engine CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2235 of 2339

heater core inlet and outlet ports. Removable heater

core tubes attach to the ports by use of a sealing

plate secured with a screw to the heater core tank.

This removable heater core tube arrangement allows

the heater core to be serviced without removing the

HVAC housing from the vehicle.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The blend door

allows control of the heater output air temperature

by regulating the amount of air that is flowing

through the heater core within the HVAC housing.

The heater core cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

FRONT HEATER CORE TUBES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Disconnect and isolate the battery negative

cable.

(3) Disconnect the heater hoses from the heater

core tubes (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/HEATER INLET HOSE -

REMOVAL) and (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/HEATER RETURN

HOSE - REMOVAL).(4) Remove the silencer from beneath the driver

side end of the instrument panel.

NOTE: Take the proper precautions to protect the

carpeting below the heater core from spilled engine

coolant and have absorbent toweling readily avail-

able to clean up any spills.

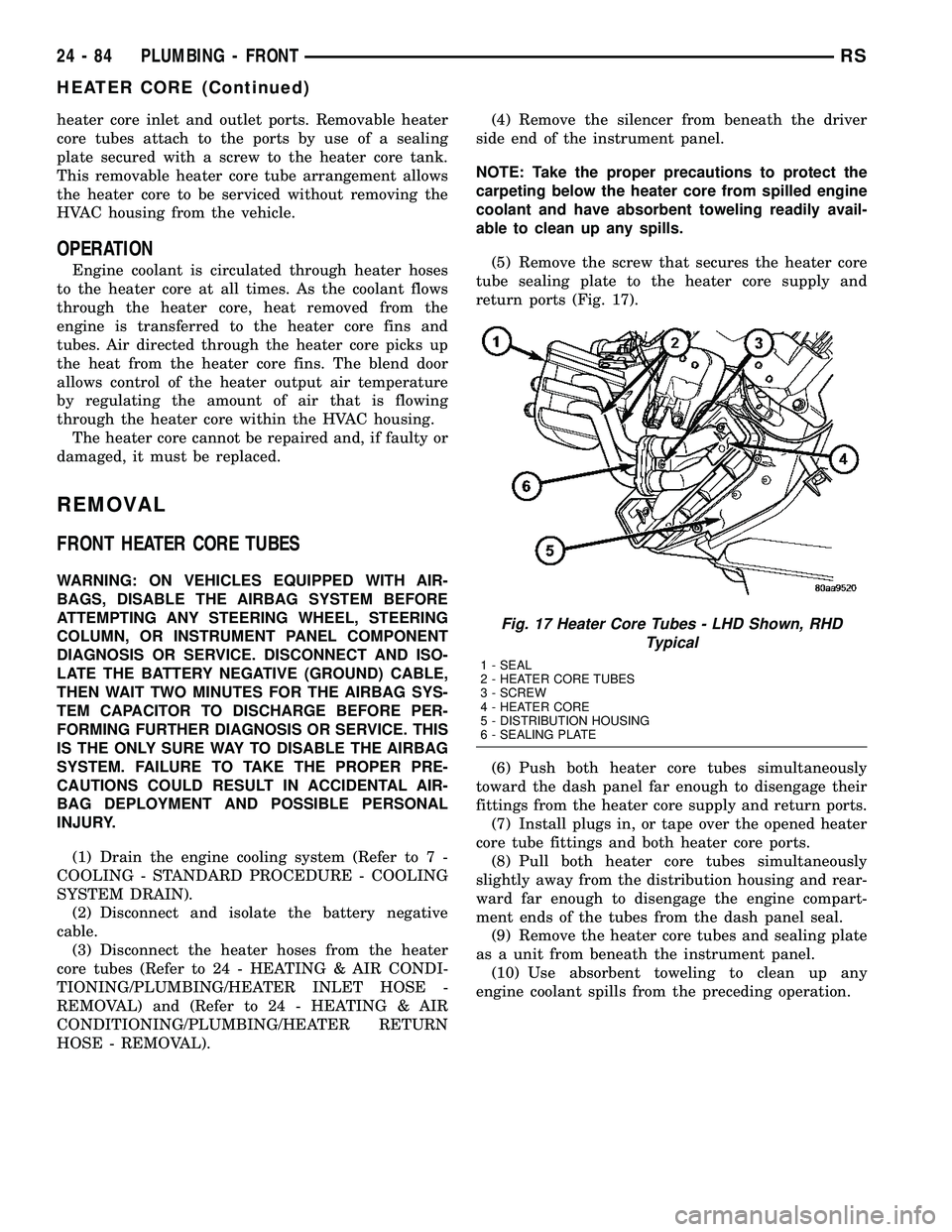

(5) Remove the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports (Fig. 17).

(6) Push both heater core tubes simultaneously

toward the dash panel far enough to disengage their

fittings from the heater core supply and return ports.

(7) Install plugs in, or tape over the opened heater

core tube fittings and both heater core ports.

(8) Pull both heater core tubes simultaneously

slightly away from the distribution housing and rear-

ward far enough to disengage the engine compart-

ment ends of the tubes from the dash panel seal.

(9) Remove the heater core tubes and sealing plate

as a unit from beneath the instrument panel.

(10) Use absorbent toweling to clean up any

engine coolant spills from the preceding operation.

Fig. 17 Heater Core Tubes - LHD Shown, RHD

Typical

1 - SEAL

2 - HEATER CORE TUBES

3 - SCREW

4 - HEATER CORE

5 - DISTRIBUTION HOUSING

6 - SEALING PLATE

24 - 84 PLUMBING - FRONTRS

HEATER CORE (Continued)

Page 2236 of 2339

FRONT HEATER CORE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the silencer boot fasteners located

around the base of the lower steering shaft from the

dash panel so that it may be pushed aside.

