check engine CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 328 of 2339

torque specifications (Refer to 8 - ELECTRICAL/

CHARGING - SPECIFICATIONS).

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications(Refer to 7 - COOLING/

ACCESSORY DRIVE - SPECIFICATIONS).

(6) Inspect decoupler pulley (if equipped). Ensure

decoupler pulley is driving the alternator rotor.(7) Inspect automatic belt tensioner (if equipped).

Refer to the Cooling System for more information.

(8) Inspect generator electrical connections at gen-

erator field, battery output, and ground terminal (if

equipped). Also check generator ground wire connec-

tion at engine (if equipped). They should all be clean

and tight. Repair as required.

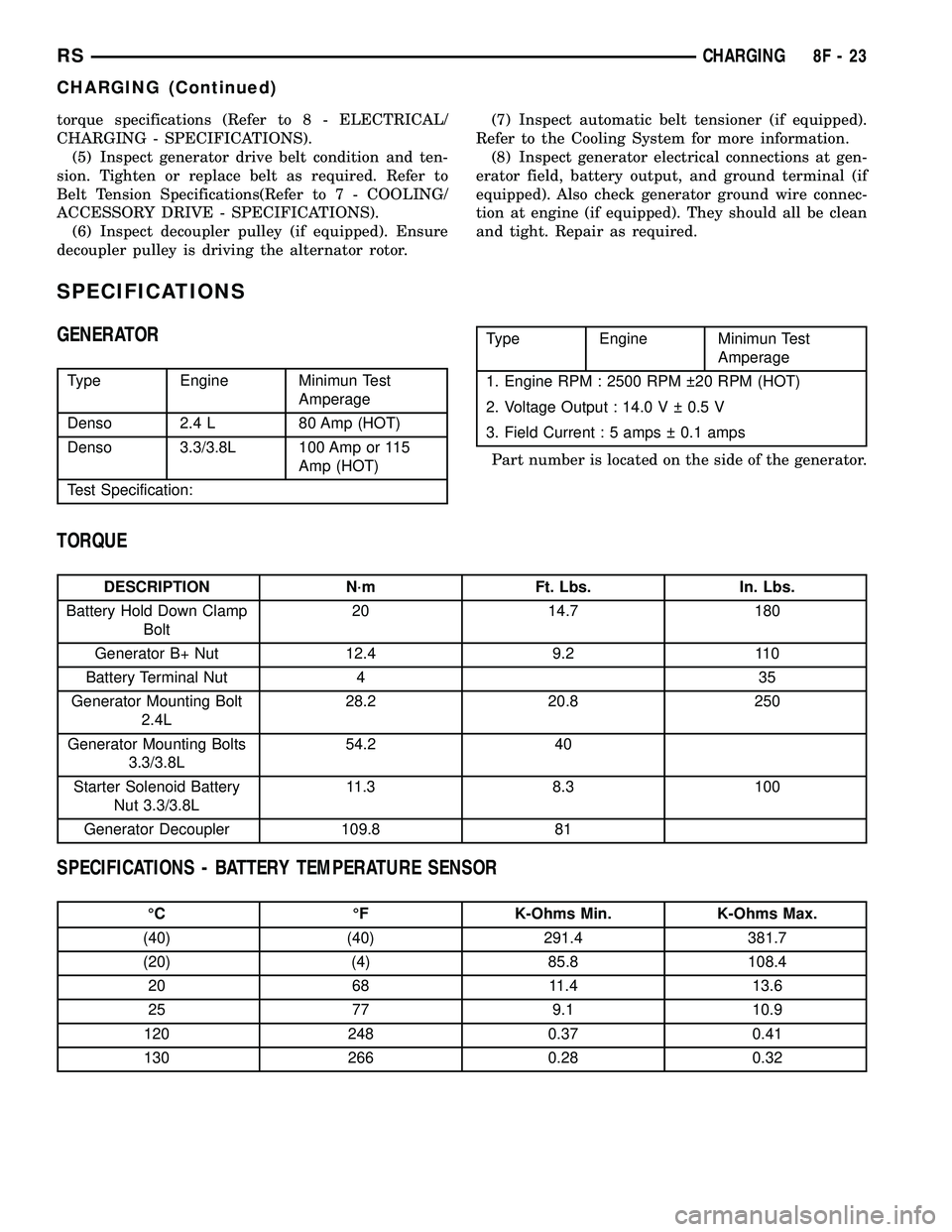

SPECIFICATIONS

GENERATOR

Type Engine Minimun Test

Amperage

Denso 2.4 L 80 Amp (HOT)

Denso 3.3/3.8L 100 Amp or 115

Amp (HOT)

Test Specification:

Type Engine Minimun Test

Amperage

1. Engine RPM : 2500 RPM 20 RPM (HOT)

2. Voltage Output : 14.0 V 0.5 V

3. Field Current : 5 amps 0.1 amps

Part number is located on the side of the generator.

TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Battery Hold Down Clamp

Bolt20 14.7 180

Generator B+ Nut 12.4 9.2 110

Battery Terminal Nut 4 35

Generator Mounting Bolt

2.4L28.2 20.8 250

Generator Mounting Bolts

3.3/3.8L54.2 40

Starter Solenoid Battery

Nut 3.3/3.8L11.3 8.3 100

Generator Decoupler 109.8 81

SPECIFICATIONS - BATTERY TEMPERATURE SENSOR

ÉC ÉF K-Ohms Min. K-Ohms Max.

(40) (40) 291.4 381.7

(20) (4) 85.8 108.4

20 68 11.4 13.6

25 77 9.1 10.9

120 248 0.37 0.41

130 266 0.28 0.32

RSCHARGING8F-23

CHARGING (Continued)

Page 337 of 2339

the battery, if required. Refer to the Battery section

for more information.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Transmission Range Sensor or Park/Neu-

tral Switch- Visually inspect the transmission

range sensor for indications of physical damage and

loose or corroded wire harness connections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post.

