGHT HAND DRIVE 202

LOWER COWL PLENUM, SUPPORT AND DASH PANEL - RIGHT HAND DRIVE 203

STEERING COLUMN REINFORCEMENT, BELT REINFORCEMENT AND DASH PANEL -

RIGHT HAND DRIVE204

INSTRUMENT PANEL TAPPING PLATE AND COWL SIDE PANEL - RIGHT HAND DRIVE 205

DASH PANEL AND BELT REINFORCEMENT - RIGHT HAND DRIVE 206

UPPER SUPPORT, UPPER REINFORCEMENT AND UPPER COWL PLENUM - RIGHT

HAND DRIVE207

UPPER SUPPORT, BRAKE PEDAL BRACKET REINFORCEMENT AND DASH PANEL -

RIGHT HAND DRIVE208

REINFORCEMENT, MOUNTING BRACKETS AND DASH PANEL - RIGHT HAND DRIVE 209

STRUT TOWER, COWL SIDE PANEL - RIGHT HAND DRIVE 210

REINFORCEMENTS, SIDE RAILS, COWL SIDE PANELS AND DASH PANEL - RIGHT

HAND DRIVE211

UPPER COWL PLENUM, GUSSETS, SIDE SHIELDS AND BODY SIDE APERTURE -

RIGHT HAND DRIVE212

SIDE GLASS ANTENNA TAPPING PLATE AND INNER BODY SIDE APERTURE - RIGHT

HAND DRIVE213

Fig. 85 FRONT FENDER SHIELD - RIGHT

RSBODY STRUCTURE23 - 237

WELD LOCATIONS (Continued)

Page 2073 of 2339

Fig. 150 BELT TAPPING PLATE - LONG WHEEL BASE ONLY

23 - 294 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2120 of 2339

Fig. 204 STEERING COLUMN REINFORCEMENT, BELT REINFORCEMENT AND DASH PANEL - RIGHT HAND

DRIVE

RSBODY STRUCTURE23 - 341

WELD LOCATIONS (Continued)

Page 2122 of 2339

Fig. 206 DASH PANEL AND BELT REINFORCEMENT - RIGHT HAND DRIVE

RSBODY STRUCTURE23 - 343

WELD LOCATIONS (Continued)

