automatic transmission CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1574 of 2339

SEAL - OIL PUMP

REMOVAL

(1) Remove transaxle from vehicle (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 41TE

- REMOVAL).

(2) Using Tool C-3981-B, remove oil pump seal

(Fig. 265).

INSTALLATION

(1) Using Tool C-4193, install oil pump seal (Fig.

266).

(2) Install transaxle to vehicle (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 41TE

- INSTALLATION).

SHIFT INTERLOCK SOLENOID

DESCRIPTION

The Brake/Transmission Shift Interlock system

consists of an electro-magnetic solenoid mounted to

the steering column (Fig. 267). The solenoid's plunger

consists of an integrated hook, which operates the

shift lever pawl (part of shift lever assembly), and a

plunger return spring (Fig. 268). The solenoid also

has an integrated bracket, which facilitates fastening

to the steering column.

Fig. 265 Remove Oil Pump Seal

1 - TOOL C-3981┬▒B

2 - OIL PUMP SEAL

Fig. 266 Install Oil Pump Seal

1 - TOOL C-4193

2 - HANDLE TOOL C-4171

Fig. 267 Brake/Transmission Shift Interlock (BTSI)

Solenoid Location

1 - BTSI SOLENOID

Fig. 268 Solenoid Plunger and Return Spring

1 - PLUNGER

2 - RETURN SPRING

3 - BTSI SOLENOID

RS40TE AUTOMATIC TRANSAXLE21 - 113

Page 1575 of 2339

OPERATION

The Brake/Transmission Shift Interlock (BTSI)

Solenoid prevents the transmission shift lever from

being moved out of PARK (P) unless the brake pedal

is applied. The BTSI solenoid is hardwired to and

controlled by the Intelligent Power Module (IPM).

Battery voltage is applied to one side of the solenoid

with the ignition key is in either the OFF, ON/RUN,

or START positions (Fig. 269). The ground side of the

solenoid is controlled by a driver within the IPM. It

relies on voltage supplied from the stop lamp switch

to the stop lamp sense circuit within the IPM to tell

when the brake pedal is depressed. When the brake

pedal is depressed, the ground circuit opens, de-ener-

gizing the solenoid. When the brake pedal is

released, the ground circuit is closed, energizing the

solenoid.

When the ignition key is in either the OFF,

ON/RUN, or START positions, the BTSI solenoid is

energized, and the solenoid plunger hook pulls the

shift lever pawl into position, prohibiting the shift

lever from moving out of PARK (P) (Fig. 270). When

the brake pedal is depressed, the ground circuit

opens, de-energizing the solenoid. This moves the

gearshift lever pawl out of the way (Fig. 271), allow-

ing the shift lever to be moved into any gear position.

Fig. 269 Ignition Key/Switch Positions

1 - ACC

2 - LOCK

3 - OFF

4 - ON/RUN

5-START

Fig. 270 Pawl Engaged to Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

Fig. 271 Pawl Disengaged From Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

21 - 114 40TE AUTOMATIC TRANSAXLERS

SHIFT INTERLOCK SOLENOID (Continued)

Page 1576 of 2339

A conventional mechanical interlock system is also

used. This system manually prohibits shifter move-

ment when the ignition switch is in the LOCK or

ACC positions. Solenoid operation is not required in

these key positions.

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK SOLENOID

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

ACTION EXPECTED RESPONSE

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system repair. Refer to the

appropriate Diagnostic Information.

