flat tire CHRYSLER VOYAGER 2005 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1778 of 2339

WHEEL MOUNTING STUDS -

FRONT

REMOVAL

NOTE: Before proceeding, (Refer to 5 - BRAKES -

WARNING)(Refer to 5 - BRAKES - CAUTION).

CAUTION: Wheel mounting studs MUST NOT be

hammered out of hub flange of hub and bearing

assembly. If a stud is removed by hammering it out,

damage to hub and bearing assembly will occur

leading to premature bearing failure.

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove front wheel and tire assembly. (Refer

to 22 - TIRES/WHEELS - REMOVAL)

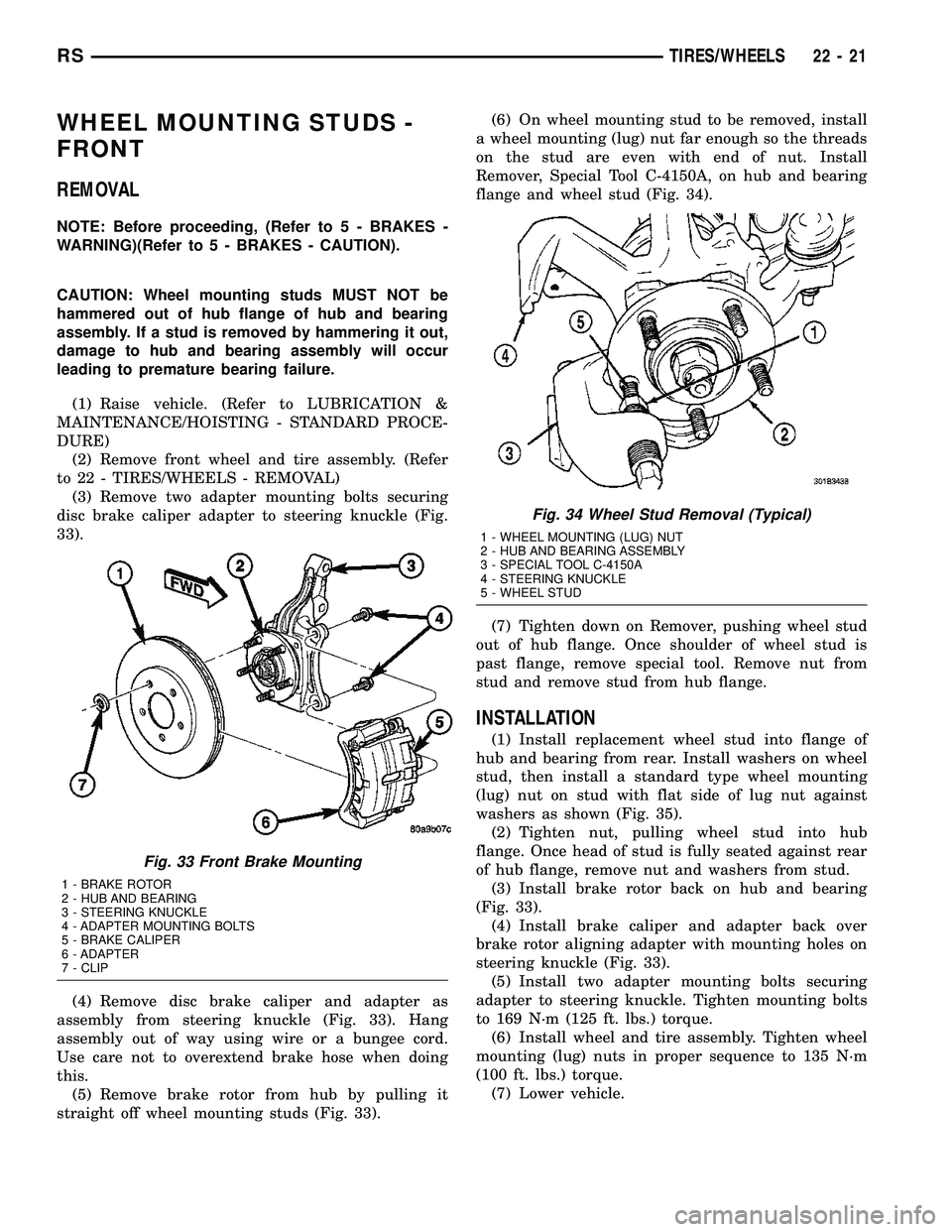

(3) Remove two adapter mounting bolts securing

disc brake caliper adapter to steering knuckle (Fig.

33).

(4) Remove disc brake caliper and adapter as

assembly from steering knuckle (Fig. 33). Hang

assembly out of way using wire or a bungee cord.

Use care not to overextend brake hose when doing

this.

(5) Remove brake rotor from hub by pulling it

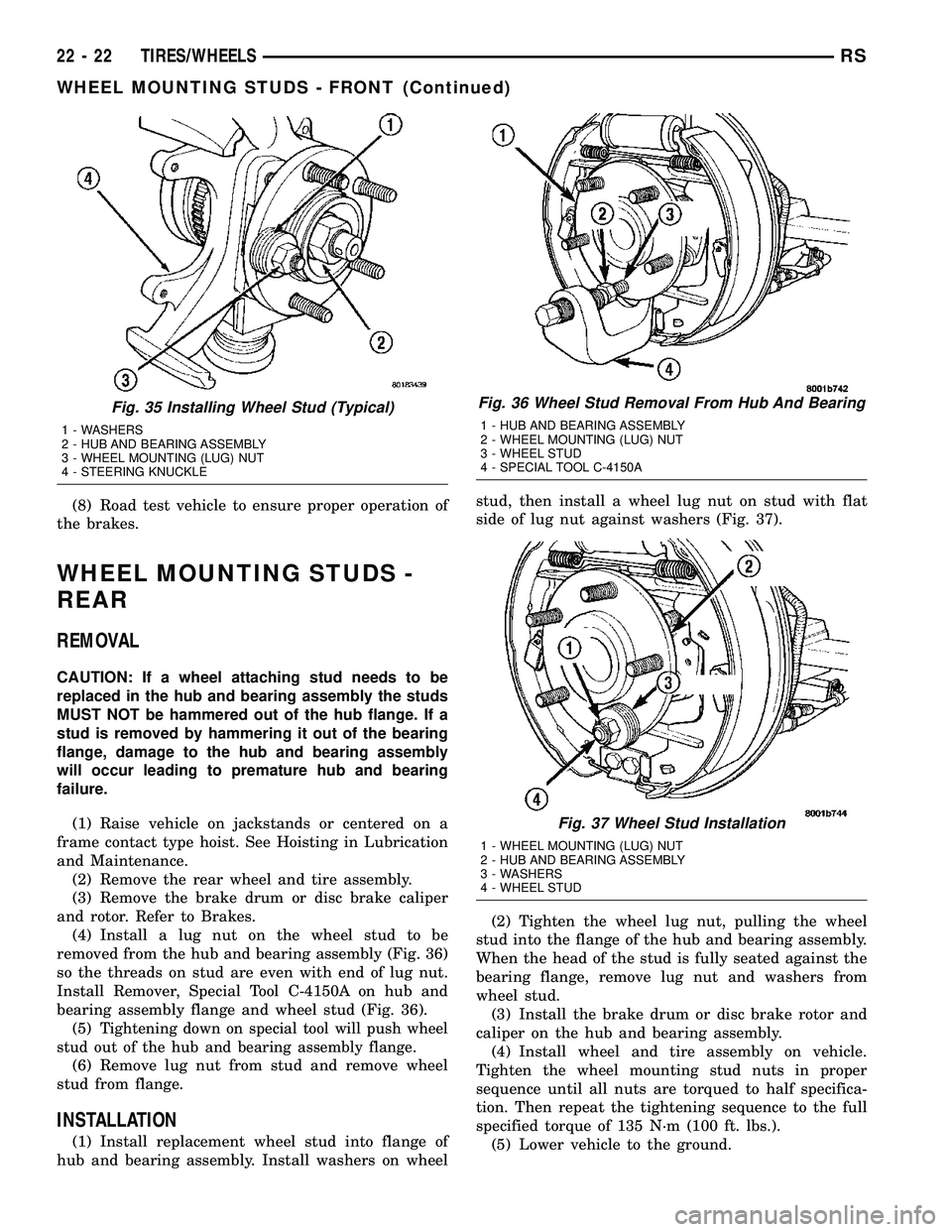

straight off wheel mounting studs (Fig. 33).(6) On wheel mounting stud to be removed, install

a wheel mounting (lug) nut far enough so the threads

on the stud are even with end of nut. Install

Remover, Special Tool C-4150A, on hub and bearing

flange and wheel stud (Fig. 34).

(7) Tighten down on Remover, pushing wheel stud

out of hub flange. Once shoulder of wheel stud is

past flange, remove special tool. Remove nut from

stud and remove stud from hub flange.