Page 2160 of 2339

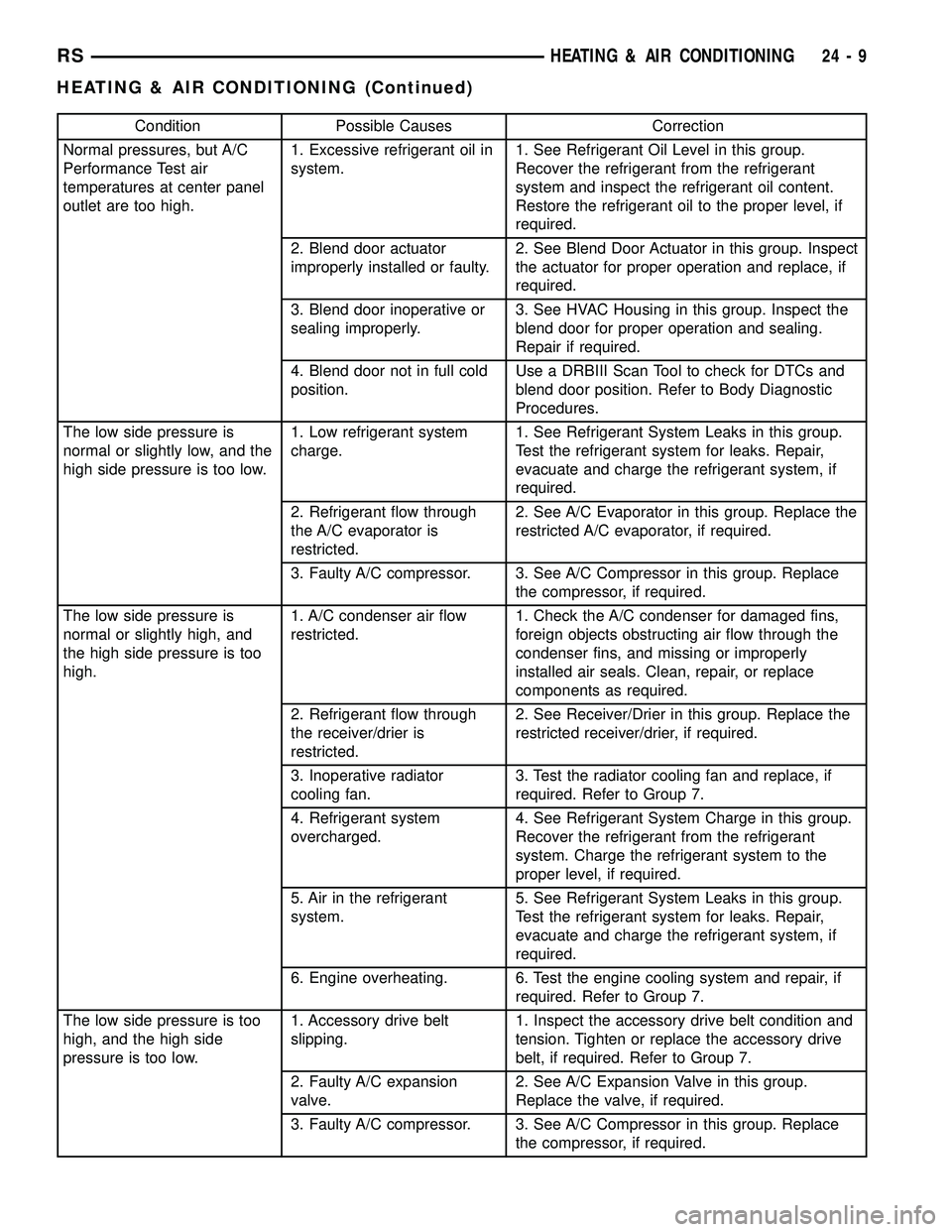

Condition Possible Causes Correction

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil Level in this group.

Recover the refrigerant from the refrigerant

system and inspect the refrigerant oil content.

Restore the refrigerant oil to the proper level, if

required.

2. Blend door actuator

improperly installed or faulty.2. See Blend Door Actuator in this group. Inspect

the actuator for proper operation and replace, if

required.

3. Blend door inoperative or

sealing improperly.3. See HVAC Housing in this group. Inspect the

blend door for proper operation and sealing.

Repair if required.

4. Blend door not in full cold

position.Use a DRBIII Scan Tool to check for DTCs and

blend door position. Refer to Body Diagnostic

Procedures.

The low side pressure is

normal or slightly low, and the

high side pressure is too low.1. Low refrigerant system

charge.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

2. Refrigerant flow through

the A/C evaporator is

restricted.2. See A/C Evaporator in this group. Replace the

restricted A/C evaporator, if required.

3. Faulty A/C compressor. 3. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. A/C condenser air flow

restricted.1. Check the A/C condenser for damaged fins,

foreign objects obstructing air flow through the

condenser fins, and missing or improperly

installed air seals. Clean, repair, or replace

components as required.

2. Refrigerant flow through

the receiver/drier is

restricted.2. See Receiver/Drier in this group. Replace the

restricted receiver/drier, if required.

3. Inoperative radiator

cooling fan.3. Test the radiator cooling fan and replace, if

required. Refer to Group 7.

4. Refrigerant system

overcharged.4. See Refrigerant System Charge in this group.

Recover the refrigerant from the refrigerant

system. Charge the refrigerant system to the

proper level, if required.

5. Air in the refrigerant

system.5. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

6. Engine overheating. 6. Test the engine cooling system and repair, if

required. Refer to Group 7.