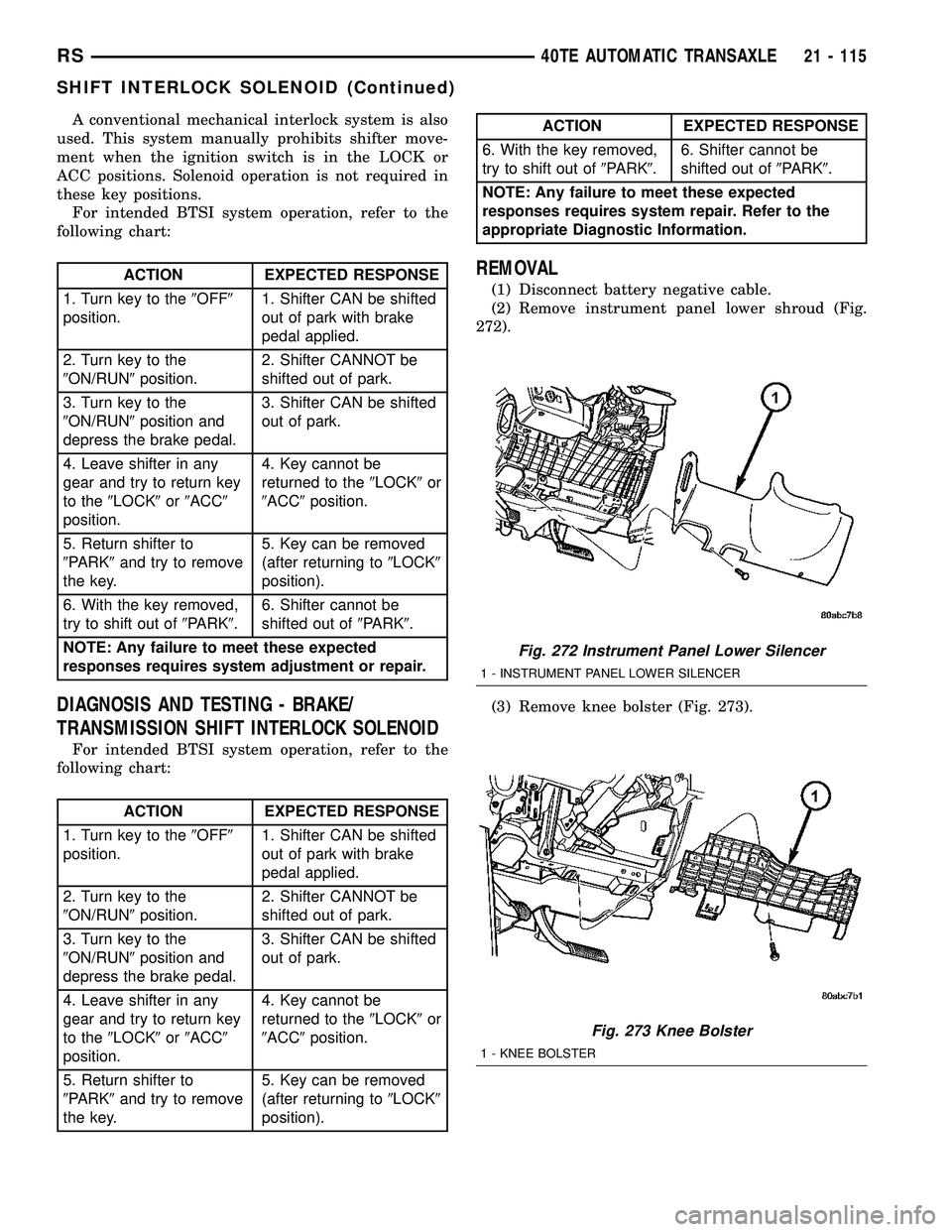

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower shroud (Fig.

272).

(3) Remove knee bolster (Fig. 273).

Fig. 272 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 273 Knee Bolster

1 - KNEE BOLSTER

RS40TE AUTOMATIC TRANSAXLE21 - 115

SHIFT INTERLOCK SOLENOID (Continued)

Page 1577 of 2339

(4) Remove steering column lower shroud.

(5) Disconnect brake/transmission shift interlock

(BTSI) solenoid connector (Fig. 274).

(6) Remove two (2) solenoid-to-column screws (Fig.

275).

(7) Remove solenoid.INSTALLATION

(1) Place interlock solenoid into position ensuring

hook on end of solenoid plunger engages gearshift

lever pawl pin. Install and tighten screws (Fig. 276).

(2) Verify gearshift lever is in PARK (P) and con-

nect solenoid connector (Fig. 277).

Fig. 274 BTSI Solenoid Connector

1 - BTSI SOLENOID

2 - SOLENOID CONNECTOR

Fig. 275 Solenoid Retaining Screw

1 - SOLENOID RETAINING SCREW (2)

Fig. 276 Solenoid Retaining Screw

1 - SOLENOID RETAINING SCREW (2)

Fig. 277 BTSI Solenoid Connector

1 - BTSI SOLENOID

2 - SOLENOID CONNECTOR

21 - 116 40TE AUTOMATIC TRANSAXLERS

SHIFT INTERLOCK SOLENOID (Continued)

Page 1578 of 2339

(3) Install steering column lower shroud.

