glove box CHRYSLER VOYAGER 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2175 of 2339

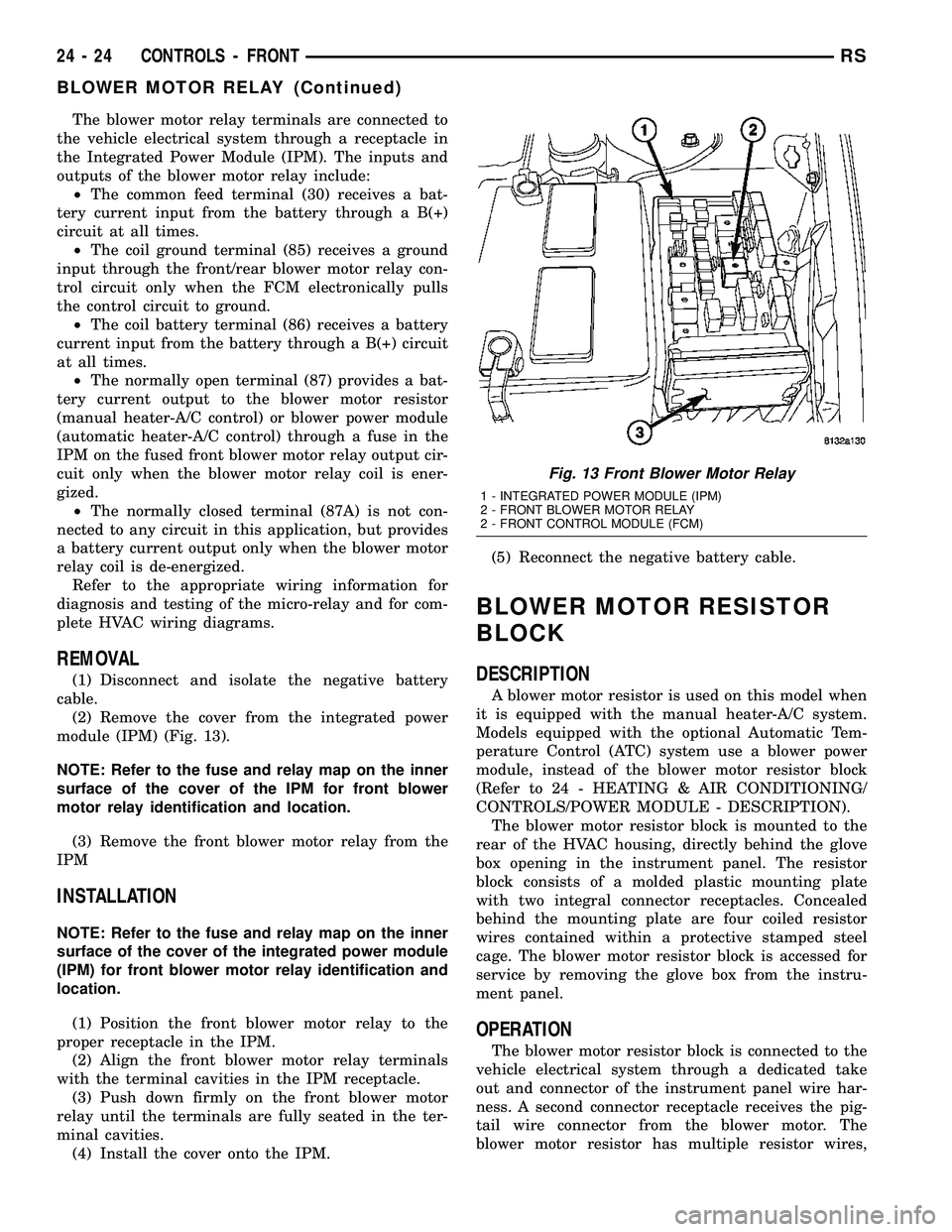

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Integrated Power Module (IPM). The inputs and

outputs of the blower motor relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused front blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the integrated power

module (IPM) (Fig. 13).

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the IPM for front blower

motor relay identification and location.

(3) Remove the front blower motor relay from the

IPM

INSTALLATION

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the integrated power module

(IPM) for front blower motor relay identification and

location.

(1) Position the front blower motor relay to the

proper receptacle in the IPM.

(2) Align the front blower motor relay terminals

with the terminal cavities in the IPM receptacle.

(3) Push down firmly on the front blower motor

relay until the terminals are fully seated in the ter-

minal cavities.

(4) Install the cover onto the IPM.(5) Reconnect the negative battery cable.

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

A blower motor resistor is used on this model when

it is equipped with the manual heater-A/C system.

Models equipped with the optional Automatic Tem-

perature Control (ATC) system use a blower power

module, instead of the blower motor resistor block

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/POWER MODULE - DESCRIPTION).

The blower motor resistor block is mounted to the

rear of the HVAC housing, directly behind the glove

box opening in the instrument panel. The resistor

block consists of a molded plastic mounting plate

with two integral connector receptacles. Concealed

behind the mounting plate are four coiled resistor

wires contained within a protective stamped steel

cage. The blower motor resistor block is accessed for

service by removing the glove box from the instru-

ment panel.

OPERATION

The blower motor resistor block is connected to the

vehicle electrical system through a dedicated take

out and connector of the instrument panel wire har-

ness. A second connector receptacle receives the pig-

tail wire connector from the blower motor. The

blower motor resistor has multiple resistor wires,

Fig. 13 Front Blower Motor Relay

1 - INTEGRATED POWER MODULE (IPM)

2 - FRONT BLOWER MOTOR RELAY

2 - FRONT CONTROL MODULE (FCM)

24 - 24 CONTROLS - FRONTRS

BLOWER MOTOR RELAY (Continued)

Page 2176 of 2339

each of which will reduce the current flow through

the blower motor to change the blower motor speed.

The blower motor switch in the manual heater-A/C

system directs the ground path for the blower motor

through the correct resistor wire to obtain the

selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through all of the resistor wires. Each higher speed

selected with the blower motor switch applies the

blower motor ground path through fewer of the resis-

tor wires, increasing the blower motor speed.

The blower motor resistor cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

DIAGNOSIS AND TESTING

FRONT BLOWER MOTOR RESISTOR BLOCK

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

from the blower motor resistor block.

(4) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor, blower motor or blower motorrelay as required. If not OK, replace the faulty

blower motor resistor block.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE BLOWER MOTOR RESISTOR

BLOCK MAY GET VERY HOT DURING NORMAL

OPERATION. IF THE BLOWER MOTOR WAS

TURNED ON PRIOR TO SERVICING THE BLOWER

MOTOR RESISTOR BLOCK, WAIT FIVE MINUTES

TO ALLOW THE BLOWER MOTOR RESISTORS TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

CAUTION: Do not operate the blower motor with the

blower motor resistor removed from the circuit.

Failure to take this precaution can result in vehicle

damage.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

from the blower motor resistor block (Fig. 14).

(4) Remove the two screws that secure the blower

motor resistor block to the HVAC housing.

(5) Remove the resistor block from the HVAC

housing.

INSTALLATION

(1) Position the blower motor resistor block into

the HVAC housing.

(2) Install the two screws that secure the blower

motor resistor block to the HVAC housing. Tighten

the screws to 2 N´m (17 in. lbs.).

(3) Connect the two wire connectors to the resistor

block.

RSCONTROLS - FRONT24-25

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2177 of 2339

(4) Install the glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION).

(5) Reconnect the battery negative cable.

EVAPORATOR TEMPERATURE

SENSOR

DESCRIPTION

The evaporator temperature sensor used for the

manual and automatic temperature control systems

on RS models is installed on the top of the HVAC

housing behind the instrument panel and measures

the air temperature downstream of the evaporator

(Fig. 15). The sensor is an electrical thermistor in a

plastic housing that is inserted into the HVAC hous-

ing. Two terminals within the molded plastic connec-

tor receptacle on the sensor connect it to the vehicle

electrical system through a take out and connector of

the HVAC wire harness.

The evaporator temperature sensor used for the

manual and automatic temperature control systems

on RG models is installed on the top of the expansion

valve in the right rear corner of the engine compart-

ment and measures the temperature of the evapora-

tor coils (Fig. 16). The sensor has a small probe that

is inserted in a small well in the body of the expan-

sion valve that is filled with a special silicone-based

thermal grease. A small molded plastic push-in

retainer secures the sensor to a threaded hole in the

top surface of the expansion valve. Two terminals

within a molded plastic connector receptacle on thesensor connect it to the vehicle electrical system

through a take out and connector of the HVAC wire

harness.

Fig. 14 Blower Motor Resistor Block - Typical

1 - BLOWER MOTOR RESISTOR

2 - INSTRUMENT PANEL WIRE HARNESS

3 - SCREW (2)

4 - GLOVE BOX OPENING REINFORCEMENT

5 - BLOWER MOTOR PIGTAIL WIRE HARNESS

6 - HVAC HOUSING

Fig. 15 Evaporator Temperature Sensor - RS Models

1 - EVAPORATOR TEMPERATURE SENSOR

2 - HVAC HOUSING

3 - A/C EVAPORATOR

Fig. 16 Evaporator Temperature Sensor - RG Models

1 - EVAPORATOR TEMPERATURE SENSOR

2 - A/C EXPANSION VALVE

24 - 26 CONTROLS - FRONTRS

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2181 of 2339

INSTALLATION

(1) Position the mode door actuator onto the HVAC

distribution housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the mode door linkage.

