Front door CHRYSLER VOYAGER 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 445 of 2339

The lock function works from the RKE transmitter

even in an out of synchronization condition, therefore

it could be verified by pressing the LOCK button on

the RKE key fob.

DOOR CYLINDER LOCK

SWITCH - EXPORT

DESCRIPTION

The Door Cylinder Lock Switch (If equipped) is

used to:

²Unlock/Lock all the doors via the Central Lock-

ing feature.

²Arm/Disarm the Vehicle Theft Security System.

²Trigger the Illuminated Entry feature.

The door cylinder lock switch is mounted to the

rear of the driver door lock cylinder. When installed

on the rear of the cylinder, there is a tab on the lock

cylinder that aligns with the switch to prevent it

from turning. An anti-rotating device. The door cylin-

der lock switch is a one time use switch. Once it is

removed from the rear of the door lock cylinder, it

may not be reinstalled and a new switch must be

used.

OPERATION

When the Door Cylinder Lock Switch is turned

either way using the door key cylinder, the BCM

reads a direct message signal from the switch.

If turning the key cylinder once, toward the front

of the vehicle, this will:

(1) Mechanically unlock the door lock.

(2) Disarm the Vehicle Theft Security System (if

equipped).

(3) Turn on the Illuminated Entry (if equipped) for

approximately 30 seconds.

If the key cylinder is turned to the unlock position

(toward the front of vehicle) twice within two sec-

onds, all the doors and liftgate will unlock (if

equipped with the central locking feature).

To lock the vehicle using the door cylinder lock

switch, turn the key cylinder toward the rear of the

vehicle once. This will lock the door that you are

using the key on. If equipped with the central locking

feature, this will lock all the other doors and liftgate.

Furthermore, this will arm the vehicle theft security

system and turn off the illuminated entry.

DIAGNOSIS AND TESTING

DOOR CYLINDER LOCK SWITCH - EXPORT

Any diagnosis of the power lock system

should begin with the use of the DRB IIItdiag-

nostic tool. For information on the use of theDRB IIIt, refer to the appropriate Diagnostic

Service Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information.

(1) Visually inspect the switch for proper installa-

tion. Make sure it is seated on the rear of the key

cylinder, with the tab of the door key cylinder prop-

erly aligned with the slot on the door cylinder lock

switch.

(2) Disconnect the switch at the harness connector

and check the resistance in each switch position.

CAUTION: Do not disconnect the switch from the

rear of the door key cylinder. This switch is a one

time use switch. Once it is removed from the rear of

the switch, it is not reusable and must be replaced.

Test the switch at the harness connector.