INSTALLATION

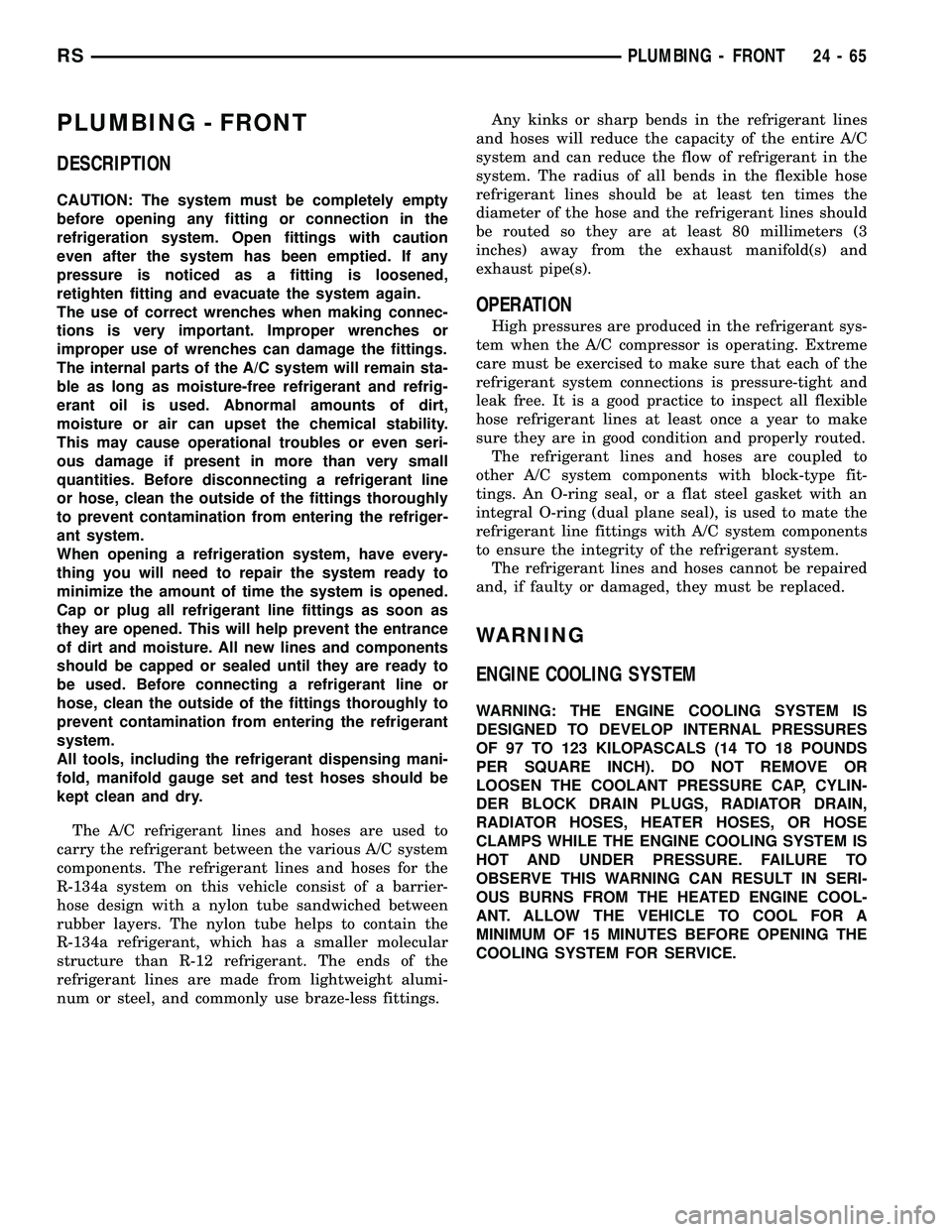

(1) Install replacement wheel stud into flange of

hub and bearing from rear. Install washers on wheel

stud, then install a standard type wheel mounting

(lug) nut on stud with flat side of lug nut against

washers as shown (Fig. 35).

(2) Tighten nut, pulling wheel stud into hub

flange. Once head of stud is fully seated against rear

of hub flange, remove nut and washers from stud.

(3) Install brake rotor back on hub and bearing

(Fig. 33).

(4) Install brake caliper and adapter back over

brake rotor aligning adapter with mounting holes on

steering knuckle (Fig. 33).

(5) Install two adapter mounting bolts securing

adapter to steering knuckle. Tighten mounting bolts

to 169 N´m (125 ft. lbs.) torque.

(6) Install wheel and tire assembly. Tighten wheel

mounting (lug) nuts in proper sequence to 135 N´m

(100 ft. lbs.) torque.

(7) Lower vehicle.

Fig. 33 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

Fig. 34 Wheel Stud Removal (Typical)

1 - WHEEL MOUNTING (LUG) NUT

2 - HUB AND BEARING ASSEMBLY

3 - SPECIAL TOOL C-4150A

4 - STEERING KNUCKLE

5 - WHEEL STUD

RSTIRES/WHEELS22-21

Page 1779 of 2339

(8) Road test vehicle to ensure proper operation of

the brakes.

WHEEL MOUNTING STUDS -

REAR

REMOVAL

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

MUST NOT be hammered out of the hub flange. If a

stud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature hub and bearing

failure.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove the rear wheel and tire assembly.

(3) Remove the brake drum or disc brake caliper

and rotor. Refer to Brakes.

(4) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly (Fig. 36)

so the threads on stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 36).

(5)

Tightening down on special tool will push wheel

stud out of the hub and bearing assembly flange.

(6) Remove lug nut from stud and remove wheel

stud from flange.

INSTALLATION

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheelstud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 37).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

(3) Install the brake drum or disc brake rotor and

caliper on the hub and bearing assembly.

(4) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(5) Lower vehicle to the ground.

Fig. 35 Installing Wheel Stud (Typical)

1 - WASHERS

2 - HUB AND BEARING ASSEMBLY

3 - WHEEL MOUNTING (LUG) NUT

4 - STEERING KNUCKLE

Fig. 36 Wheel Stud Removal From Hub And Bearing

1 - HUB AND BEARING ASSEMBLY

2 - WHEEL MOUNTING (LUG) NUT

3 - WHEEL STUD

4 - SPECIAL TOOL C-4150A

Fig. 37 Wheel Stud Installation

1 - WHEEL MOUNTING (LUG) NUT

2 - HUB AND BEARING ASSEMBLY

3 - WASHERS

4 - WHEEL STUD

22 - 22 TIRES/WHEELSRS

WHEEL MOUNTING STUDS - FRONT (Continued)

Page 2216 of 2339

PLUMBING - FRONT

DESCRIPTION

CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure is noticed as a fitting is loosened,

retighten fitting and evacuate the system again.

The use of correct wrenches when making connec-

tions is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain sta-

ble as long as moisture-free refrigerant and refrig-

erant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities. Before disconnecting a refrigerant line

or hose, clean the outside of the fittings thoroughly

to prevent contamination from entering the refriger-

ant system.

When opening a refrigeration system, have every-

thing you will need to repair the system ready to

minimize the amount of time the system is opened.

Cap or plug all refrigerant line fittings as soon as

they are opened. This will help prevent the entrance

of dirt and moisture. All new lines and components

should be capped or sealed until they are ready to

be used. Before connecting a refrigerant line or

hose, clean the outside of the fittings thoroughly to

prevent contamination from entering the refrigerant

system.

All tools, including the refrigerant dispensing mani-

fold, manifold gauge set and test hoses should be

kept clean and dry.

The A/C refrigerant lines and hoses are used to

carry the refrigerant between the various A/C system

components. The refrigerant lines and hoses for the

R-134a system on this vehicle consist of a barrier-

hose design with a nylon tube sandwiched between

rubber layers. The nylon tube helps to contain the

R-134a refrigerant, which has a smaller molecular

structure than R-12 refrigerant. The ends of the

refrigerant lines are made from lightweight alumi-

num or steel, and commonly use braze-less fittings.Any kinks or sharp bends in the refrigerant lines

and hoses will reduce the capacity of the entire A/C

system and can reduce the flow of refrigerant in the

system. The radius of all bends in the flexible hose

refrigerant lines should be at least ten times the

diameter of the hose and the refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) away from the exhaust manifold(s) and

exhaust pipe(s).

OPERATION

High pressures are produced in the refrigerant sys-

tem when the A/C compressor is operating. Extreme

care must be exercised to make sure that each of the

refrigerant system connections is pressure-tight and

leak free. It is a good practice to inspect all flexible

hose refrigerant lines at least once a year to make

sure they are in good condition and properly routed.

The refrigerant lines and hoses are coupled to

other A/C system components with block-type fit-

tings. An O-ring seal, or a flat steel gasket with an

integral O-ring (dual plane seal), is used to mate the

refrigerant line fittings with A/C system components

to ensure the integrity of the refrigerant system.

The refrigerant lines and hoses cannot be repaired

and, if faulty or damaged, they must be replaced.

WARNING

ENGINE COOLING SYSTEM

WARNING: THE ENGINE COOLING SYSTEM IS

DESIGNED TO DEVELOP INTERNAL PRESSURES

OF 97 TO 123 KILOPASCALS (14 TO 18 POUNDS

PER SQUARE INCH). DO NOT REMOVE OR

LOOSEN THE COOLANT PRESSURE CAP, CYLIN-

DER BLOCK DRAIN PLUGS, RADIATOR DRAIN,

RADIATOR HOSES, HEATER HOSES, OR HOSE

CLAMPS WHILE THE ENGINE COOLING SYSTEM IS

HOT AND UNDER PRESSURE. FAILURE TO

OBSERVE THIS WARNING CAN RESULT IN SERI-

OUS BURNS FROM THE HEATED ENGINE COOL-

ANT. ALLOW THE VEHICLE TO COOL FOR A

MINIMUM OF 15 MINUTES BEFORE OPENING THE

COOLING SYSTEM FOR SERVICE.