(2) Install the two screws that secure the mode

door actuator to the distribution housing. Tighten the

screws to 2 N´m (17 in. lbs.).

(3) Connect the wire harness connector to the

mode door actuator.

(4) Install the silencer under the driver side end of

the instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL SILENCER -

INSTALLATION).

(5) Reconnect the negative battery cable.

(6) Perform the A/C-heater control calibration pro-

cedure (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

POWER MODULE - BLOWER

MOTOR

DESCRIPTION

A blower motor power module is used on this

model when it is equipped with the optional Auto-

matic Temperature Control (ATC) system. Models

equipped with the standard manual heater-A/C sys-

tem use a blower motor resistor block, instead of the

blower motor power module (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - DESCRIPTION).

The blower motor power module is mounted to the

rear of the HVAC housing, directly behind the glove

box opening in the instrument panel. The module

consists of a molded plastic mounting plate with two

integral connector receptacles. Concealed behind the

mounting plate is the power module electronic cir-

cuitry and a large finned, heat sink. The blower

motor power module is accessed for service by remov-

ing the glove box from the instrument panel.

OPERATION

The blower motor power module is connected to the

vehicle electrical system through a dedicated lead

and connector from the instrument panel wire har-

ness. A second connector receptacle receives a wire

lead connector from the blower motor. The blower

motor power module allows the microprocessor-based

Automatic Temperature Control (ATC) heater-A/C

control module to calculate and provide infinitely

variable blower motor speeds based upon either man-

ual blower switch input or the ATC programming

using a Pulse Width Modulated (PWM) circuit strat-

egy. The PWM voltage is applied to a comparator cir-

cuit which compares the PWM signal voltage to the

blower motor feedback voltage. The resulting output

drives the power module circuitry, which adjusts the

voltage output received from the blower motor relay

to change or maintain the desired blower speed. The

blower motor power module is diagnosed using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE HEAT SINK FOR THE BLOWER

MOTOR POWER MODULE MAY GET VERY HOT

DURING NORMAL OPERATION. IF THE BLOWER

MOTOR WAS TURNED ON PRIOR TO SERVICING

THE BLOWER MOTOR POWER MODULE, WAIT

FIVE MINUTES TO ALLOW THE HEAT SINK TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

24 - 30 CONTROLS - FRONTRS

MODE DOOR ACTUATOR (Continued)

Page 2182 of 2339

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

from the blower motor power module (Fig. 21).

(4) Remove the two screws that secure the blower

motor power module to the HVAC housing.

(5) Remove the blower motor power module from

the HVAC housing.

INSTALLATION

(1) Position the blower motor power module into

the HVAC housing.

(2) Install the two screws that secure the blower

motor power module to the HVAC housing. Tighten

the screws to 2 N´m (17 in. lbs.).

(3) Connect the two wire connectors to the blower

motor power module.

(4) Install the glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION).

(5) Reconnect the negative battery cable.

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator is a reversible,

12-volt direct current (DC), servo motor. The single

recirculation door actuator is located on the passen-

ger side end of the HVAC housing, on the air inlet

housing. The recirculation door actuator is mechani-

cally connected to the recirculation-air door. The

recirculation door actuator is interchangeable with

the actuators for the blend-air door(s) and the mode

door. Each actuator is contained within an identical

black molded plastic housing with an integral wire

connector receptacle. Two integral mounting tabs

allow the actuator to be secured with two screws to

the air inlet housing. Each actuator also has an iden-

tical output shaft with splines that connects it to the

linkage that drives the recirculation-air door. The

recirculation door actuator does not require mechan-

ical indexing to the recirculation-air door, as it is

electronically calibrated by the A/C-heater control.

OPERATION

The recirculation door actuator is connected to the

heater-A/C control module through the vehicle elec-

trical system by a dedicated two-wire lead and con-

nector of the HVAC wire harness. The recirculation

door actuator can move the recirculation-air door in

two directions. When the A/C-heater control pulls the

voltage on one side of the motor connection high and

the other connection low, the recirculation-air door

will move in one direction.

When the A/C-heater control makes the voltage to

both connections high or both connections low, the

recirculation-air door stops and will not move. The

A/C-heater control uses a feedback signal positioning

system to monitor the operation and relative position

of the recirculation door actuator and the recircula-

tion-air door. The A/C-heater control learns the recir-

culation-air door stop positions during the calibration

procedure and will store a diagnostic trouble code

(DTC) for any problems it detects in the recirculation

door actuator circuits.

The recirculation door actuator is diagnosed using

a scan tool (Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING and to 24 -

HVAC Electrical Diagnostics for more information).

The recirculation door actuator cannot be adjusted

or repaired and, if faulty or damaged, it must be

replaced.

Fig. 21 Blower Motor Power Module - Typical

1 - POWER MODULE

2 - LOWER GLOVE BOX OPENING REINFORCEMENT

3 - HVAC HOUSING

RSCONTROLS - FRONT24-31

POWER MODULE - BLOWER MOTOR (Continued)

Page 2193 of 2339

DISTRIBUTION - FRONT

TABLE OF CONTENTS

page page

AIR FILTER

DESCRIPTION.........................42

REMOVAL.............................42

INSTALLATION.........................43

AIR OUTLETS

DESCRIPTION.........................43

REMOVAL

FRONT CENTER BEZEL OUTLETS........44

FRONT DEMISTER OUTLETS............44

INSTRUMENT PANEL OUTLETS..........45

INSTALLATION

FRONT CENTER BEZEL OUTLETS........45

FRONT DEMISTER OUTLETS............45

INSTRUMENT PANEL OUTLETS..........45

BLOWER MOTOR

DESCRIPTION.........................45

OPERATION...........................45

DIAGNOSIS AND TESTING

FRONT BLOWER MOTOR...............46

REMOVAL.............................48INSTALLATION.........................49

DEFROSTER DUCT

REMOVAL.............................49

INSTALLATION.........................50

FLOOR DISTRIBUTION DUCTS

REMOVAL.............................50

INSTALLATION.........................50

HVAC HOUSING

REMOVAL

REMOVAL...........................50

DISSASEMBLY.......................51

INSTALLATION

ASSEMBLY..........................53

INSTALLATION.......................53

INSTRUMENT PANEL DEMISTER DUCTS

REMOVAL.............................54

INSTALLATION.........................54

INSTRUMENT PANEL DUCTS

REMOVAL.............................55

INSTALLATION.........................55

AIR FILTER

DESCRIPTION

A dust and odor air filter is standard equipment on

models equipped with the three zone temperature

control systems (Fig. 1). The filter element is the

same size as the front air conditioner evaporator to

ensure ample filtering capacity. A removable door on

the bottom of the front HVAC housing below the

glove box provides easy access to the filter element

for replacement. The filter should be checked and

replaced at least once every 24,000 km (15,000 miles)

and checked if heater-A/C system performance seems

lower than expected.

REMOVAL

(1) Locate the air filter door on the bottom of the

lower HVAC housing just outboard of the passenger

side of the instrument panel center stack (Fig. 2).

(2) Slide the air filter door latch toward the rear of

the vehicle until it engages the opened stop on the

door.Fig. 1 Air Filter - LHD Shown, RHD Typical

1 - LOWER HVAC HOUSING

2 - LOWER EDGE OF INSTRUMENT PANEL

3 - AIR FILTER (IF EQUIPPED)

4 - CENTER FLOOR BRACKET COVER

5 - FILTER SEALING EDGES (IF EQUIPPED)

6 - AIR FILTER OPENING (IF EQUIPPED)