The low side pressure is too

high, and the high side

pressure is too low.1. Accessory drive belt

slipping.1. Inspect the accessory drive belt condition and

tension. Tighten or replace the accessory drive

belt, if required. Refer to Group 7.

2. Faulty A/C expansion

valve.2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Faulty A/C compressor. 3. See A/C Compressor in this group. Replace

the compressor, if required.

RSHEATING & AIR CONDITIONING24-9

HEATING & AIR CONDITIONING (Continued)

Page 2161 of 2339

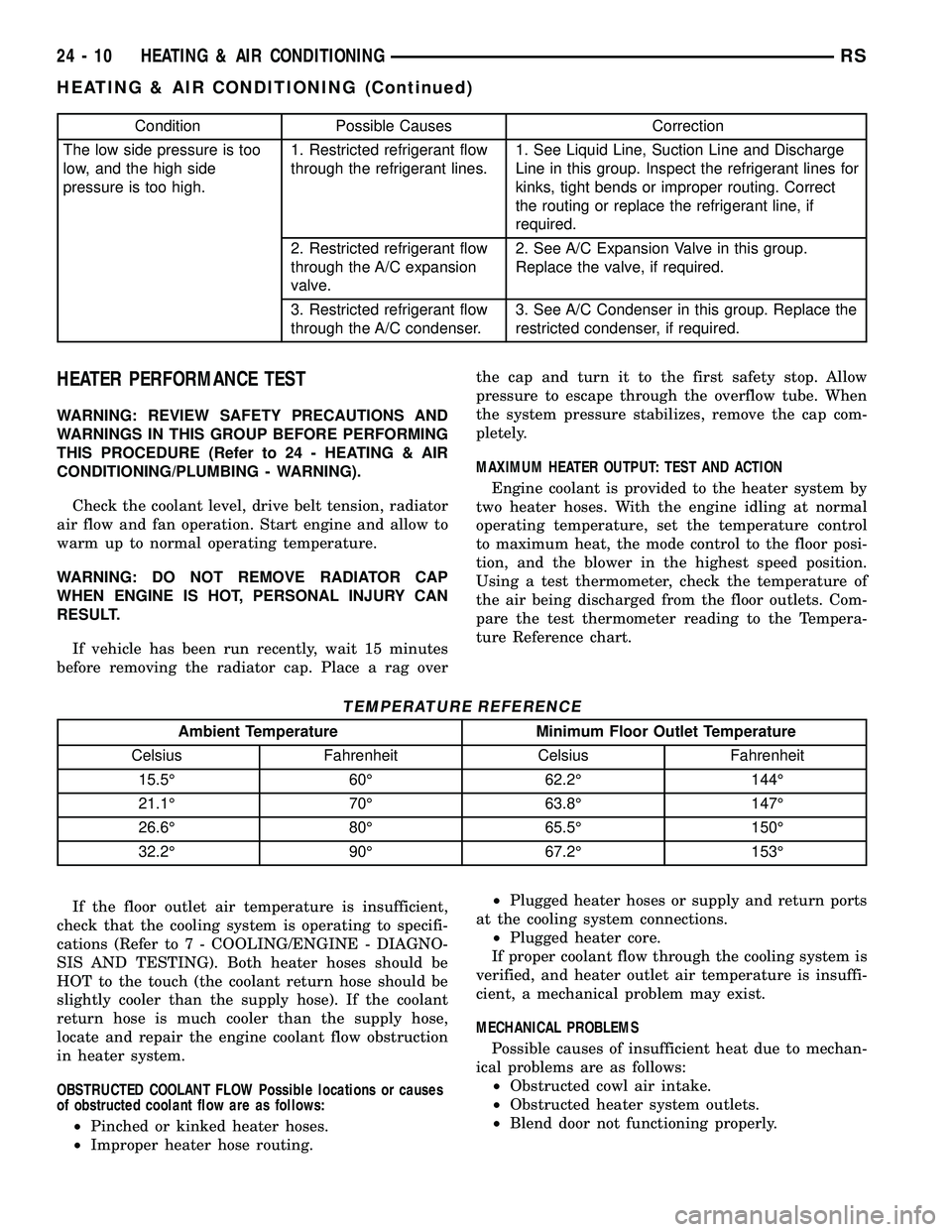

Condition Possible Causes Correction

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid Line, Suction Line and Discharge

