hood open CHRYSLER VOYAGER 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 2227 of 2339

REMOVAL

2.4L/3.3L/3.8L ENGINES

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

NOTE: Before removing the A/C condenser, note the

location of each of the radiator and condenser air

seals. These air seals are used to direct air through

the A/C condenser and radiator. The air seals must

be reinstalled in their proper locations in order for

the A/C and engine cooling systems to perform as

designed.

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

RECOVERY).

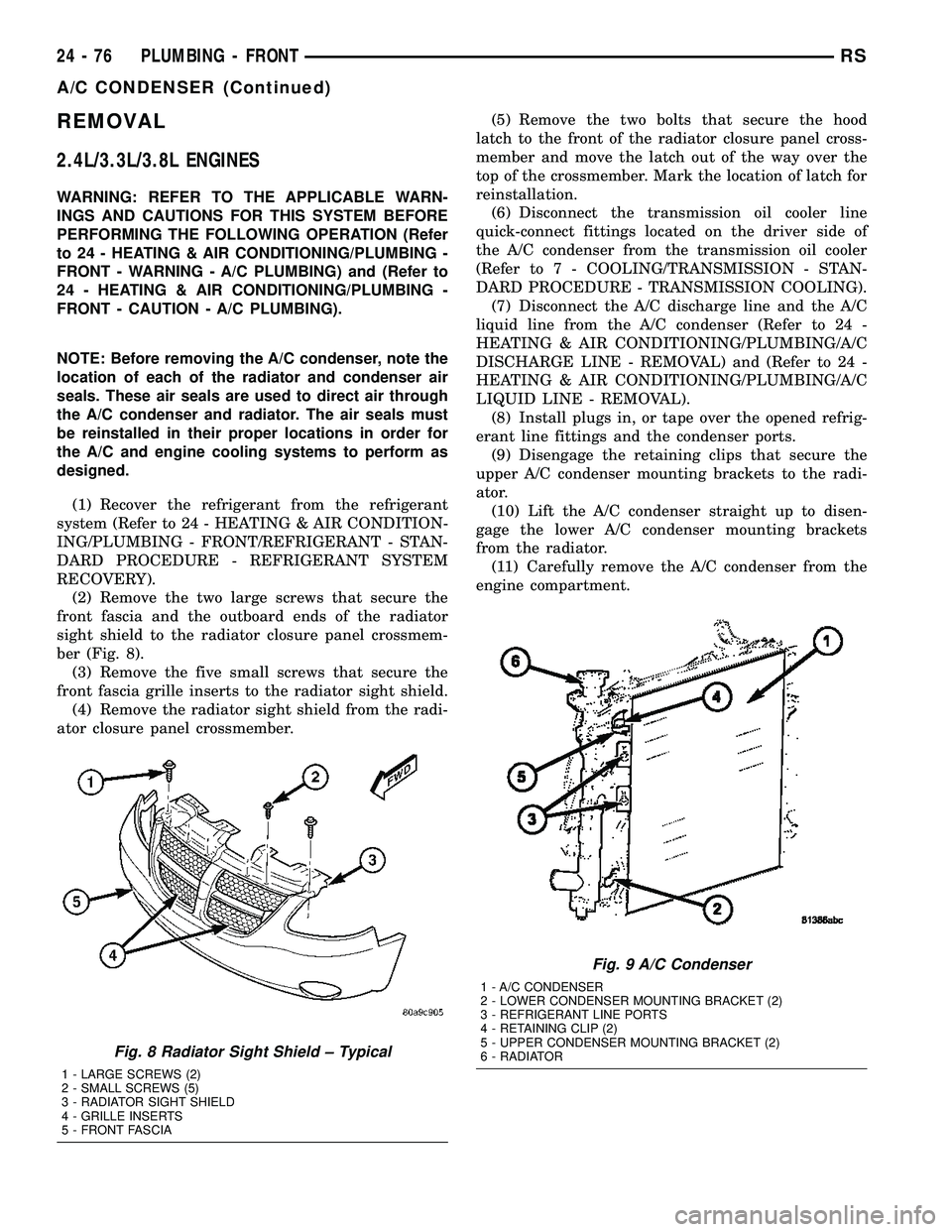

(2) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 8).

(3) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(4) Remove the radiator sight shield from the radi-

ator closure panel crossmember.(5) Remove the two bolts that secure the hood

latch to the front of the radiator closure panel cross-

member and move the latch out of the way over the

top of the crossmember. Mark the location of latch for

reinstallation.

(6) Disconnect the transmission oil cooler line

quick-connect fittings located on the driver side of

the A/C condenser from the transmission oil cooler

(Refer to 7 - COOLING/TRANSMISSION - STAN-

DARD PROCEDURE - TRANSMISSION COOLING).

