engine oil CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2231 of 2339

INSTALLATION

(1) Position the A/C discharge line into the engine

compartment.

(2) Remove the tape or plugs from the compressor

discharge port and the discharge line fitting.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it and a new gasket onto

the discharge line fitting.

(4) Install the A/C discharge line to the A/C com-

pressor.(5) Install the nut that secures the A/C discharge

line to the A/C compressor. Tighten the nut to 23

N´m (17 ft. lbs.).

(6) Remove the tape or plugs from the condenser

inlet port and the discharge line fitting.

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it and a new gasket onto

the discharge line fitting.

(8) Install the A/C discharge line to the A/C con-

denser.

(9) Install the nut that secures the A/C discharge

line to the A/C condenser. Tighten the nut to 23 N´m

(17 ft. lbs.).

(10) Position the radiator sight shield onto the

radiator closure panel crossmember.

(11) Install the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

Tighten the screws to 2 N´m (17 in. lbs.).

(12) Install the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber. Tighten the screws to 6 N´m (53 in. lbs.).

(13) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(14) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

A/C EVAPORATOR

DESCRIPTION

The A/C evaporator is located in the HVAC hous-

ing, behind the instrument panel. The evaporator is

positioned in the housing so that all air that enters

the housing must pass over the fins of the evaporator

coils before it is distributed through the system ducts

and outlets. However, air passing over the evaporator

fins will only be conditioned when the compressor is

engaged and circulating refrigerant through the

evaporator tubes.

OPERATION

Refrigerant enters the A/C evaporator from the

expansion valve as a low-temperature, low-pressure

liquid. As air flows over the fins of the evaporator,

the humidity in the air condenses on the fins, and

the heat from the air is absorbed by the refrigerant.

Heat absorption causes the refrigerant to boil and

vaporize. The refrigerant becomes a low-pressure gas

when it leaves the evaporator.

The A/C evaporator cannot be repaired and, if

faulty or damaged, it must be replaced.

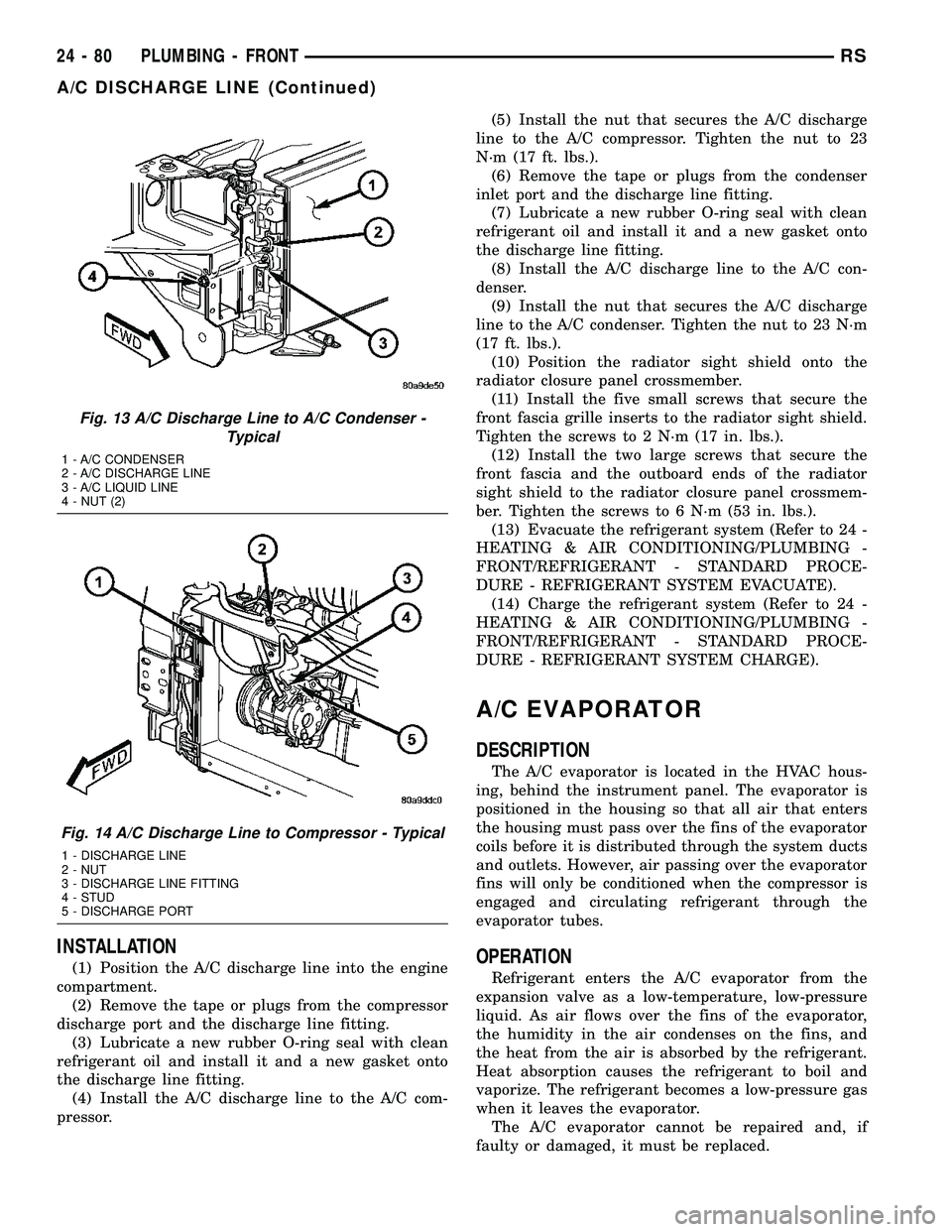

Fig. 13 A/C Discharge Line to A/C Condenser -

Typical

1 - A/C CONDENSER

2 - A/C DISCHARGE LINE

3 - A/C LIQUID LINE

4 - NUT (2)

