ail CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1941 of 2339

(4) Remove A-pillar trim panels.

(5) Place protective covers over instrument panel

and hood.

(6) Remove windshield molding. Using pliers, pull

outward on molding at the bottom of A-pillars.

(7) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 1). A power

cutting device can be used if available.

(8) Remove windshield from vehicle.

WINDSHIELD REMOVAL ± INTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove instrument panel top cover. Refer to

Group 8E, Instrument Panel and Systems.

(3) Remove A-pillar trim covers.

(4) Place protective covers over instrument panel

and hood.

(5) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the windshield

to the A-pillars, roof header and cowl pinch weld

fences. Refer to instructions provided with the equip-

ment being used.

(6) Remove windshield from vehicle.

INSTALLATION

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

CAUTION: Open the left front door glass before

installing windshield to avoid pressurizing the pas-

senger compartment. If a door is slammed before

urethane bonding is cured, water leaks can result.

Allow the urethane at least 24 hours to cure before

returning the vehicle to use.To avoid stressing the replacement windshield, the

urethane bonding material on the windshield fence

should be smooth and consistent to the shape of

the replacement windshield. The support spacers

should be cleaned and properly installed on weld

studs or repair screws at bottom of windshield

opening.

(1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the compression spacers.

(2) Verify the glass lays evenly against the pinch

urethane adhesive remaining on the weld fence at

the sides, top and bottom of the replacement wind-

shield. If not, the pinch weld fence must be formed to

the shape of the new glass.

(3) Remove replacement windshield from wind-

shield opening.

(4) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 2).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN WINDSHIELD BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(5) Clean inside of windshield with ammonia based

glass cleaner and lint-free cloth.

(6) Install molding to perimeter of windshield.

(7) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of windshield and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(8) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of windshield. Allow at least three minutes

drying time.

(9) Using a razor knife, remove as much original

urethane as possible. Do not damage paint on wind-

shield fence.

(10) Apply pinch weld primer 19 mm (0.75 in.)

wide around the windshield fence. Allow at least

three minutes drying time.

(11) If a low viscosity urethane adhesive is used,

install compression spacers on the fence around the

windshield opening (Fig. 3).

(12) Apply a 10 mm (0.4 in.) bead of urethane on

center line of windshield fence.

(13) With the aid of a helper, position the wind-

shield over the windshield opening.

(14) Slowly lower windshield glass to windshield

opening fence. Guide the molding into proper position

as necessary. Push windshield inward until molding

is flush to roof line and A-pillars (Fig. 3).

(15) Clean access urethane from exterior with

MopartSuper Kleen or equivalent.

Fig. 1 CUT URETHANE AROUND WINDSHIELD

1 - COLD KNIFE

2 - WINDSHIELD

23 - 162 STATIONARY GLASSRS

WINDSHIELD (Continued)

Page 1943 of 2339

QUARTER WINDOW

REMOVAL

(1) Remove C-pillar trim.

(2) Open quarter glass to vent position.

(3) Disengage quarter window retainer from vent

motor arm.

(4) Remove nuts attaching quarter glass to C-pillar

(Fig. 5).

(5) Use magnetic socket to prevent dropping into

the pillar.

(6) Remove quarter glass from vehicle.

INSTALLATION

(1) Place quarter glass in position on vehicle.

(2) Install nuts attaching quarter glass to C-pillar.

(3) Engage quarter window retainer to vent motor

arm.

(4) Install screw attaching quarter window

retainer to vent motor arm.

(5) Close quarter glass.

(6) Verify alignment and flushness.

(7) Install C-pillar trim.

LIFTGATE GLASS

REMOVAL

Refer to the Safety Precautions in this section for

description of tools and adhesive systems that are

recommended for use in this procedure.

REAR WINDOW REMOVAL ± EXTERIOR METHOD

(1) Remove rear window wiper arm.

(2) Remove interior trim covers.

(3) Disconnect wires for electrically heated win-

dow, if equipped.

(4) Using a sharp cold knife, cut urethane adhe-

sive attaching the rear window to the liftgate. A

power cutting device can be used if available (Fig. 1).