24 - 42 DISTRIBUTION - FRONTRS

Page 2305 of 2339

BENCH SEAT RISER - 50/50 SPLIT -INSTALLATION ...................... 23-145

BENCH SEAT RISER - 50/50 SPLIT - REMOVAL ......................... 23-145

BENCH SEAT RISER - SECOND ROW - INSTALLATION ...................... 23-145

BENCH SEAT RISER - SECOND ROW - REMOVAL ......................... 23-145

BENCH SEAT RISER - THIRD ROW - INSTALLATION ...................... 23-145

BENCH SEAT RISER - THIRD ROW - REMOVAL ......................... 23-145

BENCH SEAT TRACK - INSTALLATION . . . 23-148

BENCH SEAT TRACK - REMOVAL .......23-148

BEZEL - INSTALLATION, CLUSTER .......23-65

BEZEL - INSTALLATION, INSTRUMENT PANEL CENTER ...................... 23-72

BEZEL - INSTALLATION, SLIDING DOOR STOP BUMPER ...................... 23-25

BEZEL - REMOVAL, CLUSTER ...........23-65

BEZEL - REMOVAL, INSTRUMENT PANEL CENTER ............................ 23-71

BEZEL - REMOVAL, SLIDING DOOR STOP BUMPER ...................... 23-25

BEZEL OUTLETS, INSTALLATION - FRONT CENTER ...................... 24-45

BEZEL OUTLETS, REMOVAL - FRONT CENTER ............................ 24-44

BIN - INSTALLATION, UNDER SEAT STORAGE .......................... 23-149

BIN - REMOVAL, UNDER SEAT STORAGE . 23-149

BIN GUIDE - INSTALLATION, UNDER SEAT STORAGE ..................... 23-150

BIN GUIDE - REMOVAL, UNDER SEAT STORAGE .......................... 23-150

BIN LOCK/LATCH - INSTALLATION, UNDER SEAT STORAGE ...............23-150

BIN LOCK/LATCH - REMOVAL, UNDER SEAT STORAGE ..................... 23-150

BLADDER & PRESSURE SENSOR - DESCRIPTION, SEAT WEIGHT ...........8O-43

BLADDER & PRESSURE SENSOR - OPERATION, SEAT WEIGHT ............8O-44

BLADES - CLEANING, WIPER ...........8R-13

BLADES - INSTALLATION, WIPER ........8R-13

BLADES - REMOVAL, WIPER ...........8R-13

BLEEDING - STANDARD PROCEDURE, ANTILOCK BRAKE SYSTEM ..............5-90

BLEEDING - STANDARD PROCEDURE, BASE BRAKE ..........................5-8

BLEEDING - STANDARD PROCEDURE, MASTER CYLINDER ................... 5-36

BLEND DOOR ACTUATOR - DESCRIPTION .................. 24-22,24-34

BLEND DOOR ACTUATOR - INSTALLATION .................. 24-22,24-35

BLEND DOOR ACTUATOR - OPERATION . . 24-22, 24-35

BLEND DOOR ACTUATOR - REMOVAL ....24-22,

24-35

BLOCK - CLEANING, ENGINE .......9-115,9-37

BLOCK - DESCRIPTION, BLOWER MOTOR RESISTOR ..............24-24,24-37

BLOCK - DESCRIPTION, ENGINE .....9-115,9-36

BLOCK - DESCRIPTION, NON-ABS JUNCTION ........................... 5-33

BLOCK - INSPECTION, ENGINE ......9-115,9-37

BLOCK - INSTALLATION, NON-ABS JUNCTION ........................... 5-34

BLOCK - OPERATION, BLOWER MOTOR RESISTOR ..................... 24-24,24-37

BLOCK - OPERATION, NON-ABS JUNCTION ........................... 5-33

BLOCK - REMOVAL, NON-ABS JUNCTION . . 5-34

BLOCK, DIAGNOSIS AND TESTING - FRONT BLOWER MOTOR RESISTOR ......24-25

BLOCK, DIAGNOSIS AND TESTING - REAR BLOWER MOTOR RESISTOR ......24-38

BLOCK HEATER - DESCRIPTION, ENGINE . . . 7-20

BLOCK HEATER - INSTALLATION, ENGINE ............................. 7-21

BLOCK HEATER - OPERATION, ENGINE ....7-20

BLOCK HEATER - REMOVAL, ENGINE ......7-21

BLOCK HEATER TESTING - DIAGNOSIS AND TESTING, ENGINE .................7-21

BLOCKER AIRBAG - DESCRIPTION, KNEE . 8O-22

BLOCKER AIRBAG - INSTALLATION, KNEE .............................. 8O-23BLOCKER AIRBAG - OPERATION, KNEE . . . 8O-22

BLOCKER AIRBAG - REMOVAL, KNEE

....8O-23

BLOCKER- INFLATABLE KNEE - INSTALLATION ....................... 23-75

BLOCKER- INFLATABLE KNEE - REMOVAL .......................... 23-75

BLOCKER LATCH - INSTALLATION, FUEL FILL DOOR ......................... 23-53

BLOCKER LATCH - REMOVAL, FUEL FILL DOOR ............................. 23-53

BLOCKER LATCH STRIKER - INSTALLATION, FUEL FILL DOOR ........23-53

BLOCKER LATCH STRIKER - REMOVAL, FUEL FILL DOOR ..................... 23-53

BLOCKER LOCKOUT LINK - INSTALLATION, FUEL FILL DOOR ........23-54

BLOCKER LOCKOUT LINK - REMOVAL, FUEL FILL DOOR ..................... 23-54

BLOWER MOTOR - DESCRIPTION . . 24-45,24-57

BLOWER MOTOR - DESCRIPTION, POWER MODULE .................... 24-30

BLOWER MOTOR - DESCRIPTION, POWER MODULE - REAR ..............24-40

BLOWER MOTOR - INSTALLATION, POWER MODULE .................... 24-31

BLOWER MOTOR - INSTALLATION, POWER MODULE - REAR ..............24-41

BLOWER MOTOR - OPERATION ....24-45,24-57

BLOWER MOTOR - OPERATION, POWER MODULE ........................... 24-30

BLOWER MOTOR - OPERATION, POWER MODULE - REAR ..................... 24-40

BLOWER MOTOR - REMOVAL, POWER MODULE ........................... 24-30

BLOWER MOTOR - REMOVAL, POWER MODULE - REAR ..................... 24-41

BLOWER MOTOR, DIAGNOSIS AND TESTING - FRONT .................... 24-46

BLOWER MOTOR, DIAGNOSIS AND TESTING - REAR ..................... 24-58

BLOWER MOTOR RELAY - DESCRIPTION . 24-23, 24-36

BLOWER MOTOR RELAY - INSTALLATION .................. 24-24,24-37

BLOWER MOTOR RELAY - OPERATION . . . 24-23, 24-36

BLOWER MOTOR RELAY - REMOVAL ....24-24,

24-37

BLOWER MOTOR RESISTOR BLOCK - DESCRIPTION .................. 24-24,24-37

BLOWER MOTOR RESISTOR BLOCK - OPERATION .................... 24-24,24-37

BLOWER MOTOR RESISTOR BLOCK, DIAGNOSIS AND TESTING - FRONT ......24-25

BLOWER MOTOR RESISTOR BLOCK, DIAGNOSIS AND TESTING - REAR .......24-38

BODY - ASSEMBLY, VALVE ......21-139,21-291

BODY - DESCRIPTION, THROTTLE .......14-39

BODY - DESCRIPTION, VALVE ....21-132,21-283

BODY - DISASSEMBLY, VALVE . . . 21-135,21-286

BODY - INSTALLATION, THROTTLE .......14-40

BODY - INSTALLATION, VALVE . . . 21-144,21-295

BODY - OPERATION, THROTTLE .........14-39

BODY - OPERATION, VALVE .....21-132,21-283

BODY - REMOVAL, THROTTLE ..........14-40

BODY - REMOVAL, VALVE .......21-133,21-284

BODY AND CABLE - DESCRIPTION, ANTENNA ........................... 8A-7

BODY AND CABLE - OPERATION, ANTENNA ........................... 8A-7

BODY AND CABLE, DIAGNOSIS AND TESTING - ANTENNA ................... 8A-8

BODY CONTROL MODULE - DESCRIPTION ........................ 8E-2

BODY CONTROL MODULE - INSTALLATION ........................ 8E-4

BODY CONTROL MODULE - OPERATION . . . 8E-3

BODY CONTROL MODULE - REMOVAL .....8E-4

BODY LUBRICATION, SPECIFICATIONS ....23-12

BODY OPENING DIMENSIONS - SPECIFICATIONS .................... 23-180

BODY PANEL REPAIR - STANDARD PROCEDURE, PLASTIC .................23-3

BODY SEALING LOCATIONS - FOLD-IN- FLOOR ONLY - SPECIFICATIONS ........23-209

BODY SEALING LOCATIONS - SPECIFICATIONS .................... 23-183