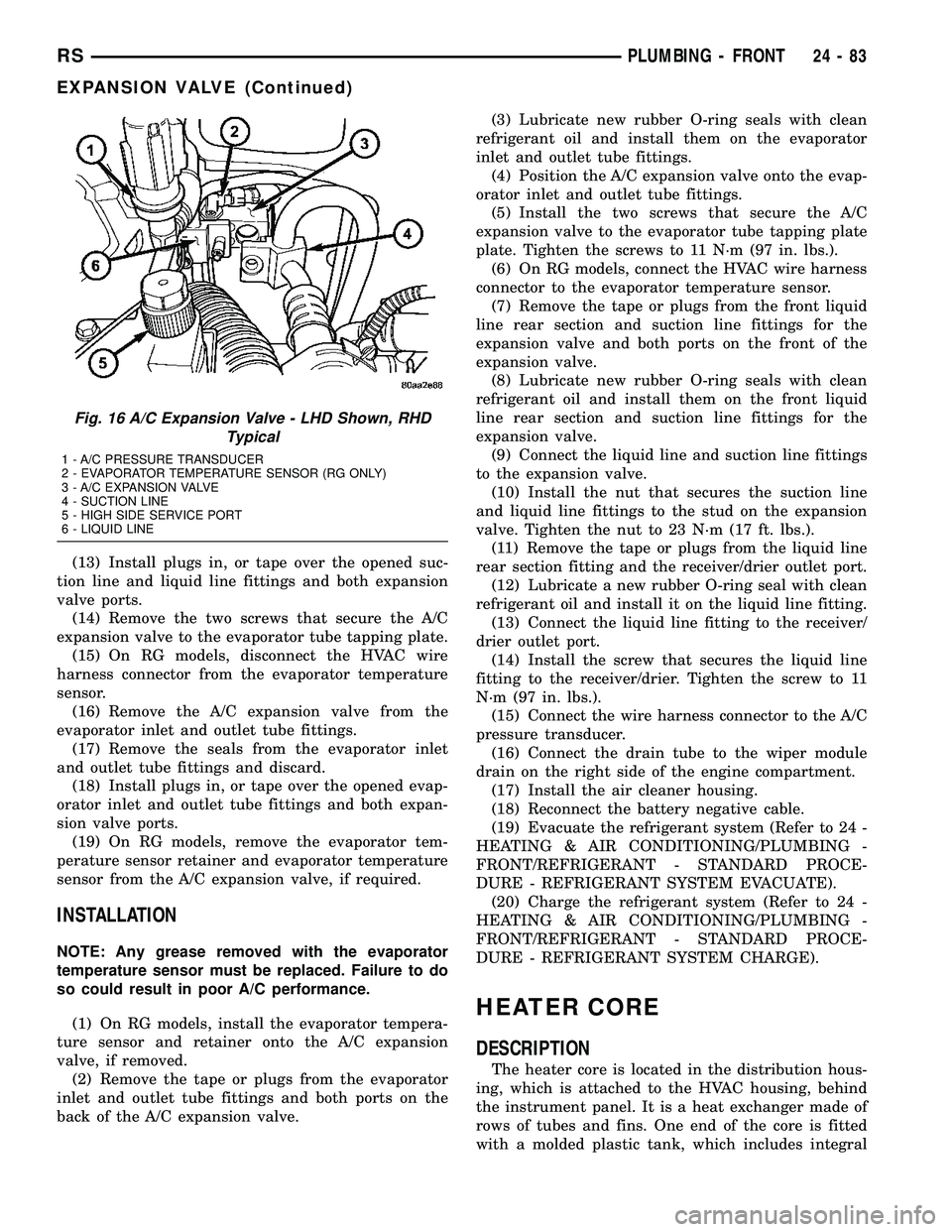

Fig. 14 A/C Discharge Line to Compressor - Typical

1 - DISCHARGE LINE

2 - NUT

3 - DISCHARGE LINE FITTING

4 - STUD

5 - DISCHARGE PORT

24 - 80 PLUMBING - FRONTRS

A/C DISCHARGE LINE (Continued)

Page 2234 of 2339

(13) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(14) Remove the two screws that secure the A/C

expansion valve to the evaporator tube tapping plate.

(15) On RG models, disconnect the HVAC wire

harness connector from the evaporator temperature

sensor.

(16) Remove the A/C expansion valve from the

evaporator inlet and outlet tube fittings.

(17) Remove the seals from the evaporator inlet

and outlet tube fittings and discard.