Line in this group. Inspect the refrigerant lines for

kinks, tight bends or improper routing. Correct

the routing or replace the refrigerant line, if

required.

2. Restricted refrigerant flow

through the A/C expansion

valve.2. See A/C Expansion Valve in this group.

Replace the valve, if required.

3. Restricted refrigerant flow

through the A/C condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

HEATER PERFORMANCE TEST

WARNING: REVIEW SAFETY PRECAUTIONS AND

WARNINGS IN THIS GROUP BEFORE PERFORMING

THIS PROCEDURE (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING).

Check the coolant level, drive belt tension, radiator

air flow and fan operation. Start engine and allow to

warm up to normal operating temperature.

WARNING: DO NOT REMOVE RADIATOR CAP

WHEN ENGINE IS HOT, PERSONAL INJURY CAN

RESULT.

If vehicle has been run recently, wait 15 minutes

before removing the radiator cap. Place a rag overthe cap and turn it to the first safety stop. Allow

pressure to escape through the overflow tube. When

the system pressure stabilizes, remove the cap com-

pletely.

MAXIMUM HEATER OUTPUT: TEST AND ACTION

Engine coolant is provided to the heater system by

two heater hoses. With the engine idling at normal

operating temperature, set the temperature control

to maximum heat, the mode control to the floor posi-

tion, and the blower in the highest speed position.

Using a test thermometer, check the temperature of

the air being discharged from the floor outlets. Com-

pare the test thermometer reading to the Tempera-

ture Reference chart.

TEMPERATURE REFERENCE

Ambient Temperature Minimum Floor Outlet Temperature

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

If the floor outlet air temperature is insufficient,

check that the cooling system is operating to specifi-

cations (Refer to 7 - COOLING/ENGINE - DIAGNO-

SIS AND TESTING). Both heater hoses should be

HOT to the touch (the coolant return hose should be

slightly cooler than the supply hose). If the coolant

return hose is much cooler than the supply hose,

locate and repair the engine coolant flow obstruction

in heater system.

OBSTRUCTED COOLANT FLOW Possible locations or causes

of obstructed coolant flow are as follows:

²Pinched or kinked heater hoses.

²Improper heater hose routing.²Plugged heater hoses or supply and return ports

at the cooling system connections.

²Plugged heater core.

If proper coolant flow through the cooling system is

verified, and heater outlet air temperature is insuffi-

cient, a mechanical problem may exist.

MECHANICAL PROBLEMS

Possible causes of insufficient heat due to mechan-

ical problems are as follows:

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend door not functioning properly.

24 - 10 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

Page 2164 of 2339

CONTROLS - FRONT

TABLE OF CONTENTS

page page

A/C COMPRESSOR CLUTCH/COIL

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING

A/C COMPRESSOR CLUTCH COIL........14

STANDARD PROCEDURE

CLUTCH INSPECTION.................15

A/C CLUTCH BREAK-IN................15

REMOVAL.............................15

INSTALLATION.........................16

A/C COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................19

INSTALLATION.........................19

A/C HEATER CONTROL

DESCRIPTION.........................19

STANDARD PROCEDURE

A/C-HEATER CONTROL CALIBRATION.....19

REMOVAL.............................20

INSTALLATION.........................20

A/C PRESSURE TRANSDUCER

DESCRIPTION.........................20

OPERATION...........................20

DIAGNOSIS AND TESTING

A/C PRESSURE TRANSDUCER..........21

REMOVAL.............................21

INSTALLATION.........................21

BLEND DOOR ACTUATOR

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

BLOWER MOTOR RELAY

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................24INSTALLATION.........................24