RSPLUMBING - FRONT24-65

Page 2318 of 2339

HYDRAULIC CIRCUITS AND VALVES -OPERATION .......................... 5-95

HYDRAULIC LASH ADJUSTER NOISE DIAGNOSIS - DIAGNOSIS AND

TESTING ............................ 9-34

HYDRAULIC LASH ADJUSTERS - INSTALLATION ........................ 9-35

HYDRAULIC LASH ADJUSTERS - REMOVAL ........................... 9-35

HYDRAULIC LIFTERS - DIAGNOSIS AND TESTING ........................... 9-116

HYDRAULIC LIFTERS (CAM IN BLOCK) - DESCRIPTION ....................... 9-116

HYDRAULIC LIFTERS (CAM IN BLOCK) - INSTALLATION ....................... 9-117

HYDRAULIC LIFTERS (CAM IN BLOCK) - REMOVAL .......................... 9-117

HYDRAULIC PRESSURE TESTS - DIAGNOSIS AND TESTING ........21-150,21-6

HYDRAULIC SCHEMATICS, SCHEMATICS AND DIAGRAMS - 4XTE TRANSAXLE ....21-199,

21-54

HYDROSTATIC LOCKED ENGINE, STANDARD PROCEDURE ............9-10,9-87

ICU - ASSEMBLY ..................... 5-106

ICU - DISASSEMBLY ..................5-105

ICU (INTEGRATED CONTROL UNIT) - DESCRIPTION ....................... 5-102

ICU (INTEGRATED CONTROL UNIT) - OPERATION ......................... 5-102

IDENTIFICATION - DESCRIPTION, VEHICLE ............................ 23-1

IDENTIFICATION AND INFORMATION - DESCRIPTION, SECTION ..............8W-01-6

IDLE AIR CONTROL MOTOR - DESCRIPTION ....................... 14-33

IDLE AIR CONTROL MOTOR - INSTALLATION ....................... 14-33

IDLE AIR CONTROL MOTOR - OPERATION ......................... 14-33

IDLE AIR CONTROL MOTOR - REMOVAL . . 14-33

IGNITION COIL - DESCRIPTION ...........8I-6

IGNITION COIL - OPERATION .............8I-6

IGNITION SENSE - PCM INPUT - OPERATION ......................... 8E-14

IGNITION SWITCH - INSTALLATION ......19-19

IGNITION SWITCH - REMOVAL ..........19-17

IGNITION SYSTEM - DESCRIPTION ........8I-1

IGNITION SYSTEM - OPERATION ..........8I-1

IGNITION-OFF DRAW TEST, STANDARD PROCEDURE ........................ 8F-13

ILLUMINATION LAMPS - INSTALLATION, CLUSTER ........................... 8L-21

ILLUMINATION LAMPS - REMOVAL, CLUSTER ........................... 8L-21

IMPACT SENSOR - DESCRIPTION .......8O-18

IMPACT SENSOR - INSTALLATION .......8O-21

IMPACT SENSOR - REMOVAL ...........8O-19

INBOARD - 50/50 BENCH - INSTALLATION, SEAT BELT BUCKLE -

SECOND ROW ....................... 8O-38

INBOARD - 50/50 BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW .....8O-37

INBOARD - INSTALLATION, SEAT BELT BUCKLE - FRONT .................... 8O-35

INBOARD - QUAD BUCKET - INSTALLATION, SEAT BELT BUCKLE -

FIRST ROW ......................... 8O-36

INBOARD - QUAD BUCKET - REMOVAL, SEAT BELT BUCKLE - FIRST ROW .......8O-35

INBOARD - REMOVAL, SEAT BELT BUCKLE - FRONT .................... 8O-35

INDICATOR - DESCRIPTION, PASSENGER AIRBAG DISABLED ................... 8O-33

INDICATOR - INSTALLATION, PASSENGER AIRBAG DISABLED .........8O-34

INDICATOR - OPERATION, PASSENGER AIRBAG DISABLED ................... 8O-33

INDICATOR - REMOVAL, PASSENGER AIRBAG DISABLED ................... 8O-34

INDICATOR LAMP - DESCRIPTION, VTSS/SKIS .......................... 8Q-8

INDICATOR LAMP - OPERATION, VTSS/SKIS .......................... 8Q-8

INDICATORS - DIAGNOSIS AND TESTING, TREAD WEAR ...............22-16

INFLATABLE KNEE - INSTALLATION, BLOCKER ........................... 23-75INFLATABLE KNEE - REMOVAL,

BLOCKER ........................... 23-75

INFLATION PRESSURES - STANDARD PROCEDURE, TIRE ................... 22-16

INFO CENTER - DESCRIPTION, ELECTRONIC VEHICLE .................8M-7

INFO CENTER - OPERATION, ELECTRONIC VEHICLE .................8M-7

INFRARED TEMPERATURE SENSOR - DESCRIPTION ....................... 24-28

INFRARED TEMPERATURE SENSOR - OPERATION ......................... 24-28

INITIAL OPERATION - STANDARD PROCEDURE, POWER STEERING

PUMP ............................. 19-37

INJECTION SYSTEM - OPERATION .......14-22

INJECTOR - DESCRIPTION, FUEL ........14-30

INJECTOR - OPERATION, FUEL ..........14-31

INLET AIR TEMPERATURE SENSOR - DESCRIPTION ....................... 14-34

INLET FILTER - INSTALLATION ..........14-17

INLET FILTER - REMOVAL ..............14-17

INLET HOSE - INSTALLATION, HEATER ....24-87

INLET HOSE - REMOVAL, HEATER .......24-86

INLET TUBE - 2.4L - DESCRIPTION, WATER PUMP ........................ 7-36

INLET TUBE - 2.4L - INSTALLATION, WATER PUMP ........................ 7-36

INLET TUBE - 2.4L - REMOVAL, WATER PUMP .............................. 7-36

INLET TUBE - 3.3/3.8L - INSTALLATION, WATER PUMP ......................... 7-37

INLET TUBE - 3.3/3.8L - REMOVAL, WATER PUMP ........................ 7-37

INNER - INSTALLATION, CV BOOT .........3-7

INNER - REMOVAL, CV BOOT .............3-6

INNER BELT MOLDING - INSTALLATION, FRONT DOOR ...................... 23-168

INNER BELT MOLDING - REMOVAL, FRONT DOOR ...................... 23-168

INPUT - DESCRIPTION, SPEED SENSOR . 21-120, 21-271

INPUT - INSTALLATION, SPEED SENSOR ..................... 21-121,21-272

INPUT - OPERATION, DATA BUS COMMUNICATION RECEIVE - PCM .......8E-14

INPUT - OPERATION, IGNITION SENSE - PCM............................... 8E-14

INPUT - OPERATION, SENSOR RETURN - PCM............................... 8E-14

INPUT - OPERATION, SPEED SENSOR . . . 21-120, 21-271

INPUT - REMOVAL, SPEED SENSOR ....21-121,

21-272

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-246, 21-95

INPUT CLUTCH ASSEMBLY - DISASSEMBLY ................. 21-237,21-86

INSERT - FOLD-IN-FLOOR - INSTALLATION, REAR FLOOR TUB

CARPETS ........................... 23-96

INSERT - FOLD-IN-FLOOR - INSTALLATION, SECOND ROW FLOOR

TUB CARPET ........................ 23-98

INSERT - FOLD-IN-FLOOR - REMOVAL, REAR FLOOR TUB CARPETS ............23-95

INSERT - FOLD-IN-FLOOR - REMOVAL, SECOND ROW FLOOR TUB CARPET ......23-98

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-1

INSTRUMENT CLUSTER - OPERATION .....8J-1

INSTRUMENT PANEL - INSTALLATION, LOWER ............................ 23-73

INSTRUMENT PANEL - REMOVAL, LOWER ............................ 23-73

INSTRUMENT PANEL ANTENNA CABLE - INSTALLATION ....................... 8A-12

INSTRUMENT PANEL ANTENNA CABLE - REMOVAL .......................... 8A-12

INSTRUMENT PANEL ASSEMBLY - INSTALLATION ....................... 23-70

INSTRUMENT PANEL ASSEMBLY - REMOVAL .......................... 23-67

INSTRUMENT PANEL CENTER BEZEL - INSTALLATION ....................... 23-72

INSTRUMENT PANEL CENTER BEZEL - REMOVAL .......................... 23-71

INSTRUMENT PANEL DEMISTER DUCTS - INSTALLATION ..................... 24-54INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL ......................... 24-54