(7) Disconnect the A/C discharge line and the A/C

liquid line from the A/C condenser (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

DISCHARGE LINE - REMOVAL) and (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

LIQUID LINE - REMOVAL).

(8) Install plugs in, or tape over the opened refrig-

erant line fittings and the condenser ports.

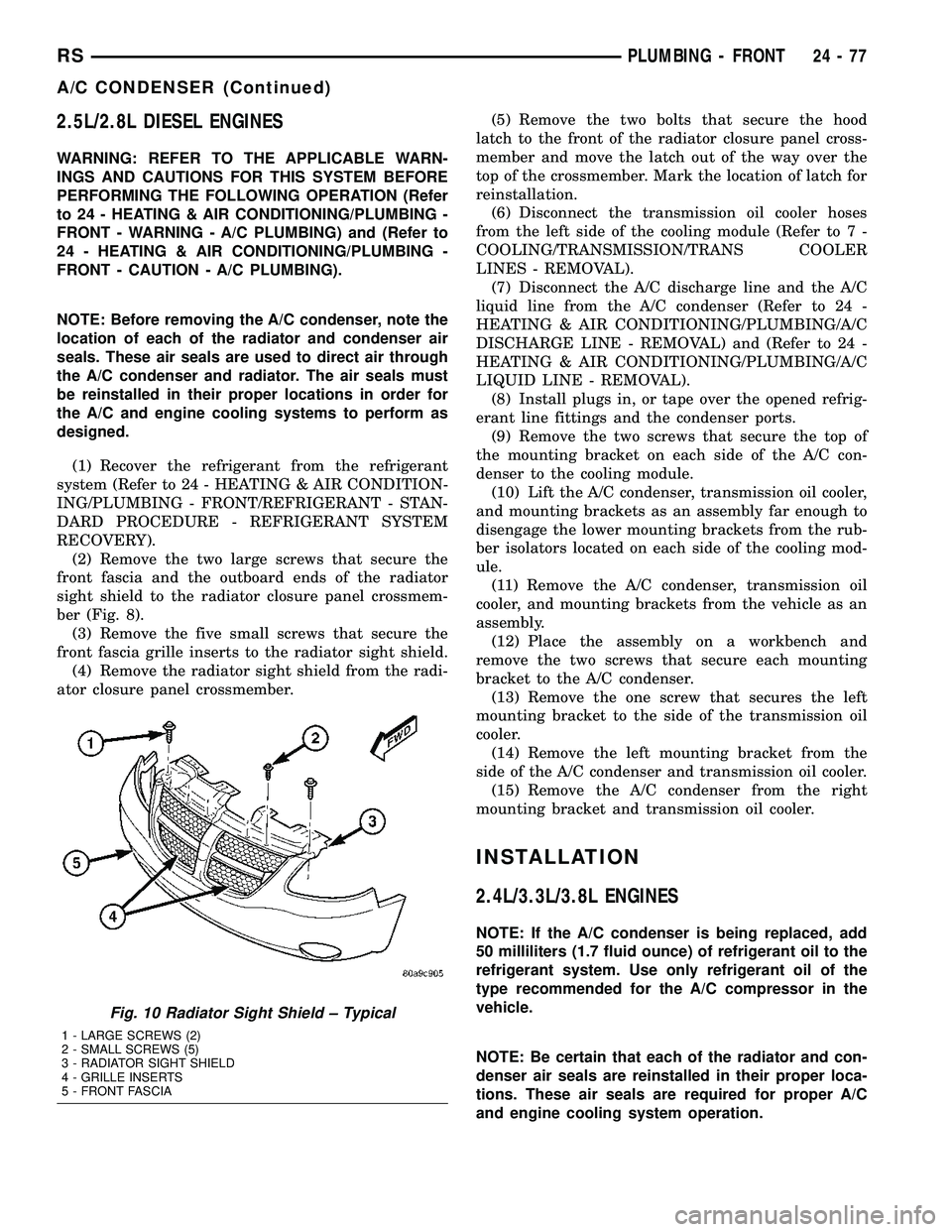

(9) Disengage the retaining clips that secure the

upper A/C condenser mounting brackets to the radi-

ator.

(10) Lift the A/C condenser straight up to disen-

gage the lower A/C condenser mounting brackets

from the radiator.

(11) Carefully remove the A/C condenser from the

engine compartment.