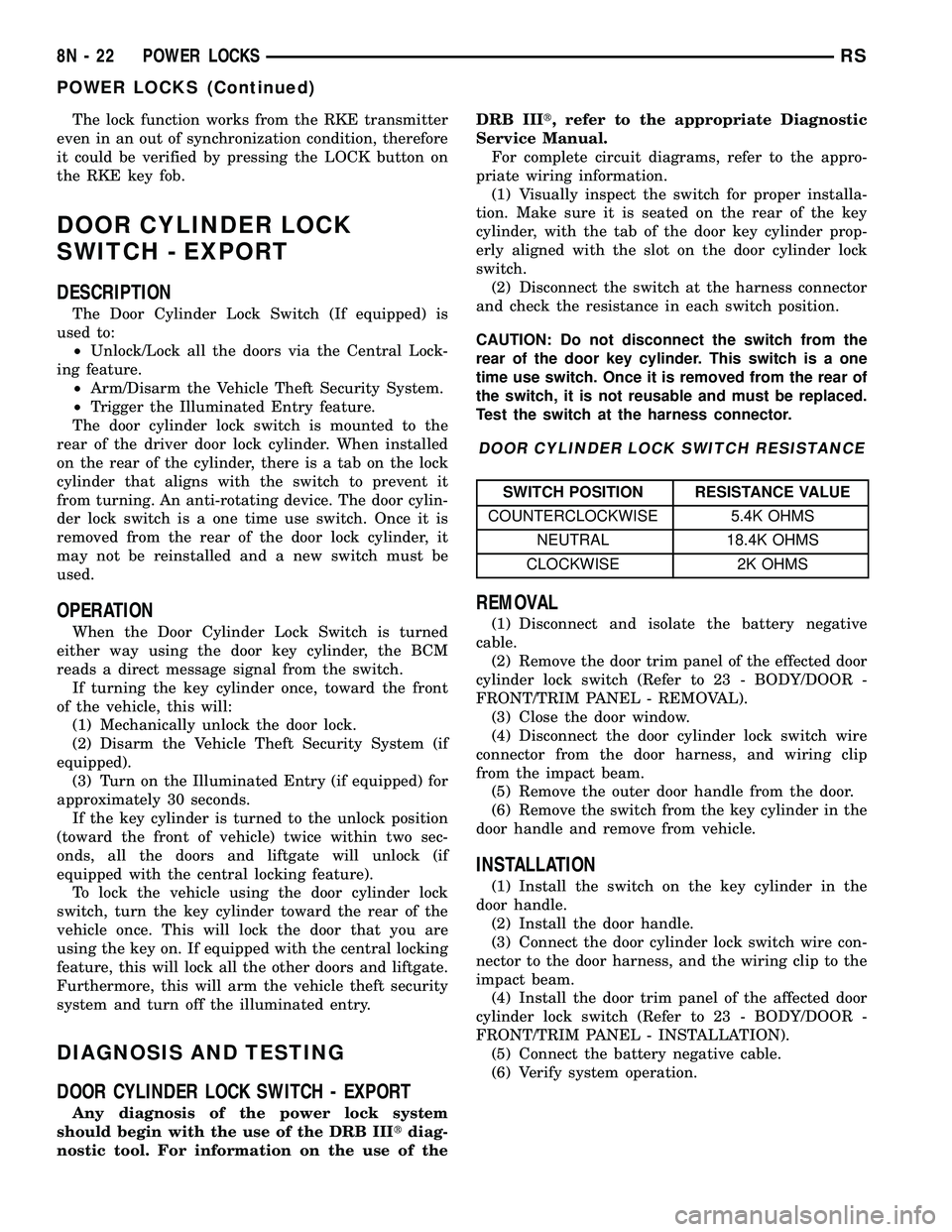

DOOR CYLINDER LOCK SWITCH RESISTANCE

SWITCH POSITION RESISTANCE VALUE

COUNTERCLOCKWISE 5.4K OHMS

NEUTRAL 18.4K OHMS

CLOCKWISE 2K OHMS

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel of the effected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - REMOVAL).

(3) Close the door window.

(4) Disconnect the door cylinder lock switch wire

connector from the door harness, and wiring clip

from the impact beam.

(5) Remove the outer door handle from the door.

(6) Remove the switch from the key cylinder in the

door handle and remove from vehicle.

INSTALLATION

(1) Install the switch on the key cylinder in the

door handle.

(2) Install the door handle.

(3) Connect the door cylinder lock switch wire con-

nector to the door harness, and the wiring clip to the

impact beam.

(4) Install the door trim panel of the affected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Verify system operation.

8N - 22 POWER LOCKSRS

POWER LOCKS (Continued)

Page 446 of 2339

DOOR LOCK MOTOR

DIAGNOSIS AND TESTING

DOOR LOCK MOTOR

Any diagnosis of the power lock system

should begin with the use of the DRB IIItdiag-

nostic tool. For information on the use of the

DRB IIIt, refer to the appropriate Diagnostic

Service Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information.

Verify battery condition before testing door lock

motor(s).

To determine which motor is faulty, check each

individual door for electrical lock and unlock or dis-

connect the motor connectors one at a time, while

operating the door lock switch. In the event that

none of the motors work, the problem may be caused

by a shorted motor or a faulty switch. Disconnecting

the faulty motor will allow the others to work.

To test an individual door lock motor, disconnect

the electrical connector from the motor. To lock the

door, connect a fused 12 volt power source to the pos-

itive pin of the lock motor and a ground wire to the

other pin. To unlock the door reverse the wire con-

nections at the motor pin terminals. If these results

are not obtained, replace the door latch.

DOOR LOCK SWITCH

DIAGNOSIS AND TESTING

DOOR LOCK SWITCH

(1) Remove door trim panel. Refer to Body, Door -

Front, Trim Panel, Removal and Installation.

(2) Disconnect wire connector from back of door

lock switch.

(3) Depress switch to LOCK position.

(4) Using an ohmmeter, test switch resistance

between Pins 2 and 3. Refer to the DOOR LOCK

SWITCH CONTINUITY test and (Fig. 1).

(5) Depress switch to UNLOCK position.

(6) Test resistance between Pins 2 and 3.

(7) Test resistance between pins 2 and 3 while

switch is in its normal unactuated mode.

(8) If resistance values are not within the param-

eters shown replace the door lock switch.

DOOR LOCK SWITCH CONTINUITY

SWITCH

POSITIONCONTINUITY

BETWEENRESISTANCE

VALUE

LOCK 2 and 3 5.3K Ohm 5%

UNLOCK 2 and 3 2.0K Ohm 5%

UNACTUATED 2 and 3 18.3K Ohms

5%

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove door trim panel. Refer to Body, Door -

Front, Trim Panel, Removal.

(3) Disconnect wire connector from back of door

lock switch.

(4) Remove two screws to door lock switch.

(5) Remove switch from vehicle.

INSTALLATION

(1) Install the switch into the vehicle.

(2) Install the two screws to door lock switch.

(3) Connect wire connector to back of door lock

switch.

(4) Install door trim panel. Refer to Body, Door -

Front, Trim Panel, Installation.

(5) Connect the battery negative cable.

Fig. 1 DOOR LOCK SWITCH

RSPOWER LOCKS8N-23

Page 455 of 2339

(Refer to 8 - ELECTRICAL/HEATED SEATS -

DESCRIPTION) for more information on the heated

seat option. (Refer to 8 - ELECTRICAL/POWER

SEATS - DESCRIPTION - MEMORY SEAT SYS-

TEM) for more information on the memory seat sys-

tem.

The power seat system includes the following com-

ponents:

²Power seat recliners

²Power seat switches

²Power seat tracks

²Circuit breaker

The power seat system with memory and heated

seat options includes the following components:

²Power seat recliner

²Power seat switch

²Power seat track.

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Heated Seat Module (HSM)

²Heated seat switch

²Electronic Vehicle Information Center (EVIC)

MEMORY SYSTEM

The memory system is able to store and recall the

driver side power seat positions (including the power

recliner position), power adjustable pedal positions

and the driver outside mirror position for two driv-

ers. On vehicles equipped with a factory radio, the

memory system is also able to store and recall radio

station presets for two drivers. The memory system

also will store and recall the last station listened to

for each driver, even if it is not one of the preset sta-

tions.

The memory system will automatically return to

its preset settings when the corresponding numbered

button of the memory switch is depressed, or when

the doors are unlocked using the corresponding

Remote Keyless Entry (RKE) transmitter. A customer

programmable feature of the memory system allows

the RKE recall of memory features to be disabled, if

desired. This programmable feature is internal in the

Electronic Vehicle Information Center (EVIC) mod-

ule, which is located in the overhead console.