(2) Remove the brake lamp switch from its mount-

ing bracket (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

REMOVAL).

(3) Disconnect the power brake booster input rod

(push rod) from the pin on the brake pedal arm

(Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/POWER BRAKE BOOSTER -

REMOVAL).

(4) Remove the heater core tubes (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

HEATER CORE - REMOVAL).

(5) Remove the two screws that secure the heater

core mounting plate to the distribution housing.

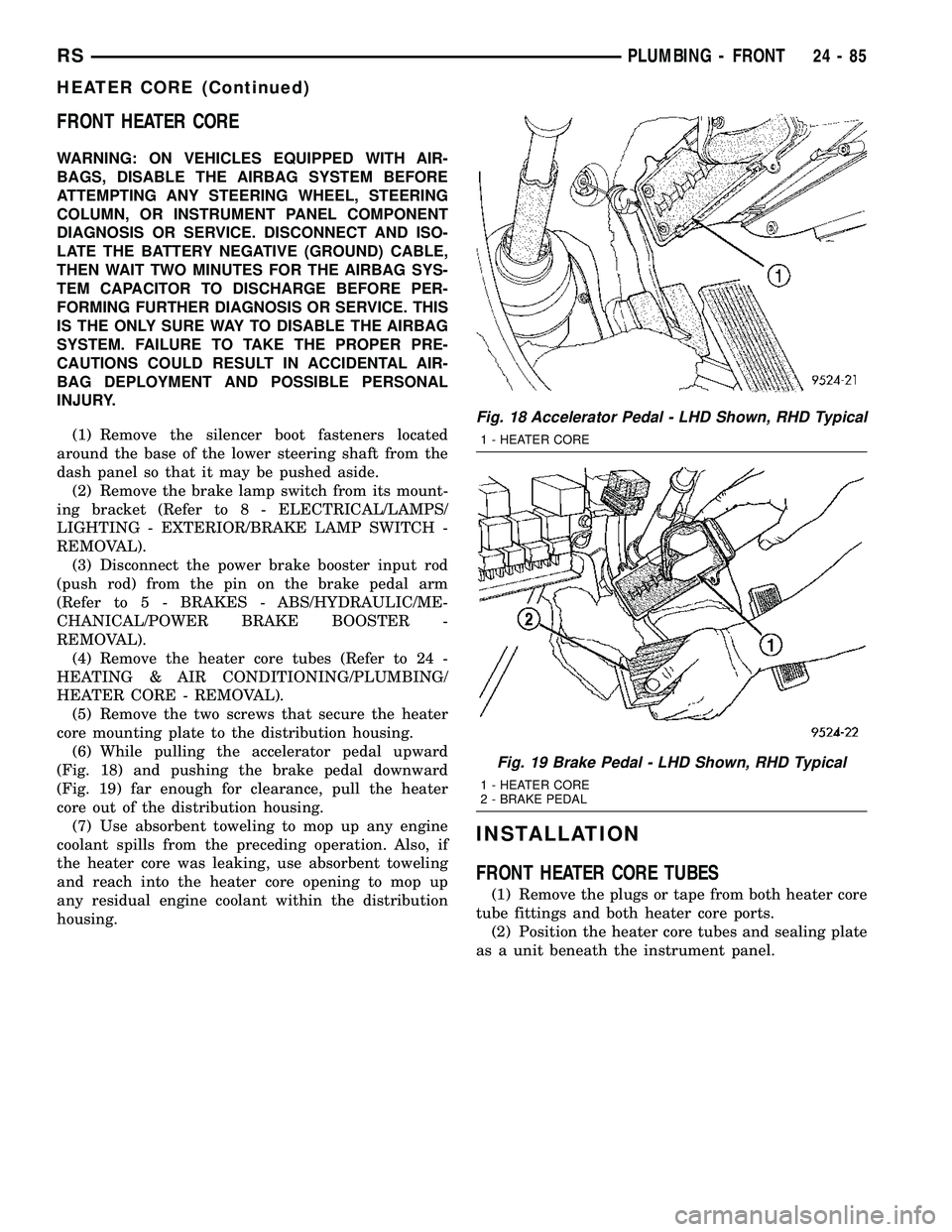

(6) While pulling the accelerator pedal upward

(Fig. 18) and pushing the brake pedal downward

(Fig. 19) far enough for clearance, pull the heater

core out of the distribution housing.

(7) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation. Also, if

the heater core was leaking, use absorbent toweling

and reach into the heater core opening to mop up

any residual engine coolant within the distribution

housing.

INSTALLATION

FRONT HEATER CORE TUBES

(1) Remove the plugs or tape from both heater core

tube fittings and both heater core ports.

(2) Position the heater core tubes and sealing plate

as a unit beneath the instrument panel.