BODY SIDE - INSTALLATION ............23-44BODY SIDE - REMOVAL

...............23-44

BODY SIDE MOLDINGS - INSTALLATION . . 23-46

BODY SIDE MOLDINGS - REMOVAL ......23-45

BODY, SPECIAL TOOLS ................23-13

BOLSTER - INSTALLATION, QUARTER TRIM .............................. 23-95

BOLSTER - REMOVAL, QUARTER TRIM . . . 23-95

BOOSTER - DESCRIPTION, POWER BRAKE .............................. 5-45

BOOSTER - DIAGNOSIS AND TESTING, POWER BRAKE ....................... 5-46

BOOSTER - OPERATION, POWER BRAKE . . . 5-46

BOOT - INNER - INSTALLATION, CV ........3-7

BOOT - INNER - REMOVAL, CV ...........3-6

BOOT - OUTER - INSTALLATION, CV ......3-11

BOOT - OUTER - REMOVAL, CV ..........3-10

BORE FITTING - STANDARD PROCEDURE, PISTON TO CYLINDER ......9-44

BORE HONING - STANDARD PROCEDURE, CYLINDER ...........9-115,9-36

BOTTOM OF SEAT CUSHION PAN PANEL-THIRD ROW - FOLD-IN-FLOOR

- INSTALLATION .................... 23-152

BOTTOM OF SEAT CUSHION PAN PANEL-THIRD ROW - FOLD-IN-FLOOR

- REMOVAL ........................ 23-152

BOX - INSTALLATION, GLOVE ...........23-66

BOX - REMOVAL, GLOVE ..............23-66

BOX LAMP SWITCH - INSTALLATION, GLOVE ............................. 8L-22

BOX LAMP SWITCH - REMOVAL, GLOVE . . 8L-22

BOX LATCH - INSTALLATION, GLOVE .....23-66

BOX LATCH - REMOVAL, GLOVE .........23-66

BOX LATCH STRIKER - INSTALLATION, GLOVE ............................. 23-66

BOX LATCH STRIKER - REMOVAL, GLOVE ............................. 23-66

B-PILLAR - INSTALLATION, A-PILLAR- HEADER, OR ........................ 23-17

B-PILLAR - REMOVAL, A-PILLAR- HEADER, OR ........................ 23-17

B-PILLAR LOWER TRIM - INSTALLATION . . 23-80

B-PILLAR LOWER TRIM - REMOVAL .....23-79

B-PILLAR SWITCH - DESCRIPTION ......8N-52

B-PILLAR SWITCH - INSTALLATION ......8N-52

B-PILLAR SWITCH - OPERATION ........8N-52

B-PILLAR SWITCH - REMOVAL .........8N-52

B-PILLAR UPPER TRIM - INSTALLATION . . 23-80

B-PILLAR UPPER TRIM - REMOVAL ......23-80

BRACKET - DESCRIPTION, TRANSVERSE . . 8N-19

BRACKET - INSTALLATION, TRANSVERSE . 8N-19

BRACKET - OPERATION, TRANSVERSE . . . 8N-19

BRACKET - REMOVAL, TRANSVERSE .....8N-19

BRACKET, 2.4L ENGINE - A/C COMPRESSOR MOUNTING ........24-74,24-75

BRAKE - DESCRIPTION, CONTROLLER ANTILOCK ........................... 8E-4

BRAKE - INSTALLATION, CONTROLLER ANTILOCK ........................... 8E-6

BRAKE - INSTALLATION, LEVER - PARKING ............................ 5-76

BRAKE - INSTALLATION, SHOES - PARKING ............................ 5-84

BRAKE - INSTALLATION, SUPPORT PLATE - DRUM ....................... 5-61

BRAKE - OPERATION, CONTROLLER ANTILOCK ........................... 8E-5

BRAKE - REMOVAL, CONTROLLER ANTILOCK ........................... 8E-5

BRAKE - REMOVAL, LEVER - PARKING ....5-75

BRAKE - REMOVAL, SHOES - PARKING ....5-78

BRAKE - REMOVAL, SUPPORT PLATE - DRUM .............................. 5-61

BRAKE AUTOMATIC ADJUSTER - DIAGNOSIS AND TESTING, DRUM ........5-14

BRAKE AUTOMATIC ADJUSTER TENSION RELEASE - STANDARD PROCEDURE,

PARKING ............................ 5-63

BRAKE AUTOMATIC ADJUSTER TENSION RESET - STANDARD PROCEDURE,

PARKING ............................ 5-64

BRAKE BLEEDING - STANDARD PROCEDURE, BASE .....................5-8

BRAKE BOOSTER - DESCRIPTION, POWER ............................. 5-45

BRAKE BOOSTER - DIAGNOSIS AND TESTING, POWER ..................... 5-46

BRAKE BOOSTER - OPERATION, POWER . . . 5-46

4 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2316 of 2339

FRONT WIPER/WASHER SWITCH -DIAGNOSIS AND TESTING ..............8R-2

FRONT-WHEEL-DRIVE - INSTALLATION ....2-36

FRONT-WHEEL-DRIVE - REMOVAL ........2-36

FUEL CORRECTION OR ADAPTIVE MEMORIES, OPERATION ...............14-24

FUEL DELIVERY SYSTEM - DIAGNOSIS AND TESTING ........................ 14-2

FUEL DOSING PUMP - DESCRIPTION ....24-117

FUEL DOSING PUMP - INSTALLATION . . . 24-117

FUEL DOSING PUMP - OPERATION .....24-117

FUEL DOSING PUMP - REMOVAL .......24-117

FUEL ENGINE OIL - DESCRIPTION, FLEXIBLE .............................0-3

FUEL FILL DOOR - INSTALLATION .......23-52

FUEL FILL DOOR - REMOVAL ...........23-52

FUEL FILL DOOR BLOCKER LATCH - INSTALLATION ....................... 23-53

FUEL FILL DOOR BLOCKER LATCH - REMOVAL .......................... 23-53

FUEL FILL DOOR BLOCKER LATCH STRIKER - INSTALLATION ..............23-53

FUEL FILL DOOR BLOCKER LATCH STRIKER - REMOVAL .................23-53

FUEL FILL DOOR BLOCKER LOCKOUT LINK - INSTALLATION .................23-54

FUEL FILL DOOR BLOCKER LOCKOUT LINK - REMOVAL ..................... 23-54

FUEL FILLER CAP - DESCRIPTION .......25-13

FUEL FILLER CAP - OPERATION .........25-13

FUEL INJECTOR - DESCRIPTION .........14-30

FUEL INJECTOR - OPERATION ..........14-31

FUEL LEVEL SENDING UNIT / SENSOR - DESCRIPTION ........................ 14-5

FUEL LEVEL SENDING UNIT / SENSOR - INSTALLATION ........................ 14-6

FUEL LEVEL SENDING UNIT / SENSOR - OPERATION .......................... 14-5

FUEL LEVEL SENDING UNIT / SENSOR - REMOVAL ........................... 14-5

FUEL LINES/HOSES AND CLAMPS - DESCRIPTION ........................ 14-7

FUEL PRESSURE GAUGE - STANDARD PROCEDURE ......................... 14-3

FUEL PRESSURE REGULATOR - INSTALLATION ........................ 14-7

FUEL PRESSURE REGULATOR - OPERATION .......................... 14-7

FUEL PRESSURE REGULATOR - REMOVAL ........................... 14-7

FUEL PUMP - DESCRIPTION .............14-8

FUEL PUMP - OPERATION ..............14-8

FUEL PUMP MODULE - DESCRIPTION .....14-8

FUEL PUMP MODULE - OPERATION .......14-9

FUEL PUMP RELAY - DESCRIPTION ......14-32

FUEL PUMP RELAY - OPERATION ........14-32

FUEL REQUIREMENTS - DESCRIPTION ......0-4

FUEL REQUIREMENTS - DIESEL ENGINE - DESCRIPTION ........................0-6

FUEL, SPECIAL TOOLS ............14-27,14-4

FUEL SYSTEM PRESSURE RELEASE PROCEDURE - STANDARD

PROCEDURE ......................... 14-2

FUEL SYSTEM PRESSURE, SPECIFICATIONS ...................... 14-4

FUEL TANK - DESCRIPTION ............14-12

FUEL TANK - OPERATION ..............14-12

FUEL TANK - STANDARD PROCEDURE, DRAINING ........................... 14-2

FUEL TANK FILLER TUBE - INSTALLATION ....................... 14-17

FUEL TANK FILLER TUBE - REMOVAL ....14-16

FULL OPEN SWITCH - DESCRIPTION ....8N-11,

8N-52

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD ...........8W-97-3

FUSE - OPERATION, IOD .............8W-97-3

FUSES POWERING SEVERAL LOADS - STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON ......8W-01-10