(18) Install plugs in, or tape over the opened evap-

orator inlet and outlet tube fittings and both expan-

sion valve ports.

(19) On RG models, remove the evaporator tem-

perature sensor retainer and evaporator temperature

sensor from the A/C expansion valve, if required.

INSTALLATION

NOTE: Any grease removed with the evaporator

temperature sensor must be replaced. Failure to do

so could result in poor A/C performance.

(1) On RG models, install the evaporator tempera-

ture sensor and retainer onto the A/C expansion

valve, if removed.

(2) Remove the tape or plugs from the evaporator

inlet and outlet tube fittings and both ports on the

back of the A/C expansion valve.(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the evaporator

inlet and outlet tube fittings.

(4) Position the A/C expansion valve onto the evap-

orator inlet and outlet tube fittings.

(5) Install the two screws that secure the A/C

expansion valve to the evaporator tube tapping plate

plate. Tighten the screws to 11 N´m (97 in. lbs.).

(6) On RG models, connect the HVAC wire harness

connector to the evaporator temperature sensor.

(7) Remove the tape or plugs from the front liquid

line rear section and suction line fittings for the

expansion valve and both ports on the front of the

expansion valve.

(8) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the front liquid

line rear section and suction line fittings for the

expansion valve.

(9) Connect the liquid line and suction line fittings

to the expansion valve.

(10) Install the nut that secures the suction line

and liquid line fittings to the stud on the expansion

valve. Tighten the nut to 23 N´m (17 ft. lbs.).

(11) Remove the tape or plugs from the liquid line

rear section fitting and the receiver/drier outlet port.

(12) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(13) Connect the liquid line fitting to the receiver/

drier outlet port.

(14) Install the screw that secures the liquid line

fitting to the receiver/drier. Tighten the screw to 11

N´m (97 in. lbs.).

(15) Connect the wire harness connector to the A/C

pressure transducer.

(16) Connect the drain tube to the wiper module

drain on the right side of the engine compartment.

(17) Install the air cleaner housing.

(18) Reconnect the battery negative cable.

(19) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(20) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