A Memory Seat Mirror Module (MSMM) is used to

control and integrate the many electronic functions

and features included in the memory seat and mirror

systems.

The memory system includes the following compo-

nents:

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Position potentiometers on the driver outside

side view mirror

²Position potentiometers on the power adjustable

pedal motor²Position potentiometers on the driver side power

seat track and power seat recliner motors

²Electronic Vehicle Information Center (EVIC)

²Radio receiver (if PCI data bus capable)

Certain functions of the memory system rely upon

resources shared with other electronic modules in the

vehicle over the Programmable Communications

Interface (PCI) data bus network. Initial diagnosis of

these electronic modules or the PCI data bus network

requires the use of a DRBIIItor equivalent scan tool

and the proper Diagnostic Procedures information. If

this method does not prove conclusive, the proper

wiring schematics and the service manual diagnostic

information are required.

The other electronic modules that may affect mem-

ory system operation are:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for additional information.

²Powertrain Control Module (PCM)- (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION) for additional information.

²Transmission Control Module (TCM)- (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

DESCRIPTION) for additional information.

(Refer to 8 - ELECTRICAL/HEATED SEATS -

DESCRIPTION) for additional information on the

heated seat system. (Refer to 8 - ELECTRICAL/

POWER LOCKS - DESCRIPTION) for additional

information on the RKE system.

OPERATION

POWER SEAT SYSTEM

The power seat system receives battery current

through fuse #22 in the Integrated Power Module

(IPM) and a circuit breaker under the front seats,

regardless of the ignition switch position.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the appropri-

ate power seat track adjuster motor. The selected

adjuster motor operates to move the seat track

through its drive unit in the selected direction until

the switch is released, or until the travel limit of the

seat track is reached. When the switch is moved in

the opposite direction, the battery feed and ground

path to the motor are reversed through the switch

contacts. This causes the adjuster motor to run in the

opposite direction.

No power seat switch should be held applied in any

direction after the seat track has reached its travel

limit. The power seat adjuster motor each contain a

8N - 32 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

Page 459 of 2339

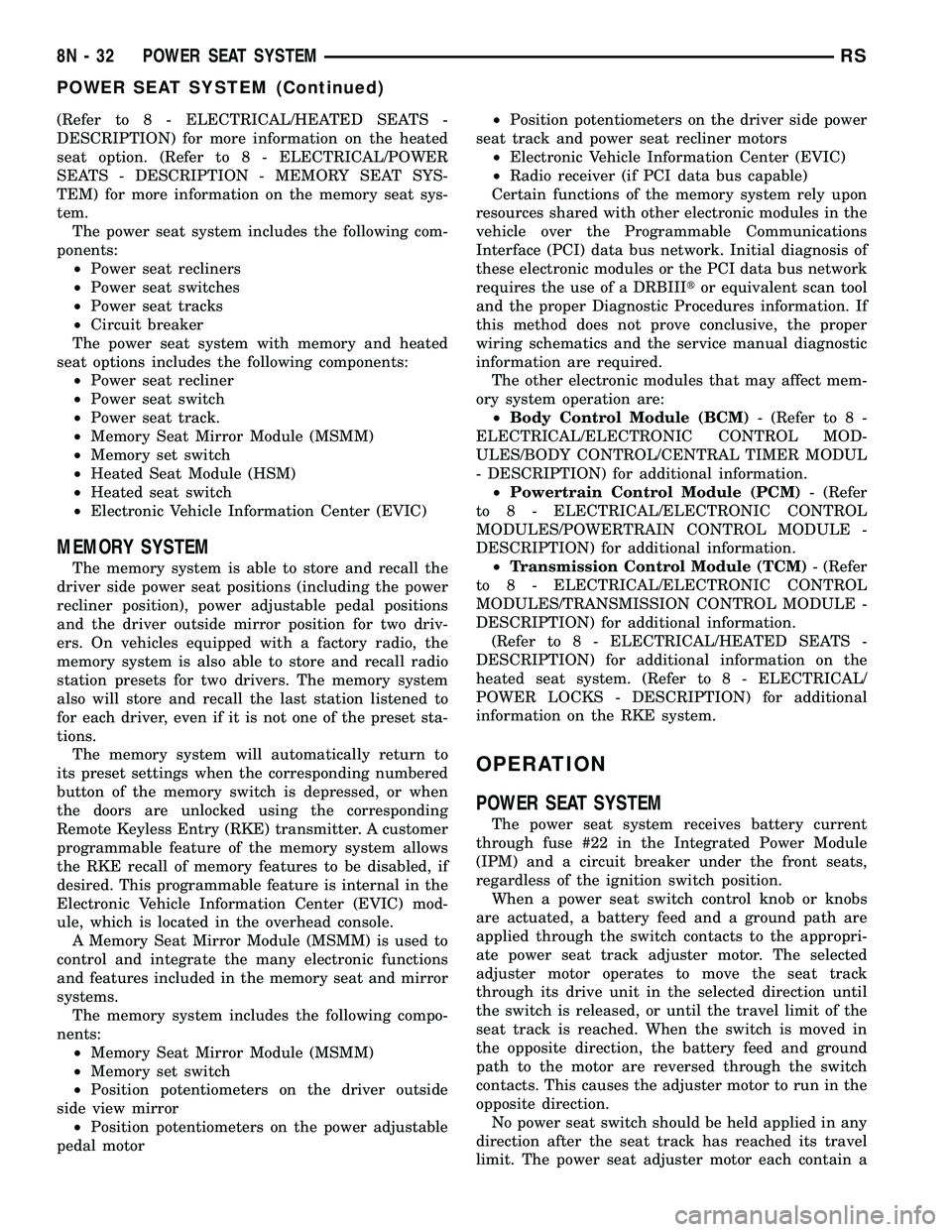

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a push pin remover or other suitable

wide flat-bladed tool, gently pry the power seat and

power recliner switch knobs off of the switch levers

(Fig. 4).