FWD - FOLD-IN-FLOOR SEATING - INSTALLATION ........................ 2-45

FWD - FOLD-IN-FLOOR SEATING - REMOVAL ........................... 2-45

FWD - INSTALLATION ..................2-45

FWD - INSTALLATION, REAR WHEEL SPEED SENSOR ....................... 5-93

FWD - INSTALLATION, SPRING ...........2-42FWD - REMOVAL

...................... 2-45

FWD - REMOVAL, REAR WHEEL SPEED SENSOR ............................ 5-93

FWD - REMOVAL, SPRING ..............2-40

GALLERY PLUGS - STANDARD PROCEDURE, ENGINE CORE AND OIL . 9-10,9-88

GAP AND FLUSH MEASUREMENTS - SPECIFICATIONS .................... 23-177

GAP, SPECIFICATIONS - WHEEL SPEED SENSOR AIR ......................... 5-91

GAS STRUT - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-139

GAS STRUT - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-138

GASKET - DIAGNOSIS AND TESTING, CYLINDER HEAD ................. 9-102,9-25

GASKET SURFACE PREPARATION - STANDARD PROCEDURE, ENGINE ....9-11,9-87

GASKETS AND SEALERS, STANDARD PROCEDURE - FORM-IN-PLACE ......9-11,9-86

GAUGE - STANDARD PROCEDURE, FUEL PRESSURE .......................... 14-3

GEAR - DESCRIPTION .................19-26

GEAR - INSTALLATION, LHD ............19-31

GEAR - INSTALLATION, RHD ............19-33

GEAR & LINK ROD - DESCRIPTION, LIFT . 8N-16

GEAR & LINK ROD - INSTALLATION, LIFT ............................... 8N-17

GEAR & LINK ROD - OPERATION, LIFT . . . 8N-16

GEAR & LINK ROD - REMOVAL, LIFT .....8N-16

GEAR - OPERATION .................... 19-26

GEAR - REMOVAL, LHD ...............19-26

GEAR - REMOVAL, RHD ...............19-29

GEAR SHIFT CABLE - INSTALLATION ....21-234

GEAR SHIFT CABLE - REMOVAL . . . 21-233,21-84

GEAR, SPECIAL TOOLS - POWER STEERING .......................... 19-34

GEARSHIFT CABLE ADJUSTMENT, ADJUSTMENTS ..................... 21-235

GEARTRAIN - DESCRIPTION, PLANETARY .................. 21-112,21-263

GEARTRAIN - OPERATION, PLANETARY . 21-112, 21-263

GENERAL - WARNINGS .............8W-01-7

GENERAL DIAGNOSIS - DIAGNOSIS AND TESTING, 4XTE TRANSAXLE .......21-149,21-5

GENERATOR - DESCRIPTION ...........8F-24

GENERATOR - OPERATION .............8F-24

GENERATOR DECOUPLER PULLEY - DESCRIPTION ....................... 8F-28

GENERATOR DECOUPLER PULLEY - DIAGNOSIS AND TESTING ..............8F-28

GENERATOR DECOUPLER PULLEY - INSTALLATION ....................... 8F-29

GENERATOR DECOUPLER PULLEY - OPERATION ......................... 8F-28

GENERATOR DECOUPLER PULLEY - REMOVAL .......................... 8F-29

GENERATOR, SPECIFICATIONS ..........8F-23

GLASS - DESCRIPTION, HEATED .........8G-1

GLASS - INSTALLATION, DOOR .........23-17

GLASS - INSTALLATION, LIFTGATE ......23-164

GLASS - INSTALLATION, SLIDING DOOR . 23-163

GLASS - OPERATION, HEATED ...........8G-2

GLASS - REMOVAL, DOOR .............23-16

GLASS - REMOVAL, LIFTGATE .........23-164

GLASS - REMOVAL, SLIDING DOOR .....23-163

GLASS INTEGRAL ANTENNA - EXPORT - DESCRIPTION, QUARTER ..............8A-13

GLASS INTEGRAL ANTENNA - EXPORT - OPERATION, QUARTER ................8A-13

GLASS INTEGRAL ANTENNA, EXPORT - QUARTER .......................... 8A-13

GLASS PANEL - INSTALLATION ........23-173

GLASS PANEL - REMOVAL ............23-173

GLASS PANEL ADJUSTMENT, ADJUSTMENTS - SUNROOF ...........23-173

GLASS RUN WEATHERSTRIP - INSTALLATION, FRONT DOOR ..........23-166

GLASS RUN WEATHERSTRIP - REMOVAL, FRONT DOOR .............23-166

GLASS-OUTSIDE REARVIEW MIRROR - INSTALLATION ....................... 23-61

GLASS-OUTSIDE REARVIEW MIRROR - REMOVAL .......................... 23-61

GLOVE BOX - INSTALLATION ...........23-66

GLOVE BOX - REMOVAL ...............23-66GLOVE BOX LAMP SWITCH -

INSTALLATION ....................... 8L-22

GLOVE BOX LAMP SWITCH - REMOVAL . . 8L-22

GLOVE BOX LATCH - INSTALLATION .....23-66

GLOVE BOX LATCH - REMOVAL .........23-66

GLOVE BOX LATCH STRIKER - INSTALLATION ....................... 23-66

GLOVE BOX LATCH STRIKER - REMOVAL . 23-66

GRID REPAIR PROCEDURE, STANDARD PROCEDURE ......................... 8G-5

GRILLE - DESCRIPTION ...............23-55

GRILLE - INSTALLATION ...............23-55

GRILLE - INSTALLATION, COWL .........23-50

GRILLE - REMOVAL ..................23-55

GRILLE - REMOVAL, COWL ............23-50

GROCERY BAG RETAINER - INSTALLATION, PLASTIC ..............23-149

GROCERY BAG RETAINER - REMOVAL, PLASTIC .......................... 23-149

GROMMET REPLACEMENT, STANDARD PROCEDURE - PUSH-PIN ..............8N-48

GROUND - OPERATION, PCM ...........8E-14

GROUND - STANDARD PROCEDURE, TESTING FOR A SHORT TO ..........8W-01-9

GROUND AND SPLICE INFORMATION - DESCRIPTION, CONNECTOR ..........8W-01-7

GROUND ON FUSES POWERING SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO.............................8W -01-10

GUIDE - INSTALLATION, UNDER SEAT STORAGE BIN ...................... 23-150

GUIDE - REMOVAL, UNDER SEAT STORAGE BIN ...................... 23-150

GUIDE PIN BUSHINGS (CONTINENTAL TEVES BRAKES) - ASSEMBLY, CALIPER ....5-25

GUIDE PIN BUSHINGS (CONTINENTAL TEVES BRAKES) - DISASSEMBLY,

CALIPER ............................ 5-24

GUIDE PINS (TRW BRAKES) - INSTALLATION, DISC BRAKE CALIPER .....5-32

GUIDE PINS (TRW BRAKES) - REMOVAL, DISC BRAKE CALIPER .................. 5-31

HALF SHAFT - DIAGNOSIS AND TESTING . . . 3-1

HALF SHAFT - FRONT - DESCRIPTION ......3-1

HALF SHAFT - FRONT - INSTALLATION .....3-4

HALF SHAFT - FRONT - REMOVAL .........3-2

HALF SHAFT - FRONT - SPECIFICATIONS ....3-6

HANDLE - INSTALLATION, ASSIST .......23-79

HANDLE - INSTALLATION, EXTERIOR ....23-22,

23-40

HANDLE - INSTALLATION, INSIDE LATCH . . 23-34

HANDLE - INSTALLATION, OUTSIDE ......23-36

HANDLE - INSTALLATION, RECLINER ....23-108

HANDLE - REMOVAL, ASSIST ...........23-79

HANDLE - REMOVAL, EXTERIOR . . . 23-21,23-40

HANDLE - REMOVAL, INSIDE LATCH .....23-34

HANDLE - REMOVAL, OUTSIDE .........23-35

HANDLE - REMOVAL, RECLINER .......23-108

HANDLE ACTUATOR - INSTALLATION, INSIDE ............................. 23-27

HANDLE ACTUATOR - REMOVAL, INSIDE . . 23-27

HANDLE CABLE - INSTALLATION, INSIDE . . 23-38

HANDLE CABLE - INSTALLATION, OUTSIDE ........................... 23-37

HANDLE CABLE - REMOVAL, INSIDE .....23-37

HANDLE CABLE - REMOVAL, OUTSIDE ....23-37

HANDLE SWITCH - DESCRIPTION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - INSTALLATION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - OPERATION, EXTERIOR .......................... 8N-10