INSTRUMENT PANEL DUCTS - INSTALLATION ....................... 24-55

INSTRUMENT PANEL DUCTS - REMOVAL . 24-55

INSTRUMENT PANEL OUTLETS, INSTALLATION ....................... 24-45

INSTRUMENT PANEL OUTLETS, REMOVAL .......................... 24-45

INSTRUMENT PANEL RIGHT END CAP - INSTALLATION ....................... 23-72

INSTRUMENT PANEL RIGHT END CAP - REMOVAL .......................... 23-72

INSTRUMENT PANEL TOP COVER - INSTALLATION ....................... 23-72

INSTRUMENT PANEL TOP COVER - REMOVAL .......................... 23-72

INSTRUMENT PANEL TOP PAD ASSEMBLY - INSTALLATION ............23-77

INSTRUMENT PANEL TOP PAD ASSEMBLY - REMOVAL ................23-77

INTAKE MANIFOLD - DESCRIPTION . . 9-147,9-60

INTAKE MANIFOLD - INSTALLATION, LOWER ............................ 9-151

INTAKE MANIFOLD - INSTALLATION, UPPER ............................. 9-149

INTAKE MANIFOLD - LOWER - CLEANING .......................... 9-151

INTAKE MANIFOLD - LOWER - INSPECTION .................... 9-151,9-62

INTAKE MANIFOLD - LOWER - INSTALLATION ........................ 9-62

INTAKE MANIFOLD - LOWER - REMOVAL ....9-62

INTAKE MANIFOLD - REMOVAL, LOWER . . 9-150

INTAKE MANIFOLD - REMOVAL, UPPER . . . 9-148

INTAKE MANIFOLD - UPPER - INSPECTION ......................... 9-61

INTAKE MANIFOLD - UPPER - INSTALLATION ........................ 9-61

INTAKE MANIFOLD - UPPER - REMOVAL . . . 9-60

INTAKE MANIFOLD LEAKS - DIAGNOSIS AND TESTING ................... 9-147,9-60

INTAKE MANIFOLD VACUUM PORT REPAIR - STANDARD PROCEDURE .......9-148

INTAKE PIPE - INSTALLATION, AIR ......24-115

INTAKE PIPE - REMOVAL, AIR .........24-115

INTAKE/EXHAUST VALVES & SEATS - CLEANING ...................... 9-108,9-33

INTAKE/EXHAUST VALVES & SEATS - DESCRIPTION ................... 9-107,9-33

INTAKE/EXHAUST VALVES & SEATS - INSPECTION ........................ 9-108

INTAKE/EXHAUST VALVES & SEATS - INSTALLATION ....................... 9-109

INTAKE/EXHAUST VALVES & SEATS - OPERATION ......................... 9-107

INTAKE/EXHAUST VALVES & SEATS - REMOVAL .......................... 9-108

INTEGRAL ANTENNA - EXPORT - DESCRIPTION, QUARTER GLASS ........8A-13

INTEGRAL ANTENNA - EXPORT - OPERATION, QUARTER GLASS ..........8A-13

INTEGRAL ANTENNA, EXPORT - QUARTER GLASS .................... 8A-13

INTEGRATED POWER MODULE - DESCRIPTION .....................8W -97-1

INTEGRATED POWER MODULE - INSTALLATION ....................8W -97-2

INTEGRATED POWER MODULE - OPERATION .......................8W -97-2

INTEGRATED POWER MODULE - REMOVAL ........................8W -97-2

INTERACTIVE SPEED CONTROL (4 SPEED EATX ONLY) - OPERATION ........8P-2

INTERFACE (PCI) BUS, OPERATION - PROGRAMMABLE COMMUNICATIONS ....14-25

INTERIOR LAMPS, SPECIFICATIONS ......8L-20

INTERLOCK SOLENOID - DESCRIPTION, SHIFT ....................... 21-113,21-264

INTERLOCK SOLENOID - DIAGNOSIS AND TESTING, BRAKE/TRANSMISSION

SHIFT ....................... 21-115,21-266

INTERLOCK SOLENOID - INSTALLATION, SHIFT ....................... 21-116,21-267

INTERLOCK SOLENOID - OPERATION, SHIFT ....................... 21-114,21-265

INTERLOCK SOLENOID - REMOVAL, SHIFT ....................... 21-115,21-266

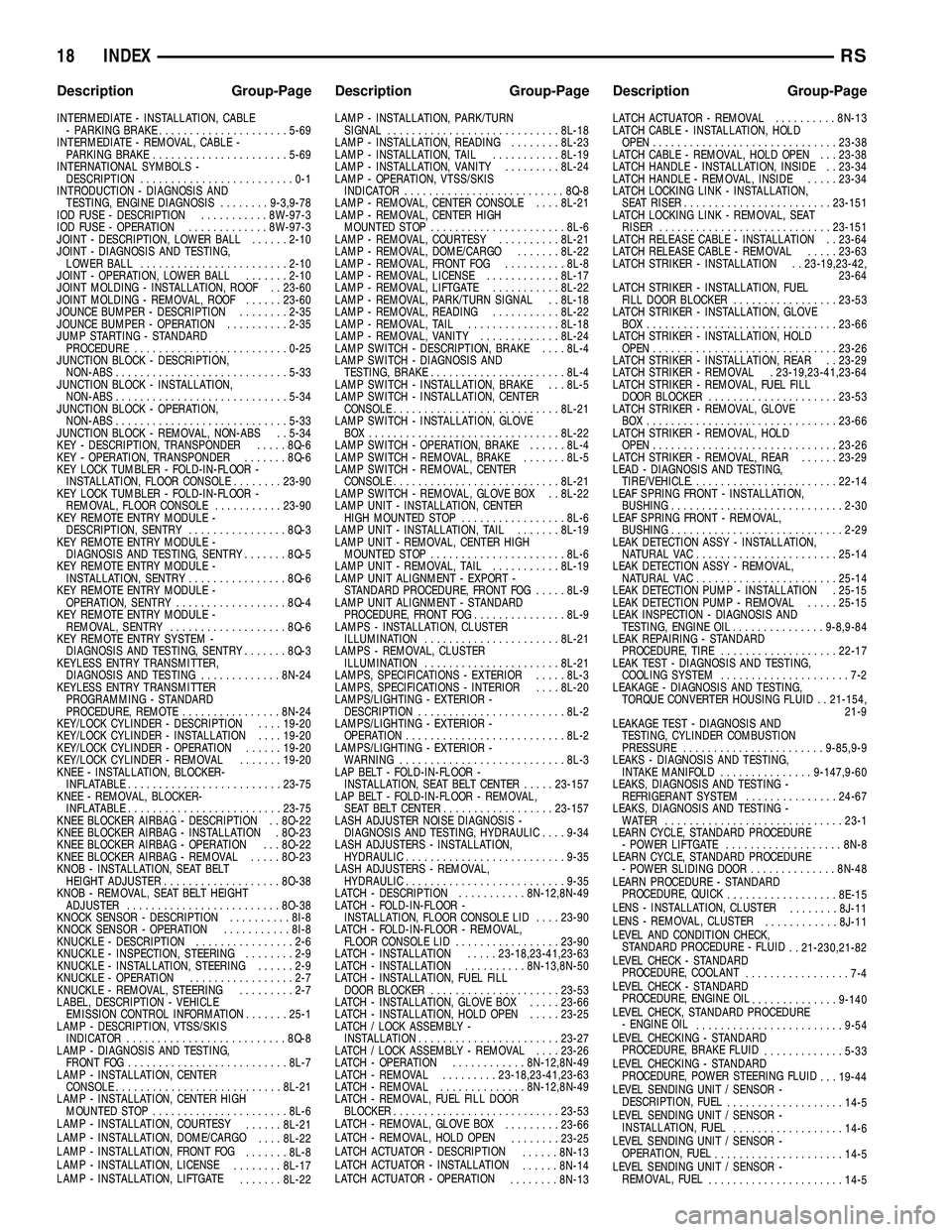

RS INDEX17

Description Group-Page Description Group-Page Description Group-Page

Page 2319 of 2339

INTERMEDIATE - INSTALLATION, CABLE- PARKING BRAKE ..................... 5-69

INTERMEDIATE - REMOVAL, CABLE - PARKING BRAKE ...................... 5-69

INTERNATIONAL SYMBOLS - DESCRIPTION .........................0-1

INTRODUCTION - DIAGNOSIS AND TESTING, ENGINE DIAGNOSIS ........9-3,9-78

IOD FUSE - DESCRIPTION ...........8W-97-3

IOD FUSE - OPERATION .............8W-97-3

JOINT - DESCRIPTION, LOWER BALL ......2-10

JOINT - DIAGNOSIS AND TESTING, LOWER BALL ........................ 2-10

JOINT - OPERATION, LOWER BALL .......2-10

JOINT MOLDING - INSTALLATION, ROOF . . 23-60

JOINT MOLDING - REMOVAL, ROOF ......23-60

JOUNCE BUMPER - DESCRIPTION ........2-35

JOUNCE BUMPER - OPERATION ..........2-35

JUMP STARTING - STANDARD PROCEDURE ......................... 0-25

JUNCTION BLOCK - DESCRIPTION, NON-ABS ............................ 5-33

JUNCTION BLOCK - INSTALLATION, NON-ABS ............................ 5-34

JUNCTION BLOCK - OPERATION, NON-ABS ............................ 5-33

JUNCTION BLOCK - REMOVAL, NON-ABS . . 5-34

KEY - DESCRIPTION, TRANSPONDER .....8Q-6

KEY - OPERATION, TRANSPONDER .......8Q-6

KEY LOCK TUMBLER - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE ........23-90

KEY LOCK TUMBLER - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE ...........23-90