HEATER CORE

DESCRIPTION

The heater core is located in the distribution hous-

ing, which is attached to the HVAC housing, behind

the instrument panel. It is a heat exchanger made of

rows of tubes and fins. One end of the core is fitted

with a molded plastic tank, which includes integral

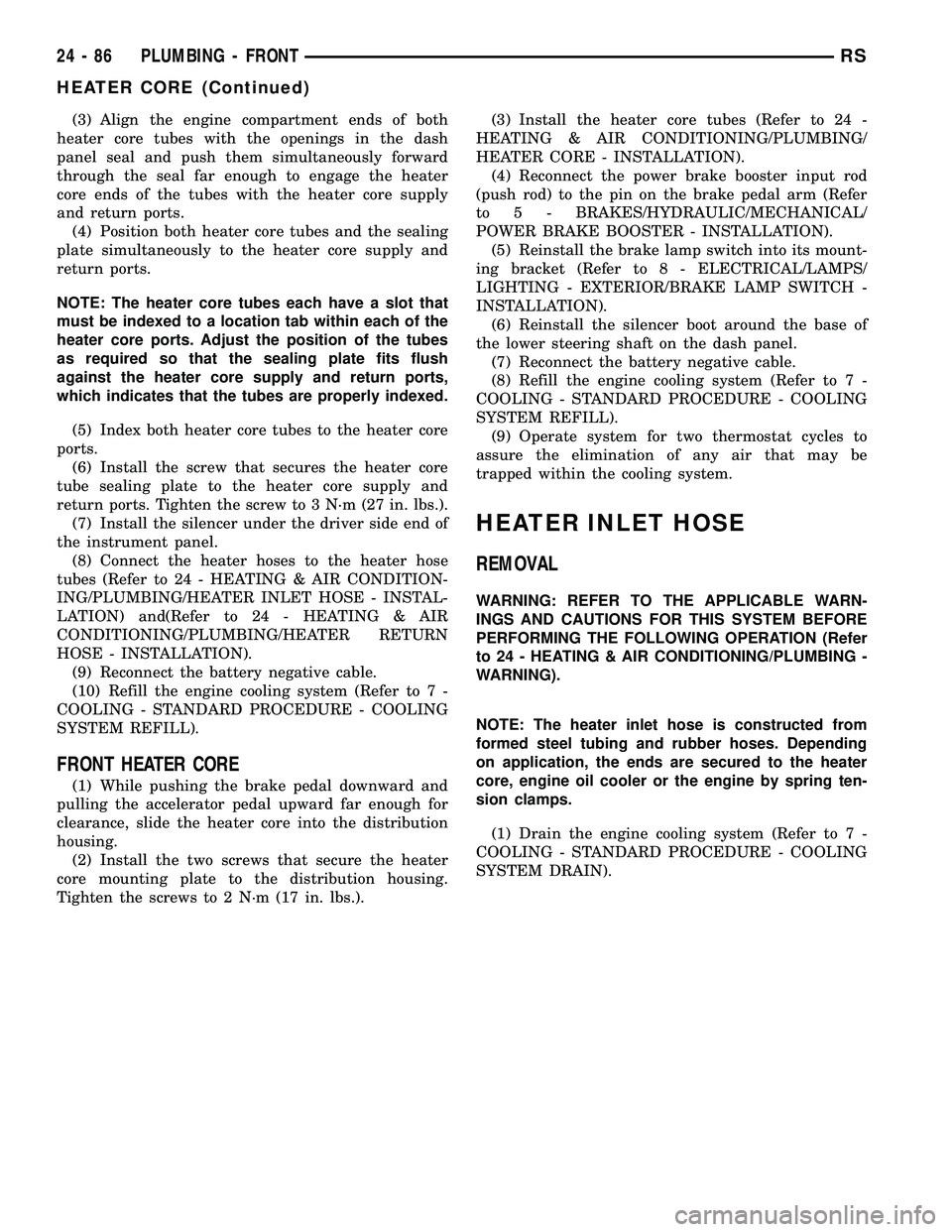

Fig. 16 A/C Expansion Valve - LHD Shown, RHD

Typical

1 - A/C PRESSURE TRANSDUCER

2 - EVAPORATOR TEMPERATURE SENSOR (RG ONLY)

3 - A/C EXPANSION VALVE

4 - SUCTION LINE

5 - HIGH SIDE SERVICE PORT

6 - LIQUID LINE

RSPLUMBING - FRONT24-83

EXPANSION VALVE (Continued)

Page 2237 of 2339

(3) Align the engine compartment ends of both

heater core tubes with the openings in the dash

panel seal and push them simultaneously forward

through the seal far enough to engage the heater

core ends of the tubes with the heater core supply

and return ports.

(4) Position both heater core tubes and the sealing

plate simultaneously to the heater core supply and

return ports.

NOTE: The heater core tubes each have a slot that

must be indexed to a location tab within each of the

heater core ports. Adjust the position of the tubes

as required so that the sealing plate fits flush

against the heater core supply and return ports,

which indicates that the tubes are properly indexed.

(5) Index both heater core tubes to the heater core

ports.

(6) Install the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports. Tighten the screw to 3 N´m (27 in. lbs.).

(7) Install the silencer under the driver side end of

the instrument panel.

(8) Connect the heater hoses to the heater hose

tubes (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/HEATER INLET HOSE - INSTAL-

LATION) and(Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/HEATER RETURN

HOSE - INSTALLATION).

(9) Reconnect the battery negative cable.

(10) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

FRONT HEATER CORE

(1) While pushing the brake pedal downward and

pulling the accelerator pedal upward far enough for

clearance, slide the heater core into the distribution

housing.

(2) Install the two screws that secure the heater

core mounting plate to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).(3) Install the heater core tubes (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

HEATER CORE - INSTALLATION).

(4) Reconnect the power brake booster input rod

(push rod) to the pin on the brake pedal arm (Refer

to 5 - BRAKES/HYDRAULIC/MECHANICAL/

POWER BRAKE BOOSTER - INSTALLATION).

(5) Reinstall the brake lamp switch into its mount-

ing bracket (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

INSTALLATION).

(6) Reinstall the silencer boot around the base of

the lower steering shaft on the dash panel.

(7) Reconnect the battery negative cable.

(8) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

(9) Operate system for two thermostat cycles to

assure the elimination of any air that may be

trapped within the cooling system.

HEATER INLET HOSE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

NOTE: The heater inlet hose is constructed from

formed steel tubing and rubber hoses. Depending

on application, the ends are secured to the heater

core, engine oil cooler or the engine by spring ten-

sion clamps.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

24 - 86 PLUMBING - FRONTRS

HEATER CORE (Continued)