BLOWER MOTOR RESISTOR BLOCK

DESCRIPTION.........................24

OPERATION...........................24

DIAGNOSIS AND TESTING

FRONT BLOWER MOTOR RESISTOR

BLOCK.............................25

REMOVAL.............................25

INSTALLATION.........................25

EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................26

OPERATION...........................27

REMOVAL

RG MODELS.........................27

RS MODELS.........................27

INSTALLATION

RG MODELS.........................27

RS MODELS.........................28

INFRARED TEMPERATURE SENSOR

DESCRIPTION.........................28

OPERATION...........................28

MODE DOOR ACTUATOR

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

INSTALLATION.........................30

POWER MODULE - BLOWER MOTOR

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................30

INSTALLATION.........................31

RECIRCULATION DOOR ACTUATOR

DESCRIPTION.........................31

OPERATION...........................31

REMOVAL.............................32

INSTALLATION.........................32

A/C COMPRESSOR CLUTCH/

COIL

DESCRIPTION

The A/C compressor clutch assembly consists of a

stationary electromagnetic A/C clutch field coil with a

zener diode, a pulley bearing and pulley assembly,

and a clutch plate (Fig. 1). These components provide

the means to engage and disengage the A/C compres-

sor from the engine accessory drive belt.The A/C clutch field coil and the pulley bearing

and pulley assembly are both retained on the nose of

the A/C compressor with snap rings. The clutch plate

is splined to the compressor shaft and secured with a

bolt.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

RSCONTROLS - FRONT24-13

Page 2166 of 2339

(b) If the compressor clutch coil current reading

is four amperes or more, the coil is shorted and

must be replaced.

STANDARD PROCEDURE

CLUTCH INSPECTION

NOTE: The compressor clutch can be serviced in

the vehicle. The refrigerant system can remain fully-

charged during compressor clutch, pulley, or coil

replacement.

Examine the friction surfaces of the clutch pulley

and the clutch plate for wear. The pulley and plate

should be replaced if there is excessive wear or scor-

ing.

If the friction surfaces are oily, inspect the shaft

and nose area of the A/C compressor for refrigerant

oil. If refrigerant oil is found, the compressor shaft

seal is leaking and the A/C compressor must be

replaced.

Check the clutch pulley bearing for roughness or

excessive leakage of grease. Replace the pulley and

bearing assembly, if required.

A/C CLUTCH BREAK-IN

After a new A/C compressor clutch has been

installed, cycle the compressor clutch approximately

twenty times (five seconds on, then five seconds off).

During this procedure, set the A/C-heater controls to

the A/C Recirculation Mode, the blower motor in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces of the compressor

clutch, which provides optimum compressor clutch

torque capability.

REMOVAL

NOTE: The compressor clutch can be serviced in

the vehicle. The refrigerant system can remain fully-

charged during compressor clutch, pulley, or coil

replacement.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the engine wire harness connector

for the compressor clutch coil from the clutch coil pig-

tail wire connector on the top of the A/C compressor.

(5) On models with the 3.3L and 3.8L engines, dis-

engage the retainer on the engine wire harness com-pressor clutch coil take out from the bracket on the

top of the A/C compressor.

(6) On models with the 2.4L, 2.5L and 2.8L

engines, remove all of the compressor mounting bolts

except the upper left (rear of the A/C compressor),

which should only be loosened. Allow the front (pul-

ley end) of the A/C compressor to tilt downward far

enough to access the clutch for removal, then tighten

the loosened upper left compressor mounting bolt.