²Power Distribution Center (PDC)- Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

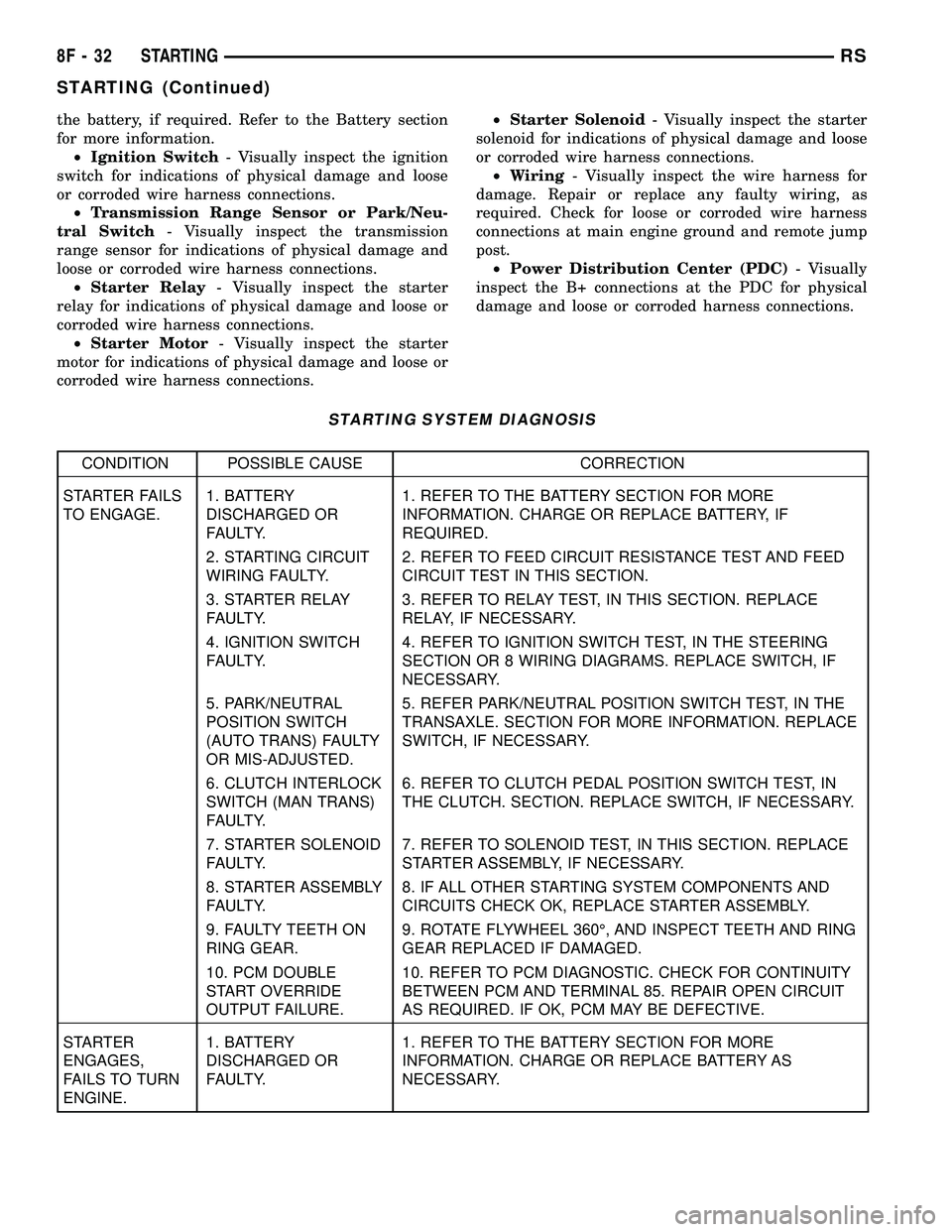

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY.3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY.4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED.5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH INTERLOCK

SWITCH (MAN TRANS)

FAULTY.6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY.7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY.8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR.9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

10. PCM DOUBLE

START OVERRIDE

OUTPUT FAILURE.10. REFER TO PCM DIAGNOSTIC. CHECK FOR CONTINUITY

BETWEEN PCM AND TERMINAL 85. REPAIR OPEN CIRCUIT

AS REQUIRED. IF OK, PCM MAY BE DEFECTIVE.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

8F - 32 STARTINGRS

STARTING (Continued)