(4) Install knee bolster (Fig. 278).

(5) Install instrument panel lower silencer (Fig.

279).

(6) Connect battery negative cable.

(7) Verify proper shift interlock system operation.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 31TH/SHIFT INTERLOCK SOLENOID -

OPERATION)SOLENOID/PRESSURE

SWITCH ASSY

DESCRIPTION

The Solenoid/Pressure Switch Assembly (Fig. 280)

is external to the transaxle and mounted to the

transaxle case. The assembly consists of four sole-

noids that control hydraulic pressure to the LR/CC,

2/4, OD, and UD friction elements. The reverse

clutch is controlled by line pressure from the manual

valve in the valve body. The solenoids are contained

within the Solenoid/Pressure Switch Assembly, and

can only be serviced by replacing the assembly.

The solenoid assembly also contains pressure

switches that monitor and send hydraulic circuit

information to the PCM/TCM. Likewise, the pressure

switches can only be service by replacing the assem-

bly.

Fig. 278 Knee Bolster

1 - KNEE BOLSTER

Fig. 279 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCERFig. 280 Solenoid/Pressure Switch Assembly

1 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

RS40TE AUTOMATIC TRANSAXLE21 - 117

SHIFT INTERLOCK SOLENOID (Continued)

Page 1579 of 2339

OPERATION

SOLENOIDS

The solenoids receive electrical power from the

Transmission Control Relay through a single wire.

The PCM/TCM energizes or operates the solenoids

individually by grounding the return wire of the sole-

noid needed. When a solenoid is energized, the sole-

noid valve shifts, and a fluid passage is opened or

closed (vented or applied), depending on its default

operating state. The result is an apply or release of a

frictional element.

The 2/4 and UD solenoids are normally applied,

which by design allow fluid to pass through in their

relaxed or ªoffº state. This allows transaxle limp-in

(P,R,N,2) in the event of an electrical failure.

The continuity of the solenoids and circuits are

periodically tested. Each solenoid is turned on or off

depending on its current state. An inductive spike

should be detected by the PCM/TCM during this test.

It no spike is detected, the circuit is tested again to

verify the failure. In addition to the periodic testing,

the solenoid circuits are tested if a speed ratio or

pressure switch error occurs.

PRESSURE SWITCHES

The PCM/TCM relies on three pressure switches to

monitor fluid pressure in the L/R, 2/4, and OD

hydraulic circuits. The primary purpose of these

switches is to help the PCM/TCM detect when clutch

circuit hydraulic failures occur. The range for the

pressure switch closing and opening points is 11-23

psi. Typically the switch opening point will be

approximately one psi lower than the closing point.

For example, a switch may close at 18 psi and open

at 17 psi. The switches are continuously monitored

by the PCM/TCM for the correct states (open or

closed) in each gear as shown in the following chart:

PRESSURE SWITCH STATES

GEAR L/R 2/4 OD

ROPOPOP

P/N CL OP OP

1st CL OP OP

2nd OP CL OP

DOPOPCL

OD OP CL CL

OP = OPEN

CL = CLOSED

A Diagnostic Trouble Code (DTC) will set if the

PCM/TCM senses any switch open or closed at the

wrong time in a given gear.The PCM/TCM also tests the 2/4 and OD pressure

switches when they are normally off (OD and 2/4 are

tested in 1st gear, OD in 2nd gear, and 2/4 in 3rd

gear). The test simply verifies that they are opera-

tional, by looking for a closed state when the corre-

sponding element is applied. Immediately after a

shift into 1st, 2nd, or 3rd gear with the engine speed

above 1000 rpm, the PCM/TCM momentarily turns

on element pressure to the 2/4 and/or OD clutch cir-

cuits to identify that the appropriate switch has

closed. If it doesn't close, it is tested again. If the

switch fails to close the second time, the appropriate

Diagnostic Trouble Code (DTC) will set.

REMOVAL

NOTE: If solenoid/pressure switch assembly is

being replaced, the ªQuick-Learnº procedure must

be performed. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly.

(3) Disconnect solenoid/pressure switch assembly

connector (Fig. 281).

(4) Disconnect input speed sensor connector (Fig.

281).