(5) Remove rear window from vehicle.

INSTALLATION

Refer to the Safety Precautions in this section for

description of tools and adhesive systems that are

recommended for use in this procedure.

CAUTION: Open the left front door glass before

installing rear window to avoid pressurizing the

passenger compartment. If a door is slammed

before urethane bonding is cured, water leaks can

result.

Allow the urethane at least 24 hours to cure before

returning the vehicle to use.

To avoid stressing the replacement rear window,

the urethane bonding material on the rear window

fence should be smooth and consistent to the

shape of the replacement glass.

(1) Place replacement glass into rear window open-

ing.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement rear window. If not, the urethane adhe-

sive remaining on the fence must be formed to the

shape of the new glass.

(3) Using a grease pencil, mark the glass and lift-

gate in several locations to aid installation.

(4) Remove replacement glass from liftgate open-

ing.

(5) Position the rear window inside up on a suit-

able work surface with two padded, wood 10 cm by

10 cm by 50 cm (4 in. by 4 in. by 20 in.) blocks,

placed parallel 75 cm (2.5 ft.) apart (Fig. 2).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN REAR WINDOW BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

Fig. 5 QUARTER GLASS

1 - VENT CONTROL

2 - QUARTER GLASS

3 - CLIP

23 - 164 STATIONARY GLASSRS

Page 1946 of 2339

(6) Install fully the entire A-pillar glass run sec-

tion by indexing the molded corner detail into the

roll frame. Slide the glass run up the A-pillar until

the rubber molded joint just touches the roll frame.

(7) Verify that the tertiary seal is on the correct

side of the roll frame prior to seating the glass run

fully onto the frame. Verify the glass runs is fully

seated for the header, and A-pillar and B-pillar

(8) Install screw attaching glass run weatherstrip

to inner door panel.

(9) Install inner belt weatherstrip.

(10) Install watershed.

(11) Push weatherstrip groove onto lip along top of

door frame.

(12) Engage clip into slot in door frame.

(13) Push weatherstrip into channel at rear of door

frame, working from the top to bottom.

(14) Install door frame closeout moldings.

(15) Install door speaker, if equipped.

(16) Install door trim panel.FRONT DOOR OUTER BELT

MOLDING

REMOVAL

(1) Remove the side view mirror. (Refer to 23 -

BODY/EXTERIOR/SIDE VIEW MIRROR -

REMOVAL)

(2) Remove door trim panel.

(3) Roll door glass down.

(4) Using a hook tool, disengage interlocking lip at

the base of the inward edge of the belt molding (Fig.

1).

(5) Remove belt molding from door.

INSTALLATION

(1) Place belt molding in position on door (Fig. 1).

NOTE: Make sure end of applique is against outer

belt.

(2) Engage interlocking lip at the base of the

inward edge of the belt molding on door panel.

(3) Install door trim panel.

Fig. 1 FRONT DOOR WEATHERSTRIP

1 - DOOR GLASS RUN WEATHERSTRIP

2 - FRONT INNER DOOR

3 - DOOR BELT OUTER WEATHERSTRIP4 - DOOR MOUNTED WEATHERSTRIP

5 - DOOR OUTER BELT WEATHERSTRIP

RSWEATHERSTRIP/SEALS23 - 167

FRONT DOOR GLASS RUN WEATHERSTRIP (Continued)

Page 1953 of 2339

(5) Verify that the sunshade move back and forth

properly.

(6) Cycle sunroof towards the closed position.

(7) Install glass panel (Refer to 23 - BODY/SUN-

ROOF/GLASS PANEL - INSTALLATION).

WIND DEFLECTOR

REMOVAL

(1) Fully open sunroof glass panel.

(2) Disconnect negative battery cable.

(3) Remove sunroof assembly (Refer to 23 - BODY/

SUNROOF/MODULE ASSEMBLY - REMOVAL).

(4) Depress the front deflector retaining tabs. (Fig.

2)

(5) Remove wind deflector.

INSTALLATION

(1) Place wind deflector arms in upward position

engage the wind deflector blade into the U-frame.