Page 2239 of 2339

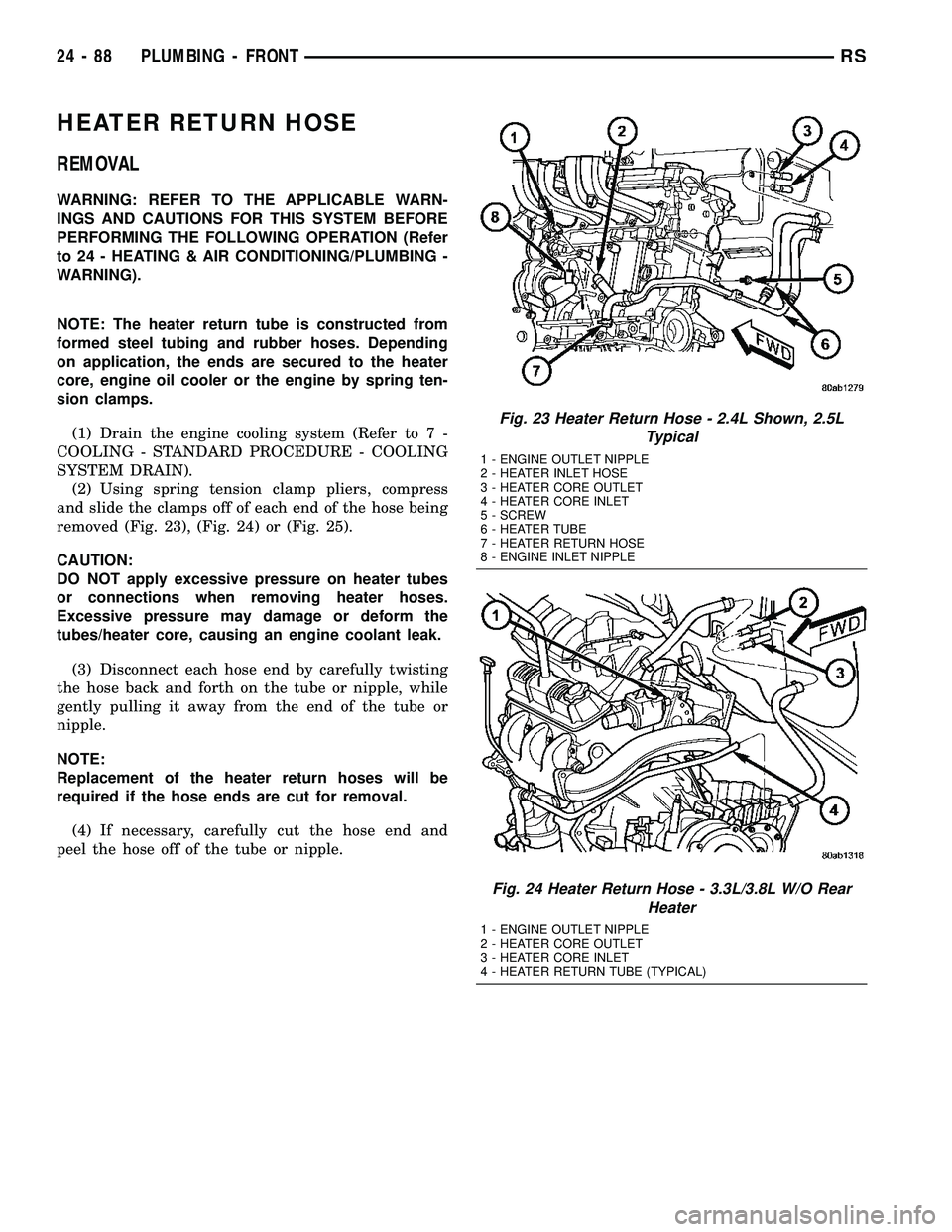

HEATER RETURN HOSE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

NOTE: The heater return tube is constructed from

formed steel tubing and rubber hoses. Depending

on application, the ends are secured to the heater

core, engine oil cooler or the engine by spring ten-

sion clamps.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Using spring tension clamp pliers, compress

and slide the clamps off of each end of the hose being

removed (Fig. 23), (Fig. 24) or (Fig. 25).

CAUTION:

DO NOT apply excessive pressure on heater tubes

or connections when removing heater hoses.

Excessive pressure may damage or deform the

tubes/heater core, causing an engine coolant leak.

(3) Disconnect each hose end by carefully twisting

the hose back and forth on the tube or nipple, while

gently pulling it away from the end of the tube or

nipple.

NOTE:

Replacement of the heater return hoses will be

required if the hose ends are cut for removal.

(4) If necessary, carefully cut the hose end and

peel the hose off of the tube or nipple.

Fig. 23 Heater Return Hose - 2.4L Shown, 2.5L

Typical

1 - ENGINE OUTLET NIPPLE

2 - HEATER INLET HOSE

3 - HEATER CORE OUTLET

4 - HEATER CORE INLET

5 - SCREW

6 - HEATER TUBE

7 - HEATER RETURN HOSE

8 - ENGINE INLET NIPPLE

Fig. 24 Heater Return Hose - 3.3L/3.8L W/O Rear

Heater

1 - ENGINE OUTLET NIPPLE

2 - HEATER CORE OUTLET

3 - HEATER CORE INLET

4 - HEATER RETURN TUBE (TYPICAL)

24 - 88 PLUMBING - FRONTRS

Page 2242 of 2339

(15) If the vehicle is equipped with the optional

rear heating-A/C system, go to Step 16. If the vehicle

is not equipped with the optional rear heating-A/C

system, go to Step 22.

(16) Raise and support the vehicle.

(17) Cut the tie strap located just forward of the

connections between the underbody plumbing and

the engine compartment plumbing for the rear heat-

ing-A/C system (Fig. 29).

(18) Disconnect the A/C liquid line extension fit-

ting from the underbody liquid line fitting for the

rear A/C system.

(19) Remove the O-ring seal from the underbody

liquid line fitting and discard.

(20) Install plugs in, or tape over the opened liquid

line fittings.

(21) Lower the vehicle.

(22) Remove the rear section of the A/C liquid line

from the engine compartment.

INSTALLATION

FRONT SECTION

(1) Position the front section of the A/C liquid line

into the engine compartment.

(2) Remove the tape or plugs from the liquid line

fitting and the receiver/drier inlet port.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it onto the liquid line fit-

ting.

(4) Connect the A/C liquid line to the receiver/

drier.(5) Install the bolt that secures the A/C liquid line

to the receiver/drier. Tighten the bolt to 11 N´m (97

in. lbs.).

(6) Engage the retainer that secures the liquid line

routing clip to the top of the right frame rail ahead of

the front strut tower in the engine compartment.

(7) Remove the tape or plugs from the condenser

outlet port and the liquid line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it and a new gasket onto

the liquid line fitting.

(9) Connect the A/C liquid line to the A/C con-

denser.