Fig. 281 Transmission Connectors

1 - SOLENOID PACK CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

21 - 118 40TE AUTOMATIC TRANSAXLERS

SOLENOID/PRESSURE SWITCH ASSY (Continued)

Page 1580 of 2339

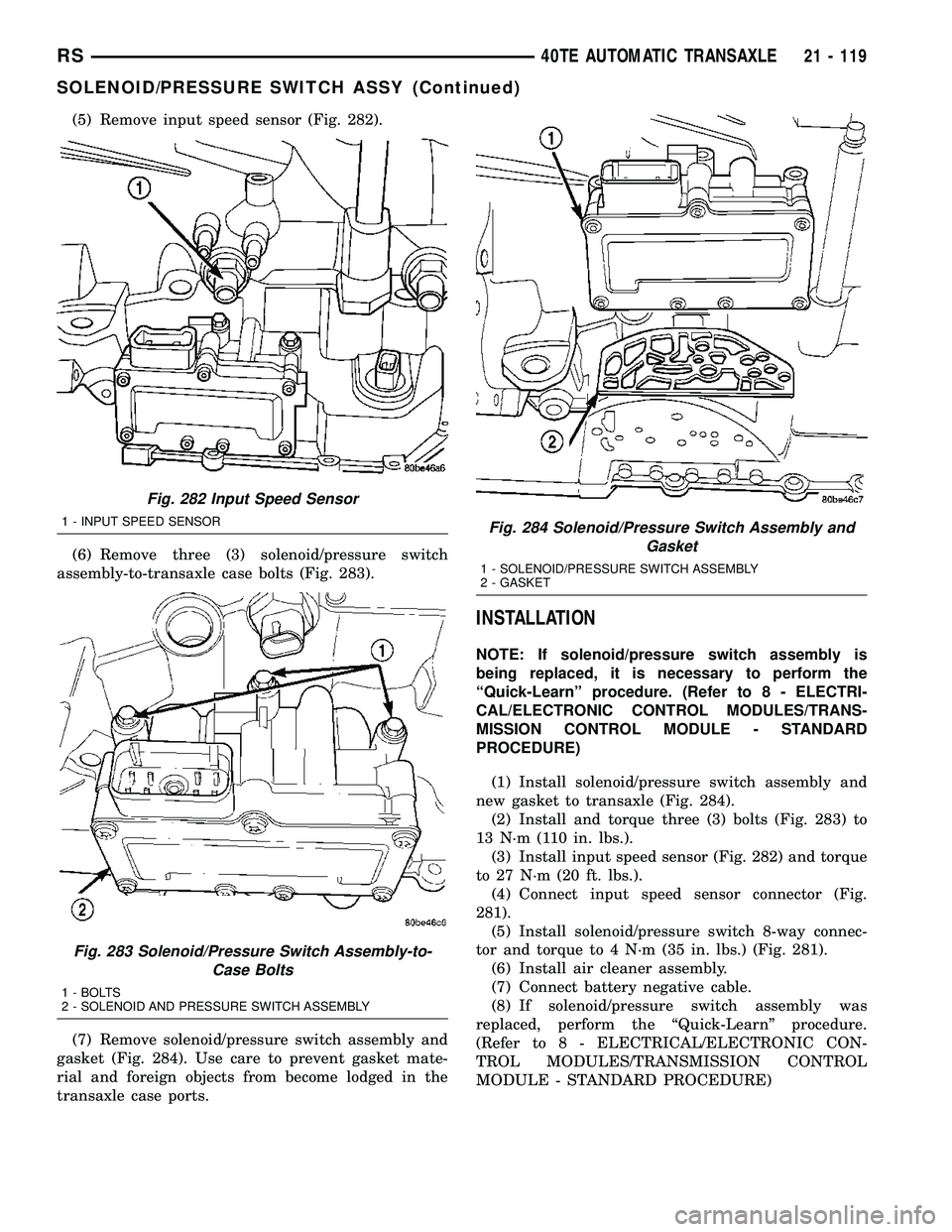

(5) Remove input speed sensor (Fig. 282).

(6) Remove three (3) solenoid/pressure switch

assembly-to-transaxle case bolts (Fig. 283).

(7) Remove solenoid/pressure switch assembly and

gasket (Fig. 284). Use care to prevent gasket mate-

rial and foreign objects from become lodged in the

transaxle case ports.

INSTALLATION

NOTE: If solenoid/pressure switch assembly is

being replaced, it is necessary to perform the

ªQuick-Learnº procedure. (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/TRANS-

MISSION CONTROL MODULE - STANDARD

PROCEDURE)

(1) Install solenoid/pressure switch assembly and

new gasket to transaxle (Fig. 284).