(2) Engage the retaining clips (Fig. 1).

(3) Verify wind deflector operation.

(4) Install the sun roof assembly (Refer to 23 -

BODY/SUNROOF/MODULE ASSEMBLY - INSTAL-

LATION).

WATER CHANNEL

REMOVAL

(1) Remove glass panel (Refer to 23 - BODY/SUN-

ROOF/GLASS PANEL - REMOVAL).

(2) Remove the retaining screws (Fig. 1).

(3) Carefully slide water channel forward to

release tabs from U-frame and remove from vehicle.

INSTALLATION

(1) Carefully place water channel onto U-frame

and slide it rearward to lock tabs (Fig. 1).

(2) Install the water channel attaching screws

(Fig. 1).

(3) Position glass panel on to mechanism lift arms.

(4) Start the glass attaching screws, and hand

tighten.

(5) Adjust sunroof glass (Refer to 23 - BODY/SUN-

ROOF/GLASS PANEL - ADJUSTMENTS).

(6) Verify sunroof operation and alignment.

SUNROOF MOTOR

REMOVAL

(1) Remove the sunroof (Refer to 23 - BODY/SUN-

ROOF/MODULE ASSEMBLY - REMOVAL).

(2) Remove the sunroof motor retaining bolts and

remove motor (Fig. 1).

INSTALLATION

CAUTION: THE SUNROOF MOTOR MUST BE TIMED

WITH THE SUNROOF ASSEMBLY. FAILURE TO DO

SO WILL RESULT IN IMPROPER SUNROOF OPERA-

TION AND POSSIBLE LEAKAGE OR DAMAGE TO

THE ASSEMBLY.

(1) Assure proper sunroof motor timing before

installation (Refer to 23 - BODY/SUNROOF/DRIVE

MOTOR - ADJUSTMENTS).

(2) Position the sunroof motor to the sunroof

assembly and install the retaining bolts (Fig. 1).

Tighten sunroof motor retaining bolts to 4.2Nm (40

lbs.in.).

(3) Connect the timed sunroof assembly to a

power source and assure proper operation before

installing the sunroof assembly into the vehicle.

Fig. 2 WIND DEFLECTOR

1 - Sun Roof

2 - Retaing Clip

3 - Sun Roof Assembly Trim

23 - 174 SUNROOFRS

SUNSHADE (Continued)