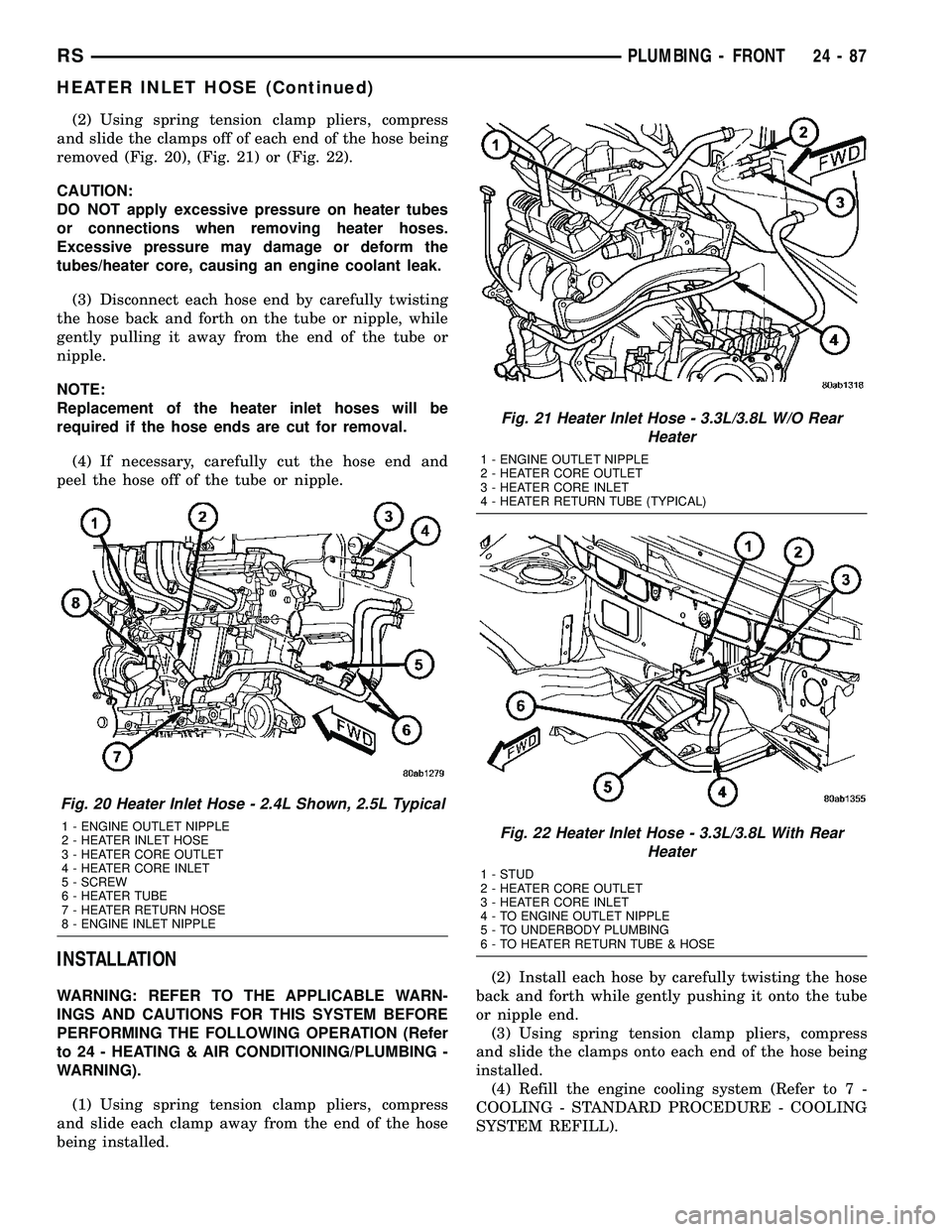

Fig. 18 Accelerator Pedal - LHD Shown, RHD Typical

1 - HEATER CORE

Fig. 19 Brake Pedal - LHD Shown, RHD Typical

1 - HEATER CORE

2 - BRAKE PEDAL

RSPLUMBING - FRONT24-85

HEATER CORE (Continued)

Page 2237 of 2339

(3) Align the engine compartment ends of both

heater core tubes with the openings in the dash

panel seal and push them simultaneously forward

through the seal far enough to engage the heater

core ends of the tubes with the heater core supply

and return ports.

(4) Position both heater core tubes and the sealing

plate simultaneously to the heater core supply and

return ports.

NOTE: The heater core tubes each have a slot that

must be indexed to a location tab within each of the

heater core ports. Adjust the position of the tubes

as required so that the sealing plate fits flush

against the heater core supply and return ports,

which indicates that the tubes are properly indexed.

(5) Index both heater core tubes to the heater core

ports.

(6) Install the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports. Tighten the screw to 3 N´m (27 in. lbs.).

(7) Install the silencer under the driver side end of

the instrument panel.

(8) Connect the heater hoses to the heater hose

tubes (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/HEATER INLET HOSE - INSTAL-

LATION) and(Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/HEATER RETURN

HOSE - INSTALLATION).

(9) Reconnect the battery negative cable.

(10) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

FRONT HEATER CORE

(1) While pushing the brake pedal downward and

pulling the accelerator pedal upward far enough for

clearance, slide the heater core into the distribution

housing.

(2) Install the two screws that secure the heater

core mounting plate to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).(3) Install the heater core tubes (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

HEATER CORE - INSTALLATION).

(4) Reconnect the power brake booster input rod

(push rod) to the pin on the brake pedal arm (Refer

to 5 - BRAKES/HYDRAULIC/MECHANICAL/

POWER BRAKE BOOSTER - INSTALLATION).

(5) Reinstall the brake lamp switch into its mount-

ing bracket (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

INSTALLATION).

(6) Reinstall the silencer boot around the base of

the lower steering shaft on the dash panel.

(7) Reconnect the battery negative cable.

(8) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

(9) Operate system for two thermostat cycles to

assure the elimination of any air that may be

trapped within the cooling system.

