power modul CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1726 of 2339

OPERATION

The Brake/Transmission Shift Interlock (BTSI)

Solenoid prevents the transmission shift lever from

being moved out of PARK (P) unless the brake pedal

is applied. The BTSI solenoid is hardwired to and

controlled by the Intelligent Power Module (IPM).

Battery voltage is applied to one side of the solenoid

with the ignition key is in either the OFF, ON/RUN,

or START positions (Fig. 293). The ground side of the

solenoid is controlled by a driver within the IPM. It

relies on voltage supplied from the stop lamp switch

to the stop lamp sense circuit within the IPM to tell

when the brake pedal is depressed. When the brake

pedal is depressed, the ground circuit opens, de-ener-

gizing the solenoid. When the brake pedal is

released, the ground circuit is closed, energizing the

solenoid.

When the ignition key is in either the OFF,

ON/RUN, or START positions, the BTSI solenoid is

energized, and the solenoid plunger hook pulls the

shift lever pawl into position, prohibiting the shift

lever from moving out of PARK (P) (Fig. 294). When

the brake pedal is depressed, the ground circuit

opens, de-energizing the solenoid. This moves the

gearshift lever pawl out of the way (Fig. 295), allow-

ing the shift lever to be moved into any gear position.

Fig. 293 Ignition Key/Switch Positions

1 - ACC

2 - LOCK

3 - OFF

4 - ON/RUN

5-START

Fig. 294 Pawl Engaged to Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

Fig. 295 Pawl Disengaged From Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

RS41TE AUTOMATIC TRANSAXLE21 - 265

SHIFT INTERLOCK SOLENOID (Continued)