KEY REMOTE ENTRY MODULE - DESCRIPTION, SENTRY ................8Q-3

KEY REMOTE ENTRY MODULE - DIAGNOSIS AND TESTING, SENTRY .......8Q-5

KEY REMOTE ENTRY MODULE - INSTALLATION, SENTRY ................8Q-6

KEY REMOTE ENTRY MODULE - OPERATION, SENTRY .................. 8Q-4

KEY REMOTE ENTRY MODULE - REMOVAL, SENTRY ................... 8Q-6

KEY REMOTE ENTRY SYSTEM - DIAGNOSIS AND TESTING, SENTRY .......8Q-3

KEYLESS ENTRY TRANSMITTER, DIAGNOSIS AND TESTING .............8N-24

KEYLESS ENTRY TRANSMITTER PROGRAMMING - STANDARD

PROCEDURE, REMOTE ................8N-24

KEY/LOCK CYLINDER - DESCRIPTION ....19-20

KEY/LOCK CYLINDER - INSTALLATION ....19-20

KEY/LOCK CYLINDER - OPERATION ......19-20

KEY/LOCK CYLINDER - REMOVAL .......19-20

KNEE - INSTALLATION, BLOCKER- INFLATABLE ......................... 23-75

KNEE - REMOVAL, BLOCKER- INFLATABLE ......................... 23-75

KNEE BLOCKER AIRBAG - DESCRIPTION . . 8O-22

KNEE BLOCKER AIRBAG - INSTALLATION . 8O-23

KNEE BLOCKER AIRBAG - OPERATION . . . 8O-22

KNEE BLOCKER AIRBAG - REMOVAL .....8O-23

KNOB - INSTALLATION, SEAT BELT HEIGHT ADJUSTER ................... 8O-38

KNOB - REMOVAL, SEAT BELT HEIGHT ADJUSTER ......................... 8O-38

KNOCK SENSOR - DESCRIPTION ..........8I-8

KNOCK SENSOR - OPERATION ...........8I-8

KNUCKLE - DESCRIPTION ................2-6

KNUCKLE - INSPECTION, STEERING ........2-9

KNUCKLE - INSTALLATION, STEERING ......2-9

KNUCKLE - OPERATION .................2-7

KNUCKLE - REMOVAL, STEERING .........2-7

LABEL, DESCRIPTION - VEHICLE EMISSION CONTROL INFORMATION .......25-1

LAMP - DESCRIPTION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - DIAGNOSIS AND TESTING, FRONT FOG .......................... 8L-7

LAMP - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP - INSTALLATION, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - INSTALLATION, COURTESY ......8L-21

LAMP - INSTALLATION, DOME/CARGO ....8L-22

LAMP - INSTALLATION, FRONT FOG .......8L-8

LAMP - INSTALLATION, LICENSE ........8L-17

LAMP - INSTALLATION, LIFTGATE .......8L-22 LAMP - INSTALLATION, PARK/TURN

SIGNAL ............................ 8L-18

LAMP - INSTALLATION, READING ........8L-23

LAMP - INSTALLATION, TAIL ...........8L-19

LAMP - INSTALLATION, VANITY .........8L-24

LAMP - OPERATION, VTSS/SKIS INDICATOR .......................... 8Q-8

LAMP - REMOVAL, CENTER CONSOLE ....8L-21

LAMP - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP - REMOVAL, COURTESY ..........8L-21

LAMP - REMOVAL, DOME/CARGO .......8L-22

LAMP - REMOVAL, FRONT FOG ..........8L-8

LAMP - REMOVAL, LICENSE ............8L-17

LAMP - REMOVAL, LIFTGATE ...........8L-22

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-18

LAMP - REMOVAL, READING ...........8L-22

LAMP - REMOVAL, TAIL ...............8L-18

LAMP - REMOVAL, VANITY .............8L-24

LAMP SWITCH - DESCRIPTION, BRAKE ....8L-4

LAMP SWITCH - DIAGNOSIS AND TESTING, BRAKE ...................... 8L-4

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-5

LAMP SWITCH - INSTALLATION, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - INSTALLATION, GLOVE BOX ............................... 8L-22

LAMP SWITCH - OPERATION, BRAKE ......8L-4

LAMP SWITCH - REMOVAL, BRAKE .......8L-5

LAMP SWITCH - REMOVAL, CENTER CONSOLE ........................... 8L-21

LAMP SWITCH - REMOVAL, GLOVE BOX . . 8L-22

LAMP UNIT - INSTALLATION, CENTER HIGH MOUNTED STOP .................8L-6

LAMP UNIT - INSTALLATION, TAIL .......8L-19

LAMP UNIT - REMOVAL, CENTER HIGH MOUNTED STOP ...................... 8L-6

LAMP UNIT - REMOVAL, TAIL ...........8L-19

LAMP UNIT ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT FOG .....8L-9

LAMP UNIT ALIGNMENT - STANDARD PROCEDURE, FRONT FOG ...............8L-9

LAMPS - INSTALLATION, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS - REMOVAL, CLUSTER ILLUMINATION ...................... 8L-21

LAMPS, SPECIFICATIONS - EXTERIOR .....8L-3

LAMPS, SPECIFICATIONS - INTERIOR ....8L-20

LAMPS/LIGHTING - EXTERIOR - DESCRIPTION ........................ 8L-2

LAMPS/LIGHTING - EXTERIOR - OPERATION .......................... 8L-2

LAMPS/LIGHTING - EXTERIOR - WARNING ........................... 8L-3

LAP BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER .....23-157

LAP BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER .................. 23-157