HANDLE SWITCH - REMOVAL, EXTERIOR . 8N-10

HANDLING AIRBAGS - STANDARD PROCEDURE ......................... 8O-6

HANDLING TUBING AND FITTINGS, STANDARD PROCEDURE ...............24-69

HANDS FREE MODULE - INSTALLATION ....8T-3

HANDS FREE MODULE - REMOVAL .......8T-3

HARNESS - DESCRIPTION, WIRING ......8N-59

HARNESS - DIAGNOSIS AND TESTING, WIRING ..........................8W -01-7

HARNESS - INSTALLATION, WIRING .....8N-59

HARNESS - OPERATION, WIRING ........8N-59

HARNESS - REMOVAL, WIRING .........8N-59

HCU (HYDRAULIC CONTROL UNIT) - DESCRIPTION ....................... 5-100

RS INDEX15

Description Group-Page Description Group-Page Description Group-Page

Page 2319 of 2339

INTERMEDIATE - INSTALLATION, CABLE- PARKING BRAKE ..................... 5-69

INTERMEDIATE - REMOVAL, CABLE - PARKING BRAKE ...................... 5-69

INTERNATIONAL SYMBOLS - DESCRIPTION .........................0-1

INTRODUCTION - DIAGNOSIS AND TESTING, ENGINE DIAGNOSIS ........9-3,9-78

IOD FUSE - DESCRIPTION ...........8W-97-3

IOD FUSE - OPERATION .............8W-97-3

JOINT - DESCRIPTION, LOWER BALL ......2-10

JOINT - DIAGNOSIS AND TESTING, LOWER BALL ........................ 2-10

JOINT - OPERATION, LOWER BALL .......2-10

JOINT MOLDING - INSTALLATION, ROOF . . 23-60

JOINT MOLDING - REMOVAL, ROOF ......23-60

JOUNCE BUMPER - DESCRIPTION ........2-35

JOUNCE BUMPER - OPERATION ..........2-35

JUMP STARTING - STANDARD PROCEDURE ......................... 0-25

JUNCTION BLOCK - DESCRIPTION, NON-ABS ............................ 5-33

JUNCTION BLOCK - INSTALLATION, NON-ABS ............................ 5-34

JUNCTION BLOCK - OPERATION, NON-ABS ............................ 5-33

JUNCTION BLOCK - REMOVAL, NON-ABS . . 5-34

KEY - DESCRIPTION, TRANSPONDER .....8Q-6

KEY - OPERATION, TRANSPONDER .......8Q-6

KEY LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE ........23-90

KEY LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE ...........23-90

KEY REMOTE ENTRY MODULE - DESCRIPTION, SENTRY ................8Q-3

KEY REMOTE ENTRY MODULE - DIAGNOSIS AND TESTING, SENTRY .......8Q-5

KEY REMOTE ENTRY MODULE - INSTALLATION, SENTRY ................8Q-6

KEY REMOTE ENTRY MODULE - OPERATION, SENTRY .................. 8Q-4

KEY REMOTE ENTRY MODULE - REMOVAL, SENTRY ................... 8Q-6

KEY REMOTE ENTRY SYSTEM - DIAGNOSIS AND TESTING, SENTRY .......8Q-3

KEYLESS ENTRY TRANSMITTER, DIAGNOSIS AND TESTING .............8N-24

KEYLESS ENTRY TRANSMITTER PROGRAMMING - STANDARD

PROCEDURE, REMOTE ................8N-24

KEY/LOCK CYLINDER - DESCRIPTION ....19-20

KEY/LOCK CYLINDER - INSTALLATION ....19-20

KEY/LOCK CYLINDER - OPERATION ......19-20

KEY/LOCK CYLINDER - REMOVAL .......19-20

KNEE - INSTALLATION, BLOCKER- INFLATABLE ......................... 23-75

KNEE - REMOVAL, BLOCKER- INFLATABLE ......................... 23-75

KNEE BLOCKER AIRBAG - DESCRIPTION . . 8O-22

KNEE BLOCKER AIRBAG - INSTALLATION . 8O-23

KNEE BLOCKER AIRBAG - OPERATION . . . 8O-22

KNEE BLOCKER AIRBAG - REMOVAL .....8O-23

KNOB - INSTALLATION, SEAT BELT HEIGHT ADJUSTER ................... 8O-38

KNOB - REMOVAL, SEAT BELT HEIGHT ADJUSTER ......................... 8O-38

KNOCK SENSOR - DESCRIPTION ..........8I-8

KNOCK SENSOR - OPERATION ...........8I-8

KNUCKLE - DESCRIPTION ................2-6

KNUCKLE - INSPECTION, STEERING ........2-9

KNUCKLE - INSTALLATION, STEERING ......2-9

KNUCKLE - OPERATION .................2-7

KNUCKLE - REMOVAL, STEERING .........2-7

LABEL, DESCRIPTION - VEHICLE EMISSION CONTROL INFORMATION .......25-1

LAMP - DESCRIPTION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - DIAGNOSIS AND TESTING, FRONT FOG .......................... 8L-7

LAMP - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP - INSTALLATION, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - INSTALLATION, COURTESY ......8L-21

LAMP - INSTALLATION, DOME/CARGO ....8L-22

LAMP - INSTALLATION, FRONT FOG .......8L-8

LAMP - INSTALLATION, LICENSE ........8L-17

LAMP - INSTALLATION, LIFTGATE .......8L-22 LAMP - INSTALLATION, PARK/TURN

SIGNAL ............................ 8L-18

LAMP - INSTALLATION, READING ........8L-23

LAMP - INSTALLATION, TAIL ...........8L-19

LAMP - INSTALLATION, VANITY .........8L-24

LAMP - OPERATION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - REMOVAL, CENTER CONSOLE ....8L-21

LAMP - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - REMOVAL, COURTESY ..........8L-21

LAMP - REMOVAL, DOME/CARGO .......8L-22

LAMP - REMOVAL, FRONT FOG ..........8L-8

LAMP - REMOVAL, LICENSE ............8L-17

LAMP - REMOVAL, LIFTGATE ...........8L-22

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-18

LAMP - REMOVAL, READING ...........8L-22

LAMP - REMOVAL, TAIL ...............8L-18

LAMP - REMOVAL, VANITY .............8L-24

LAMP SWITCH - DESCRIPTION, BRAKE ....8L-4

LAMP SWITCH - DIAGNOSIS AND TESTING, BRAKE ...................... 8L-4

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-5

LAMP SWITCH - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - INSTALLATION, GLOVE BOX ............................... 8L-22

LAMP SWITCH - OPERATION, BRAKE ......8L-4

LAMP SWITCH - REMOVAL, BRAKE .......8L-5

LAMP SWITCH - REMOVAL, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - REMOVAL, GLOVE BOX . . 8L-22

LAMP UNIT - INSTALLATION, CENTER HIGH MOUNTED STOP .................8L-6

LAMP UNIT - INSTALLATION, TAIL .......8L-19

LAMP UNIT - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP UNIT - REMOVAL, TAIL ...........8L-19

LAMP UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT FOG .....8L-9

LAMP UNIT ALIGNMENT - STANDARD PROCEDURE, FRONT FOG ...............8L-9

LAMPS - INSTALLATION, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS - REMOVAL, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS, SPECIFICATIONS - EXTERIOR .....8L-3

LAMPS, SPECIFICATIONS - INTERIOR ....8L-20

LAMPS/LIGHTING - EXTERIOR - DESCRIPTION ........................ 8L-2

LAMPS/LIGHTING - EXTERIOR - OPERATION .......................... 8L-2

LAMPS/LIGHTING - EXTERIOR - WARNING ........................... 8L-3

LAP BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER .....23-157

LAP BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER .................. 23-157

LASH ADJUSTER NOISE DIAGNOSIS - DIAGNOSIS AND TESTING, HYDRAULIC ....9-34

LASH ADJUSTERS - INSTALLATION, HYDRAULIC .......................... 9-35

LASH ADJUSTERS - REMOVAL, HYDRAULIC .......................... 9-35

LATCH - DESCRIPTION ...........8N-12,8N-49

LATCH - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE LID ....23-90

LATCH - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE LID .................23-90

LATCH - INSTALLATION .....23-18,23-41,23-63

LATCH - INSTALLATION ..........8N-13,8N-50

LATCH - INSTALLATION, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH - INSTALLATION, GLOVE BOX .....23-66

LATCH - INSTALLATION, HOLD OPEN .....23-25

LATCH / LOCK ASSEMBLY - INSTALLATION ....................... 23-27

LATCH / LOCK ASSEMBLY - REMOVAL ....23-26

LATCH - OPERATION ............8N-12,8N-49

LATCH - REMOVAL .........23-18,23-41,23-63

LATCH - REMOVAL ..............8N-12,8N-49

LATCH - REMOVAL, FUEL FILL DOOR BLOCKER ........................... 23-53

LATCH - REMOVAL, GLOVE BOX .........23-66

LATCH - REMOVAL, HOLD OPEN ........23-25

LATCH ACTUATOR - DESCRIPTION ......8N-13

LATCH ACTUATOR - INSTALLATION ......8N-14

LATCH ACTUATOR - OPERATION ........8N-13 LATCH ACTUATOR - REMOVAL

..........8N-13

LATCH CABLE - INSTALLATION, HOLD OPEN .............................. 23-38

LATCH CABLE - REMOVAL, HOLD OPEN . . . 23-38

LATCH HANDLE - INSTALLATION, INSIDE . . 23-34

LATCH HANDLE - REMOVAL, INSIDE .....23-34

LATCH LOCKING LINK - INSTALLATION, SEAT RISER ........................ 23-151

LATCH LOCKING LINK - REMOVAL, SEAT RISER ............................ 23-151

LATCH RELEASE CABLE - INSTALLATION . . 23-64

LATCH RELEASE CABLE - REMOVAL .....23-63

LATCH STRIKER - INSTALLATION . . 23-19,23-42, 23-64

LATCH STRIKER - INSTALLATION, FUEL FILL DOOR BLOCKER .................23-53

LATCH STRIKER - INSTALLATION, GLOVE BOX ............................... 23-66

LATCH STRIKER - INSTALLATION, HOLD OPEN .............................. 23-26

LATCH STRIKER - INSTALLATION, REAR . . 23-29

LATCH STRIKER - REMOVAL . 23-19,23-41,23-64

LATCH STRIKER - REMOVAL, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH STRIKER - REMOVAL, GLOVE BOX ............................... 23-66