Page 1732 of 2339

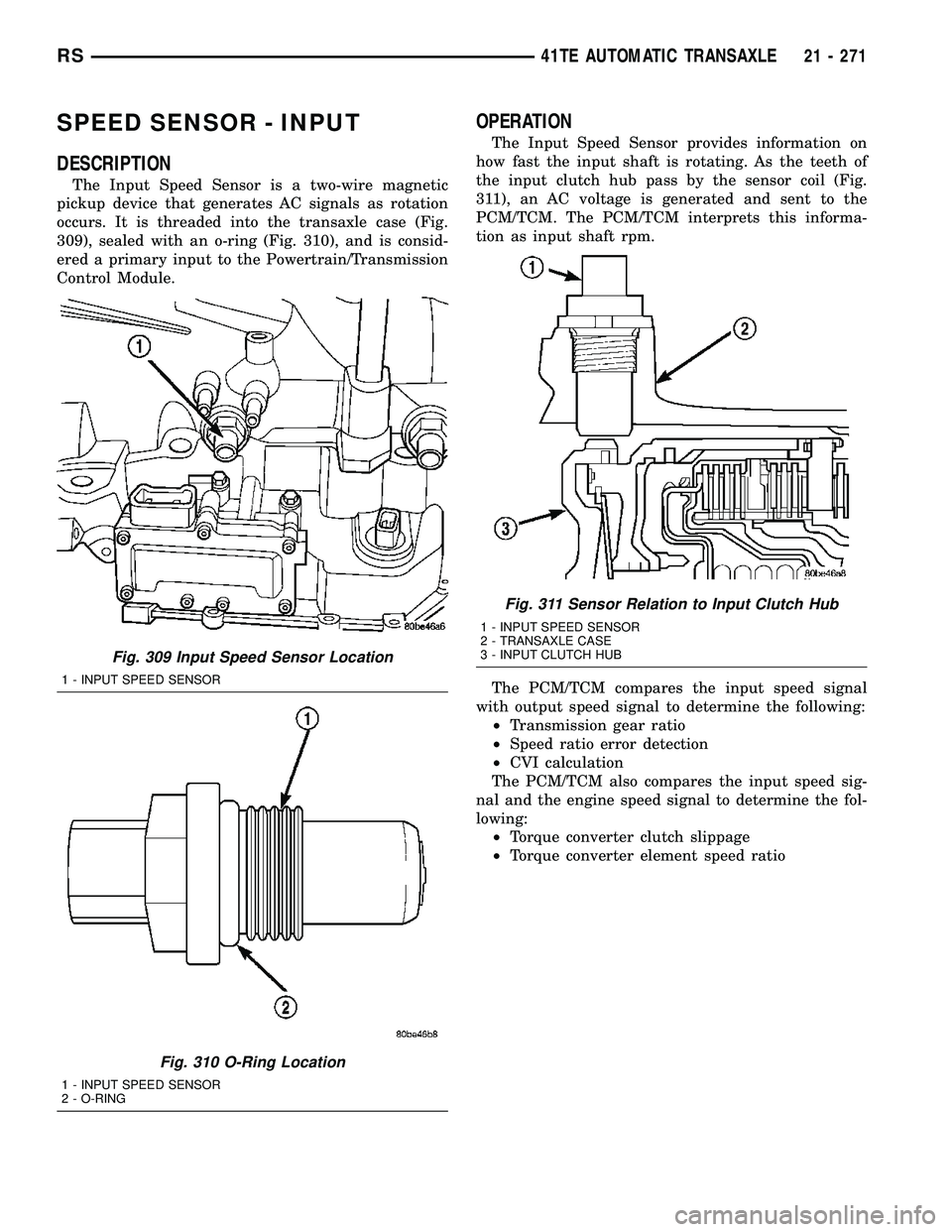

SPEED SENSOR - INPUT

DESCRIPTION

The Input Speed Sensor is a two-wire magnetic

pickup device that generates AC signals as rotation

occurs. It is threaded into the transaxle case (Fig.

309), sealed with an o-ring (Fig. 310), and is consid-

ered a primary input to the Powertrain/Transmission

Control Module.

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil (Fig.

311), an AC voltage is generated and sent to the

PCM/TCM. The PCM/TCM interprets this informa-

tion as input shaft rpm.

The PCM/TCM compares the input speed signal

with output speed signal to determine the following:

²Transmission gear ratio

²Speed ratio error detection

²CVI calculation

The PCM/TCM also compares the input speed sig-

nal and the engine speed signal to determine the fol-

lowing:

²Torque converter clutch slippage

²Torque converter element speed ratio

Fig. 309 Input Speed Sensor Location

1 - INPUT SPEED SENSOR

Fig. 310 O-Ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

Fig. 311 Sensor Relation to Input Clutch Hub

1 - INPUT SPEED SENSOR

2 - TRANSAXLE CASE

3 - INPUT CLUTCH HUB

RS41TE AUTOMATIC TRANSAXLE21 - 271

Page 1741 of 2339

ment can be obtained. The result of this engagement

is a direct 1:1 mechanical link between the engine

and the transmission.

The engagement and disengagement of the TCC

are automatic and controlled by the Powertrain Con-

trol Module (PCM). The engagement cannot be acti-

vated in the lower gears because it eliminates the

torque multiplication effect of the torque converter

necessary for acceleration. Inputs that determine

clutch engagement are: coolant temperature, vehicle

speed and throttle position. The torque converter

clutch is engaged by the clutch solenoid on the valve

body. The clutch will engage at approximately 56

km/h (35 mph) with light throttle, after the shift to

third gear.

REMOVAL

(1) Remove transmission and torque converter

from vehicle. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE - REMOVAL)

(2) Place a suitable drain pan under the converter

housing end of the transmission.

CAUTION: Verify that transmission is secure on the

lifting device or work surface, the center of gravity

of the transmission will shift when the torque con-

verter is removed creating an unstable condition.

The torque converter is a heavy unit. Use caution

when separating the torque converter from the

transmission.

(3) Pull the torque converter forward until the cen-

ter hub clears the oil pump seal.

(4) Separate the torque converter from the trans-

mission.