(2) Install and torque three (3) bolts (Fig. 283) to

13 N┬┤m (110 in. lbs.).

(3) Install input speed sensor (Fig. 282) and torque

to 27 N┬┤m (20 ft. lbs.).

(4) Connect input speed sensor connector (Fig.

281).

(5) Install solenoid/pressure switch 8-way connec-

tor and torque to 4 N┬┤m (35 in. lbs.) (Fig. 281).

(6) Install air cleaner assembly.

(7) Connect battery negative cable.

(8) If solenoid/pressure switch assembly was

replaced, perform the ªQuick-Learnº procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

Fig. 282 Input Speed Sensor

1 - INPUT SPEED SENSOR

Fig. 283 Solenoid/Pressure Switch Assembly-to-

Case Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 284 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

RS40TE AUTOMATIC TRANSAXLE21 - 119

SOLENOID/PRESSURE SWITCH ASSY (Continued)

Page 1581 of 2339

SPEED SENSOR - INPUT

DESCRIPTION

The Input Speed Sensor is a two-wire magnetic

pickup device that generates AC signals as rotation

occurs. It is threaded into the transaxle case (Fig.

285), sealed with an o-ring (Fig. 286), and is consid-

ered a primary input to the Powertrain/Transmission

Control Module.

OPERATION

The Input Speed Sensor provides information on

how fast the input shaft is rotating. As the teeth of

the input clutch hub pass by the sensor coil (Fig.

287), an AC voltage is generated and sent to the

PCM/TCM. The PCM/TCM interprets this informa-

tion as input shaft rpm.

The PCM/TCM compares the input speed signal

with output speed signal to determine the following:

┬▓Transmission gear ratio

┬▓Speed ratio error detection

┬▓CVI calculation

The PCM/TCM also compares the input speed sig-

nal and the engine speed signal to determine the fol-

lowing:

┬▓Torque converter clutch slippage

┬▓Torque converter element speed ratio

Fig. 285 Input Speed Sensor Location

1 - INPUT SPEED SENSOR

Fig. 286 O-Ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

Fig. 287 Sensor Relation to Input Clutch Hub

1 - INPUT SPEED SENSOR

2 - TRANSAXLE CASE

3 - INPUT CLUTCH HUB

21 - 120 40TE AUTOMATIC TRANSAXLERS

Page 1582 of 2339

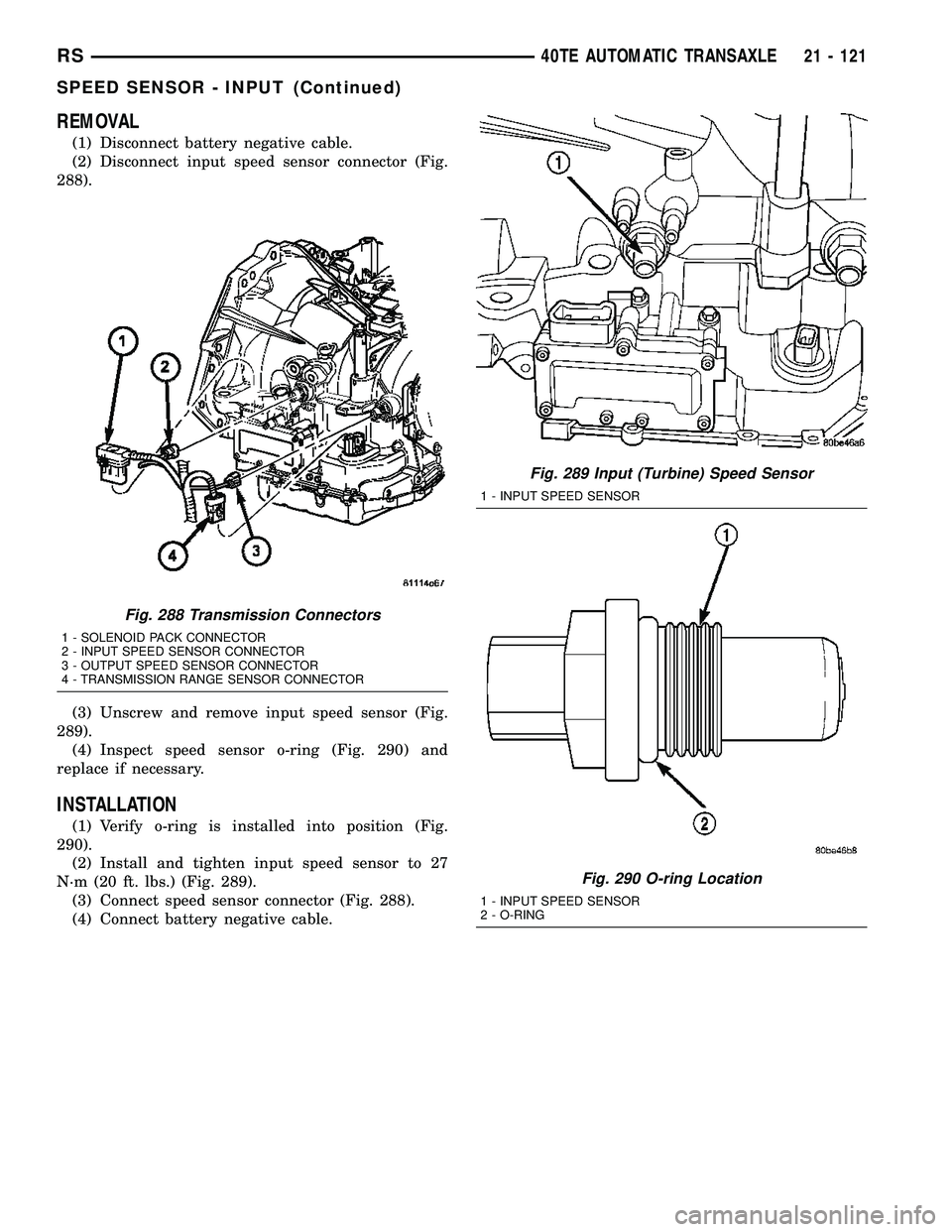

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect input speed sensor connector (Fig.

288).

(3) Unscrew and remove input speed sensor (Fig.

289).

(4) Inspect speed sensor o-ring (Fig. 290) and

replace if necessary.

INSTALLATION

(1) Verify o-ring is installed into position (Fig.

290).

(2) Install and tighten input speed sensor to 27

N┬┤m (20 ft. lbs.) (Fig. 289).

(3) Connect speed sensor connector (Fig. 288).

(4) Connect battery negative cable.

Fig. 288 Transmission Connectors

1 - SOLENOID PACK CONNECTOR

2 - INPUT SPEED SENSOR CONNECTOR

3 - OUTPUT SPEED SENSOR CONNECTOR

4 - TRANSMISSION RANGE SENSOR CONNECTOR

Fig. 289 Input (Turbine) Speed Sensor

1 - INPUT SPEED SENSOR

Fig. 290 O-ring Location

1 - INPUT SPEED SENSOR

2 - O-RING

RS40TE AUTOMATIC TRANSAXLE21 - 121

SPEED SENSOR - INPUT (Continued)

Page 1583 of 2339

SPEED SENSOR - OUTPUT

DESCRIPTION

The Output Speed Sensor is a two-wire magnetic

pickup device that generates an AC signal as rotation

occurs. It is threaded into the transaxle case (Fig.

291), sealed with an o-ring (Fig. 292), and is consid-

ered a primary input to the Powetrain/Transmission

Control Module.

OPERATION

The Output Speed Sensor provides information on

how fast the output shaft is rotating. As the rear

planetary carrier park pawl lugs pass by the sensor

coil (Fig. 293), an AC voltage is generated and sent to

the PCM/TCM. The PCM/TCM interprets this infor-

mation as output shaft rpm.

The PCM/TCM compares the input and output

speed signals to determine the following:

┬▓Transmission gear ratio

┬▓Speed ratio error detection

┬▓CVI calculation

Fig. 291 Output Speed Sensor

1 - OUTPUT SPEED SENSOR

Fig. 292 O-Ring Location

1 - OUTPUT SPEED SENSOR

2 - O-RING

Fig. 293 Sensor Relation to Planet Carrier Park Pawl

1 - OUTPUT SPEED SENSOR

2 - REAR PLANET CARRIER/OUTPUT SHAFT ASSEMBLY

3 - TRANSAXLE CASE

21 - 122 40TE AUTOMATIC TRANSAXLERS