HEATER INLET HOSE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

NOTE: The heater inlet hose is constructed from

formed steel tubing and rubber hoses. Depending

on application, the ends are secured to the heater

core, engine oil cooler or the engine by spring ten-

sion clamps.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

24 - 86 PLUMBING - FRONTRS

HEATER CORE (Continued)

Page 2238 of 2339

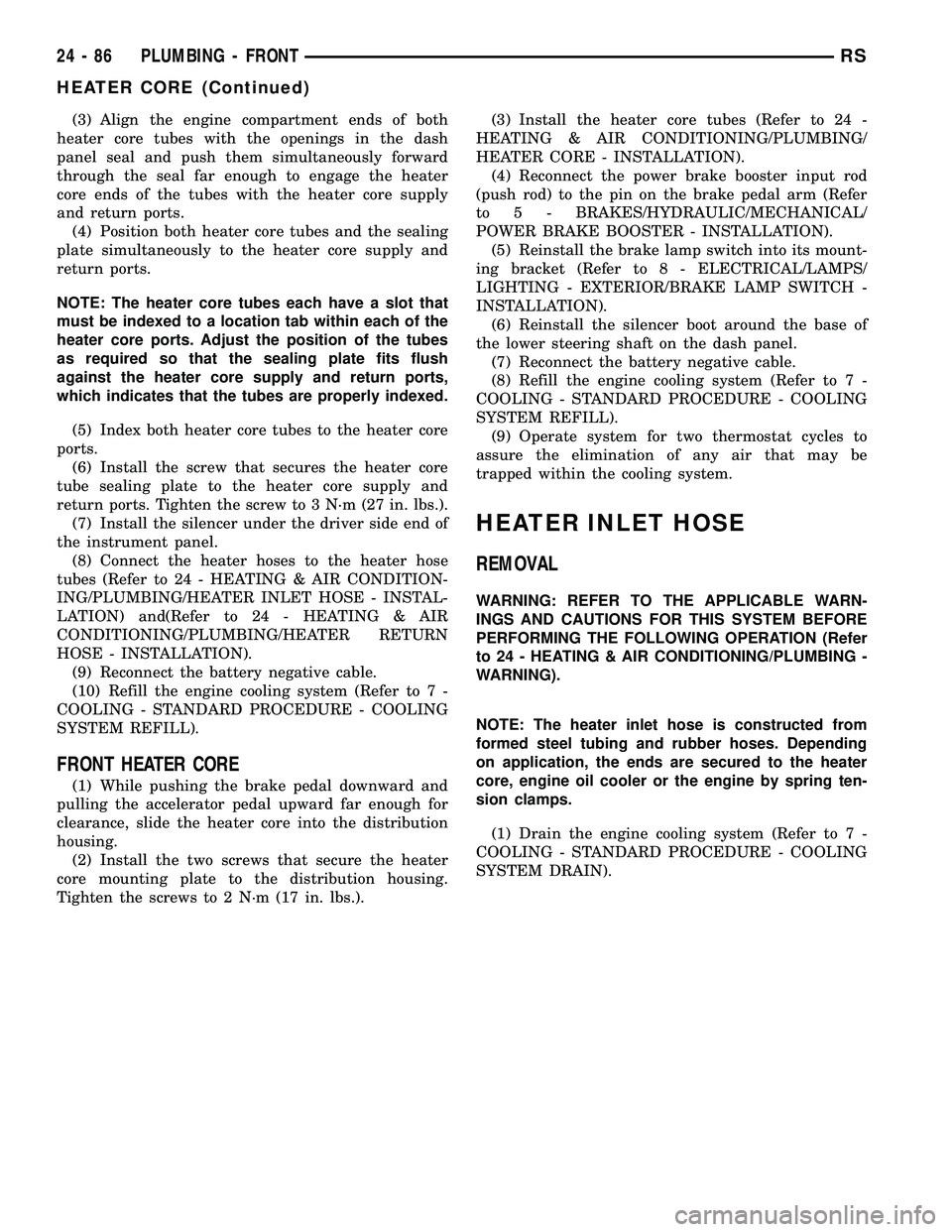

(2) Using spring tension clamp pliers, compress

and slide the clamps off of each end of the hose being

removed (Fig. 20), (Fig. 21) or (Fig. 22).

CAUTION:

DO NOT apply excessive pressure on heater tubes

or connections when removing heater hoses.

Excessive pressure may damage or deform the

tubes/heater core, causing an engine coolant leak.

(3) Disconnect each hose end by carefully twisting

the hose back and forth on the tube or nipple, while

gently pulling it away from the end of the tube or

nipple.

NOTE:

Replacement of the heater inlet hoses will be

required if the hose ends are cut for removal.

(4) If necessary, carefully cut the hose end and

peel the hose off of the tube or nipple.

INSTALLATION

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

(1) Using spring tension clamp pliers, compress

and slide each clamp away from the end of the hose

being installed.(2) Install each hose by carefully twisting the hose

back and forth while gently pushing it onto the tube

or nipple end.

(3) Using spring tension clamp pliers, compress

and slide the clamps onto each end of the hose being

installed.

(4) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

Fig. 20 Heater Inlet Hose - 2.4L Shown, 2.5L Typical

1 - ENGINE OUTLET NIPPLE

2 - HEATER INLET HOSE

3 - HEATER CORE OUTLET

4 - HEATER CORE INLET

5 - SCREW

6 - HEATER TUBE

7 - HEATER RETURN HOSE

8 - ENGINE INLET NIPPLE

Fig. 21 Heater Inlet Hose - 3.3L/3.8L W/O Rear

Heater

1 - ENGINE OUTLET NIPPLE

2 - HEATER CORE OUTLET

3 - HEATER CORE INLET

4 - HEATER RETURN TUBE (TYPICAL)