(10) Install the nut that secures the A/C liquid line

to the A/C condenser. Tighten the nut to 23 N´m (17

ft. lbs.).

(11) Position the radiator sight shield onto the

radiator closure panel crossmember.

(12) Install the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

Tighten the screws to 2 N´m (17 in. lbs.).

(13) Install the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber. Tighten the screws to 6 N´m (53 in. lbs.).

(14) Reinstall the air cleaner housing into the

right side of the engine compartment.

(15) Reconnect the negative battery cable.

(16) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(17) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

REAR SECTION

(1) Position the rear section of the A/C liquid line

into the engine compartment.

(2) Remove the tape or plugs from the suction line

and liquid line fittings and both expansion valve

ports.

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them onto the suction line

and liquid line fittings.

(4) Reconnect the A/C liquid line and the A/C suc-

tion line to the A/C expansion valve.

(5) Install the nut that secures the rear section of

the A/C liquid line and the A/C suction line to the

A/C expansion valve. Tighten the nut to 23 N´m (17

ft. lbs.).

(6) Remove the tape or plugs from the liquid line

fitting and the receiver/drier outlet port.

Fig. 29 Underbody A/C Line Connections

1 - SUCTION LINE EXTENSION TUBE

2 - LIQUID LINE EXTENSION TUBE

3 - RETAINING STRAP

4 - REAR HEATER EXTENSION TUBES

5 - UNDERBODY REFRIGERANT LINES

RSPLUMBING - FRONT24-91

LIQUID LINE (Continued)

Page 2243 of 2339

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(8) Reconnect the A/C liquid line to the receiver/

drier.

(9) Install the bolt that secures the A/C liquid line

to the receiver/drier. Tighten the bolt to 11 N´m (97

in. lbs.).

(10) If equipped, reinstall the A/C ground strap

eyelet terminal connector onto the weld stud on the

top of the right front strut tower (if equipped).

(11) If equipped, install the nut that secures the

A/C ground strap to the weld stud. Tighten the nut

to 12 N´m (106 in. lbs.)

(12) Install the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER - INSTAL-

LATION).

(13) Connect the drain tube to the wiper module

drain on the right side of the engine compartment.

(14) Install the air cleaner housing into the right

side of the engine compartment.

(15) On RHD models, install the liquid line into

the retaining bracket located at the top of the dash

panel.

(16) If the vehicle is equipped with the optional

rear heating-A/C system, go to Step 17. If the vehicle

does not have the optional rear heating-A/C system,

go to Step 23.

(17) Raise and support the vehicle.

(18) Remove the tape or plugs from the A/C liquid

line extension fitting and the underbody liquid line

fitting.

(19) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody liquid

line fitting.

(20) Connect the A/C liquid line extension fitting

to the underbody liquid line fitting. Tighten the fit-

tings to 23 N´m (17 ft. lbs.).

(21) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heating-

A/C system.

(22) Lower the vehicle.

(23) Reconnect the negative battery cable.

(24) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(25) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).RECEIVER / DRIER

DESCRIPTION

The receiver/drier is mounted in a bracket secured

to the right front strut tower in the engine compart-

ment. The receiver/drier is connected between the

front and rear sections of the liquid line between the

condenser outlet and the evaporator inlet. The receiv-

er/drier cannot be repaired. If the receiver/drier is

faulty or damaged, or if the refrigerant system has

been contaminated or left open to the atmosphere for

an indeterminable period or if the A/C compressor

has failed, it must be replaced.

OPERATION

The receiver/drier performs a filtering action to

prevent foreign material in the refrigerant from con-

taminating the expansion valve. Desiccant inside the

receiver/drier canister absorbs any moisture which

may have entered and become trapped within the

refrigerant system. In addition, during periods of

high demand air conditioner operation, the receiver/

drier acts as a reservoir to store surplus refrigerant.

Refrigerant enters the receiver/drier as a high-pres-

sure, low temperature liquid.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Remove the air cleaner housing from the right

side of the engine compartment.

(3) Remove the bolt that secures the liquid line

front section fitting to the top of the receiver/drier

(Fig. 30).

(4) Disconnect the liquid line fitting from the

receiver/drier inlet port.

(5) Remove the O-ring seal from the liquid line fit-

ting and discard.

(6) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier inlet port.

24 - 92 PLUMBING - FRONTRS

LIQUID LINE (Continued)

Page 2244 of 2339

(7) Remove the bolt that secures the liquid line

rear section fitting to the top of the receiver/drier.

(8) Disconnect the liquid line fitting from the

receiver/drier outlet port.

(9) Remove the seal from the liquid line fitting and

discard.

(10) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier outlet port.

(11) Remove the two nuts that secure the receiver/

drier mounting bracket to the weld studs on the side

of the right front strut tower.

(12) Remove the receiver/drier and mounting

bracket unit from the studs.

INSTALLATION

NOTE: If the receiver/drier is being replaced, add 25

milliliters (0.8 fluid ounce) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the A/C compressor in the

vehicle.(1) Position the receiver/drier and mounting

bracket unit onto the weld studs on the side of the

right front strut tower.

(2) Install the two nuts that secure the receiver/

drier mounting bracket to the studs. Tighten the

nuts to 10 N´m (89 in. lbs.).