Page 1954 of 2339

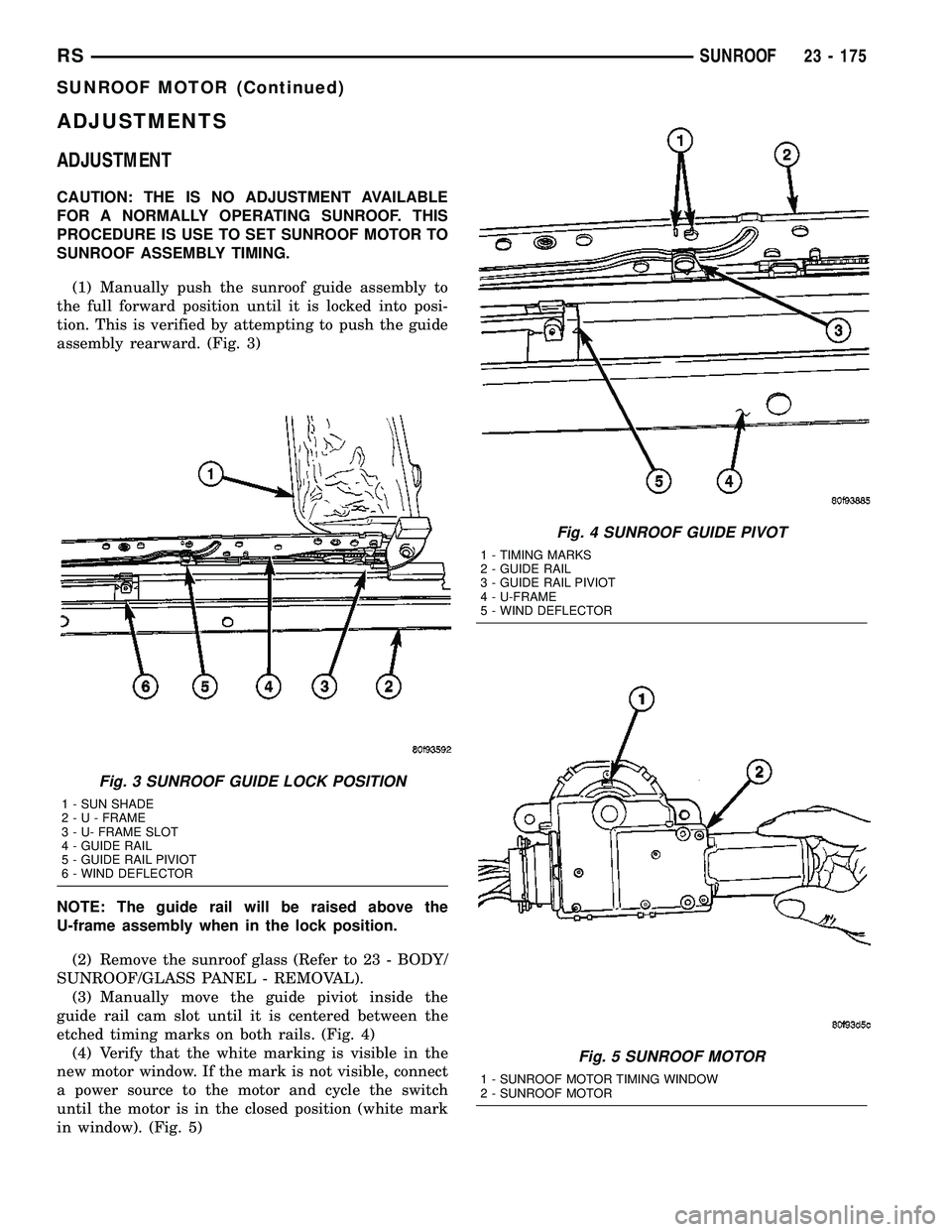

ADJUSTMENTS

ADJUSTMENT

CAUTION: THE IS NO ADJUSTMENT AVAILABLE

FOR A NORMALLY OPERATING SUNROOF. THIS

PROCEDURE IS USE TO SET SUNROOF MOTOR TO

SUNROOF ASSEMBLY TIMING.

(1) Manually push the sunroof guide assembly to

the full forward position until it is locked into posi-

tion. This is verified by attempting to push the guide

assembly rearward. (Fig. 3)

NOTE: The guide rail will be raised above the

U-frame assembly when in the lock position.

(2) Remove the sunroof glass (Refer to 23 - BODY/

SUNROOF/GLASS PANEL - REMOVAL).

(3) Manually move the guide piviot inside the

guide rail cam slot until it is centered between the

etched timing marks on both rails. (Fig. 4)

(4) Verify that the white marking is visible in the

new motor window. If the mark is not visible, connect

a power source to the motor and cycle the switch

until the motor is in the closed position (white mark

in window). (Fig. 5)

Fig. 3 SUNROOF GUIDE LOCK POSITION

1 - SUN SHADE

2-U-FRAME

3 - U- FRAME SLOT

4 - GUIDE RAIL

5 - GUIDE RAIL PIVIOT

6 - WIND DEFLECTOR

Fig. 4 SUNROOF GUIDE PIVOT

1 - TIMING MARKS

2 - GUIDE RAIL

3 - GUIDE RAIL PIVIOT

4 - U-FRAME

5 - WIND DEFLECTOR

Fig. 5 SUNROOF MOTOR

1 - SUNROOF MOTOR TIMING WINDOW

2 - SUNROOF MOTOR

RSSUNROOF23 - 175

SUNROOF MOTOR (Continued)

Page 1958 of 2339

SPECIFICATIONS

ITEM LOCATION GAP FLUSH

A HOOD TO FASCIA (VOYAGER ONLY)