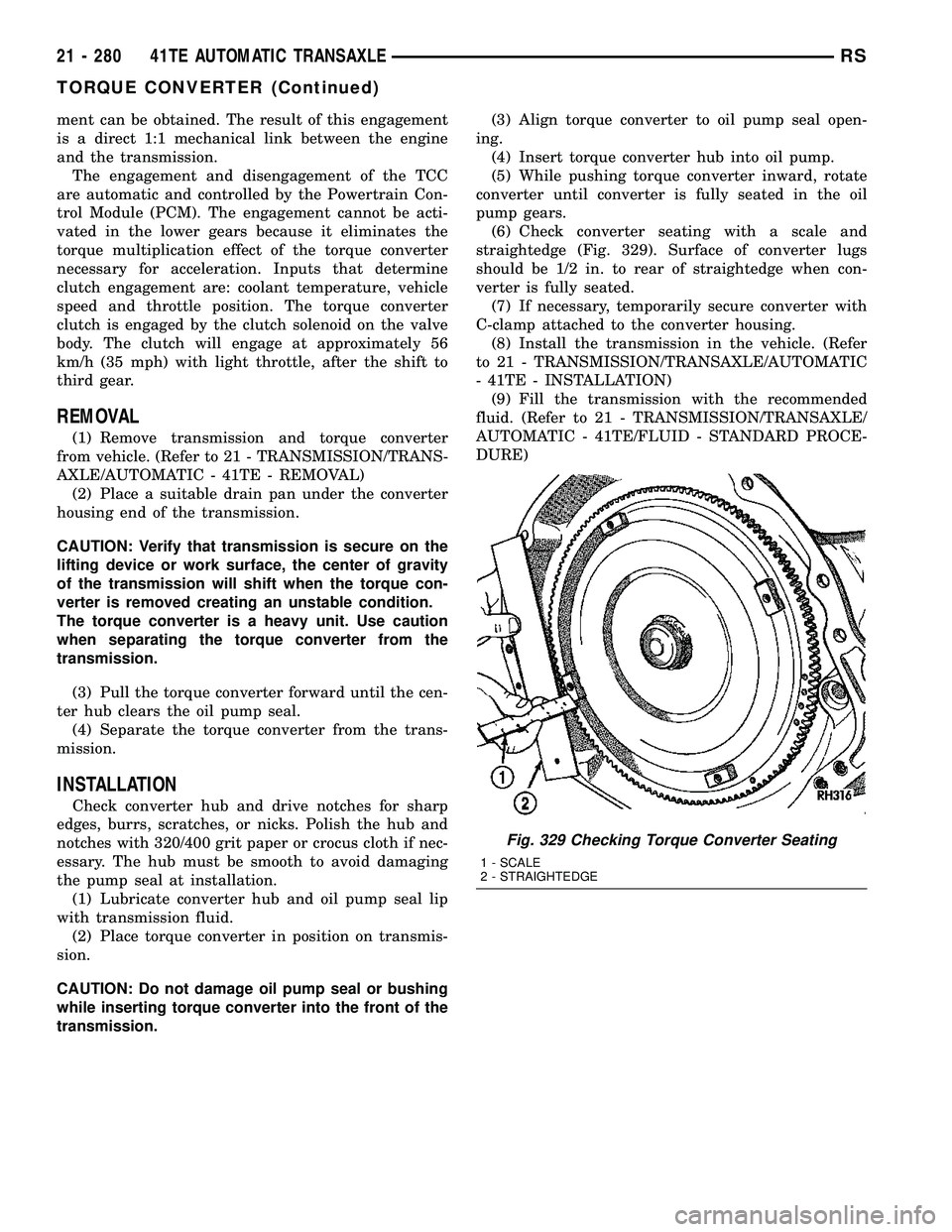

INSTALLATION

Check converter hub and drive notches for sharp

edges, burrs, scratches, or nicks. Polish the hub and

notches with 320/400 grit paper or crocus cloth if nec-

essary. The hub must be smooth to avoid damaging

the pump seal at installation.

(1) Lubricate converter hub and oil pump seal lip

with transmission fluid.

(2) Place torque converter in position on transmis-

sion.

CAUTION: Do not damage oil pump seal or bushing

while inserting torque converter into the front of the

transmission.(3) Align torque converter to oil pump seal open-

ing.

(4) Insert torque converter hub into oil pump.

(5) While pushing torque converter inward, rotate

converter until converter is fully seated in the oil

pump gears.