Page 338 of 2339

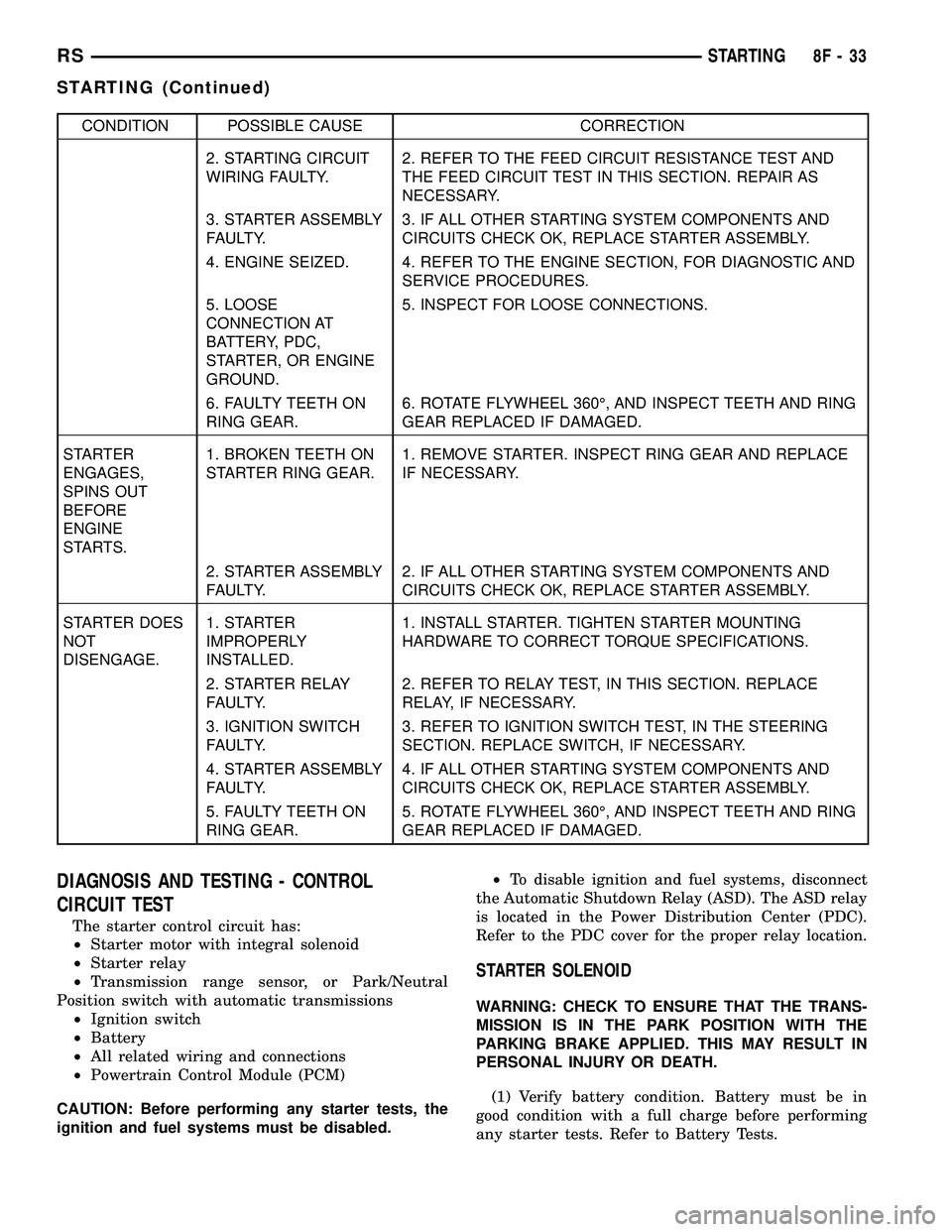

CONDITION POSSIBLE CAUSE CORRECTION

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO THE FEED CIRCUIT RESISTANCE TEST AND

THE FEED CIRCUIT TEST IN THIS SECTION. REPAIR AS

NECESSARY.

3. STARTER ASSEMBLY

FAULTY.3. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

4. ENGINE SEIZED. 4. REFER TO THE ENGINE SECTION, FOR DIAGNOSTIC AND

SERVICE PROCEDURES.

5. LOOSE

CONNECTION AT

BATTERY, PDC,

STARTER, OR ENGINE

GROUND.5. INSPECT FOR LOOSE CONNECTIONS.

6. FAULTY TEETH ON

RING GEAR.6. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

STARTER

ENGAGES,

SPINS OUT

BEFORE

ENGINE

STARTS.1. BROKEN TEETH ON

STARTER RING GEAR.1. REMOVE STARTER. INSPECT RING GEAR AND REPLACE

IF NECESSARY.

2. STARTER ASSEMBLY

FAULTY.2. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

STARTER DOES

NOT

DISENGAGE.1. STARTER

IMPROPERLY

INSTALLED.1. INSTALL STARTER. TIGHTEN STARTER MOUNTING

HARDWARE TO CORRECT TORQUE SPECIFICATIONS.

2. STARTER RELAY

FAULTY.2. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

3. IGNITION SWITCH

FAULTY.3. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION. REPLACE SWITCH, IF NECESSARY.

4. STARTER ASSEMBLY

FAULTY.4. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

5. FAULTY TEETH ON

RING GEAR.5. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST

The starter control circuit has:

²Starter motor with integral solenoid

²Starter relay

²Transmission range sensor, or Park/Neutral

Position switch with automatic transmissions

²Ignition switch

²Battery

²All related wiring and connections

²Powertrain Control Module (PCM)

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for the proper relay location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED. THIS MAY RESULT IN

PERSONAL INJURY OR DEATH.

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

RSSTARTING8F-33

STARTING (Continued)

Page 339 of 2339

(2) Perform Starter Solenoid test BEFORE per-

forming the starter relay test.

(3) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(4) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(5) Connect a remote starter switch or a jumper

wire between the remote battery positive post and

terminal 87 of the starter relay connector.

(a) If engine cranks, starter/starter solenoid is

good. Go to the Starter Relay Test.

(b) If engine does not crank or solenoid chatters,

check wiring and connectors from starter relay to

starter solenoid and from the battery positive ter-

minal to starter post for loose or corroded connec-

tions. Particularly at starter terminals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter. Inspect the ring gear

teeth.

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK/NEUTRAL POSITION

WITH THE PARKING BRAKE APPLIED. THIS MAY

RESULT IN PERSONAL INJURY OR DEATH.