(3) Remove the tape or plugs from the liquid line

rear section fitting for the receiver/drier and the

receiver/drier outlet port.

(4) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(5) Reconnect the liquid line fitting to the receiver/

drier outlet port on the top of the receiver/drier.

(6) Install the bolt that secures the liquid line fit-

ting to the receiver/drier. Tighten the bolt to 11 N´m

(97 in. lbs.).

(7) Remove the tape or plugs from the liquid line

front section fitting for the receiver/drier and the

receiver/drier inlet port.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(9) Reconnect the liquid line fitting to the receiver/

drier inlet port on the top of the receiver/drier.

(10) Install the bolt that secures the liquid line fit-

ting to the receiver/drier. Tighten the bolt to 11 N´m

(97 in. lbs.).

(11) Reinstall the air cleaner housing into the

right side of the engine compartment.

(12) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(13) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas. Even though

R-134a does not contain chlorine, it must be

reclaimed and recycled just like CFC-type refriger-

ants. This is because R-134a is a greenhouse gas and

can contribute to global warming.

Fig. 30 Reciever/Drier - LHD Shown, RHD Typical

1 - A/C GROUND STRAP (IF EQUIPPED)

2 - NUT (IF EQUIPPED)

3 - WELD STUD (IF EQUIPPED)

4 - A/C PRESSURE TRANSDUCER

5 - WELD STUD (2)

6 - A/C EXPANSION VALVE

7 - A/C LIQUID LINE (REAR SECTION)

8 - LIQUID LINE EXTENSION (REAR A/C ONLY)

9 - NUT (2)

10 - RECEIVER/DRIER

11 - ROUTING CLIP

12 - A/C LIQUID LINE (FRONT SECTION)

RSPLUMBING - FRONT24-93

RECEIVER / DRIER (Continued)

Page 2245 of 2339

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system. R-134a

refrigerant system service ports, service tool couplers

and refrigerant dispensing bottles have all been

designed with unique fittings to ensure that an

R-134a system is not accidentally contaminated with

the wrong refrigerant (R-12). There are also labels

posted in the engine compartment of the vehicle and

on the compressor identifying to service technicians

that the air conditioning system is equipped with

R-134a.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each con-

tains a different additive package. The compressor

used in this vehicle is designed to use an ND-8 PAG

refrigerant oil. Use only refrigerant oil of this same

type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance. PAG

refrigerant oil is much more hygroscopic than min-

eral oil, and will absorb any moisture it comes into

contact with, even moisture in the air. The PAG oil

container should always be kept tightly capped until

it is ready to be used. After use, recap the oil con-

tainer immediately to prevent moisture contamina-

tion.

STANDARD PROCEDURE

REFRIGERANT OIL LEVEL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

CAUTION: Use only PAG oils that are designed to

work with R-134a refrigerant and the A/C compres-

sor in the vehicle. Refer to the underhood A/C Sys-

tem Specification Label.

It is important to have the correct amount of lubri-

cant in the A/C refrigerant system to ensure proper

lubrication of the A/C compressor. Too little lubricant

will result in damage to the compressor. Too much

lubricant will reduce the cooling capacity of the A/C

system and consequently result in higher discharge

air temperatures.

The lubricant used in the compressor is polyalka-

lene glycol PAG lubricant. Only the refrigerant lubri-

cant approved for use with this vehicle should be

used to service the system. Do not use any other

lubricant. The lubricant container should be kept

tightly capped until it is ready for use. Refrigerant

lubricant will quickly absorb any moisture it comes

in contact with.

It will not be necessary to check the oil level in the

A/C compressor or to add oil, unless there has been

an oil loss. An oil loss may occur due to a rupture or

leak from a refrigerant line, connector fitting, compo-

nent or component seal. If a leak occurs, add 30 mil-

liliters (1 fluid ounce) of the recommended

refrigerant oil to the refrigerant system after the

repair has been made. Refrigerant oil loss will be evi-

dent at the leak point by the presence of a wet, shiny

surface around the leak.

REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assembled

at the factory, all components (except the A/C com-

pressor) are refrigerant oil free. After the refrigerant

system has been charged with (R-134a) refrigerant

and operated, the oil in the A/C compressor is dis-

persed through the lines and components. The A/C

evaporator, A/C condenser, and receiver/drier will

retain a significant amount of oil. Refer to the A/C

Component Refrigerant Oil Capacities table. When a

component is replaced, the specified amount of refrig-

erant oil must be added. When the compressor is

replaced, the amount of oil that is retained in the

24 - 94 PLUMBING - FRONTRS

REFRIGERANT (Continued)

Page 2248 of 2339

(18) Disconnect the suction line extension fitting

from the underbody suction line fitting for the rear

air conditioner.

(19) Remove the O-ring seal from the underbody

suction line fitting and discard.

(20) Install plugs in, or tape over the opened suc-

tion line fittings.

(21) Lower the vehicle.

(22) Remove the suction line from the engine com-

partment.

INSTALLATION

(1) Position the suction line into the engine com-

partment.

(2) Remove the tape or plugs from the suction line

and liquid line fittings and both expansion valve

ports.

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction line

and liquid line fittings.