LASH ADJUSTER NOISE DIAGNOSIS - DIAGNOSIS AND TESTING, HYDRAULIC ....9-34

LASH ADJUSTERS - INSTALLATION, HYDRAULIC .......................... 9-35

LASH ADJUSTERS - REMOVAL, HYDRAULIC .......................... 9-35

LATCH - DESCRIPTION ...........8N-12,8N-49

LATCH - FOLD-IN-FLOOR - INSTALLATION, FLOOR CONSOLE LID ....23-90

LATCH - FOLD-IN-FLOOR - REMOVAL, FLOOR CONSOLE LID .................23-90

LATCH - INSTALLATION .....23-18,23-41,23-63

LATCH - INSTALLATION ..........8N-13,8N-50

LATCH - INSTALLATION, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH - INSTALLATION, GLOVE BOX .....23-66

LATCH - INSTALLATION, HOLD OPEN .....23-25

LATCH / LOCK ASSEMBLY - INSTALLATION ....................... 23-27

LATCH / LOCK ASSEMBLY - REMOVAL ....23-26

LATCH - OPERATION ............8N-12,8N-49

LATCH - REMOVAL .........23-18,23-41,23-63

LATCH - REMOVAL ..............8N-12,8N-49

LATCH - REMOVAL, FUEL FILL DOOR BLOCKER ........................... 23-53

LATCH - REMOVAL, GLOVE BOX .........23-66

LATCH - REMOVAL, HOLD OPEN ........23-25

LATCH ACTUATOR - DESCRIPTION ......8N-13

LATCH ACTUATOR - INSTALLATION ......8N-14

LATCH ACTUATOR - OPERATION ........8N-13 LATCH ACTUATOR - REMOVAL

..........8N-13

LATCH CABLE - INSTALLATION, HOLD OPEN .............................. 23-38

LATCH CABLE - REMOVAL, HOLD OPEN . . . 23-38

LATCH HANDLE - INSTALLATION, INSIDE . . 23-34

LATCH HANDLE - REMOVAL, INSIDE .....23-34

LATCH LOCKING LINK - INSTALLATION, SEAT RISER ........................ 23-151

LATCH LOCKING LINK - REMOVAL, SEAT RISER ............................ 23-151

LATCH RELEASE CABLE - INSTALLATION . . 23-64

LATCH RELEASE CABLE - REMOVAL .....23-63

LATCH STRIKER - INSTALLATION . . 23-19,23-42, 23-64

LATCH STRIKER - INSTALLATION, FUEL FILL DOOR BLOCKER .................23-53

LATCH STRIKER - INSTALLATION, GLOVE BOX ............................... 23-66

LATCH STRIKER - INSTALLATION, HOLD OPEN .............................. 23-26

LATCH STRIKER - INSTALLATION, REAR . . 23-29

LATCH STRIKER - REMOVAL . 23-19,23-41,23-64

LATCH STRIKER - REMOVAL, FUEL FILL DOOR BLOCKER ..................... 23-53

LATCH STRIKER - REMOVAL, GLOVE BOX ............................... 23-66

LATCH STRIKER - REMOVAL, HOLD OPEN .............................. 23-26

LATCH STRIKER - REMOVAL, REAR ......23-29

LEAD - DIAGNOSIS AND TESTING, TIRE/VEHICLE ......................... 22-14

LEAF SPRING FRONT - INSTALLATION, BUSHING ............................ 2-30

LEAF SPRING FRONT - REMOVAL, BUSHING ............................ 2-29

LEAK DETECTION ASSY - INSTALLATION, NATURAL VAC ....................... 25-14

LEAK DETECTION ASSY - REMOVAL, NATURAL VAC ....................... 25-14

LEAK DETECTION PUMP - INSTALLATION . 25-15

LEAK DETECTION PUMP - REMOVAL .....25-15

LEAK INSPECTION - DIAGNOSIS AND TESTING, ENGINE OIL ...............9-8,9-84

LEAK REPAIRING - STANDARD PROCEDURE, TIRE ................... 22-17

LEAK TEST - DIAGNOSIS AND TESTING, COOLING SYSTEM .....................7-2

LEAKAGE - DIAGNOSIS AND TESTING, TORQUE CONVERTER HOUSING FLUID . . 21-154, 21-9

LEAKAGE TEST - DIAGNOSIS AND TESTING, CYLINDER COMBUSTION

PRESSURE ....................... 9-85,9-9

LEAKS - DIAGNOSIS AND TESTING, INTAKE MANIFOLD ...............9-147,9-60

LEAKS, DIAGNOSIS AND TESTING - REFRIGERANT SYSTEM ...............24-67

LEAKS, DIAGNOSIS AND TESTING - WATER ............................. 23-1

LEARN CYCLE, STANDARD PROCEDURE - POWER LIFTGATE ................... 8N-8

LEARN CYCLE, STANDARD PROCEDURE - POWER SLIDING DOOR ..............8N-48

LEARN PROCEDURE - STANDARD PROCEDURE, QUICK .................. 8E-15

LENS - INSTALLATION, CLUSTER ........8J-11

LENS - REMOVAL, CLUSTER ............8J-11

LEVEL AND CONDITION CHECK, STANDARD PROCEDURE - FLUID . . 21-230,21-82

LEVEL CHECK - STANDARD PROCEDURE, COOLANT .................7-4

LEVEL CHECK - STANDARD PROCEDURE, ENGINE OIL ..............9-140

LEVEL CHECK, STANDARD PROCEDURE - ENGINE OIL ........................ 9-54

LEVEL CHECKING - STANDARD PROCEDURE, BRAKE FLUID .............5-33

LEVEL CHECKING - STANDARD PROCEDURE, POWER STEERING FLUID . . . 19-44

LEVEL SENDING UNIT / SENSOR - DESCRIPTION, FUEL ................... 14-5

LEVEL SENDING UNIT / SENSOR - INSTALLATION, FUEL .................. 14-6

LEVEL SENDING UNIT / SENSOR - OPERATION, FUEL ..................... 14-5

LEVEL SENDING UNIT / SENSOR - REMOVAL, FUEL ...................... 14-5

18 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2325 of 2339

POWER MODULE - INSTALLATION,INTEGRATED ......................8W -97-2

POWER MODULE - OPERATION, INTEGRATED ......................8W -97-2

POWER MODULE - REAR BLOWER MOTOR - DESCRIPTION ...............24-40

POWER MODULE - REAR BLOWER MOTOR - INSTALLATION ...............24-41

POWER MODULE - REAR BLOWER MOTOR - OPERATION .................24-40

POWER MODULE - REAR BLOWER MOTOR - REMOVAL .................. 24-41

POWER MODULE - REMOVAL, INTEGRATED ......................8W -97-2

POWER OUTLET - DESCRIPTION ......8W-97-3

POWER OUTLET - DIAGNOSIS & TESTING .........................8W -97-3

POWER OUTLET - OPERATION ........8W-97-3

POWER SEAT SYSTEM, DESCRIPTION ....8N-31

POWER SEAT SYSTEM, DIAGNOSIS AND TESTING ........................... 8N-33

POWER SEAT SYSTEM, OPERATION .....8N-32

POWER SEAT TRACK - DESCRIPTION ....8N-37

POWER SEAT TRACK - OPERATION ......8N-38

POWER SEAT TRACK, DIAGNOSIS AND TESTING ........................... 8N-38

POWER SLIDING DOOR ADJUSTMENT, STANDARD PROCEDURE ..............8N-49

POWER SLIDING DOOR LEARN CYCLE, STANDARD PROCEDURE ..............8N-48

POWER SLIDING DOOR SYSTEM - DESCRIPTION ........................ 8N-40

POWER SLIDING DOOR SYSTEM - OPERATION ......................... 8N-41

POWER SLIDING DOOR SYSTEM, DIAGNOSIS AND TESTING .............8N-42

POWER STEERING BELT TENSION - STANDARD PROCEDURE, CHECKING .......7-8

POWER STEERING FASTENER TORQUE, SPECIFICATIONS ...................... 19-9

POWER STEERING FLUID LEVEL CHECKING - STANDARD PROCEDURE ....19-44

POWER STEERING GEAR, SPECIAL TOOLS ............................. 19-34

POWER STEERING PUMP INITIAL OPERATION - STANDARD PROCEDURE . . . 19-37

POWER STEERING PUMP, SPECIAL TOOLS ............................. 19-44

POWER STEERING, SPECIAL TOOLS ......19-9

POWER STEERING SYSTEM - DESCRIPTION ........................ 19-1

POWER STEERING SYSTEM - OPERATION .......................... 19-1

POWER STEERING SYSTEM FLOW AND PRESSURE TEST - DIAGNOSIS AND

TESTING ............................ 19-1

POWER TRANSFER UNIT FLUID - DESCRIPTION, AWD ....................0-6

POWER WINDOWS - DESCRIPTION ......8N-61

POWER WINDOWS - OPERATION ........8N-61

POWER WINDOWS, DIAGNOSIS AND TESTING ........................... 8N-61

POWERING SEVERAL LOADS - STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-10

PRELOAD - ADJUSTMENT, DIFFERENTIAL BEARING ..............21-228

PRELOAD MEASUREMENT AND ADJUSTMENT, ADJUSTMENTS -

DIFFERENTIAL BEARING ...............21-79

PREPARATION - STANDARD PROCEDURE, ENGINE GASKET

SURFACE ........................ 9-11,9-87

PRESSURE - DIAGNOSIS AND TESTING, CHECKING ENGINE OIL .................9-53

PRESSURE - DIAGNOSIS AND TESTING, ENGINE OIL ......................... 9-138

PRESSURE CAP - DESCRIPTION, RADIATOR ........................... 7-27

PRESSURE CAP - OPERATION, RADIATOR ........................... 7-27

PRESSURE CAP TESTING - DIAGNOSIS AND TESTING, COOLING SYSTEM ........7-28

PRESSURE FOR HIGH SPEED OPERATION - STANDARD PROCEDURE,

TIRE ............................... 22-17

PRESSURE GAUGE - STANDARD PROCEDURE, FUEL .................... 14-3PRESSURE LEAKAGE TEST - DIAGNOSIS

AND TESTING, CYLINDER

COMBUSTION ..................... 9-85,9-9

PRESSURE MONITORING - DESCRIPTION, TIRE ................... 22-9

PRESSURE MONITORING - OPERATION, TIRE ............................... 22-10

PRESSURE REGULATOR - INSTALLATION, FUEL .................. 14-7

PRESSURE REGULATOR - OPERATION, FUEL ............................... 14-7

PRESSURE REGULATOR - REMOVAL, FUEL ............................... 14-7

PRESSURE RELEASE PROCEDURE - STANDARD PROCEDURE, FUEL

SYSTEM ............................ 14-2

PRESSURE RELIEF VALVE - INSTALLATION, OIL ................... 9-144

PRESSURE RELIEF VALVE - REMOVAL, OIL................................ 9-143

PRESSURE RELIEF VALVE, DESCRIPTION - HIGH ............................. 24-72

PRESSURE RELIEF VALVE, OPERATION - HIGH .............................. 24-72

PRESSURE SENSOR - DESCRIPTION, SEAT WEIGHT BLADDER ...............8O-43

PRESSURE SENSOR - DIAGNOSIS AND TESTING, TIRE ...................... 22-11

PRESSURE SENSOR - OPERATION, SEAT WEIGHT BLADDER ................... 8O-44

PRESSURE, SPECIFICATIONS - FUEL SYSTEM ............................ 14-4

PRESSURE SWITCH - DESCRIPTION, OIL . 9-144

PRESSURE SWITCH - INSTALLATION, OIL ........................... 9-144,9-56

PRESSURE SWITCH - OPERATION, OIL . . . 9-144

PRESSURE SWITCH - REMOVAL, OIL ....9-144,

9-56

PRESSURE TEST - DIAGNOSIS AND TESTING, CYLINDER COMPRESSION . . . 9-85,9-9

PRESSURE TEST - DIAGNOSIS AND TESTING, POWER STEERING SYSTEM

FLOW ............................... 19-1

PRESSURE TESTS - DIAGNOSIS AND TESTING, CLUTCH AIR ...........21-153,21-8

PRESSURE TESTS - DIAGNOSIS AND TESTING, HYDRAULIC ............21-150,21-6

PRESSURE TRANSDUCER - DESCRIPTION, A/C ................... 24-20

PRESSURE TRANSDUCER - OPERATION, A/C................................ 24-20

PRESSURE TRANSDUCER, DIAGNOSIS AND TESTING - A/C ................... 24-21

PRESSURES - STANDARD PROCEDURE, TIRE INFLATION ..................... 22-16

PROGRAMMABLE COMMUNICATIONS INTERFACE (PCI) BUS, OPERATION ......14-25

PROGRAMMING - STANDARD PROCEDURE, PCM/SKIM ................8E-1

PROGRAMMING - STANDARD PROCEDURE, REMOTE KEYLESS

ENTRY TRANSMITTER ................8N-24

PROGRAMMING - STANDARD PROCEDURE, TRANSPONDER ...........8Q-6

PROGRAMMING, STANDARD PROCEDURE - ELECTRONIC VEHICLE

INFORMATION CENTER ................8M-8

PROP ROD - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION, SEAT .........23-140