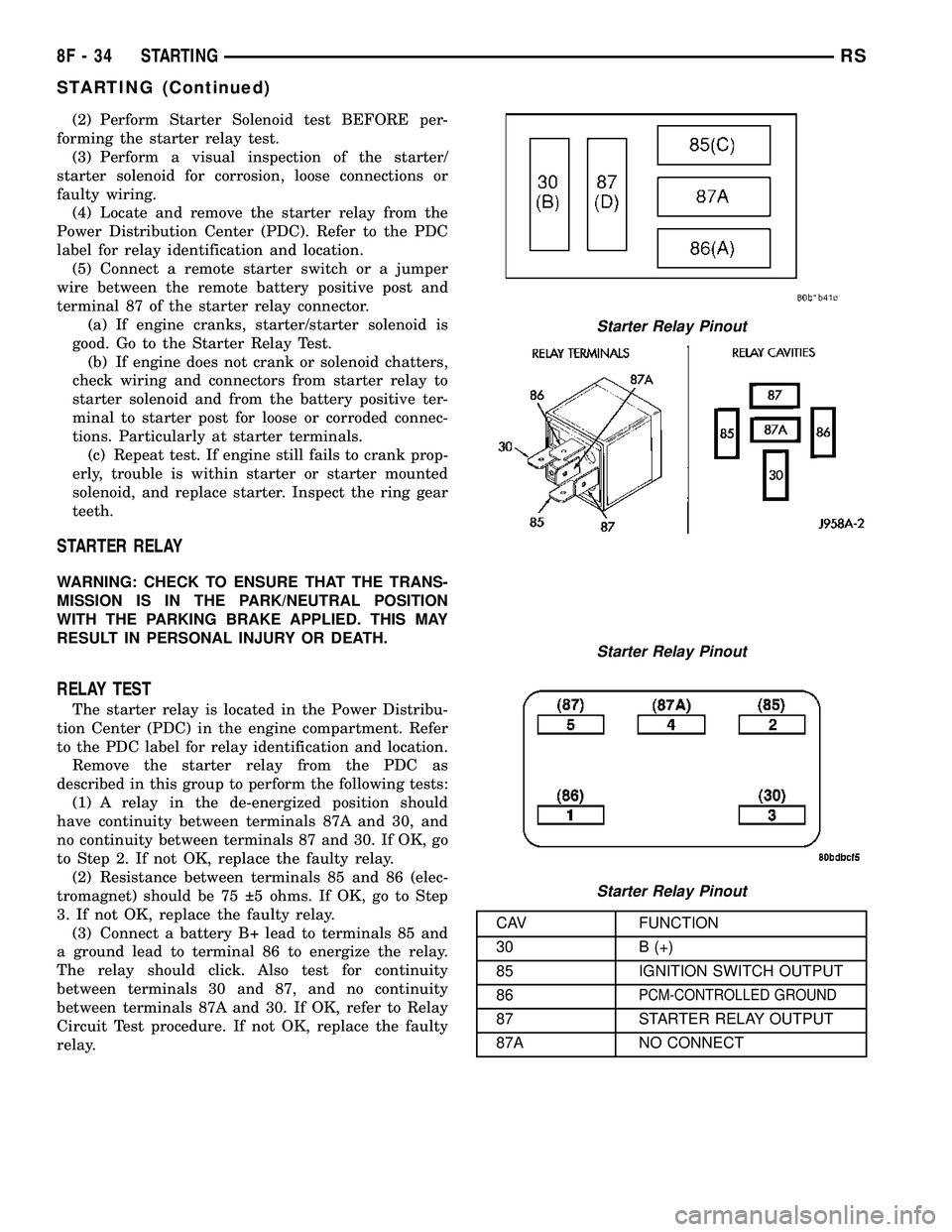

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

Remove the starter relay from the PDC as

described in this group to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery B+ lead to terminals 85 and

a ground lead to terminal 86 to energize the relay.

The relay should click. Also test for continuity

between terminals 30 and 87, and no continuity

between terminals 87A and 30. If OK, refer to Relay

Circuit Test procedure. If not OK, replace the faulty

relay.

CAV FUNCTION

30 B (+)

85 IGNITION SWITCH OUTPUT

86

PCM-CONTROLLED GROUND

87 STARTER RELAY OUTPUT

87A NO CONNECT

Starter Relay Pinout

Starter Relay Pinout

Starter Relay Pinout

8F - 34 STARTINGRS

STARTING (Continued)

Page 340 of 2339

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (85) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position and

the clutch pedal is depressed (manual trans). Check

for battery voltage at the cavity for relay terminal 86

with the ignition switch in the Start position and the

clutch pedal is depressed (manual trans), and no

voltage when the ignition switch is released to the

On position. If OK, go to Step 5. If not OK, check for

an open or short circuit to the ignition switch and

repair, if required. If the circuit to the ignition switch

is OK, see the Ignition Switch Test procedure in this

group.

(5) The coil ground terminal (86) is connected to

the electromagnet in the relay. It is grounded by the

PCM if the conditions are right to start the car. For

automatic trans. cars the PCM must see Park Neu-

tral switch low and near zero engine speed (rpm).

For manual trans. cars the PCM only needs to see

near zero engine speed (rpm) and low clutch inter-

lock input and see near zero engine speed (rpm). To

diagnose the Park Neutral switch of the trans range

sensor refer to the transaxle section. Check for conti-

nuity to ground while the ignition switch is in the

start position and if equipped the clutch pedal

depressed. If not OK and the vehicle has an auto-

matic trans. verify Park Neutral switch operation. If

that checks OK check for continuity between PCM

and the terminal 86. Repair open circuit as required.

Also check the clutch interlock switch operation if

equipped with a manual transmission. If OK, the

PCM may be defective.

SAFETY SWITCHES

For diagnostics of the Transmission Range Sensor,

refer to the Transaxle section for more information.

If equipped with Clutch Interlock/Upstop Switch,

refer to Diagnosis and Testing in the Clutch section.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Refer to the Ignition Section

or Wiring Diagrams for more information. Check all

wiring for opens or shorts, and all connectors for

being loose or corroded.