(7) On models with the 3.3L and 3.8L engines,

remove the two bolts and two nuts that secure the

A/C compressor to the engine. Disengage the mount-

ing ear at the front of the A/C compressor from the

stud on the engine, allow the front (pulley end) of the

A/C compressor to tilt downward far enough to access

the clutch for removal, then reinstall and tighten the

upper left compressor mounting bolt.

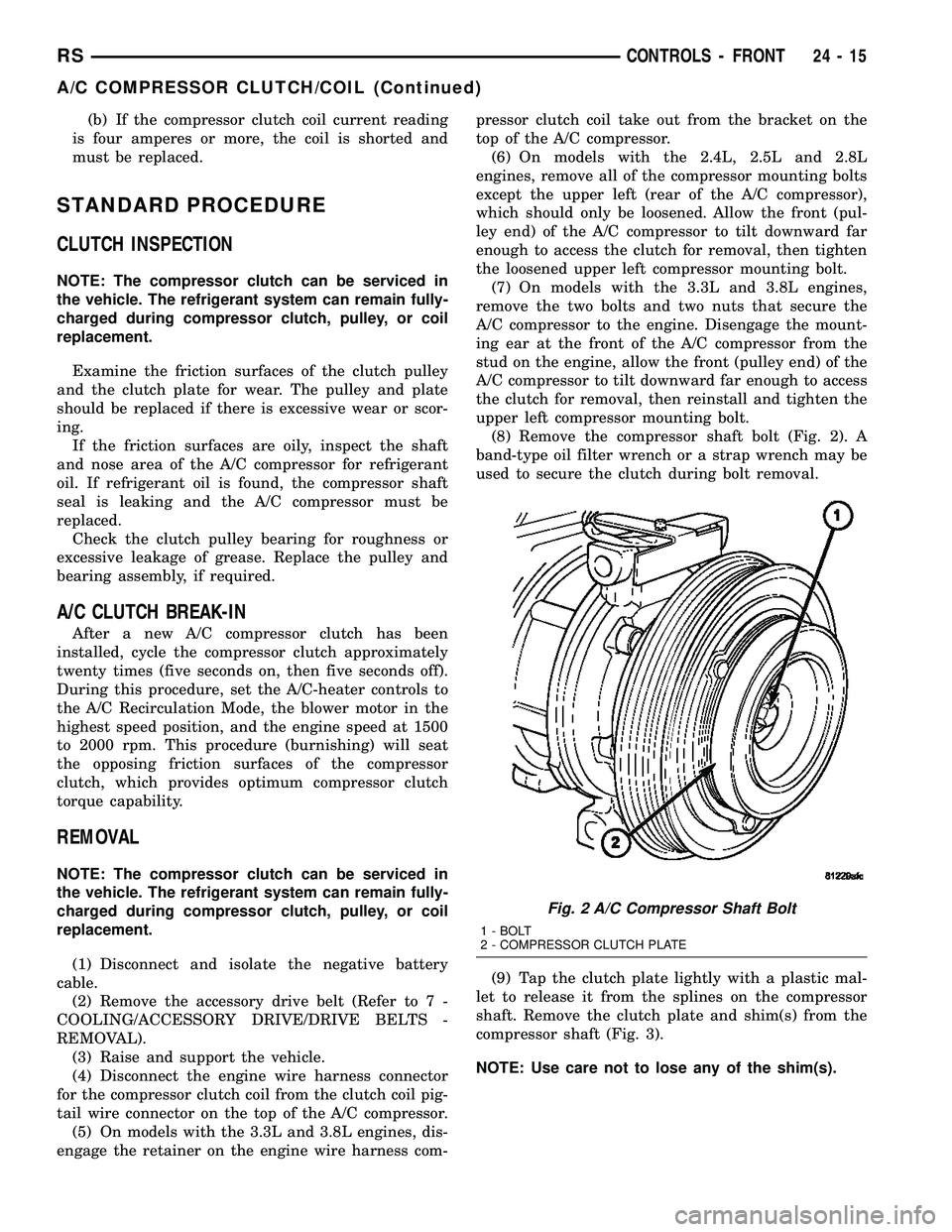

(8) Remove the compressor shaft bolt (Fig. 2). A

band-type oil filter wrench or a strap wrench may be

used to secure the clutch during bolt removal.