PROP ROD - SECOND ROW - FOLD-IN- FLOOR - REMOVAL, SEAT .............23-139

PROPORTIONING - DESCRIPTION, ELECTRONIC VARIABLE BRAKE ..........5-88

PROPORTIONING - OPERATION, ELECTRONIC VARIABLE BRAKE ..........5-89

PROPORTIONING VALVE (HEIGHT SENSING) - DESCRIPTION ..............5-53

PROPORTIONING VALVE (HEIGHT SENSING) - DIAGNOSIS AND TESTING .....5-54

PROPORTIONING VALVE (HEIGHT SENSING) - INSTALLATION ..............5-55

PROPORTIONING VALVE (HEIGHT SENSING) - OPERATION ................5-53

PROPORTIONING VALVE (HEIGHT SENSING) - REMOVAL .................5-55

PULLEY - DESCRIPTION, GENERATOR DECOUPLER ........................ 8F-28PULLEY - DIAGNOSIS AND TESTING,

GENERATOR DECOUPLER ..............8F-28

PULLEY - INSTALLATION, GENERATOR DECOUPLER ........................ 8F-29

PULLEY - INSTALLATION, TIMING BELT TENSIONER .......................... 9-70

PULLEY - OPERATION, GENERATOR DECOUPLER ........................ 8F-28

PULLEY - REMOVAL, GENERATOR DECOUPLER ........................ 8F-29

PULLEY - REMOVAL, TIMING BELT TENSIONER .......................... 9-69

PUMP - 2.4L - CLEANING, WATER ........7-32

PUMP - 2.4L - DESCRIPTION, WATER .....7-32

PUMP - 2.4L - INSPECTION, WATER ......7-32

PUMP - 2.4L - INSTALLATION, WATER .....7-32

PUMP - 2.4L - REMOVAL, WATER ........7-32

PUMP - 3.3/3.8L - CLEANING, WATER .....7-35

PUMP - 3.3/3.8L - DESCRIPTION, WATER ............................. 7-34

PUMP - 3.3/3.8L - INSPECTION, WATER . . . 7-35

PUMP - 3.3/3.8L - INSTALLATION, WATER ............................. 7-35

PUMP - 3.3/3.8L - REMOVAL, WATER .....7-34

PUMP - ASSEMBLY, OIL ...........9-146,9-58

PUMP - ASSEMBLY, OIL ........21-112,21-263

PUMP - CLEANING, OIL ...........9-145,9-57

PUMP - DESCRIPTION, FUEL ............14-8

PUMP - DESCRIPTION, FUEL DOSING . . . 24-117

PUMP - DESCRIPTION, OIL .............9-144

PUMP - DESCRIPTION, OIL ......21-110,21-261

PUMP - DISASSEMBLY, OIL ........9-145,9-57

PUMP - DISASSEMBLY, OIL .....21-110,21-261

PUMP - INSPECTION, OIL ..........9-145,9-58

PUMP - INSTALLATION, FUEL DOSING . . . 24-117

PUMP - INSTALLATION, LEAK DETECTION ......................... 25-15

PUMP - INSTALLATION, OIL ........9-146,9-59

PUMP - INSTALLATION, SEAL - OIL ....21-113,

21-264

PUMP - OPERATION, FUEL ..............14-8

PUMP - OPERATION, FUEL DOSING .....24-117

PUMP - OPERATION, OIL .......21-110,21-261

PUMP - REMOVAL, FUEL DOSING ......24-117

PUMP - REMOVAL, LEAK DETECTION ....25-15

PUMP - REMOVAL, OIL ............9-144,9-56

PUMP - REMOVAL, SEAL - OIL . . . 21-113,21-264

PUMP (2.4L ENGINE) - INSTALLATION ....19-43

PUMP (2.4L ENGINE) - REMOVAL .......19-38

PUMP (2.4L/3.3L/3.8L ENGINE) - DESCRIPTION ....................... 19-36

PUMP (3.3L/3.8L ENGINE) - INSTALLATION ....................... 19-43

PUMP (3.3L/3.8L ENGINE) - REMOVAL . . . 19-40

PUMP (DIESEL) - DESCRIPTION .........19-37

PUMP (DIESEL) - INSTALLATION ........19-43

PUMP (DIESEL) - REMOVAL ............19-41

PUMP INITIAL OPERATION - STANDARD PROCEDURE, POWER STEERING ........19-37

PUMP INLET TUBE - 2.4L - DESCRIPTION, WATER .................7-36

PUMP INLET TUBE - 2.4L - INSTALLATION, WATER .................7-36

PUMP INLET TUBE - 2.4L - REMOVAL, WATER ............................. 7-36

PUMP INLET TUBE - 3.3/3.8L - INSTALLATION, WATER .................7-37

PUMP INLET TUBE - 3.3/3.8L - REMOVAL, WATER .................... 7-37

PUMP MODULE - DESCRIPTION, FUEL ....14-8

PUMP MODULE - OPERATION, FUEL ......14-9

PUMP MOTOR - INSTALLATION, WASHER ........................... 8R-12

PUMP MOTOR - REMOVAL, WASHER ....8R-12

PUMP (PULLEY) - ASSEMBLY ..........19-42

PUMP (PULLEY) - DISASSEMBLY ........19-41

PUMP RELAY - DESCRIPTION, FUEL .....14-32

PUMP RELAY - OPERATION, FUEL .......14-32

PUMP, SPECIAL TOOLS - POWER STEERING .......................... 19-44

PUSH-PIN GROMMET REPLACEMENT, STANDARD PROCEDURE ..............8N-48

PUSHRODS - DESCRIPTION ............9-112

PUSHRODS - OPERATION ..............9-112

QUAD BUCKET - INSTALLATION, BUCKET SEAT BACK ........................ 23-141

QUAD BUCKET - INSTALLATION, SEAT BELT BUCKLE - FIRST ROW INBOARD ....8O-36

24 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2333 of 2339

TANK - STANDARD PROCEDURE,DRAINING FUEL ...................... 14-2

TANK FILLER TUBE - INSTALLATION, FUEL .............................. 14-17

TANK FILLER TUBE - REMOVAL, FUEL ....14-16

TAPE ATTACHED - INSTALLATION, EXTERIOR NAME PLATES ..............23-51

TAPE ATTACHED - REMOVAL, EXTERIOR NAME PLATES ....................... 23-51

TASK MANAGER - DESCRIPTION ........25-25

TASK MANAGER - OPERATION ..........25-25

TELECOMMUNICATION, DIAGNOSIS AND TESTING ............................8T-1

TEMP SENSOR - DESCRIPTION, AMBIENT .......................... 8M-12

TEMP SENSOR - OPERATION, AMBIENT . . 8M-12

TEMPERATURE CONTROL, DESCRIPTION - AUTOMATIC ........................ 24-3

TEMPERATURE CONTROL, OPERATION - AUTOMATIC .......................... 24-5

TEMPERATURE CONTROL SYSTEM, OPERATION - AUTOMATIC ............24-114

TEMPERATURE CONTROL SYSTEM, OPERATION - MANUAL ...............24-113

TEMPERATURE SENSOR - 2.4L - DESCRIPTION, ENGINE COOLANT .........7-21

TEMPERATURE SENSOR - 2.4L - INSTALLATION, ENGINE COOLANT ........7-21

TEMPERATURE SENSOR - 2.4L - REMOVAL, ENGINE COOLANT ............7-21

TEMPERATURE SENSOR - 3.3/3.8L - DESCRIPTION, ENGINE COOLANT .........7-21

TEMPERATURE SENSOR - 3.3/3.8L - INSTALLATION, ENGINE COOLANT ........7-23

TEMPERATURE SENSOR - 3.3/3.8L - REMOVAL, ENGINE COOLANT ............7-21

TEMPERATURE SENSOR - DESCRIPTION, BATTERY ........................... 8F-24

TEMPERATURE SENSOR - DESCRIPTION, EVAPORATOR ....................... 24-26

TEMPERATURE SENSOR - DESCRIPTION, INFRARED .......................... 24-28

TEMPERATURE SENSOR - DESCRIPTION, INLET AIR .......................... 14-34

TEMPERATURE SENSOR - OPERATION, BATTERY ........................... 8F-24

TEMPERATURE SENSOR - OPERATION, EVAPORATOR ....................... 24-27

TEMPERATURE SENSOR - OPERATION, INFRARED .......................... 24-28

TEMPERATURE SENSOR - REMOVAL, BATTERY ........................... 8F-24

TEMPERATURE SENSOR - SPECIFICATIONS, BATTERY .............8F-23

TEMPERATURE SENSOR CIRCUIT, DIAGNOSIS AND TESTING - AMBIENT ....8M-12

TEMPERATURE SENSOR, DIAGNOSIS AND TESTING - AMBIENT .............8M-12

TENSION - STANDARD PROCEDURE, CHECKING POWER STEERING BELT ........7-8

TENSION RELEASE - STANDARD PROCEDURE, PARKING BRAKE

AUTOMATIC ADJUSTER ................5-63

TENSION RESET - STANDARD PROCEDURE, PARKING BRAKE

AUTOMATIC ADJUSTER ................5-64

TENSION SENSOR - DESCRIPTION, BELT . . 8O-8

TENSION SENSOR - OPERATION, BELT ....8O-9

TENSION, SPECIFICATIONS - ACCESSORY DRIVE BELT ................7-5

TENSIONER - 2.4L - INSTALLATION, BELT ............................... 7-11

TENSIONER - 2.4L - REMOVAL, BELT ......7-11

TENSIONER - 3.3/3.8L - INSTALLATION, BELT ............................... 7-12

TENSIONER - 3.3/3.8L - REMOVAL, BELT . . . 7-12

TENSIONER - DESCRIPTION, SEAT BELT . . 8O-43

TENSIONER - OPERATION, SEAT BELT ....8O-43

TENSIONER & PULLEY - INSTALLATION, TIMING BELT ......................... 9-70

TENSIONER & PULLEY - REMOVAL, TIMING BELT ......................... 9-69

TERMINAL - INSTALLATION .........8W-01-14

TERMINAL - REMOVAL .............8W-01-14

TEST - DIAGNOSIS AND TESTING, CONTROL CIRCUIT ................... 8F-33

TEST - DIAGNOSIS AND TESTING, COOLING SYSTEM LEAK .................7-2 TEST - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE

LEAKAGE ......................... 9-85,9-9

TEST - DIAGNOSIS AND TESTING, CYLINDER COMPRESSION PRESSURE . . 9-85,9-9

TEST - DIAGNOSIS AND TESTING, FEED CIRCUIT ............................ 8F-36

TEST - DIAGNOSIS AND TESTING, FEED CIRCUIT RESISTANCE .................8F-35

TEST - DIAGNOSIS AND TESTING, POWER STEERING SYSTEM FLOW

AND PRESSURE ...................... 19-1

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-3

TEST - DIAGNOSIS AND TESTING, ROAD ......................... 21-150,21-5

TEST - DIAGNOSIS AND TESTING, STARTING SYSTEM ................... 8F-31

TEST, DIAGNOSIS AND TESTING - A/C COOL DOWN ......................... 24-6

TEST, DIAGNOSIS AND TESTING - A/C PERFORMANCE ....................... 24-7

TEST, DIAGNOSIS AND TESTING - HEATER PERFORMANCE ...............24-10

TEST, DIAGNOSIS AND TESTING - SYSTEM CHARGE LEVEL ...............24-67

TEST MODE, OPERATION - DRB III T

STATE DISPLAY ...................... 25-10

TEST, STANDARD PROCEDURE - IGNITION-OFF DRAW .................. 8F-13

TEST, STANDARD PROCEDURE - OPEN-CIRCUIT VOLTAGE ...............8F-13

TESTER, STANDARD PROCEDURE - MICRO 420 BATTERY .................8F-15

TESTS - DIAGNOSIS AND TESTING, CLUTCH AIR PRESSURE ..........21-153,21-8

TESTS - DIAGNOSIS AND TESTING, HYDRAULIC PRESSURE ..........21-150,21-6

THEFT SECURITY - DESCRIPTION, VEHICLE ............................ 8Q-1

THEFT SECURITY - OPERATION, VEHICLE . . 8Q-1

THEFT SECURITY SYSTEM - DIAGNOSIS AND TESTING, VEHICLE ................8Q-3

THERMOSTAT - 2.4L - INSTALLATION, ENGINE COOLANT ..................... 7-24

THERMOSTAT - 2.4L - REMOVAL, ENGINE COOLANT ..................... 7-24

THERMOSTAT - 3.3/3.8L - INSTALLATION, ENGINE COOLANT ........7-25

THERMOSTAT - 3.3/3.8L - REMOVAL, ENGINE COOLANT ..................... 7-24

THERMOSTAT - DESCRIPTION, ENGINE COOLANT ............................ 7-23

THERMOSTAT - DIAGNOSIS AND TESTING, ENGINE COOLANT .............7-23

THERMOSTAT - OPERATION, ENGINE COOLANT ............................ 7-23

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, HEADREST SLEEVE .....23-153

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT .................23-154

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACK COVER/

FOAM ............................. 23-156

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACK FRAME .....23-157

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACKSTOW

STRAP ............................ 23-158

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT CUSHION

COVER/FOAM ....................... 23-159

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, HEADREST SLEEVE .........23-152

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT .................... 23-153

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACK COVER/FOAM ....23-155

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACK FRAME .........23-156

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACKSTOW STRAP ....23-158

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT CUSHION COVER/

FOAM ............................. 23-159

THIRD ROW - INSTALLATION, BENCH SEAT RISER ........................ 23-145

THIRD ROW - REMOVAL, BENCH SEAT RISER ............................ 23-145THIRD ROW -FOLD-IN-FLOOR -

INSTALLATION, SEAT BACK PANEL ......23-158

THIRD ROW -FOLD-IN-FLOOR - REMOVAL, SEAT BACK PANEL .........23-158

THREAD REPAIR - DESCRIPTION, FRONT CRADLE CROSSMEMBER ..............13-14

THREAD REPAIR - STANDARD PROCEDURE, MANIFOLD STRIPPED ......9-147

THREADS - STANDARD PROCEDURE, REPAIR OF DAMAGED OR WORN .....9-10,9-88

THREE PASSENGER BENCH - INSTALLATION, SEAT BELT BUCKLE -

SECOND ROW ....................... 8O-40

THREE PASSENGER BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW .....8O-40

THREE ZONE, DESCRIPTION - MANUAL ....24-2

THREE ZONE, OPERATION - MANUAL .....24-5

THROTTLE BODY - DESCRIPTION ........14-39

THROTTLE BODY - INSTALLATION .......14-40

THROTTLE BODY - OPERATION .........14-39

THROTTLE BODY - REMOVAL ...........14-40

THROTTLE CONTROL CABLE - INSTALLATION ....................... 14-40

THROTTLE CONTROL CABLE - REMOVAL . . 14-40

THROTTLE POSITION SENSOR - DESCRIPTION ....................... 14-40

THROTTLE POSITION SENSOR - OPERATION ......................... 14-41

TIE ROD - INSTALLATION, OUTER .......19-35

TIE ROD - REMOVAL, OUTER ...........19-34

TIMING BELT - INSTALLATION .............9-67

TIMING BELT - REMOVAL ...............9-65

TIMING BELT COVER(S) - INSTALLATION . . . 9-64

TIMING BELT COVER(S) - REMOVAL ......9-63

TIMING BELT TENSIONER & PULLEY - INSTALLATION ........................ 9-70

TIMING BELT TENSIONER & PULLEY - REMOVAL ........................... 9-69

TIMING CHAIN AND CAMSHAFT SPROCKET - INSTALLATION ............9-160

TIMING CHAIN AND CAMSHAFT SPROCKET - REMOVAL ................9-159

TIMING CHAIN COVER - INSTALLATION . . . 9-157

TIMING CHAIN COVER - REMOVAL ......9-156

TIMING CHAIN WEAR - STANDARD PROCEDURE, MEASURING .............9-155

TIMING VERIFICATION - STANDARD PROCEDURE, VALVE .................. 9-155

TIRE - DESCRIPTION ..................22-13

TIRE AND WHEEL ASSEMBLY (ALUMINUM WHEEL) - INSTALLATION .....22-8

TIRE AND WHEEL ASSEMBLY (ALUMINUM WHEEL) - REMOVAL ........22-8

TIRE AND WHEEL ASSEMBLY (STEEL WHEEL) - INSTALLATION ...............22-8

TIRE AND WHEEL ASSEMBLY (STEEL WHEEL) - REMOVAL ................... 22-8

TIRE AND WHEEL BALANCE - STANDARD PROCEDURE ................22-5

TIRE AND WHEEL MATCH MOUNTING - STANDARD PROCEDURE ................22-7

TIRE AND WHEEL ROTATION - STANDARD PROCEDURE ................22-7

TIRE AND WHEEL VIBRATION - DIAGNOSIS AND TESTING ..............22-1

TIRE INFLATION PRESSURES - STANDARD PROCEDURE ...............22-16

TIRE LEAK REPAIRING - STANDARD PROCEDURE ........................ 22-17

TIRE NOISE - DIAGNOSIS AND TESTING . . 22-14

TIRE PRESSURE FOR HIGH SPEED OPERATION - STANDARD PROCEDURE . . . 22-17

TIRE PRESSURE MONITORING - DESCRIPTION ........................ 22-9

TIRE PRESSURE MONITORING - OPERATION ......................... 22-10

TIRE PRESSURE SENSOR - DIAGNOSIS AND TESTING ....................... 22-11

TIRE (TEMPORARY) - DESCRIPTION, SPARE ............................. 22-14

TIRE WEAR PATTERNS - DIAGNOSIS AND TESTING ....................... 22-16

TIRES - CLEANING ................... 22-18

TIRES - DESCRIPTION, RADIAL-PLY ......22-13

TIRES - DESCRIPTION, REPLACEMENT . . . 22-14

TIRE/VEHICLE LEAD - DIAGNOSIS AND TESTING ........................... 22-14

32 INDEXRS

Description Group-Page Description Group-Page Description Group-Page