(3) Remove the screws that secure the outboard

seat cushion side cover to the seat cushion frame,

(Refer to 23 - BODY/SEATS/SEAT CUSHION SIDE

COVERS - REMOVAL).

(4) Pull the outboard seat cushion side cover away

from the seat cushion frame far enough to access the

power seat switch wire harness connector.

(5) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle.

(6) Remove the screws that secure the power seat

switch to the inside of the outboard seat cushion side

cover.

(7) Remove the power seat switch from the out-

board seat cushion side cover.

INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side cover.

(2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side cover. Tighten the screws to 1.5 N´m (14

in. lbs.).

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.(4) Install the outboard seat cushion side cover,

(Refer to 23 - BODY/SEATS/SEAT CUSHION SIDE

COVERS - INSTALLATION).

(5) Install the power seat and power recliner

switch knobs onto the switch control levers.

(6) Reconnect the battery negative cable.

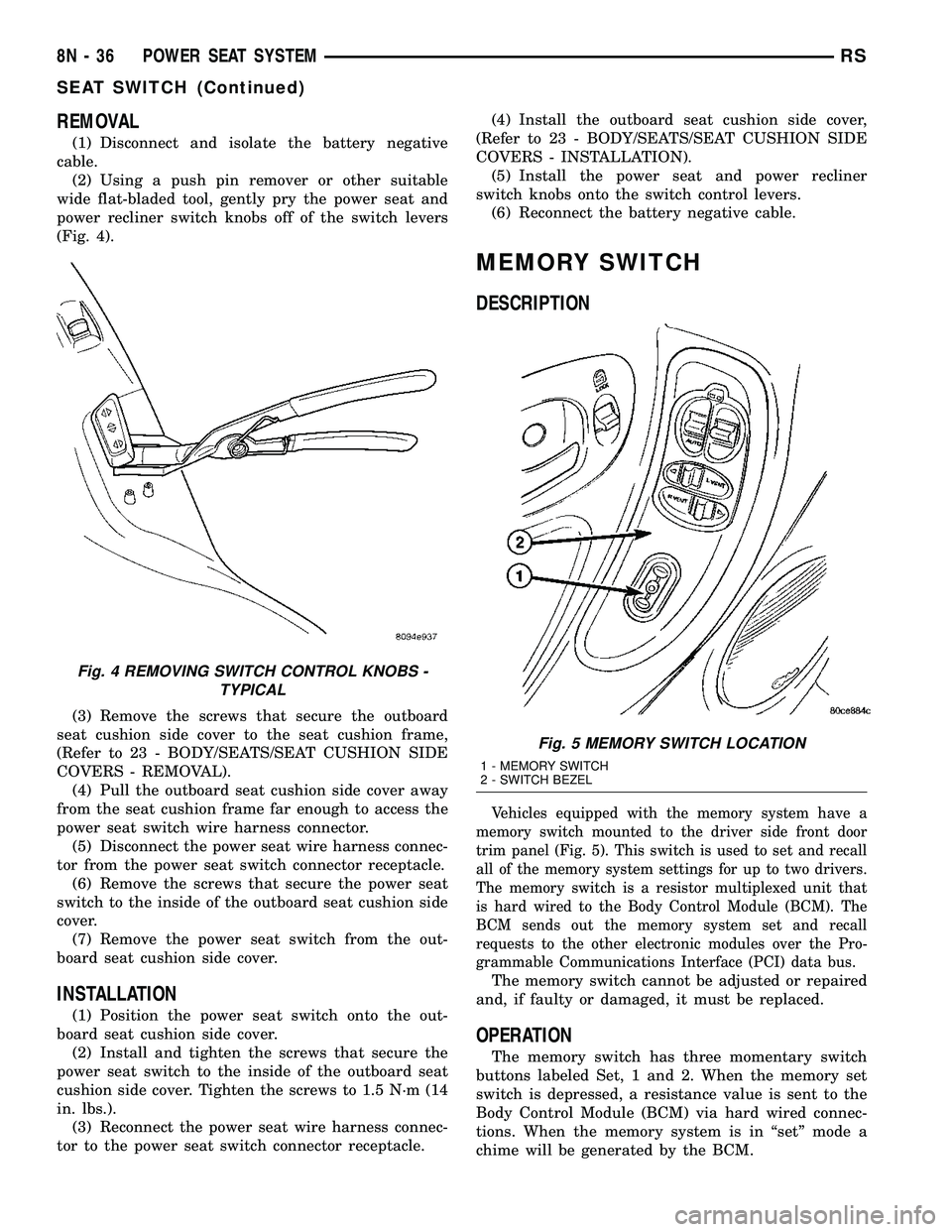

MEMORY SWITCH

DESCRIPTION

Vehicles equipped with the memory system have a

memory switch mounted to the driver side front door

trim panel (Fig. 5). This switch is used to set and recall

all of the memory system settings for up to two drivers.

The memory switch is a resistor multiplexed unit that

is hard wired to the Body Control Module (BCM). The

BCM sends out the memory system set and recall

requests to the other electronic modules over the Pro-

grammable Communications Interface (PCI) data bus.