BATTERY

For battery diagnosis and testing, refer to the Bat-

tery section for procedures.

ALL RELATED WIRING AND CONNECTORS

Refer to Wiring Diagrams for more information.

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition and Fuel systems must be dis-

abled to prevent engine start while performing the

following tests.

(1) To disable the Ignition and Fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) Gain access to battery terminals.

(3) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp. Rotate and hold the

ignition switch in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp. Rotate and hold the igni-

tion switch key in the START position. Observe the

voltmeter. If voltage is detected, correct poor con-

tact between the cable clamp and post.

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point.

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at ground cable attaching point. If

voltage reading is still above 0.2 volt after correct-

ing poor contacts, replace ground cable.

(4) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal. Hold the ignition switch key in

RSSTARTING8F-35

STARTING (Continued)

Page 341 of 2339

the START position. If voltage reads above 0.2 volt,

correct poor starter to engine ground.

(a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid. Rotate and

hold the ignition switch in the START position. If

voltage reads above 0.2 volt, correct poor contact at

battery cable to solenoid connection. If reading is

still above 0.2 volt after correcting poor contacts,

replace battery positive cable.

(b) If resistance tests do not detect feed circuit

failures, replace the starter motor.

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST

NOTE: The following results are based upon the

vehicle being at room temperature.

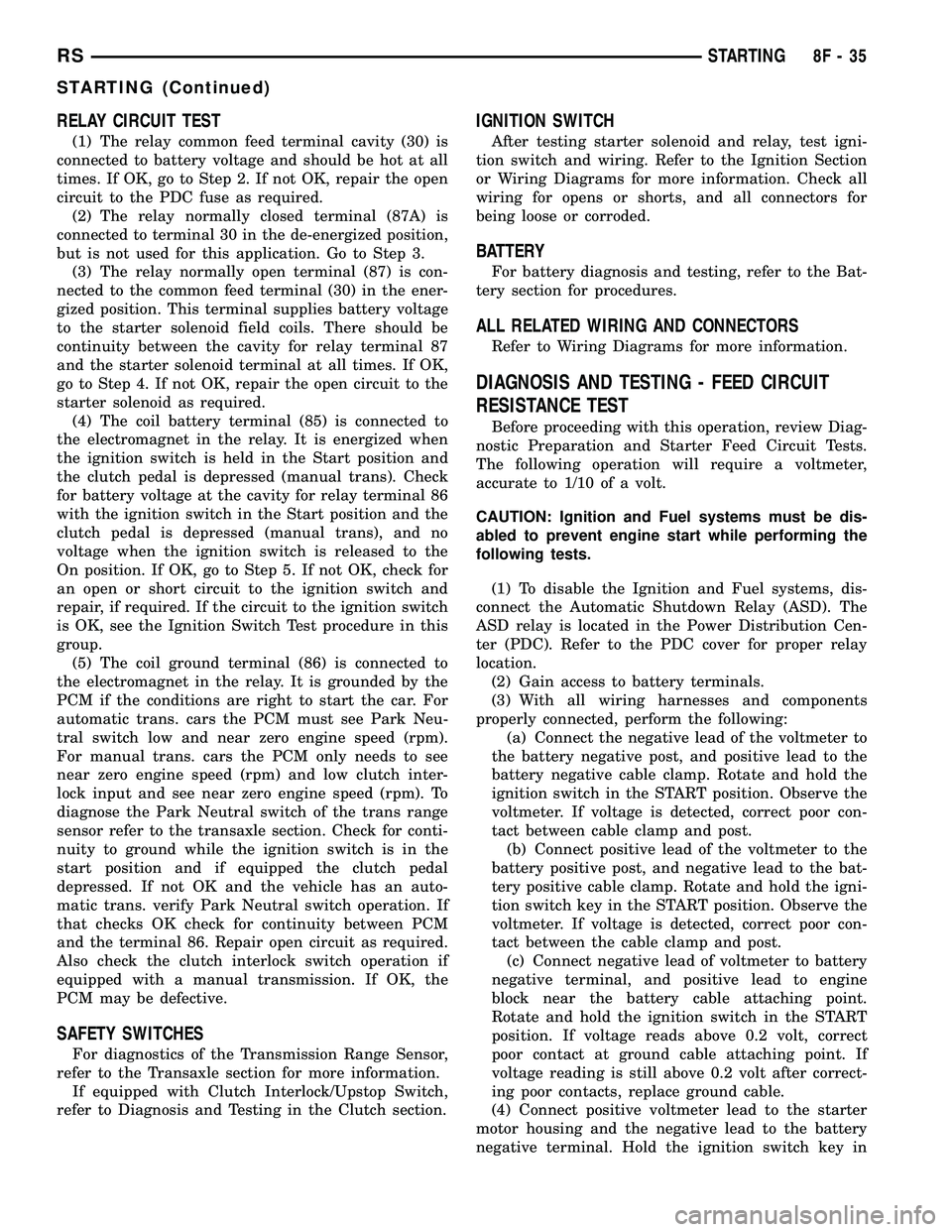

The following procedure will require a suitable

volt-ampere tester (Fig. 1).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.(1) Check battery before performing this test. Bat-

tery must be fully charged.

(2) Connect a volt-ampere tester to the battery ter-

minals. Refer to the operating instructions provided

with the tester being used.

(3) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(4) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

and SET parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(5) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

1).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²Voltage below 9.6 volts and amperage draw

above 300 amps, the problem is the starter. Replace

the starter refer to starter removal.

(6) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testing

equipment and connect ASD relay. Start the vehicle

several times to assure the problem has been cor-

rected.