Fig. 22 Heater Inlet Hose - 3.3L/3.8L With Rear

Heater

1 - STUD

2 - HEATER CORE OUTLET

3 - HEATER CORE INLET

4 - TO ENGINE OUTLET NIPPLE

5 - TO UNDERBODY PLUMBING

6 - TO HEATER RETURN TUBE & HOSE

RSPLUMBING - FRONT24-87

HEATER INLET HOSE (Continued)

Page 2239 of 2339

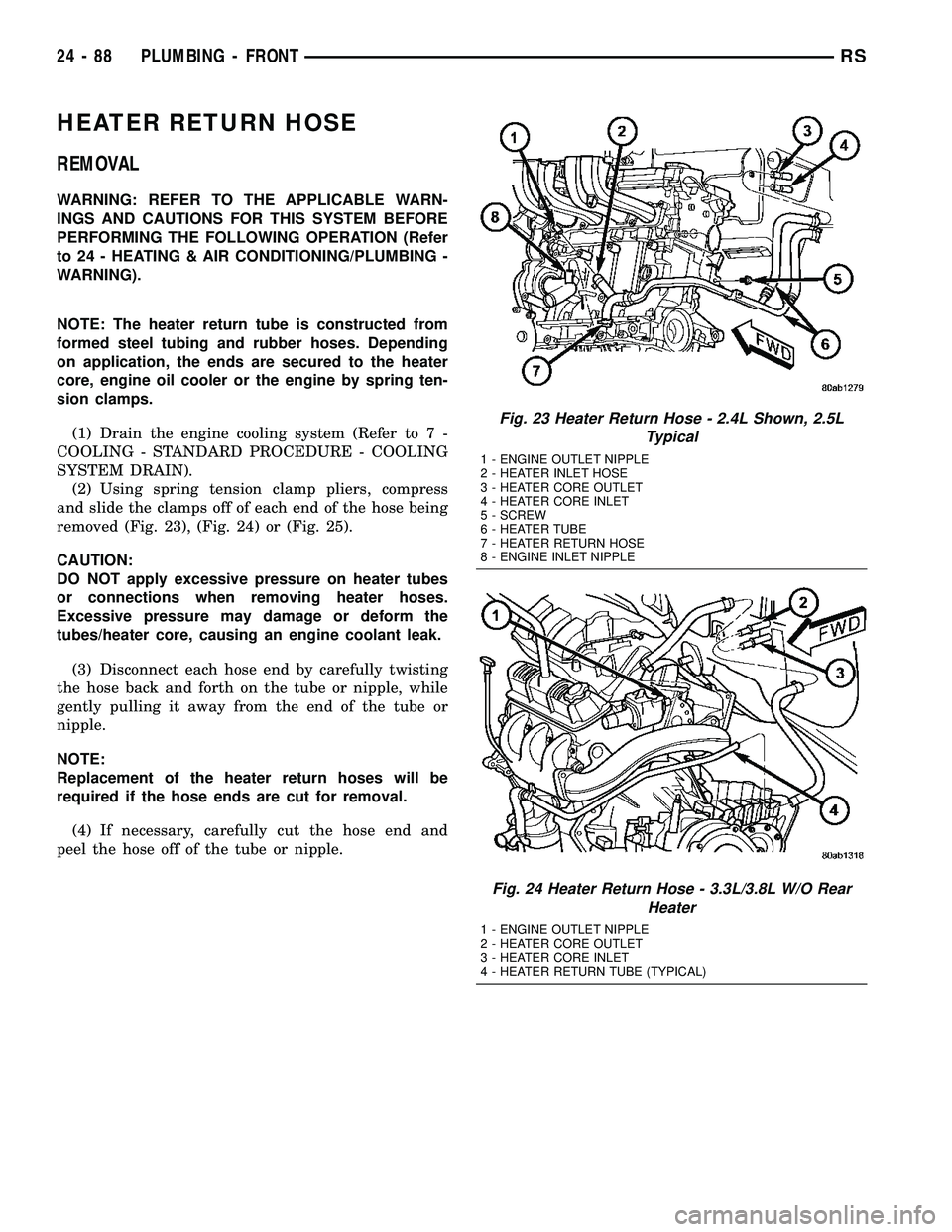

HEATER RETURN HOSE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

NOTE: The heater return tube is constructed from

formed steel tubing and rubber hoses. Depending

on application, the ends are secured to the heater

core, engine oil cooler or the engine by spring ten-

sion clamps.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Using spring tension clamp pliers, compress

and slide the clamps off of each end of the hose being

removed (Fig. 23), (Fig. 24) or (Fig. 25).

CAUTION:

DO NOT apply excessive pressure on heater tubes

or connections when removing heater hoses.

Excessive pressure may damage or deform the

tubes/heater core, causing an engine coolant leak.

(3) Disconnect each hose end by carefully twisting

the hose back and forth on the tube or nipple, while

gently pulling it away from the end of the tube or

nipple.

NOTE:

Replacement of the heater return hoses will be

required if the hose ends are cut for removal.

(4) If necessary, carefully cut the hose end and

peel the hose off of the tube or nipple.

Fig. 23 Heater Return Hose - 2.4L Shown, 2.5L

Typical

1 - ENGINE OUTLET NIPPLE

2 - HEATER INLET HOSE

3 - HEATER CORE OUTLET

4 - HEATER CORE INLET

5 - SCREW

6 - HEATER TUBE

7 - HEATER RETURN HOSE

8 - ENGINE INLET NIPPLE

Fig. 24 Heater Return Hose - 3.3L/3.8L W/O Rear

Heater

1 - ENGINE OUTLET NIPPLE

2 - HEATER CORE OUTLET

3 - HEATER CORE INLET

4 - HEATER RETURN TUBE (TYPICAL)

24 - 88 PLUMBING - FRONTRS

Page 2240 of 2339

INSTALLATION

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

(1) Using spring tension clamp pliers, compress

and slide the clamp away from the end of the heater

return hose.