The memory switch cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The memory switch has three momentary switch

buttons labeled Set, 1 and 2. When the memory set

switch is depressed, a resistance value is sent to the

Body Control Module (BCM) via hard wired connec-

tions. When the memory system is in ªsetº mode a

chime will be generated by the BCM.

Fig. 4 REMOVING SWITCH CONTROL KNOBS -

TYPICAL

Fig. 5 MEMORY SWITCH LOCATION

1 - MEMORY SWITCH

2 - SWITCH BEZEL

8N - 36 POWER SEAT SYSTEMRS

SEAT SWITCH (Continued)

Page 460 of 2339

DIAGNOSIS AND TESTING

MEMORY SWITCH

(1) Remove the memory switch from the drivers

door panel (Refer to 8 - ELECTRICAL/POWER

SEATS/MEMORY SET SWITCH - REMOVAL).

(2) Using an ohmmeter, check the continuity of the

memory select switch MUX circuit between the C2

wire harness connector for the Body Control Module

(BCM) and the wire harness connector for the mem-

ory switch. There should be continuity. If OK, go to

Step 3. If not OK, repair the open or shorted MUX

circuit as required.

(3) Using an ohmmeter, check the continuity of the

memory select switch return circuit between the C2

wire harness connector for the BCM and the wire

harness connector for the memory switch. There

should be continuity. If OK, go to Step 4. If not OK,

repair the open or shorted return circuit as required.

(4) Using an ohmmeter, test the resistances of the

memory switch, refer to the MEMORY SWITCH

TEST TABLE. If OK, (Refer to 8 - ELECTRICAL/

POWER SEATS - DIAGNOSIS AND TESTING -

MEMORY SYSTEM). If not OK, replace the memory

switch, (Refer to 8 - ELECTRICAL/POWER SEATS/

MEMORY SET SWITCH - REMOVAL).

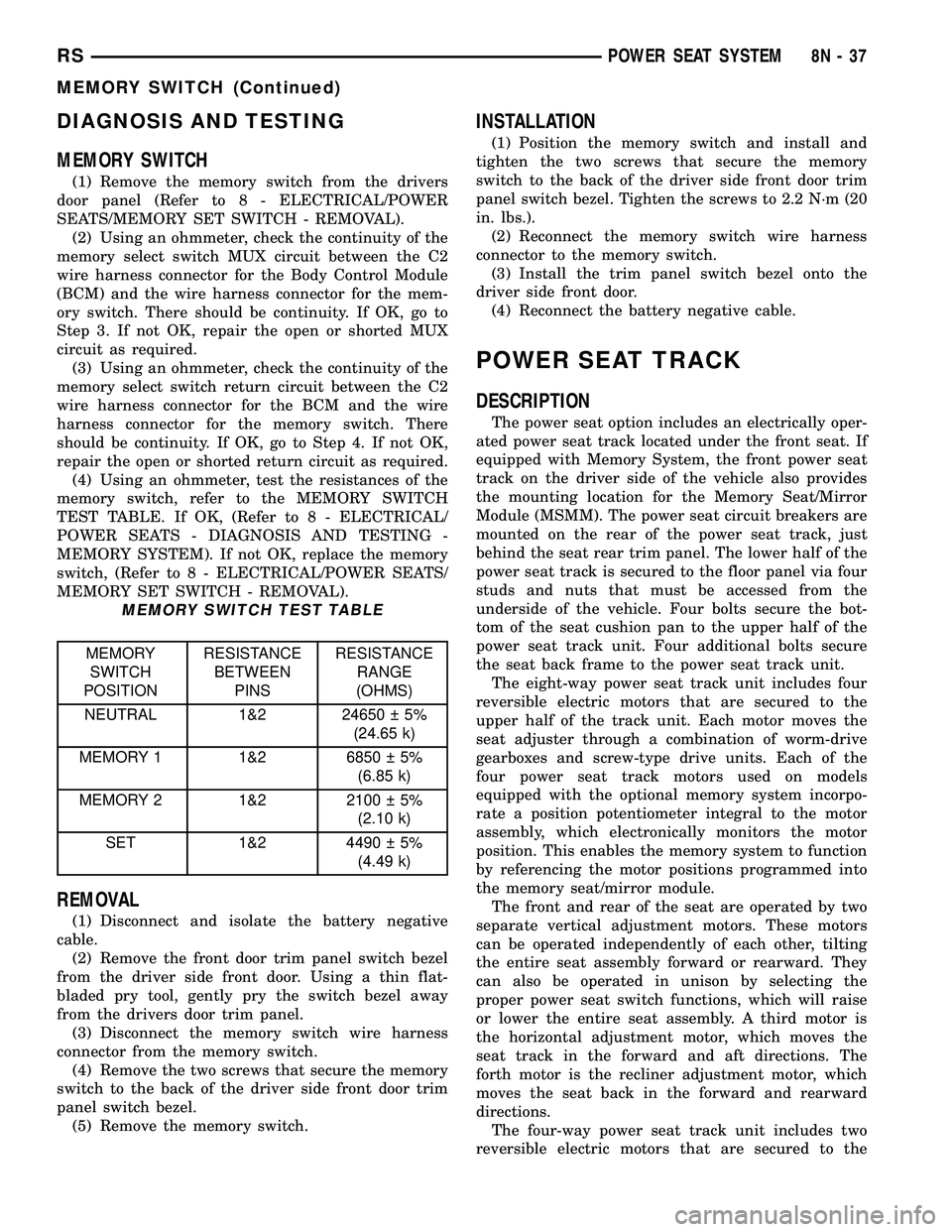

MEMORY SWITCH TEST TABLE

MEMORY

SWITCH

POSITIONRESISTANCE

BETWEEN

PINSRESISTANCE

RANGE

(OHMS)

NEUTRAL 1&2 24650 5%

(24.65 k)

MEMORY 1 1&2 6850 5%

(6.85 k)

MEMORY 2 1&2 2100 5%

(2.10 k)

SET 1&2 4490 5%

(4.49 k)

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel switch bezel

from the driver side front door. Using a thin flat-

bladed pry tool, gently pry the switch bezel away

from the drivers door trim panel.