SPECIFICATIONS

Torques

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Starter Mounting Bolts 47.4 35

Starter Solenoid Battery

Nut11.3 8.3 100

Fig. 1 Volt Ampere Tester

8F - 36 STARTINGRS

STARTING (Continued)

Page 360 of 2339

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

HORN SYSTEM........................1

HORN

DIAGNOSIS AND TESTING

HORN...............................3REMOVAL.............................4

INSTALLATION..........................4

HORN SWITCH

DESCRIPTION..........................4

HORN SYSTEM

DESCRIPTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, REFER TO ELECTRICAL, RESTRAINTS FOR

SAFETY PRECAUTIONS. DISCONNECT THE NEGA-

TIVE CABLE FROM THE BATTERY BEFORE SER-

VICING COMPONENTS INVOLVING THE AIRBAG

SYSTEM. ACCIDENTAL DEPLOYMENT OF AIRBAG

AND PERSONAL INJURY CAN RESULT.

The horn circuit consists of a horn switch, clock-

spring, horn relay, horns and Integrated Power Mod-

ule (IPM). The horn switch is a membrane switch

located in the airbag trim cover. The horns are

located forward of the left front wheel behind the

bumper fascia.

OPERATION

The horn relay plugs into the Integrated Power

Module (IPM) which is located in the engine com-

partment. For circuit information and component

locations, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

The horns will not function if the switch is

ªCLOSEDº for more than 30 seconds. Once the

switch is ªOPENº, a 20±30 second delay will occur

before the horns are functional again.

DIAGNOSIS AND TESTING

HORN SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Refer to Horn System Test below. If the horn does

not sound, check horn fuse located in the Integrated

Power Module (IPM). If the fuse is blown, replace

with the correct fuse. If the horns fail to sound and

the new fuse blows when depressing the horn switch,

a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble, or a defective horn switch allowed the horn to

burn out is responsible.

If the fuse is OK, test horn relay.

If the relay is OK, test horn.

CAUTION: Continuous sounding of horn may

cause horn failure.

Should the horn sound continuously, unplug the

horn relay from IPM.

Refer to the appropriate wiring information.

RSHORN8H-1

Page 366 of 2339

FIRING ORDERAUTO SHUT DOWN RELAY

DESCRIPTION

The relay is located in the Power Distribution Cen-

ter (PDC). For the location of the relay within the

PDC, refer to the PDC cover for location. Check elec-

trical terminals for corrosion and repair as necessary

OPERATION

The engine switched battery (NGC vehicles)

informs the PCM when the ASD relay energizes. A 12

volt signal at this input indicates to the PCM that

the ASD has been activated. This input is also used

to power certain drivers on NGC vehicles.

When energized, the ASD relay on NGC vehicles

provides power to operate the injectors, ignition coil,

generator field, O2 sensor heaters (both upstream

and downstream), evaporative purge solenoid, EGR

solenoid (if equipped) wastegate solenoid (if

equipped), and NVLD solenoid (if equipped).

The ASD relay also provides a sense circuit to the

PCM for diagnostic purposes. If the PCM does not

receive 12 volts from this input after grounding the

control side of the ASD relay, it sets a Diagnostic

Trouble Code (DTC). The PCM energizes the ASD

any time there is an engine speed that exceeds a pre-

determined value (typically about 50 rpm). The ASD

relay can also be energized after the engine has been

turned off to perform an O2 sensor heater test, if

vehicle is equipped with OBD II diagnostics.

As mentioned earlier, the PCM energizes the ASD

relay during an O2 sensor heater test. On NGC vehi-

cles it checks the O2 heater upon vehicle start. The

PCM still operates internally to perform several

checks, including monitoring the O2 sensor heaters.

FIRING ORDER 2.4L

Firing Order 1-2-3-4-5-6 3.3/3.8L

1 - Electrical Connector

RSIGNITION CONTROL8I-3

IGNITION CONTROL (Continued)

Page 372 of 2339

(4) Lower vehicle.

(5) Connect the negative cable.

SPARK PLUG

DESCRIPTION

DESCRIPTION - STANDARD 4 CYLINDER

All engines use resistor spark plugs. They have

resistance values ranging from 6,000 to 20,000 ohms

when checked with at least a 1000 volt spark plug

tester.

Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

Refer to the Specifications section for gap and type

of spark plug.

DESCRIPTION - PLATINUM PLUGS

The V6 engines use platinum resistor spark plugs.

They have resistance values of 6,000 to 20,000 ohms

when checked with at least a 1000 volt tester. For

spark plug identification and specifications, Refer to

the Specifications section.

Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

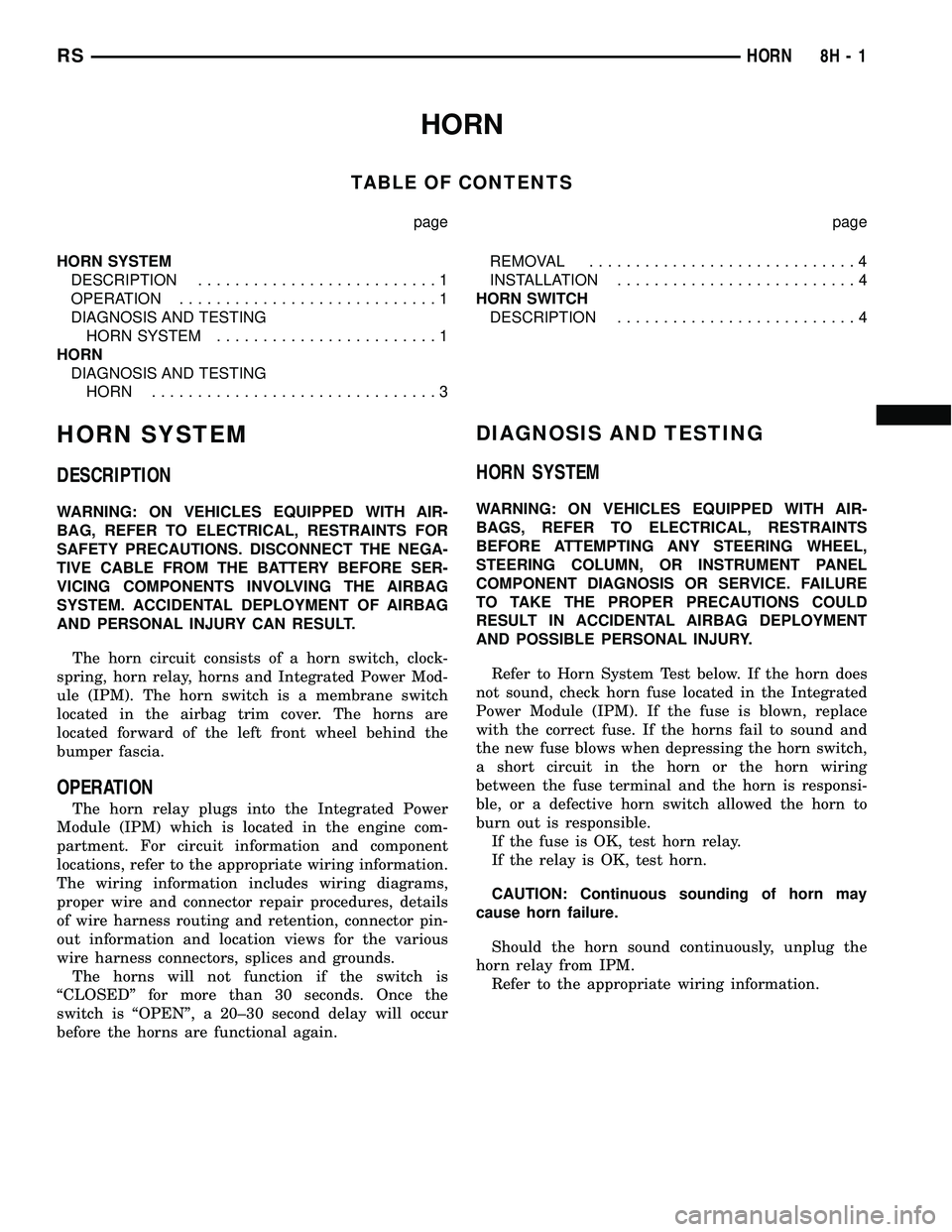

curate reading.When the spark plugs use a single or double plat-

inum tips and they have a recommended service life

of 100,000 miles for normal driving conditions per

schedule A in this manual. The spark plugs have a

recommended service life of 75,000 miles for severe

driving conditions per schedule B in this manual. A

thin platinum pad is welded to both or just the cen-

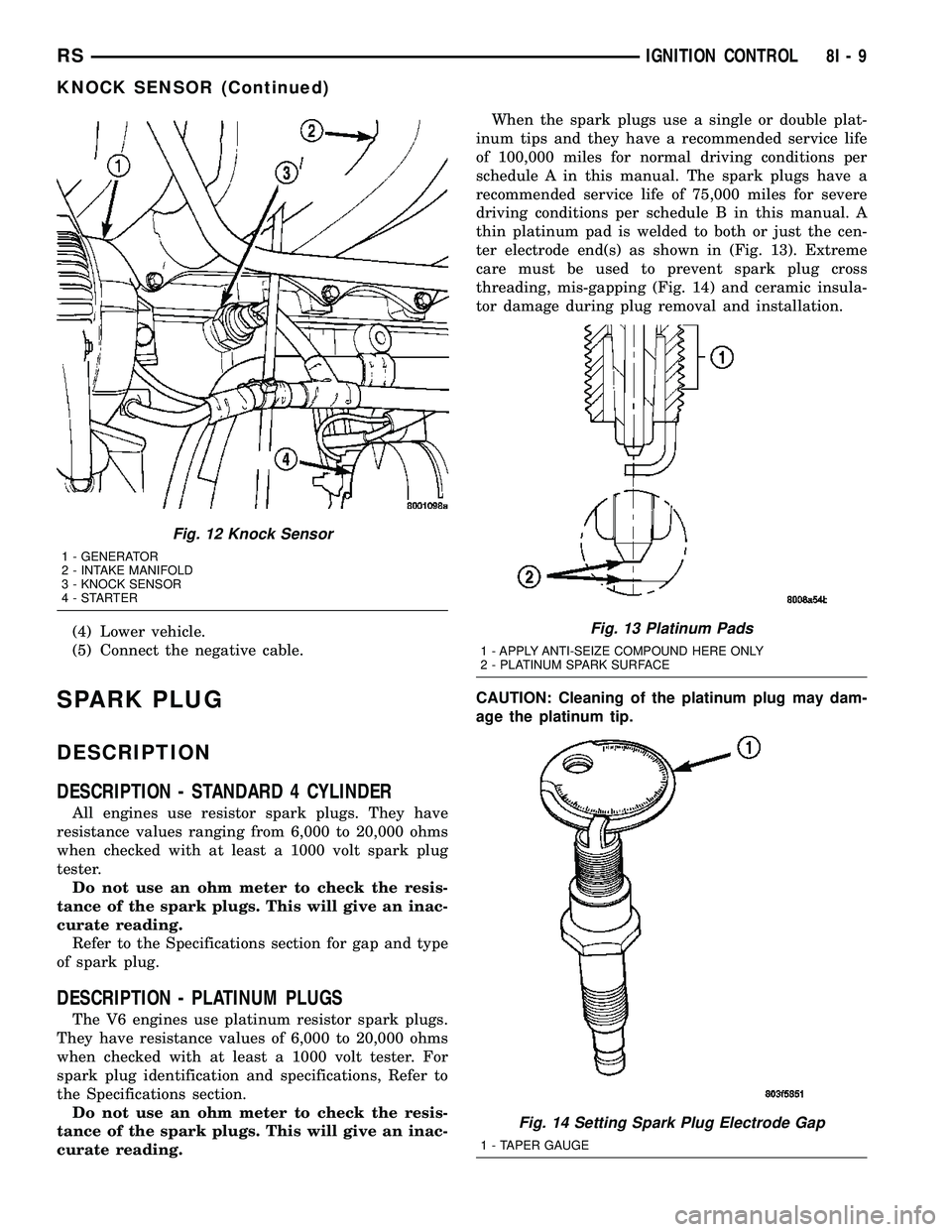

ter electrode end(s) as shown in (Fig. 13). Extreme

care must be used to prevent spark plug cross

threading, mis-gapping (Fig. 14) and ceramic insula-

tor damage during plug removal and installation.

CAUTION: Cleaning of the platinum plug may dam-

age the platinum tip.

Fig. 12 Knock Sensor

1 - GENERATOR

2 - INTAKE MANIFOLD

3 - KNOCK SENSOR