(6) Check converter seating with a scale and

straightedge (Fig. 329). Surface of converter lugs

should be 1/2 in. to rear of straightedge when con-

verter is fully seated.

(7) If necessary, temporarily secure converter with

C-clamp attached to the converter housing.

(8) Install the transmission in the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE - INSTALLATION)

(9) Fill the transmission with the recommended

fluid. (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 41TE/FLUID - STANDARD PROCE-

DURE)

Fig. 329 Checking Torque Converter Seating

1 - SCALE

2 - STRAIGHTEDGE

21 - 280 41TE AUTOMATIC TRANSAXLERS

TORQUE CONVERTER (Continued)

Page 1742 of 2339

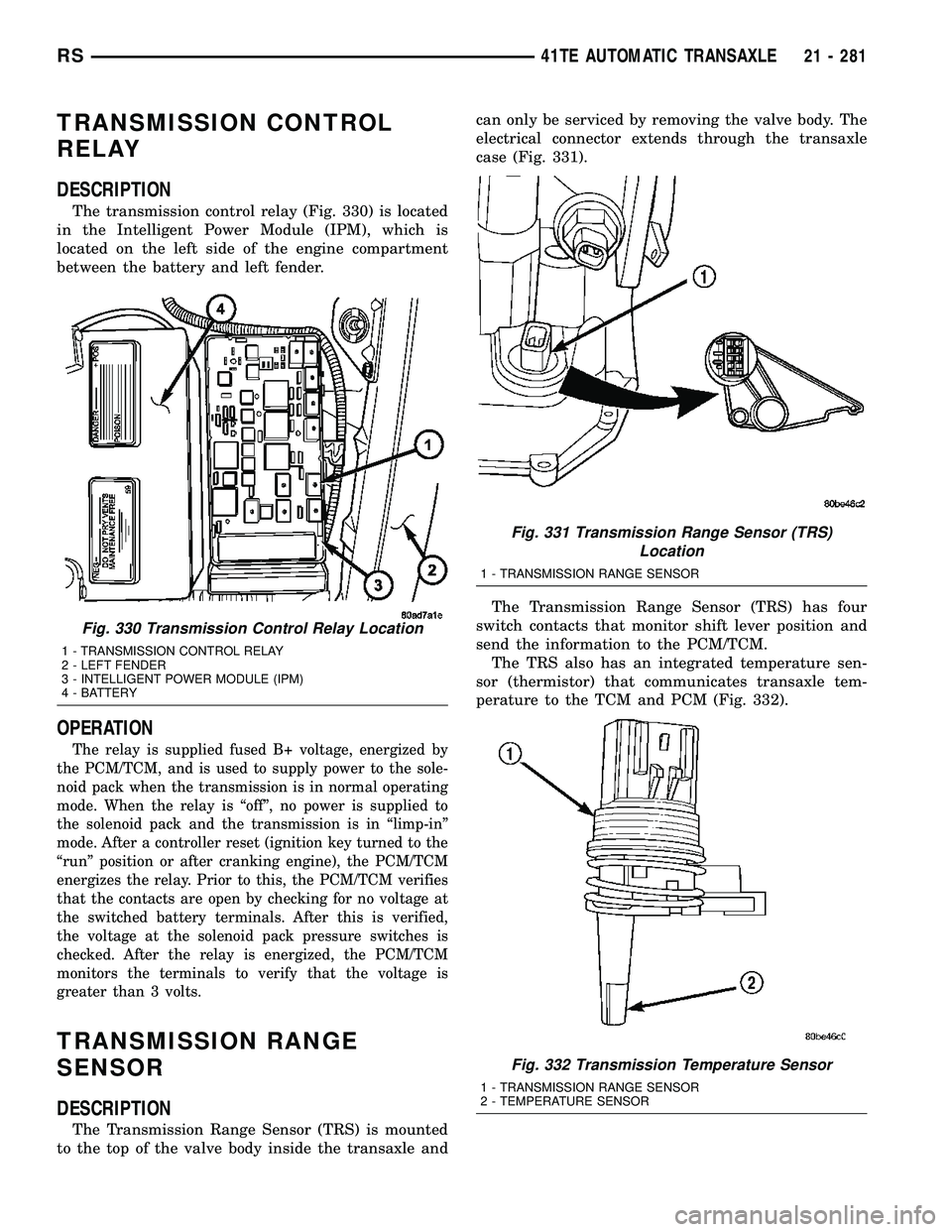

TRANSMISSION CONTROL

RELAY

DESCRIPTION

The transmission control relay (Fig. 330) is located

in the Intelligent Power Module (IPM), which is

located on the left side of the engine compartment

between the battery and left fender.