(4) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(5) Install the nut that secures the suction line

and liquid line fittings to the expansion valve.

Tighten the nut to 23 N´m (17 ft. lbs.).

(6) Install the retainer that secures the suction

line routing clip to the receiver/drier mounting

bracket on the side of the right front strut tower in

the engine compartment.(7) Remove the tape or plugs from the compressor

suction port and the suction line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the suction line fit-

ting.

(9) Install a new dual plan seal and reconnect the

suction line fitting to the compressor suction port.

(10) Install the nut that secures the suction line

fitting to the A/C compressor. Tighten the nut to 23

N´m (17 ft. lbs.).

(11) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(12) Install the air cleaner top cover and snorkel

onto the air cleaner housing located on the right side

of the engine compartment.

(13) On RHD models, install the suction line into

the retaining bracket located at the top of the dash

panel.

(14) If the vehicle is equipped with the optional

rear air conditioner, go to Step 15. If the vehicle does

not have the optional rear air conditioner, go to Step

21.

(15) Raise and support the vehicle.

(16) Remove the tape or plugs from the suction

line extension fitting and the underbody suction line

fitting.

(17) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody suction

line fitting.

(18) Reconnect the suction line extension fitting to

the underbody suction line fitting. Tighten the fit-

tings to 23 N´m (17 ft. lbs.).

(19) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heater

and air conditioner.

(20) Lower the vehicle.

(21) Reconnect the battery negative cable.

(22) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(23) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

Fig. 32 Underbody A/C Line Connections

1 - SUCTION LINE EXTENSION TUBE

2 - LIQUID LINE EXTENSION TUBE

3 - RETAINING STRAP

4 - REAR HEATER EXTENSION TUBES

5 - UNDERBODY REFRIGERANT LINES

RSPLUMBING - FRONT24-97

SUCTION LINE (Continued)

Page 2252 of 2339

DIAGNOSIS AND TESTING

REAR A/C EXPANSION VALVE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: The expansion valve should only be tested

following testing of the compressor.

NOTE: Liquid CO

2is required to test the expansion

valve. This material is available from most welding

supply facilities. Liquid CO

2is also available from

companies which service and sell fire extinguish-

ers.

When testing the expansion valve, the work area

and the vehicle temperature must be 21É to 27É C

(70É to 85É F). To test the expansion valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

(2) Close all doors, windows and vents to the pas-

senger compartment.

(3) Set the heater-air conditioner controls so that

the compressor is operating, the temperature control

is in the highest temperature position, the mode door

is directing the output to the floor outlets, and the

blower is operating at the highest speed setting.

(4) Start the engine and allow it to idle at 1000

rpm. After the engine has reached normal operating

temperature, allow the passenger compartment to

heat up. This will create the need for maximum

refrigerant flow into the evaporator.

(5) If the refrigerant charge is sufficient, the dis-

charge (high pressure) gauge should read 965 to 1655

kPa (140 to 240 psi). The suction (low pressure)

gauge should read 140 kPa to 207 kPa (20 psi to 30

psi). If OK, go to Step 6. If not OK, replace the faulty

expansion valve.

WARNING: PROTECT THE SKIN AND EYES FROM

EXPOSURE TO LIQUID CO

2. PERSONAL INJURY

CAN RESULT.

(6)

If the suction (low pressure) gauge reads within

the specified range, freeze the expansion valve control

head for 30 seconds using liquid CO

2or another suit-

able super-cold material.Do not spray R-134a or

R-12 refrigerant on the expansion valve controlhead for this test.

The suction (low pressure) gauge

reading should drop by 10 psi. If OK, go to Step 7 If

not OK, replace the faulty expansion valve.

(7) Allow the expansion valve control head to thaw.

The suction (low pressure) gauge reading should sta-

bilize at 140 kPa to 240 kPa (20 psi to 30 psi). If not

OK, replace the faulty expansion valve.

(8) When expansion valve testing is complete, test

the overall air conditioner performance (Refer to 24 -

HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING - A/C PERFORMANCE TEST).

Remove all test equipment before returning the vehi-

cle to service.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING), (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING), and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - HEATER PLUMBING).

(1) Remove the rear HVAC housing from the vehi-

cle (Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Carefully remove the foam insulator wrap from

the rear expansion valve.

(3) Remove the rear evaporator line extension from

the expansion valve (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - REAR/EVAPORA-

TOR - REMOVAL - EVAPORATOR LINE EXTEN-

SION).

(4) Remove the two screws that secure the expan-

sion valve to the evaporator tube sealing plate.

(5) Remove the expansion valve from the evapora-

tor tubes.

(6) Remove the seals from the evaporator tube fit-

tings and discard.

(7) Install plugs in, or tape over the opened evap-

orator tube fittings and both expansion valve ports.

INSTALLATION

(1) Remove the tape or plugs from the rear A/C

evaporator tube fittings and both expansion valve

ports.

(2) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the rear evapora-

tor tube fittings.

(3) Position the expansion valve onto the evapora-

tor tubes.

(4) Install the two screws that secure the rear A/C

expansion valve to the evaporator tube sealing plate.

Tighten the screws to 11 N´m (97 in. lbs.).

RSPLUMBING - REAR24 - 101

A/C EXPANSION VALVE (Continued)