4-STARTER

Fig. 13 Platinum Pads

1 - APPLY ANTI-SEIZE COMPOUND HERE ONLY

2 - PLATINUM SPARK SURFACE

Fig. 14 Setting Spark Plug Electrode Gap

1 - TAPER GAUGE

RSIGNITION CONTROL8I-9

KNOCK SENSOR (Continued)

Page 375 of 2339

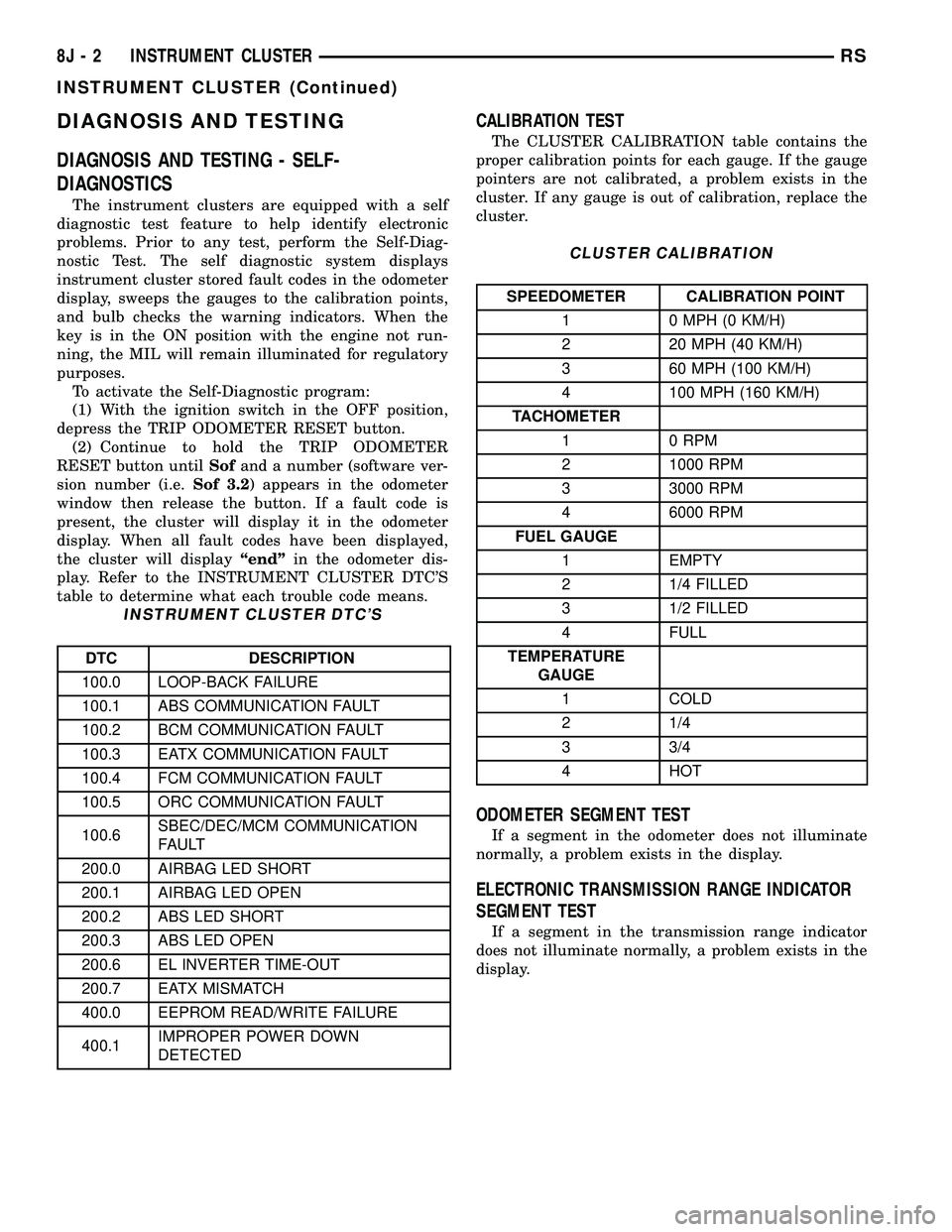

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic

problems. Prior to any test, perform the Self-Diag-

nostic Test. The self diagnostic system displays

instrument cluster stored fault codes in the odometer

display, sweeps the gauges to the calibration points,

and bulb checks the warning indicators. When the

key is in the ON position with the engine not run-

ning, the MIL will remain illuminated for regulatory

purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

400.0 EEPROM READ/WRITE FAILURE

400.1IMPROPER POWER DOWN

DETECTED

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)