OPERATION

The relay is supplied fused B+ voltage, energized by

the PCM/TCM, and is used to supply power to the sole-

noid pack when the transmission is in normal operating

mode. When the relay is ªoffº, no power is supplied to

the solenoid pack and the transmission is in ªlimp-inº

mode. After a controller reset (ignition key turned to the

ªrunº position or after cranking engine), the PCM/TCM

energizes the relay. Prior to this, the PCM/TCM verifies

that the contacts are open by checking for no voltage at

the switched battery terminals. After this is verified,

the voltage at the solenoid pack pressure switches is

checked. After the relay is energized, the PCM/TCM

monitors the terminals to verify that the voltage is

greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle andcan only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 331).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 332).

Fig. 330 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 331 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 332 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

RS41TE AUTOMATIC TRANSAXLE21 - 281

Page 1846 of 2339

INSTRUMENT PANEL

ASSEMBLY

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

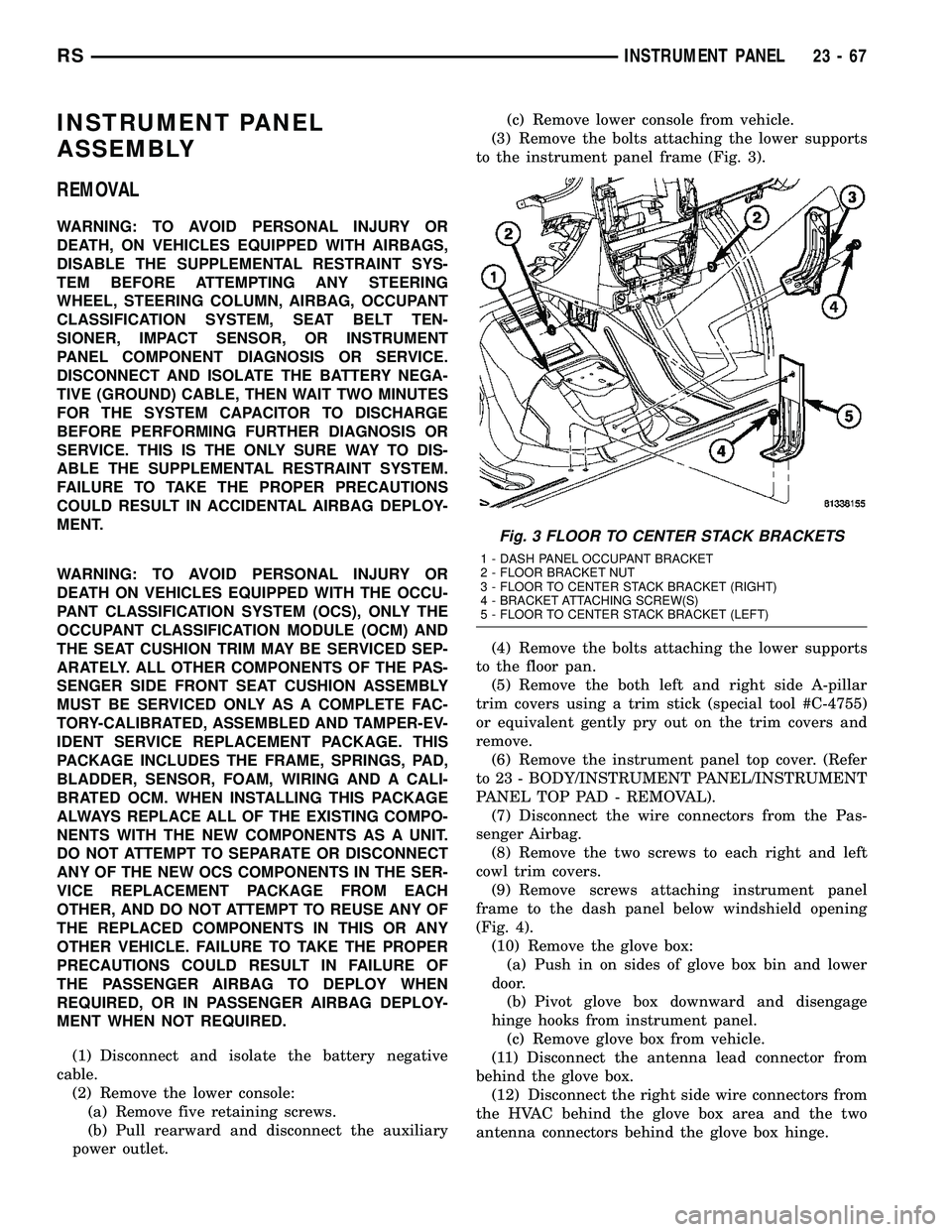

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the lower console:

(a) Remove five retaining screws.

(b) Pull rearward and disconnect the auxiliary

power outlet.(c) Remove lower console from vehicle.

(3) Remove the bolts attaching the lower supports

to the instrument panel frame (Fig. 3).

(4) Remove the bolts attaching the lower supports

to the floor pan.

(5) Remove the both left and right side A-pillar

trim covers using a trim stick (special tool #C-4755)

or equivalent gently pry out on the trim covers and

remove.

(6) Remove the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP PAD - REMOVAL).

(7) Disconnect the wire connectors from the Pas-

senger Airbag.

(8) Remove the two screws to each right and left

cowl trim covers.

(9) Remove screws attaching instrument panel

frame to the dash panel below windshield opening

(Fig. 4).

(10) Remove the glove box:

(a) Push in on sides of glove box bin and lower