8.0 2.0

PARALLEL WITHIN 2.0 RIGHT TO

LEFT2.5 OVER FLUSH TO HOOD

1.5 CONSISTENT WITHIN 2.0

B HEADLAMP MODULE TO

HOOD8.0 2.0

PARALLEL WITHIN 2.0 RIGHT TO

LEFT

C HOOD TO FENDER (FORE &

AFT)0.0 1.5

LEFT TO RIGHT WITHIN 1.5

D HOOD TO FENDER 4.0 1.5

PARALLEL WITHIN 2.5 AND

WITHIN 1.5 LEFT TO RIGHTUNDER FLUSH 2.0

E FENDER TO DOOR 5.0 1.5

PARALLEL WITHIN 2.0UNDER FLUSH 0.5 1.5

CONSISTENT WITHIN 2.0

F FRONT DOOR TO9A9PILLAR

COVERUNDER FLUSH 0.5 2.0

G9A9PILLAR COVER TO

SLIDING DOOR5.0 2.0

PARALLEL WITHIN 1.01.0 UNDER FLUSH 2.0

CONSISTENT WITHIN 1.0

H FRONT DOOR APPLIQUE TO

SLIDING DOOR GLASS5.0 2.0

PARALLEL WITHIN 2.01.0 OVER FLUSH 2.0

CONSISTENT WITHIN 3.0

I FRONT DOOR TO SLIDING

DOOR5.0 2.0

PARALLEL WITHIN 2.0 2.0 CONSISTENT WITHIN

2.0

J SLIDING DOOR TO REAR

APERTURE GLASS5.0 2.0

PARALLEL WITHIN 1.5 3.0 CONSISTENT WITHIN

3.0

K SLIDING DOOR TO REAR

APERTURE5.0 1.5

PARALLEL WITHIN 2.0 1.5 CONSISTENT WITHIN

1.5

L TAIL LAMP TO BODY SIDE

APERTURE1.0 1.0

PARALLEL WITHIN 1.5OVER FLUSH

M TAIL LAMP TO LIFTGATE 4.0 2.0 OVER FLUSH

N LIFTGATE TO BODY SIDE

APERTURE4.0 1.5 UNDER FLUSH 1.0 2.5

CONSISTENT WITHIN 2.0

O LIFTGATE TO ROOF 8.0 2.0 UNDER FLUSH 1.5

P LIFTGATE TO FASCIA 8.0 2.5

PARALLEL WITHIN 3.0OVER FLUSH

Q LIFTGATE TO REAR FASCIA 2.0 0.5 UNDER FLUSH TO 1.0

MAXIMUM

R FUEL FILLER DOOR TO BODY

SIDE APERTUREUNDER FLUSH 0.5 1.0

NOTE: All measurements are in mm.

RSBODY STRUCTURE23 - 179

GAP AND FLUSH (Continued)