(2) Install each hose end by carefully twisting the

hose back and forth while gently pushing it onto the

tube.

(3) Using spring tension clamp pliers, compress

and slide the clamps onto each end of the heater

return hose.

(4) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

LIQUID LINE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).NOTE: The front A/C liquid line is serviced in two

sections. The front section connects between the

A/C condenser and the receiver/drier and includes

the high side service port. The rear section con-

nects between the receiver/drier and the expansion

valve and includes the fitting for the A/C pressure

transducer. On models equipped with the optional

rear heating-A/C system, the rear section of the

front A/C liquid line also includes a hose and tube

extension that connects the front liquid line to the

liquid line for the rear A/C system.

FRONT SECTION

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

RECOVERY).

(2) Disconnect and isolate the negative battery

cable.

(3) Remove the air cleaner housing from the right

side of the engine compartment.

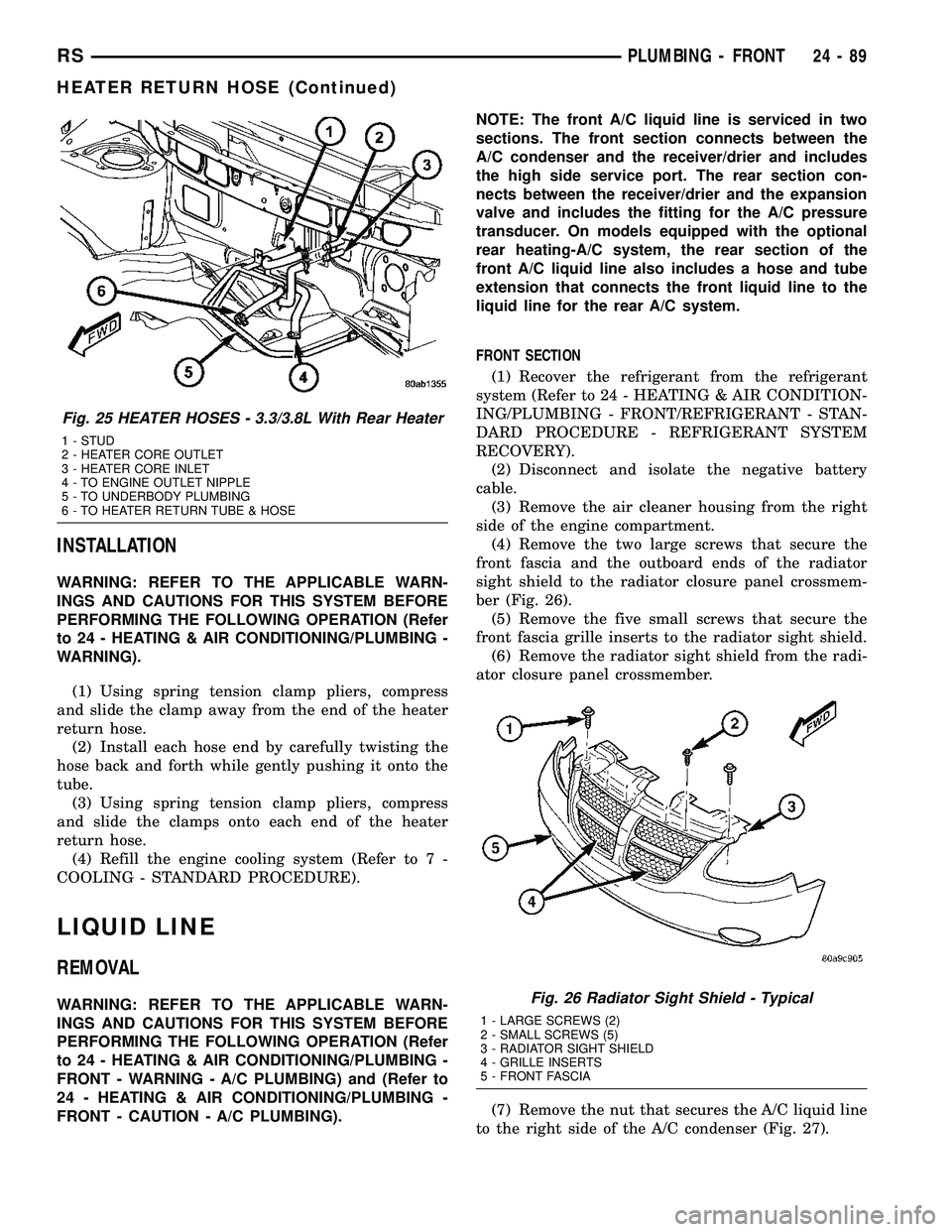

(4) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 26).

(5) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(6) Remove the radiator sight shield from the radi-

ator closure panel crossmember.

(7) Remove the nut that secures the A/C liquid line

to the right side of the A/C condenser (Fig. 27).

Fig. 25 HEATER HOSES - 3.3/3.8L With Rear Heater

1 - STUD

2 - HEATER CORE OUTLET

3 - HEATER CORE INLET

4 - TO ENGINE OUTLET NIPPLE

5 - TO UNDERBODY PLUMBING

6 - TO HEATER RETURN TUBE & HOSE

Fig. 26 Radiator Sight Shield - Typical

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSPLUMBING - FRONT24-89

HEATER RETURN HOSE (Continued)

Page 2241 of 2339

(8) Disconnect the A/C liquid line from the A/C

condenser and remove and discard the O-ring seal

and gasket.