door.

(b) Pivot glove box downward and disengage

hinge hooks from instrument panel.

(c) Remove glove box from vehicle.

(11) Disconnect the antenna lead connector from

behind the glove box.

(12) Disconnect the right side wire connectors from

the HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

Fig. 3 FLOOR TO CENTER STACK BRACKETS

1 - DASH PANEL OCCUPANT BRACKET

2 - FLOOR BRACKET NUT

3 - FLOOR TO CENTER STACK BRACKET (RIGHT)

4 - BRACKET ATTACHING SCREW(S)

5 - FLOOR TO CENTER STACK BRACKET (LEFT)

RSINSTRUMENT PANEL23-67

Page 1849 of 2339

(29) Remove both the left and right power mirrors:

(a) Using a trim stick or equivalent, gently pry

out on mirror trim cover.

(b) Open door and remove the three torx retain-

ing screws.

(c) Disconnect the wire connector and remove

mirror from the vehicle.

(30) Feed power mirror wire harness inboard

through the A-pillar.

(31) Loosen the left side roll down bolt (Fig. 8).

(32) Remove the left side A-pillar retaining bolts.

There are two 13 mm bolts and one 10 mm bolt (Fig.

8).

(33) With the help of an assistant remove the

instrument panel from vehicle. Lift the instrument

panel up off the HVAC so you won't damage the seal-

ing surface of the distribution duct.

(34) If the instrument panel is being replaced,

transfer all parts to the new instrument panel

assembly.

INSTALLATION

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTESFOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) With the help of an assistant place the instru-

ment panel into vehicle on roll down bolts. As you

roll the instrument panel up, lift the instrument

panel up so the duct work does not bind or bend and

you can set it down on the HVAC housing to get the

proper seal at the distribution duct. Get one bolt

started in the dash panel.

(2) Start the locator screw and install the right

side A-pillar retaining bolts (Fig. 5). There are two 13

mm bolts and one 10 mm bolt.

(3) Install the left side A-pillar retaining bolts.

There are two 13 mm bolts and one 10 mm bolt (Fig.

8).

(4) Tighten the right and left side cowl side roll

down bolt.

(5) Feed power mirror wire harness outboard

through the A-pillar.