Page 1962 of 2339

SEALER LOCATIONS

SPECIFICATIONS

SPECIFICATIONS - BODY SEALING LOCATIONS

INDEX

DESCRIPTION FIGURE

METHODS OF APPLYING AUTO BODY SEALANT 5

LOWER WINDSHIELD OPENING - RIGHT AND LEFT SIDES 6

COWL SIDE - LEFT AND RIGHT SIDES 7

SIDE QUARTER WINDSHIELD OPENING - LEFT AND RIGHT SIDES 8

UPPER WINDSHIELD A-PILLAR - LEFT AND RIGHT SIDES 9

ROOF TRACK C-PILLAR - LEFT AND RIGHT SIDES 10

SLIDING DOOR UPPER FLANGE SEAMS - LEFT AND RIGHT SIDES 11

QUARTER PANEL EXTERIOR AREA - LEFT AND RIGHT SIDES 12

LOWER REAR EXTERIOR CORNER PANELS - LEFT AND RIGHT SIDES 13

LOWER SILL LIFT GATE OPENING - LEFT AND RIGHT SIDES 14

C-PILLAR CAN - LEFT AND RIGHT SIDES 15

SHOCK TOWER AREA - LEFT AND RIGHT SIDES 16

OUTER SHOCK TOWER AREA - LEFT AND RIGHT SIDES 17

CROSS MEMBER SUPPORT - LEFT AND RIGHT SIDES 18

A & B-PILLAR FLOOR PAN RISERS - LEFT AND RIGHT SIDES 19

REAR WHEEL HOUSE FLOOR PAN - LEFT AND RIGHT SIDES 20

REAR WHEELHOUSE TO FLOOR PAN - LEFT AND RIGHT SIDES 21

UPPER SLIDING DOOR FLANGE - LEFT AND RIGHT SIDES 22

UPPER LIFTGATE HINGE AREA - LEFT AND RIGHT SIDES 23

REAR BRACKET SUPPORT REAR HANGER - LEFT AND RIGHT SIDES 24

LIFTGATE PANEL OPENING - UNDERSIDE 25

D-PILLAR INSIDE SEAM - LEFT AND RIGHT SIDES 26

REAR TAIL LAMP AREA SEAMS - LEFT AND RIGHT SIDES 27

UPPER LIFTGATE PANEL SILL - LEFT AND RIGHT SIDES 28

FRONT WHEELHOUSE & SHOCK TOWER - LEFT AND RIGHT SIDES 29

REAR QUARTER WHEELHOUSE LIP & SEAT ANCHOR BOLT - LEFT AND RIGHT

SIDES30

TAIL LAMP CAN - LEFT AND RIGHT SIDES 31

B-PILLAR AND SILL AREAS - LEFT AND RIGHT SIDES 32

FRONT FLOOR PAN & RISER 33

FLOOR PAN SEAMS - LEFT AND RIGHT SIDES 34

FLOOR PAN & REAR WHEELHOUSE AREA - LEFT AND RIGHT SIDES 35

FLOOR PAN SILL & D-PILLAR SEAMS - LEFT AND RIGHT SIDES 36

LEFT SIDE SEAT ANCHOR REINFORCEMENT - SHORT WHEEL BASE ONLY 37

UNDERBODY - LEFT AND RIGHT SIDES 38

RSBODY STRUCTURE23 - 183

Page 1975 of 2339

Fig. 26 D-PILLAR INSIDE SEAM - LEFT AND RIGHT SIDES

Fig. 27 REAR TAIL LAMP AREA SEAMS - LEFT AND RIGHT SIDES

23 - 196 BODY STRUCTURERS

SEALER LOCATIONS (Continued)

Page 1977 of 2339

Fig. 30 REAR QUARTER WHEELHOUSE LIP & SEAT ANCHOR BOLT - LEFT AND RIGHT SIDES

Fig. 31 TAIL LAMP CAN - LEFT AND RIGHT SIDES

23 - 198 BODY STRUCTURERS

SEALER LOCATIONS (Continued)

Page 1997 of 2339

STRUCTURAL ADHESIVE

LOCATIONS

SPECIFICATIONS

SPECIFICATIONS - STRUCTURAL ADHESIVE

LOCATIONS

INDEX

DESCRIPTION FIGURE

UPPER COWL PLENUM, UPPER AND LOWER DASH PANEL 65

ROOF AND REAR QUARTER PANELS - LONG WHEEL BASE ONLY 66

FLOOR PAN - LONG WHEEL BASE ONLY 67

SUSPENSION HANGER REINFORCEMENTS - LONG WHEEL BASE ONLY 68

FRONT HINGE PILLAR REINFORCEMENTS - LONG WHEEL BASE ONLY 69

ROOF AND REAR QUARTER PANELS - SHORT WHEEL BASE ONLY 70

FLOOR PAN - SHORT WHEEL BASE ONLY 71

FRONT SIDE RAILS/OUTER CROSS MEMBER BRACKETS 72

OUTER ROOF PANEL/UPPER WINDSHIELD FRAME 73

COWL SIDE PANEL / BODY SIDE APERTURE, B-PILLAR / SLIDING DOOR TRACK

SUPPORT74

FRONT HINGE PILLAR REINFORCEMENT / COWL SIDE TAPPING PLATE 75

UPPER COWL PLENUM / UPPER AND LOWER DASH PANEL - RIGHT HAND DRIVE

ONLY76

23 - 218 BODY STRUCTURERS