(9) Tap the clutch plate lightly with a plastic mal-

let to release it from the splines on the compressor

shaft. Remove the clutch plate and shim(s) from the

compressor shaft (Fig. 3).

NOTE: Use care not to lose any of the shim(s).

Fig. 2 A/C Compressor Shaft Bolt

1 - BOLT

2 - COMPRESSOR CLUTCH PLATE

RSCONTROLS - FRONT24-15

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2168 of 2339

compressor. The bevel side of the snap ring must face

outward and both snap ring eyelets must be oriented

to the right or the left of the clutch coil dowel pin

location on the A/C compressor. Be certain that the

snap ring is fully and properly seated in the groove.

CAUTION: If the snap ring is not fully seated in the

groove it will vibrate out, resulting in a clutch fail-

ure and severe damage to the compressor front

cover.

(3) Install and securely tighten the screw that

secures the clutch coil pigtail wire connector bracket

and ground clip to the top of the compressor housing.

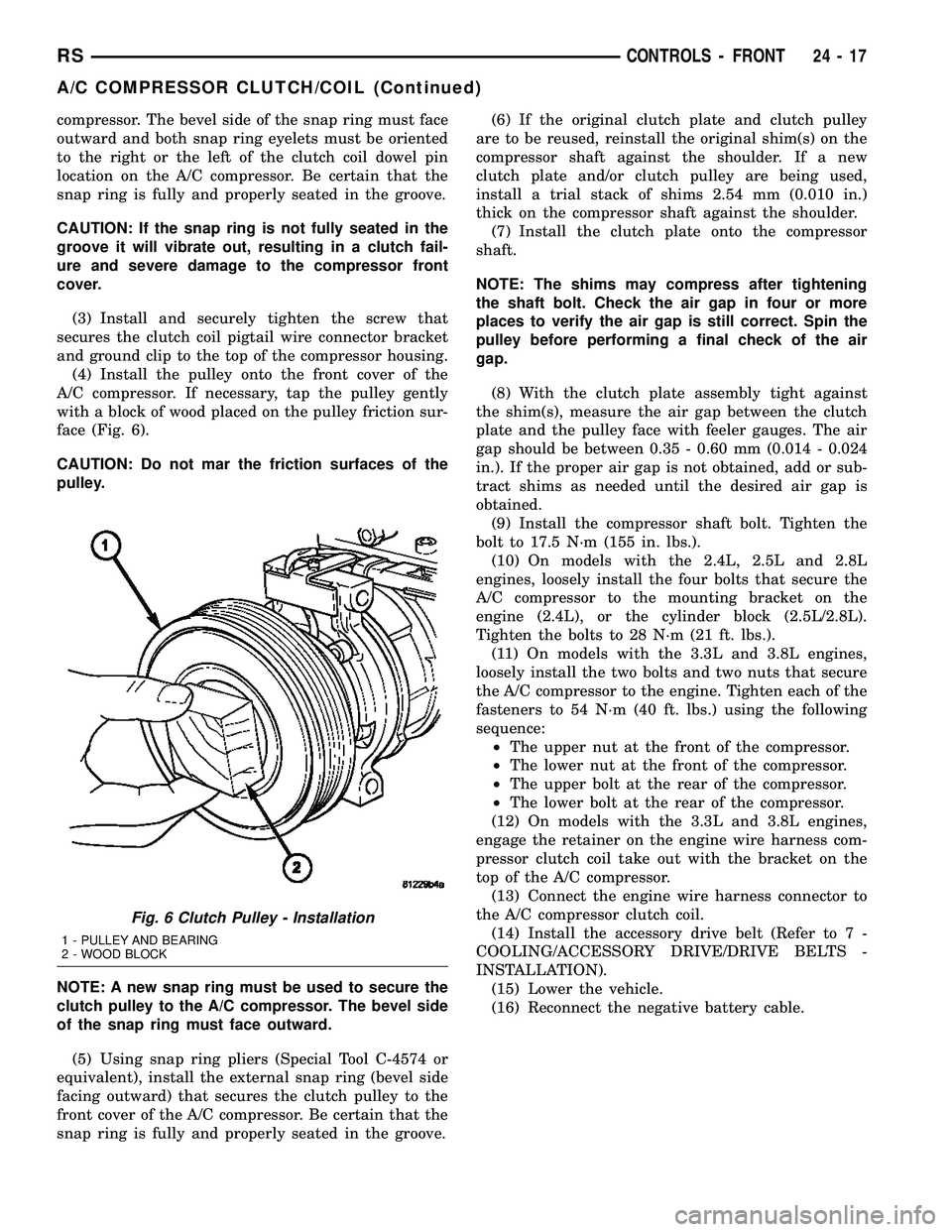

(4) Install the pulley onto the front cover of the

A/C compressor. If necessary, tap the pulley gently

with a block of wood placed on the pulley friction sur-

face (Fig. 6).

CAUTION: Do not mar the friction surfaces of the

pulley.

NOTE: A new snap ring must be used to secure the

clutch pulley to the A/C compressor. The bevel side

of the snap ring must face outward.

(5) Using snap ring pliers (Special Tool C-4574 or

equivalent), install the external snap ring (bevel side

facing outward) that secures the clutch pulley to the

front cover of the A/C compressor. Be certain that the

snap ring is fully and properly seated in the groove.(6) If the original clutch plate and clutch pulley

are to be reused, reinstall the original shim(s) on the

compressor shaft against the shoulder. If a new

clutch plate and/or clutch pulley are being used,

install a trial stack of shims 2.54 mm (0.010 in.)