(6) Install both the left and right power mirrors:

(a) Connect the wire connector and install the

mirror onto the vehicle.

(b) Install the three torx retaining screws.

(c) Using a firm push, snap the mirror trim

cover into place.

Fig. 9 INSTRUMENT PANEL LOWER

REINFORCEMENT

1 - LOWER RIGHT REINFORCEMENT

2 - STEERING WHEEL ASSEMBLY

23 - 70 INSTRUMENT PANELRS

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 1881 of 2339

SEATS

TABLE OF CONTENTS

page page

CHILD SEAT MODULE, BENCH SEAT

REMOVAL............................104

INSTALLATION

INSTALLATION......................105

SYNCHRONIZING CABLE ADJUSTMENT . . 105

QUAD CHILD SEAT

REMOVAL............................106

INSTALLATION........................106

HEADREST

REMOVAL............................106

INSTALLATION........................106

HEADREST SLEEVE

REMOVAL............................107

INSTALLATION........................107

RECLINER HANDLE

REMOVAL............................108

INSTALLATION........................108

ARMREST

REMOVAL............................108

INSTALLATION........................108

FRONT SEAT

REMOVAL............................108

INSTALLATION........................110

FRONT SEAT BACK

REMOVAL............................111

INSTALLATION........................111

FRONT SEAT BACK ASSIST STRAP

REMOVAL............................112

INSTALLATION........................112

FRONT SEAT BACK PANEL

REMOVAL............................112

INSTALLATION........................113

FRONT SEAT BACK COVER

REMOVAL............................113

INSTALLATION........................116

FRONT SEAT CUSHION

REMOVAL............................117

INSTALLATION........................118

FRONT SEAT CUSHION - OCS

REMOVAL............................119

INSTALLATION........................120

FRONT SEAT CUSHION SIDE COVER

REMOVAL............................120

INSTALLATION........................121

FRONT SEAT CUSHION SIDE COVER - OCS

REMOVAL............................121

INSTALLATION........................122

FRONT SEAT RISER - MANUAL - OCS

REMOVAL............................123INSTALLATION........................123

FRONT SEAT TRACK POWER ADJUSTER

REMOVAL............................124

INSTALLATION........................124

FRONT SEAT TRACK ADJUSTER/POWER -

OCS

REMOVAL............................124

INSTALLATION........................125

FRONT SEAT TRACK MANUAL ADJUSTER

REMOVAL............................125

INSTALLATION........................126

FRONT SEAT TRACK ADJUSTER/MANUAL -

OCS

REMOVAL............................126

INSTALLATION........................128

FRONT SEAT TRACK - REAR COVER

REMOVAL............................128

INSTALLATION........................128

FRONT SEAT TRACK REAR COVER - OCS

REMOVAL............................129

INSTALLATION........................129

ARMREST - SECOND ROW - FOLD-IN-FLOOR

REMOVAL............................130

INSTALLATION........................130

ARMREST ROTATING ASSEMBLY - SECOND

ROW - FOLD-IN-FLOOR

REMOVAL............................130

INSTALLATION........................130

HEADREST SLEEVE - SECOND ROW -

FOLD-IN-FLOOR

REMOVAL............................131

INSTALLATION........................131

SEAT - SECOND ROW - FOLD-IN-FLOOR

REMOVAL............................132

INSTALLATION........................132

SEAT BACK COVER/FOAM - SECOND ROW -

FOLD-IN-FLOOR

REMOVAL............................133

INSTALLATION........................133

SEAT BACK FRAME - SECOND ROW -

FOLD-IN-FLOOR

REMOVAL............................134

INSTALLATION........................134

SEAT BACK PANEL - SECOND ROW -FOLD-IN-

FLOOR

REMOVAL............................134

INSTALLATION........................134

23 - 102 SEATSRS

Page 1900 of 2339

(5) If equipped, disconnect wire connector from

power seat switch (Fig. 33).

INSTALLATION

(1) Place side cover in position on seat cushion.

(2) If equipped, connect wire connector into power

seat switch (Fig. 33).