(9) Install plugs in, or tape over the opened liquid

line fitting and the condenser outlet port.

(10) Disengage the retainer that secures the liquid

line routing clip to the top of the right frame rail

ahead of the front strut tower in the engine compart-

ment (Fig. 28).

(11) Remove the bolt that secures the front section

of the A/C liquid line to the receiver/drier.

(12) Disconnect the A/C liquid line from the receiv-

er/drier and remove and discard the O-ring seal.

(13) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier inlet port.

(14) Remove the front section of the A/C liquid line

from the engine compartment.

REAR SECTION

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Disconnect and isolate the negative battery

cable.

(3) Remove the air cleaner housing from the right

side of the engine compartment.

(4) Disconnect the drain tube from the wiper mod-

ule drain on the right side of the engine compart-

ment.

(5) Remove the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER -

REMOVAL).(6) If equipped, remove the nut that secures the

A/C ground strap to the weld stud on the top of the

right front strut tower (Fig. 28).

(7) If equipped, remove the A/C ground strap eye-

let terminal connector from the weld stud.

(8) Remove the bolt that secures the rear section

of the A/C liquid line to the receiver/drier.

(9) Disconnect the A/C liquid line from the receiv-

er/drier and remove and discard the O-ring seal.

(10) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier outlet port.

(11) Remove the nut that secures the A/C suction

line and the A/C liquid line to the A/C expansion

valve.

(12) Disconnect the A/C suction line and the A/C

liquid line from the A/C expansion valve and remove

and discard the O-ring seals.

(13) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(14) On RHD models, remove the rear section of

the A/C liquid line from the retaining bracket located

at the top of the dash panel

Fig. 27 A/C Condenser Connections

1 - A/C CONDENSER

2 - A/C DISCHARGE LINE

3 - A/C LIQUID LINE

4 - NUT (2)Fig. 28 A/C Liquid Line - LHD Shown, RHD Typical

1 - A/C GROUND STRAP (IF EQUIPPED)

2 - NUT (IF EQUIPPED)

3 - WELD STUD (IF EQUIPPED)

4 - A/C PRESSURE TRANSDUCER

5 - WELD STUD (2)

6 - A/C EXPANSION VALVE

7 - A/C LIQUID LINE (REAR SECTION)

8 - LIQUID LINE EXTENSION (REAR A/C ONLY)

9 - NUT (2)

10 - RECEIVER/DRIER

11 - ROUTING CLIP

12 - A/C LIQUID LINE (FRONT SECTION)

24 - 90 PLUMBING - FRONTRS

LIQUID LINE (Continued)

Page 2242 of 2339

(15) If the vehicle is equipped with the optional

rear heating-A/C system, go to Step 16. If the vehicle

is not equipped with the optional rear heating-A/C

system, go to Step 22.

(16) Raise and support the vehicle.

(17) Cut the tie strap located just forward of the

connections between the underbody plumbing and

the engine compartment plumbing for the rear heat-

ing-A/C system (Fig. 29).

(18) Disconnect the A/C liquid line extension fit-

ting from the underbody liquid line fitting for the

rear A/C system.

(19) Remove the O-ring seal from the underbody

liquid line fitting and discard.

(20) Install plugs in, or tape over the opened liquid

line fittings.

(21) Lower the vehicle.

(22) Remove the rear section of the A/C liquid line

from the engine compartment.

INSTALLATION

FRONT SECTION

(1) Position the front section of the A/C liquid line

into the engine compartment.

(2) Remove the tape or plugs from the liquid line

fitting and the receiver/drier inlet port.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it onto the liquid line fit-

ting.

(4) Connect the A/C liquid line to the receiver/

drier.(5) Install the bolt that secures the A/C liquid line

to the receiver/drier. Tighten the bolt to 11 N´m (97

in. lbs.).

(6) Engage the retainer that secures the liquid line

routing clip to the top of the right frame rail ahead of

the front strut tower in the engine compartment.

(7) Remove the tape or plugs from the condenser

outlet port and the liquid line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it and a new gasket onto

the liquid line fitting.

(9) Connect the A/C liquid line to the A/C con-

denser.

(10) Install the nut that secures the A/C liquid line

to the A/C condenser. Tighten the nut to 23 N´m (17

ft. lbs.).

(11) Position the radiator sight shield onto the

radiator closure panel crossmember.

(12) Install the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

Tighten the screws to 2 N´m (17 in. lbs.).

(13) Install the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber. Tighten the screws to 6 N´m (53 in. lbs.).

(14) Reinstall the air cleaner housing into the

right side of the engine compartment.

(15) Reconnect the negative battery cable.

(16) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(17) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

REAR SECTION

(1) Position the rear section of the A/C liquid line

into the engine compartment.

(2) Remove the tape or plugs from the suction line

and liquid line fittings and both expansion valve

ports.

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them onto the suction line

and liquid line fittings.

(4) Reconnect the A/C liquid line and the A/C suc-

tion line to the A/C expansion valve.

(5) Install the nut that secures the rear section of

the A/C liquid line and the A/C suction line to the

A/C expansion valve. Tighten the nut to 23 N´m (17

ft. lbs.).

(6) Remove the tape or plugs from the liquid line

fitting and the receiver/drier outlet port.

Fig. 29 Underbody A/C Line Connections

1 - SUCTION LINE EXTENSION TUBE

2 - LIQUID LINE EXTENSION TUBE

3 - RETAINING STRAP

4 - REAR HEATER EXTENSION TUBES

5 - UNDERBODY REFRIGERANT LINES

RSPLUMBING - FRONT24-91

LIQUID LINE (Continued)

Page 2243 of 2339

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(8) Reconnect the A/C liquid line to the receiver/

drier.