(3) Disconnect the memory switch wire harness

connector from the memory switch.

(4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel.

(5) Remove the memory switch.

INSTALLATION

(1) Position the memory switch and install and

tighten the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel. Tighten the screws to 2.2 N´m (20

in. lbs.).

(2) Reconnect the memory switch wire harness

connector to the memory switch.

(3) Install the trim panel switch bezel onto the

driver side front door.

(4) Reconnect the battery negative cable.

POWER SEAT TRACK

DESCRIPTION

The power seat option includes an electrically oper-

ated power seat track located under the front seat. If

equipped with Memory System, the front power seat

track on the driver side of the vehicle also provides

the mounting location for the Memory Seat/Mirror

Module (MSMM). The power seat circuit breakers are

mounted on the rear of the power seat track, just

behind the seat rear trim panel. The lower half of the

power seat track is secured to the floor panel via four

studs and nuts that must be accessed from the

underside of the vehicle. Four bolts secure the bot-

tom of the seat cushion pan to the upper half of the

power seat track unit. Four additional bolts secure

the seat back frame to the power seat track unit.

The eight-way power seat track unit includes four

reversible electric motors that are secured to the

upper half of the track unit. Each motor moves the

seat adjuster through a combination of worm-drive

gearboxes and screw-type drive units. Each of the

four power seat track motors used on models

equipped with the optional memory system incorpo-

rate a position potentiometer integral to the motor

assembly, which electronically monitors the motor

position. This enables the memory system to function

by referencing the motor positions programmed into

the memory seat/mirror module.

The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward. They

can also be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. A third motor is

the horizontal adjustment motor, which moves the

seat track in the forward and aft directions. The

forth motor is the recliner adjustment motor, which

moves the seat back in the forward and rearward

directions.

The four-way power seat track unit includes two

reversible electric motors that are secured to the

RSPOWER SEAT SYSTEM8N-37

MEMORY SWITCH (Continued)

Page 463 of 2339

POWER SLIDING DOOR SYSTEM

TABLE OF CONTENTS

page page

POWER SLIDING DOOR SYSTEM

DESCRIPTION.........................40

OPERATION...........................41

DIAGNOSIS AND TESTING

POWER SLIDING DOOR SYSTEM........42

STANDARD PROCEDURE

POWER SLIDING DOOR LEARN CYCLE....48

PUSH-PIN GROMMET REPLACEMENT.....48

POWER SLIDING DOOR ADJUSTMENT....49

LATCH

DESCRIPTION.........................49

OPERATION...........................49

REMOVAL.............................49

INSTALLATION.........................50

SLIDING DOOR MOTOR

DESCRIPTION.........................51

OPERATION...........................51

REMOVAL.............................51

INSTALLATION.........................51

FULL OPEN SWITCH

DESCRIPTION.........................52

OPERATION...........................52

B-PILLAR SWITCH

DESCRIPTION.........................52OPERATION...........................52

REMOVAL.............................52

INSTALLATION.........................52

LOWER DRIVE UNIT

DESCRIPTION.........................53

OPERATION...........................53

REMOVAL.............................53

INSTALLATION.........................54

FLEX DRIVE

DESCRIPTION.........................55

OPERATION...........................55

REMOVAL.............................55

INSTALLATION.........................56

LOWER DRIVE UNIT TRACK & RACK

DESCRIPTION.........................57

OPERATION...........................57

REMOVAL.............................57

INSTALLATION.........................58

WIRING HARNESS

DESCRIPTION.........................59

OPERATION...........................59

REMOVAL.............................59

INSTALLATION.........................59

POWER SLIDING DOOR

SYSTEM

DESCRIPTION

Some vehicles are equipped with a power sliding

door system. Vehicles may be equipped with only a

right side power sliding door or a right and left side

power sliding doors. The components of the power

sliding door system are:

²Door motor assembly

²Latch assembly

²Sliding door control module

²Lower drive unit assembly

²Flex drive assembly

²Wire harness and track

²Lower drive unit track and rack assembly

²Full open switch

²B-pillar switch

²Overhead console switch

²Key fob switches (Fig. 1)

²Pawl switch

²Ratchet switch

²Child lockout and handle switchesEach power sliding door has its own door control

module, located in the center of the door behind the

door trim panel. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/DOOR CONTROL

MODULE - DESCRIPTION) The power sliding door

motor is located in the front portion of the door, on

the inner door panel sheet metal. The latch assembly

is located in the rear of the power sliding door, near

the body line. The lower drive unit is attached to the

lower door hinge. The flex drive assembly connects

the door motor to the lower drive unit. The wire har-

ness and track and the lower drive unit track are vis-

ible with the door open in the lower door sill area.

The power sliding door full open switch is located

under the lower drive unit and is part of the hold

open latch assembly. The pawl, ratchet, handle and

child lockout switches are all located on the power

sliding door latch assembly. The B-pillar switch is an

open and close command switch located on the inte-

rior B-pillar trim. The overhead console switch, is an

open and close command switch located in the vehi-

cle's overhead console.