(3) Install screw attaching rear of side cover to

seat cushion frame. Tighten screw to 1 N´m (9 in.

lbs.) torque.

(4) Engage J-strap along rear of seat cushion to

access screw.

(5) Install screws attaching seat cushion side cover

to bucket seat (Fig. 32).

FRONT SEAT CUSHION SIDE

COVER - OCS

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Remove screws and plastic push pin attaching

seat cushion side cover to bucket seat (Fig. 34).

(2) Disengage J-strap along rear of seat cushion to

access screw.

(3) Remove screw attaching rear of side cover to

seat cushion frame.

Fig. 32 FRONT SEAT SIDE SHIELD

1 - SCREWS

2 - SIDE SHIELD

3 - SEAT CUSHION

Fig. 33 POWER SEAT SWITCH WIRE CONNECTOR

1 - SEAT CUSHION SIDE COVER

2 - POWER SEAT SWITCH

3 - WIRE CONNECTOR

RSSEATS23 - 121

FRONT SEAT CUSHION SIDE COVER (Continued)

Page 1901 of 2339

(4) Remove side cover from seat cushion.

(5) If equipped, disconnect wire connector from

power seat switch (Fig. 35).INSTALLATION

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Place side cover in position on seat cushion.

(2) If equipped, connect wire connector into power

seat switch.

(3) Install screw attaching rear of side cover to

seat cushion frame. Tighten screw to 1 N´m (9 in.

lbs.) torque.

(4) Engage J-strap along rear of seat cushion to

access screw.

(5) Install screws attaching seat cushion side cover

to bucket seat (Fig. 34).

Fig. 34 FRONT SEAT SIDE SHIELD

1 - SCREWS

2 - SIDE SHIELD

3 - SEAT CUSHION

Fig. 35 POWER SEAT SWITCH WIRE CONNECTOR

1 - SEAT CUSHION SIDE COVER

2 - POWER SEAT SWITCH

3 - WIRE CONNECTOR

23 - 122 SEATSRS

FRONT SEAT CUSHION SIDE COVER - OCS (Continued)

Page 1903 of 2339

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Place riser in position on seat.

(2) Install nuts attaching riser to manual seat

track (Fig. 36). Tighten fasteners to 88 N´m (65 ft.

lbs.) torque.

(3) If equipped, install storage bin into riser. (Refer

to 23 - BODY/SEATS/UNDER SEAT STORAGE BIN

- INSTALLATION)

(4) Install seat into vehicle. Tighten fasteners to

88 N´m (65 ft. lbs.) torque. (Refer to 23 - BODY/

SEATS/FRONT SEAT - INSTALLATION)

FRONT SEAT TRACK POWER

ADJUSTER

REMOVAL

The power seat track and motors are serviced as

an assembly.

(1) Remove seat from vehicle. (Refer to 23 - BODY/

SEATS/FRONT SEAT - REMOVAL)

(2) Remove seat cushion. (Refer to 23 - BODY/

SEATS/FRONT/QUAD SEAT CUSHION -

REMOVAL)(3) Remove nut attaching recliner to seat back

frame.

(4) Remove bolts attaching seat back frame to seat

track.

(5) Remove stud on seat back frame from recliner.

(6) Remove seat back.

(7) If power seat track is being replaced, transfer

power recliner, wire harness and trim covers to

replacement seat track.

INSTALLATION

The power seat track and motors are serviced as

an assembly.

(1) Install wire harness.

(2) Place seat back in position.

(3) Insert stud on seat back frame into recliner.

(4) Install bolts to hold seat back frame to seat

track.

(5) Install nut attaching recliner to seat back

frame.

(6) Install seat cushion. (Refer to 23 - BODY/

SEATS/FRONT/QUAD SEAT CUSHION - INSTAL-

LATION)

(7) Install seat in vehicle. Tighten fasteners to 60

N´m (44 ft. lbs.) torque. (Refer to 23 - BODY/SEATS/

FRONT SEAT - INSTALLATION)

FRONT SEAT TRACK

ADJUSTER/POWER - OCS

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

23 - 124 SEATSRS

FRONT SEAT RISER - MANUAL - OCS (Continued)