(9) Install the bolt that secures the A/C liquid line

to the receiver/drier. Tighten the bolt to 11 N´m (97

in. lbs.).

(10) If equipped, reinstall the A/C ground strap

eyelet terminal connector onto the weld stud on the

top of the right front strut tower (if equipped).

(11) If equipped, install the nut that secures the

A/C ground strap to the weld stud. Tighten the nut

to 12 N´m (106 in. lbs.)

(12) Install the A/C pressure transducer (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/A/C PRESSURE TRANSDUCER - INSTAL-

LATION).

(13) Connect the drain tube to the wiper module

drain on the right side of the engine compartment.

(14) Install the air cleaner housing into the right

side of the engine compartment.

(15) On RHD models, install the liquid line into

the retaining bracket located at the top of the dash

panel.

(16) If the vehicle is equipped with the optional

rear heating-A/C system, go to Step 17. If the vehicle

does not have the optional rear heating-A/C system,

go to Step 23.

(17) Raise and support the vehicle.

(18) Remove the tape or plugs from the A/C liquid

line extension fitting and the underbody liquid line

fitting.

(19) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody liquid

line fitting.

(20) Connect the A/C liquid line extension fitting

to the underbody liquid line fitting. Tighten the fit-

tings to 23 N´m (17 ft. lbs.).

(21) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heating-

A/C system.

(22) Lower the vehicle.

(23) Reconnect the negative battery cable.

(24) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(25) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).RECEIVER / DRIER

DESCRIPTION

The receiver/drier is mounted in a bracket secured

to the right front strut tower in the engine compart-

ment. The receiver/drier is connected between the

front and rear sections of the liquid line between the

condenser outlet and the evaporator inlet. The receiv-

er/drier cannot be repaired. If the receiver/drier is

faulty or damaged, or if the refrigerant system has

been contaminated or left open to the atmosphere for

an indeterminable period or if the A/C compressor

has failed, it must be replaced.

OPERATION

The receiver/drier performs a filtering action to

prevent foreign material in the refrigerant from con-

taminating the expansion valve. Desiccant inside the

receiver/drier canister absorbs any moisture which

may have entered and become trapped within the

refrigerant system. In addition, during periods of

high demand air conditioner operation, the receiver/

drier acts as a reservoir to store surplus refrigerant.

Refrigerant enters the receiver/drier as a high-pres-

sure, low temperature liquid.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Remove the air cleaner housing from the right

side of the engine compartment.

(3) Remove the bolt that secures the liquid line

front section fitting to the top of the receiver/drier

(Fig. 30).

(4) Disconnect the liquid line fitting from the

receiver/drier inlet port.

(5) Remove the O-ring seal from the liquid line fit-

ting and discard.

(6) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier inlet port.

24 - 92 PLUMBING - FRONTRS

LIQUID LINE (Continued)

Page 2244 of 2339

(7) Remove the bolt that secures the liquid line

rear section fitting to the top of the receiver/drier.

(8) Disconnect the liquid line fitting from the

receiver/drier outlet port.

(9) Remove the seal from the liquid line fitting and

discard.

(10) Install plugs in, or tape over the opened liquid

line fitting and the receiver/drier outlet port.

(11) Remove the two nuts that secure the receiver/

drier mounting bracket to the weld studs on the side

of the right front strut tower.

(12) Remove the receiver/drier and mounting

bracket unit from the studs.

INSTALLATION

NOTE: If the receiver/drier is being replaced, add 25

milliliters (0.8 fluid ounce) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the A/C compressor in the

vehicle.(1) Position the receiver/drier and mounting

bracket unit onto the weld studs on the side of the

right front strut tower.

(2) Install the two nuts that secure the receiver/

drier mounting bracket to the studs. Tighten the

nuts to 10 N´m (89 in. lbs.).

(3) Remove the tape or plugs from the liquid line

rear section fitting for the receiver/drier and the

receiver/drier outlet port.

(4) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(5) Reconnect the liquid line fitting to the receiver/

drier outlet port on the top of the receiver/drier.

(6) Install the bolt that secures the liquid line fit-

ting to the receiver/drier. Tighten the bolt to 11 N´m

(97 in. lbs.).

(7) Remove the tape or plugs from the liquid line

front section fitting for the receiver/drier and the

receiver/drier inlet port.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(9) Reconnect the liquid line fitting to the receiver/

drier inlet port on the top of the receiver/drier.

(10) Install the bolt that secures the liquid line fit-

ting to the receiver/drier. Tighten the bolt to 11 N´m

(97 in. lbs.).

(11) Reinstall the air cleaner housing into the

right side of the engine compartment.

(12) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(13) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas. Even though

R-134a does not contain chlorine, it must be

reclaimed and recycled just like CFC-type refriger-

ants. This is because R-134a is a greenhouse gas and

can contribute to global warming.

Fig. 30 Reciever/Drier - LHD Shown, RHD Typical

1 - A/C GROUND STRAP (IF EQUIPPED)

2 - NUT (IF EQUIPPED)

3 - WELD STUD (IF EQUIPPED)

4 - A/C PRESSURE TRANSDUCER

5 - WELD STUD (2)

6 - A/C EXPANSION VALVE

7 - A/C LIQUID LINE (REAR SECTION)

8 - LIQUID LINE EXTENSION (REAR A/C ONLY)

9 - NUT (2)

10 - RECEIVER/DRIER

11 - ROUTING CLIP

12 - A/C LIQUID LINE (FRONT SECTION)

RSPLUMBING - FRONT24-93

RECEIVER / DRIER (Continued)