LATCH STRIKER - REMOVAL, HOLD OPEN .............................. 23-26

LATCH STRIKER - REMOVAL, REAR ......23-29

LEAD - DIAGNOSIS AND TESTING, TIRE/VEHICLE ......................... 22-14

LEAF SPRING FRONT - INSTALLATION, BUSHING ............................ 2-30

LEAF SPRING FRONT - REMOVAL, BUSHING ............................ 2-29

LEAK DETECTION ASSY - INSTALLATION, NATURAL VAC ....................... 25-14

LEAK DETECTION ASSY - REMOVAL, NATURAL VAC ....................... 25-14

LEAK DETECTION PUMP - INSTALLATION . 25-15

LEAK DETECTION PUMP - REMOVAL .....25-15

LEAK INSPECTION - DIAGNOSIS AND TESTING, ENGINE OIL ...............9-8,9-84

LEAK REPAIRING - STANDARD PROCEDURE, TIRE ................... 22-17

LEAK TEST - DIAGNOSIS AND TESTING, COOLING SYSTEM .....................7-2

LEAKAGE - DIAGNOSIS AND TESTING, TORQUE CONVERTER HOUSING FLUID . . 21-154, 21-9

LEAKAGE TEST - DIAGNOSIS AND TESTING, CYLINDER COMBUSTION

PRESSURE ....................... 9-85,9-9

LEAKS - DIAGNOSIS AND TESTING, INTAKE MANIFOLD ...............9-147,9-60

LEAKS, DIAGNOSIS AND TESTING - REFRIGERANT SYSTEM ...............24-67

LEAKS, DIAGNOSIS AND TESTING - WATER ............................. 23-1

LEARN CYCLE, STANDARD PROCEDURE - POWER LIFTGATE ................... 8N-8

LEARN CYCLE, STANDARD PROCEDURE - POWER SLIDING DOOR ..............8N-48

LEARN PROCEDURE - STANDARD PROCEDURE, QUICK .................. 8E-15

LENS - INSTALLATION, CLUSTER ........8J-11

LENS - REMOVAL, CLUSTER ............8J-11

LEVEL AND CONDITION CHECK, STANDARD PROCEDURE - FLUID . . 21-230,21-82

LEVEL CHECK - STANDARD PROCEDURE, COOLANT .................7-4

LEVEL CHECK - STANDARD PROCEDURE, ENGINE OIL ..............9-140

LEVEL CHECK, STANDARD PROCEDURE - ENGINE OIL ........................ 9-54

LEVEL CHECKING - STANDARD PROCEDURE, BRAKE FLUID .............5-33

LEVEL CHECKING - STANDARD PROCEDURE, POWER STEERING FLUID . . . 19-44

LEVEL SENDING UNIT / SENSOR - DESCRIPTION, FUEL ................... 14-5

LEVEL SENDING UNIT / SENSOR - INSTALLATION, FUEL .................. 14-6

LEVEL SENDING UNIT / SENSOR - OPERATION, FUEL ..................... 14-5

LEVEL SENDING UNIT / SENSOR - REMOVAL, FUEL ...................... 14-5

18 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2332 of 2339

STORAGE BIN GUIDE - INSTALLATION,UNDER SEAT ....................... 23-150

STORAGE BIN GUIDE - REMOVAL, UNDER SEAT ....................... 23-150

STORAGE BIN LOCK/LATCH - INSTALLATION, UNDER SEAT ..........23-150

STORAGE BIN LOCK/LATCH - REMOVAL, UNDER SEAT ....................... 23-150

STRAP - INSTALLATION, CHECK .........23-15

STRAP - INSTALLATION, FRONT SEAT BACK ASSIST ...................... 23-112

STRAP - REMOVAL, CHECK ............23-15

STRAP - REMOVAL, FRONT SEAT BACK ASSIST ........................... 23-112

STRAP - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACKSTOW .....23-158

STRAP - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACKSTOW .........23-158

STRIKER - INSTALLATION, CENTER ......23-28

STRIKER - INSTALLATION, FUEL FILL DOOR BLOCKER LATCH ...............23-53

STRIKER - INSTALLATION, GLOVE BOX LATCH ............................. 23-66

STRIKER - INSTALLATION, HOLD OPEN LATCH ............................. 23-26

STRIKER - INSTALLATION, LATCH . . 23-19,23-42, 23-64

STRIKER - INSTALLATION, REAR LATCH . . 23-29

STRIKER - REMOVAL, CENTER ..........23-28

STRIKER - REMOVAL, FUEL FILL DOOR BLOCKER LATCH ..................... 23-53

STRIKER - REMOVAL, GLOVE BOX LATCH ............................. 23-66

STRIKER - REMOVAL, HOLD OPEN LATCH ............................. 23-26

STRIKER - REMOVAL, LATCH . 23-19,23-41,23-64

STRIKER - REMOVAL, REAR LATCH ......23-29

STRIPPED THREAD REPAIR - STANDARD PROCEDURE, MANIFOLD ..............9-147

STRUCTURAL ADHESIVE LOCATIONS - FOLD-IN-FLOOR ONLY -

SPECIFICATIONS .................... 23-228

STRUCTURAL ADHESIVE LOCATIONS - SPECIFICATIONS .................... 23-218

STRUCTURAL COLLAR - INSTALLATION ....9-49

STRUCTURAL COLLAR - REMOVAL .......9-49

STRUT - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION, SEAT GAS .....23-139

STRUT - SECOND ROW - FOLD-IN- FLOOR - REMOVAL, SEAT GAS .........23-138

STRUT ASSEMBLY - ASSEMBLY ..........2-23

STRUT ASSEMBLY - DESCRIPTION .......2-19

STRUT ASSEMBLY - DIAGNOSIS AND TESTING ............................ 2-20

STRUT ASSEMBLY - DISASSEMBLY .......2-21

STRUT ASSEMBLY - INSTALLATION .......2-25

STRUT ASSEMBLY - OPERATION .........2-19

STRUT ASSEMBLY - REMOVAL ...........2-20

STUDS - FRONT - INSTALLATION, WHEEL MOUNTING ................... 22-21

STUDS - FRONT - REMOVAL, WHEEL MOUNTING ......................... 22-21

STUDS - REAR - INSTALLATION, WHEEL MOUNTING ......................... 22-22

STUDS - REAR - REMOVAL, WHEEL MOUNTING ......................... 22-22

SUCTION LINE - INSTALLATION . . . 24-107,24-97

SUCTION LINE - REMOVAL .......24-106,24-96

SUN VISOR - INSTALLATION ...........23-99

SUN VISOR - REMOVAL ...............23-99

SUN VISOR SUPPORT - INSTALLATION . . . 23-99

SUN VISOR SUPPORT - REMOVAL .......23-99

SUNROOF - DESCRIPTION ............23-169

SUNROOF ASSEMBLY - INSTALLATION . . 23-173

SUNROOF ASSEMBLY - REMOVAL ......23-173

SUNROOF DIAGNOSIS AND TESTING, DIAGNOSIS AND TESTING ............23-169

SUNROOF GLASS PANEL ADJUSTMENT, ADJUSTMENTS ..................... 23-173

SUNROOF MOTOR - INSTALLATION .....23-174

SUNROOF MOTOR - REMOVAL .........23-174

SUNROOF SWITCH - INSTALLATION .....23-176

SUNROOF SWITCH - REMOVAL ........23-176

SUNSHADE - INSTALLATION ...........23-173

SUNSHADE - REMOVAL ..............23-173

SUPPLEMENTAL CABIN HEATER, DIAGNOSIS AND TESTING ............24-114SUPPLY - PCM OUTPUT - OPERATION, 5

VOLT .............................. 8E-15

SUPPORT - INSTALLATION, LUMBAR ....23-150

SUPPORT - INSTALLATION, SUN VISOR . . . 23-99

SUPPORT - REMOVAL, LUMBAR .......23-150

SUPPORT - REMOVAL, SUN VISOR ......23-99

SUPPORT CYLINDER - INSTALLATION ....23-43

SUPPORT CYLINDER - REMOVAL ........23-42

SUPPORT PLATE - DRUM BRAKE - INSTALLATION ........................ 5-61

SUPPORT PLATE - DRUM BRAKE - REMOVAL ........................... 5-61

SUPPRESSION COMPONENTS - DESCRIPTION, RADIO NOISE ...........8A-15

SUPPRESSION COMPONENTS - OPERATION, RADIO NOISE .............8A-15

SURFACE PREPARATION - STANDARD PROCEDURE, ENGINE GASKET .......9-11,9-87

SUSPENSION - DESCRIPTION, FRONT ......2-2

SUSPENSION - DESCRIPTION, REAR ......2-26

SUSPENSION - OPERATION, FRONT ........2-2

SUSPENSION AND STEERING - DIAGNOSIS AND TESTING ..............2-50

SUSPENSION FASTENER TORQUE, SPECIFICATIONS - FRONT ................2-3

SUSPENSION FASTENER TORQUE, SPECIFICATIONS - REAR ................2-28

SUSPENSION, SPECIAL TOOLS - FRONT ....2-3

SUSPENSION, SPECIAL TOOLS - REAR ....2-28

SWITCH - DESCRIPTION .................8P-5

SWITCH - DESCRIPTION, B-PILLAR ......8N-52

SWITCH - DESCRIPTION, BRAKE FLUID LEVEL .............................. 5-10

SWITCH - DESCRIPTION, BRAKE LAMP ....8L-4

SWITCH - DESCRIPTION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - DESCRIPTION, FULL OPEN ....8N-11,

8N-52

SWITCH - DESCRIPTION, HEATED SEAT . . . 8G-8

SWITCH - DESCRIPTION, HORN ..........8H-4

SWITCH - DESCRIPTION, MEMORY ......8N-36

SWITCH - DESCRIPTION, OIL PRESSURE . 9-144

SWITCH - DESCRIPTION, REAR WINDOW DEFOGGER .................. 8G-4

SWITCH - DESCRIPTION, REAR WIPER/WASHER ..................... 8R-10

SWITCH - DESCRIPTION, SEAT .........8N-34

SWITCH - DIAGNOSIS AND TESTING, BRAKE LAMP ........................ 8L-4

SWITCH - DIAGNOSIS AND TESTING, FAILED PARK ........................ 8R-2

SWITCH - DIAGNOSIS AND TESTING, FRONT WIPER/WASHER ................8R-2

SWITCH - DIAGNOSIS AND TESTING, HEADLAMP ......................... 8L-13

SWITCH - DIAGNOSIS AND TESTING, MULTI-FUNCTION .................... 8L-18

SWITCH - DIAGNOSIS AND TESTING, TRACTION CONTROL ................... 5-94

SWITCH - EXPORT - DESCRIPTION, DOOR CYLINDER LOCK ...............8N-22

SWITCH - EXPORT - DESCRIPTION, POWER FOLDAWAY MIRROR ...........8N-29

SWITCH - EXPORT - INSTALLATION, HOOD AJAR ......................... 8Q-3

SWITCH - EXPORT - INSTALLATION, POWER FOLDAWAY MIRROR ...........8N-30

SWITCH - EXPORT - OPERATION, DOOR CYLINDER LOCK ..................... 8N-22

SWITCH - EXPORT - OPERATION, POWER FOLDAWAY MIRROR ...........8N-29

SWITCH - EXPORT - REMOVAL, HOOD AJAR ............................... 8Q-3

SWITCH - EXPORT - REMOVAL, POWER FOLDAWAY MIRROR .................. 8N-29

SWITCH - INSTALLATION ...............8P-6

SWITCH - INSTALLATION, ADJUSTABLE PEDALS ............................. 5-11

SWITCH - INSTALLATION, B-PILLAR .....8N-52

SWITCH - INSTALLATION, BRAKE FLUID LEVEL .............................. 5-11

SWITCH - INSTALLATION, BRAKE LAMP . . . 8L-5

SWITCH - INSTALLATION, CENTER CONSOLE LAMP ..................... 8L-21

SWITCH - INSTALLATION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - INSTALLATION, FULL OPEN ....8N-11 SWITCH - INSTALLATION, GLOVE BOX