Software technology has enabled the power sliding

door control module to detect resistance to door

8N - 40 POWER SLIDING DOOR SYSTEMRS

Page 471 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

Binding or sticking of components Establish location of binding and replace

necessary components

Squeaks, Noises and rattles Foreign material in door compartment Remove foreign material

Loose components Check and tighten loose components

Missing stabilizers, bumpers or

anti-rattle componentsCheck to ensure components are present.

Replace as necessary

Misadjusted stabilizers, bumpers or

anti-rattle componentsAdjust components as necessary

Poor door track lubrication Lubricate the front portions of the side door

tracks with9Door EaseT9or equivalent

STANDARD PROCEDURE

POWER SLIDING DOOR LEARN CYCLE

Any time a power sliding door component is removed,

replaced, door adjustment is performed or diagnostic

trouble codes are addressed and erased, a learn cycle

mustbe performed. This learn cycle enables the power

sliding door control module to learn or relearn its critical

information (travel limits, resistance to door travel, etc.)

which allows it to perform properly and safely. To per-

form a power sliding door learn cycle do the following:

(1)Obtain a DRB IIIt, or equivalent scan tool.

Connect the scan tool to the vehicle and check for

any power sliding door system stored diagnostic trou-

ble codes, erase any stored codes. Operate the system

and check to see if any trouble codes return. If any

diagnostic trouble codes return, diagnose, correct and

erase the codes before performing the learn cycle. If a

DRB IIIt, or equivalent scan tool is not available, the

learn cycle can be performed by opening and closing

the power sliding door using any of the normal open/

close command switches. Be certain to cycle the

power sliding door through a complete openand

close cycle or the procedure will not be complete.

(2) Using the scan tool, Go into Test Routine Menu

and select a power open command.

(3) Select a power close command.

(4) The power side door learn cycle is complete.

NOTE: If the power sliding door will not complete a

full cycle, a problem exists with the power sliding door

system. (Refer to 8 - ELECTRICAL/POWER DOORS -

DIAGNOSIS AND TESTING) for additional information.

PUSH-PIN GROMMET REPLACEMENT

Push-pin grommets are used to hold and isolate

the power sliding door motor to and from the door

inner panel. This secures the door motor assembly to

the inner panel and keeps the audible motor vibra-

tions to a minimum. If a push-pin grommet showssigns of wear, it must be replaced. Follow the proce-

dure below if replacement is necessary.

(1) Remove the door motor from the door inner

panel. (Refer to 8 - ELECTRICAL/POWER DOORS/

MOTOR - REMOVAL).

(2) Using a trim panel tool (special tool #C-4755)

or equivalent, remove the push-pin grommets from

the inner panel by pulling them straight out (Fig. 2).

(3) Install the replacement push-pin grommets in

the inner panel and install the door motor(Refer to 8

- ELECTRICAL/POWER DOORS/MOTOR - INSTAL-

LATION).

Fig. 2 SIDE DOOR MOTOR PUSH-PIN GROMMETS

1 - PUSH-PIN GROMMETS

2 - SIDE DOOR INNER PANEL

8N - 48 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

Page 484 of 2339

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................61

OPERATION...........................61

DIAGNOSIS AND TESTING

POWER WINDOWS....................61

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING

VENT WINDOW MOTOR................62

REMOVAL.............................62INSTALLATION.........................62

WINDOW MOTOR

REMOVAL.............................62

WINDOW SWITCH

DIAGNOSIS AND TESTING

WINDOW SWITCH....................63

REMOVAL.............................64

INSTALLATION.........................64

POWER WINDOWS

DESCRIPTION

The Power Window System is activated through

switches mounted on the driver and passenger door

panels.

OPERATION

Front door window lift motors use permanent type

magnets. The B+ and ground applied at the motor

terminal pins will cause the motor to rotate in one

direction. Reversing current through the motor ter-

minals will cause the motor to rotate in the opposite

direction.

The power window motors ground through the

master switch in the driver door by a black wire

attached to the left cowl panel. Refer to the appropri-

ate wiring information.

The power rear vent windows, if equipped, are

operated by switches mounted in the driver door

switch bezel. A separate switch is used for each win-

dow. Permanent magnet type motors connected to a

crank system are used to open and close the rear

vent windows. A battery positive and negative con-

nection to either of the two motor terminals will

cause the motor to rotate in one direction. Reversing

current through these same two connections will

cause the motor to rotate in the opposite direction.

DIAGNOSIS AND TESTING

POWER WINDOWS

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed withmotor test. Refer to the appropriate wiring informa-

tion.

(1) Remove front door trim panel and sound pad as

necessary to gain access to power window motor wire

connector, (Refer to 23 - BODY/DOOR - FRONT/

TRIM PANEL - REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the power window switch and bezel

assembly from the driver door. (Refer to 8 - ELEC-

TRICAL/POWER WINDOWS/POWER WINDOW

SWITCH - REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

RSPOWER WINDOWS8N-61

Page 485 of 2339

(3) Switch ignition ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 13 in door harness connector at the window

switch. Touch the test light probe to Pin 9 and then

to Pin 11.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check the

25 amp circuit breaker attached to the electrical dis-

tribution wiring bracket. If the circuit breaker is OK,

then check the 40 amp fuse (#28) in the Integrated

Power Module (IPM). If both components are OK,

then check for a broken wire.

VENT WINDOW MOTOR

DIAGNOSIS AND TESTING

VENT WINDOW MOTOR

If the power vent window motor is receiving proper

current and ground and does not operate proceed

with motor test. Refer to the appropriate wiring

information.

(1) Remove D-pillar trim panel necessary to gain

access to power vent window motor wire connector,

(Refer to 23 - BODY/INTERIOR/LEFT D-PILLAR

TRIM PANEL - REMOVAL) or (Refer to 23 - BODY/

INTERIOR/RIGHT D-PILLAR TRIM PANEL -

REMOVAL).