thick on the compressor shaft against the shoulder.

(7) Install the clutch plate onto the compressor

shaft.

NOTE: The shims may compress after tightening

the shaft bolt. Check the air gap in four or more

places to verify the air gap is still correct. Spin the

pulley before performing a final check of the air

gap.

(8) With the clutch plate assembly tight against

the shim(s), measure the air gap between the clutch

plate and the pulley face with feeler gauges. The air

gap should be between 0.35 - 0.60 mm (0.014 - 0.024

in.). If the proper air gap is not obtained, add or sub-

tract shims as needed until the desired air gap is

obtained.

(9) Install the compressor shaft bolt. Tighten the

bolt to 17.5 N´m (155 in. lbs.).

(10) On models with the 2.4L, 2.5L and 2.8L

engines, loosely install the four bolts that secure the

A/C compressor to the mounting bracket on the

engine (2.4L), or the cylinder block (2.5L/2.8L).

Tighten the bolts to 28 N´m (21 ft. lbs.).

(11) On models with the 3.3L and 3.8L engines,

loosely install the two bolts and two nuts that secure

the A/C compressor to the engine. Tighten each of the

fasteners to 54 N´m (40 ft. lbs.) using the following

sequence:

²The upper nut at the front of the compressor.

²The lower nut at the front of the compressor.

²The upper bolt at the rear of the compressor.

²The lower bolt at the rear of the compressor.

(12) On models with the 3.3L and 3.8L engines,

engage the retainer on the engine wire harness com-

pressor clutch coil take out with the bracket on the

top of the A/C compressor.

(13) Connect the engine wire harness connector to

the A/C compressor clutch coil.

(14) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(15) Lower the vehicle.

(16) Reconnect the negative battery cable.

Fig. 6 Clutch Pulley - Installation

1 - PULLEY AND BEARING

2 - WOOD BLOCK

RSCONTROLS - FRONT24-17

A/C COMPRESSOR CLUTCH/COIL (Continued)