LAMP .............................. 8L-22

SWITCH - INSTALLATION, HEADLAMP ....8L-13

SWITCH - INSTALLATION, IGNITION ......19-19

SWITCH - INSTALLATION, MULTI- FUNCTION .......................... 8L-18

SWITCH - INSTALLATION, OIL PRESSURE ..................... 9-144,9-56

SWITCH - INSTALLATION, SUNROOF ....23-176

SWITCH - INSTALLATION, TRACTION CONTROL ........................... 5-95

SWITCH - INSTALLATION, WASHER FLUID LEVEL ........................ 8R-11

SWITCH - OPERATION .................8P-5

SWITCH - OPERATION, B-PILLAR ........8N-52

SWITCH - OPERATION, BRAKE FLUID LEVEL .............................. 5-10

SWITCH - OPERATION, BRAKE LAMP ......8L-4

SWITCH - OPERATION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - OPERATION, FULL OPEN . 8N-11,8N-52

SWITCH - OPERATION, HEATED SEAT .....8G-9

SWITCH - OPERATION, MEMORY ........8N-36

SWITCH - OPERATION, OIL PRESSURE . . . 9-144

SWITCH - OPERATION, REAR WINDOW DEFOGGER .......................... 8G-4

SWITCH - OPERATION, REAR WIPER/ WASHER ........................... 8R-11

SWITCH - OPERATION, SEAT ...........8N-34

SWITCH - REMOVAL .................... 8P-5

SWITCH - REMOVAL, ADJUSTABLE PEDALS ............................. 5-11

SWITCH - REMOVAL, B-PILLAR .........8N-52

SWITCH - REMOVAL, BRAKE FLUID LEVEL .............................. 5-11

SWITCH - REMOVAL, BRAKE LAMP .......8L-5

SWITCH - REMOVAL, CENTER CONSOLE LAMP .............................. 8L-21

SWITCH - REMOVAL, EXTERIOR HANDLE . 8N-10

SWITCH - REMOVAL, FULL OPEN .......8N-11

SWITCH - REMOVAL, GLOVE BOX LAMP . . 8L-22

SWITCH - REMOVAL, HEADLAMP ........8L-13

SWITCH - REMOVAL, IGNITION .........19-17

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-18

SWITCH - REMOVAL, OIL PRESSURE ....9-144,

9-56

SWITCH - REMOVAL, SUNROOF ........23-176

SWITCH - REMOVAL, TRACTION CONTROL ........................... 5-95

SWITCH - REMOVAL, WASHER FLUID LEVEL ............................. 8R-11

SWITCH ASSY - DESCRIPTION, SOLENOID/PRESSURE ..........21-117,21-268

SWITCH ASSY - INSTALLATION, SOLENOID/PRESSURE ..........21-119,21-270

SWITCH ASSY - OPERATION, SOLENOID/ PRESSURE .................. 21-118,21-268

SWITCH ASSY - REMOVAL, SOLENOID/ PRESSURE .................. 21-118,21-269

SWITCH, DIAGNOSIS AND TESTING - DOOR LOCK ........................ 8N-23

SWITCH, DIAGNOSIS AND TESTING - DRIVER HEATED SEAT .................8G-9

SWITCH, DIAGNOSIS AND TESTING - DRIVER SEAT ....................... 8N-34

SWITCH, DIAGNOSIS AND TESTING - MEMORY ........................... 8N-37

SWITCH, DIAGNOSIS AND TESTING - REMOTE ........................... 8N-30

SWITCH, DIAGNOSIS AND TESTING - WINDOW ........................... 8N-63

SWITCH, EXPORT - DOOR CYLINDER LOCK .............................. 8N-22

SWITCHES - DESCRIPTION, REMOTE .....8A-16

SWITCHES - OPERATION, REMOTE ......8A-16

SWITCHES, DIAGNOSIS AND TESTING - REMOTE ........................... 8A-16

SYMBOLS - DESCRIPTION, INTERNATIONAL .......................0-1

SYNCHRONIZING CABLE ADJUSTMENT, INSTALLATION ................ 23-105,23-147

TAIL LAMP - INSTALLATION ............8L-19

TAIL LAMP - REMOVAL ................8L-18

TAIL LAMP UNIT - INSTALLATION .......8L-19

TAIL LAMP UNIT - REMOVAL ...........8L-19

TANK - DESCRIPTION, FUEL ............14-12

TANK - OPERATION, FUEL ..............14-12

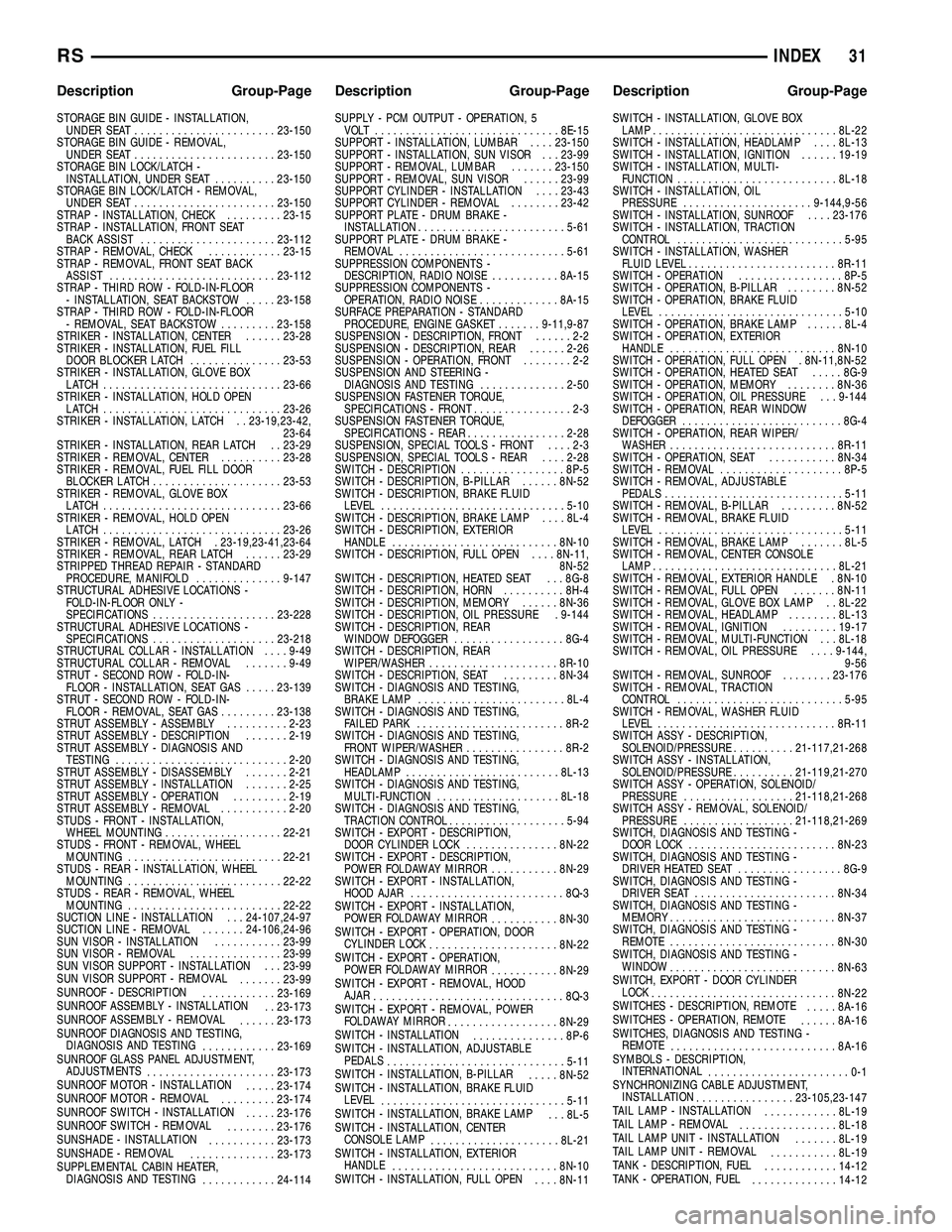

RS INDEX31

Description Group-Page Description Group-Page Description Group-Page