(2) Disconnect power vent window motor wire con-

nector from body harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window open or

closed. If window is all the way open or closed the

motor will grunt and the crank system will flex when

actuated in that one direction.

Reverse jumper probes at the motor connector ter-

minals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely open or closed, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that

crank system is not binding.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.(2) Remove D-pillar trim panel. (Refer to 23 -

BODY/INTERIOR/LEFT D-PILLAR TRIM PANEL -

REMOVAL) or (Refer to 23 - BODY/INTERIOR/

RIGHT D-PILLAR TRIM PANEL - REMOVAL).

(3) Disconnect wire connector from power vent

motor.

(4) Using a flat bladed tool, carefully lift the circu-

lar actuator link tab. Remove link from window ball

socket.

(5) Remove bolts holding power vent motor to

D-pillar (Fig. 1).

(6) Remove power vent motor.

INSTALLATION

(1) Obtain new vent window motor.

(2) Snap the actuator link socket onto the quarter

window ball socket. Using a soft rubber mallet, push

the circular link tab flush with link surface.

(3) Install bolts holding power vent motor to D-pil-

lar.

(4) Reconnect wire connector to power vent motor.

(5) Reconnect the battery negative cable.

(6) Cycle quarter window open/close to verify func-

tion.

(7) Install D-pillar trim panel.

WINDOW MOTOR

REMOVAL

The window motor is incorporated into the window

regulator assembly. If the window motor requires

replacement, the window regulator must be replaced.

(Refer to 23 - BODY/DOOR - FRONT/WINDOW

REGULATOR - REMOVAL).

Fig. 1 VENT WINDOW MOTOR

1 - VENT WINDOW MOTOR

2 - WIRE HARNESS CONNECTOR

3 - BOLT

4 - VENT WINDOW

8N - 62 POWER WINDOWSRS

POWER WINDOWS (Continued)

Page 489 of 2339

SEAT BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD

REMOVAL.............................40

INSTALLATION.........................40

SEAT BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR HVAC - LWB

REMOVAL.............................41

INSTALLATION.........................41

SEAT BELT & RETRACTOR - SECOND ROW -

LEFT OUTBOARD

REMOVAL.............................42INSTALLATION.........................42

SEAT BELT TENSIONER

DESCRIPTION.........................43

OPERATION...........................43

SEAT WEIGHT BLADDER & PRESSURE

SENSOR

DESCRIPTION.........................43

OPERATION...........................44

RESTRAINTS

DESCRIPTION

This vehicle is equipped with a Frontal Impact Air-

bag System, which utilizes the driver/passenger air-

bags, two front impact sensors, and seat belt

tensioners located in the front seat belt buckles. This

system is designed to protect occupants in the event

of a front impact collision. These airbags are all ser-

viceable parts. The tensioners are integral to the

front seat belt buckles. If these pyrotechnics are

deployed or defective, they must be replaced.

Vehicles equipped with the Side Impact Airbag

System utilize a curtain airbag, three side impact

sensors, and the Occupant Restraint Controller

(ORC) to determine if the airbag should be deployed.

Following a side impact event where the side airbag

was deployed, the headliner as well as the curtain

airbag must be replaced.

The occupant restraints include both active and

passive types. Active restraints are those which

require the vehicle occupants to take some action to

employ, such as fastening a seat belt; while passive

restraints require no action by the vehicle occupants

to be employed.

ACTIVE RESTRAINTS

The active restraints include:

²Front Seat Belts- Both front seating positions

are equipped with three-point seat belt systems

employing a lower B-pillar mounted inertia latch-

type retractor, height-adjustable upper B-pillar

mounted turning loops, a fixed lower seat belt anchor

secured to the lower B-pillar, and a traveling end-re-

lease buckle secured to the inboard side of the seat

cushion frame. The driver side front seat belt buckle

includes an integral Hall-effect seat belt switch that

detects whether the driver side front seat belt has

been fastened.²Rear Seat Belts- Both outboard rear second

and third seating positions are equipped with three-

point seat belt systems. The outboard seating posi-

tion belts employ a lower C or D-pillar mounted

inertia latch-type retractor, a fixed position upper C

or D-pillar mounted turning loop, and a fixed lower

seat belt anchor secured to the inboard side of the

seat cushion frame.

²Child Restraint Anchors- Also equipped in

this vehicle are two, fixed-position, child seat upper

tether anchors located on the lower seat cushion, in

the rear of the lower seat cushion. There is one

anchor integral to the back of the third row seat back

panel, one on each seat back panel. Two lower second

row anchors are also provided for each rear outboard

seating position. The lower anchors are integral to

the seat cushion frame and are accessed from the

front of the second row seat where the seat back

meets the seat cushion.

PASSIVE RESTRAINTS

The passive restraints available for this model

include the following:

²Dual Front Airbags- Multistage driver. front

passenger, and driver knee blocker airbags are avail-

able for this model. This airbag system is a passive,

inflatable, Supplemental Restraint System (SRS) and

vehicles with this equipment can be readily identified

by the ªSRS - AIRBAGº logo molded into the driver

airbag trim cover in the center of the steering wheel

and also into the passenger airbag door on the

instrument panel above the glove box. Vehicles with

the airbag system can also be identified by the airbag

indicator, which will illuminate in the instrument

cluster for about seven seconds as a bulb test each

time the ignition switch is turned to the ON position.

A pyrotechnic-type seat belt tensioner is integral to

the driver and passenger front seat belt buckle of all

models equipped with dual front airbags.

8O - 2 RESTRAINTSRS