Fig. 8 Radiator Sight Shield ± Typical

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

Fig. 9 A/C Condenser

1 - A/C CONDENSER

2 - LOWER CONDENSER MOUNTING BRACKET (2)

3 - REFRIGERANT LINE PORTS

4 - RETAINING CLIP (2)

5 - UPPER CONDENSER MOUNTING BRACKET (2)

6 - RADIATOR

24 - 76 PLUMBING - FRONTRS

A/C CONDENSER (Continued)

Page 2228 of 2339

2.5L/2.8L DIESEL ENGINES

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

NOTE: Before removing the A/C condenser, note the

location of each of the radiator and condenser air

seals. These air seals are used to direct air through

the A/C condenser and radiator. The air seals must

be reinstalled in their proper locations in order for

the A/C and engine cooling systems to perform as

designed.

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

RECOVERY).

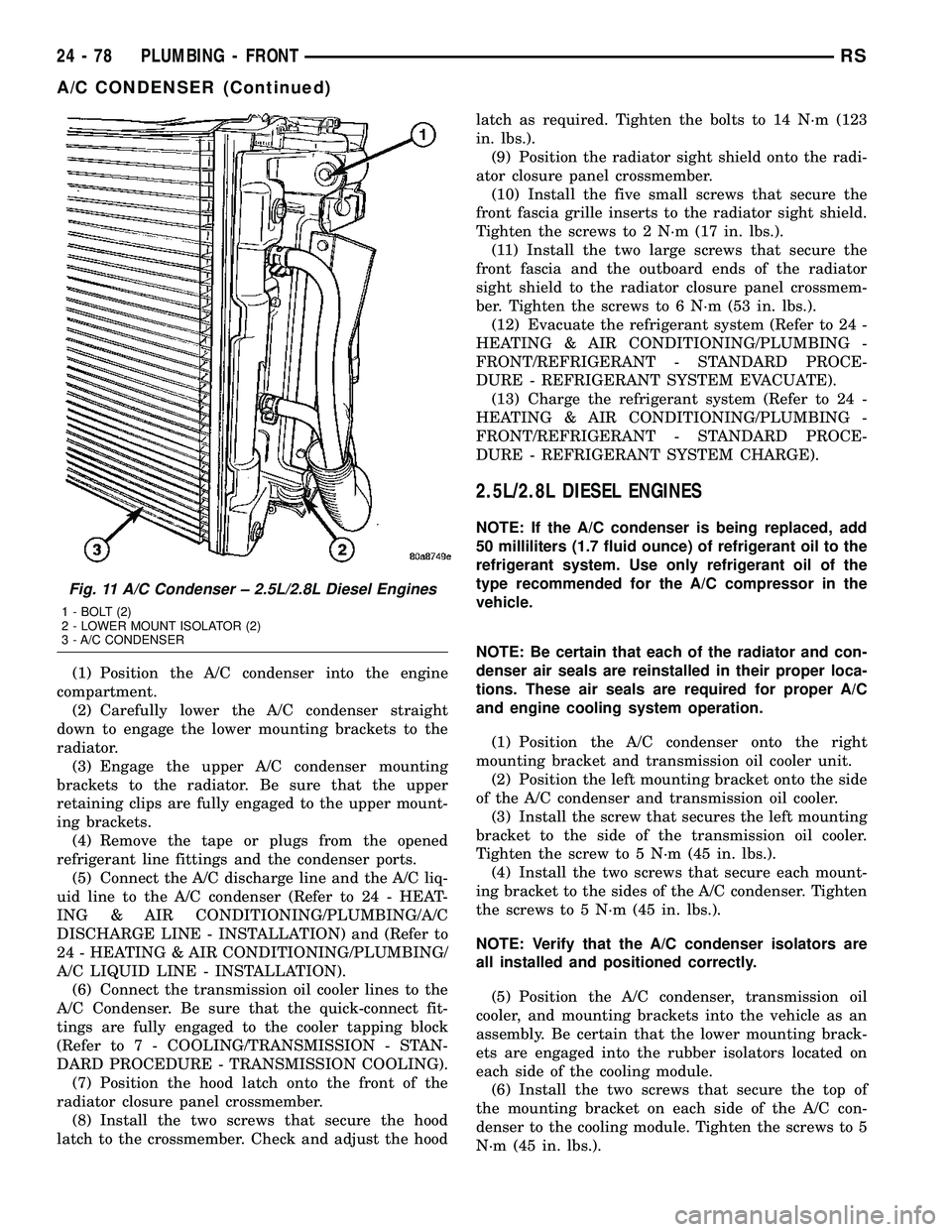

(2) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 8).

(3) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(4) Remove the radiator sight shield from the radi-

ator closure panel crossmember.(5) Remove the two bolts that secure the hood

latch to the front of the radiator closure panel cross-

member and move the latch out of the way over the

top of the crossmember. Mark the location of latch for

reinstallation.

(6) Disconnect the transmission oil cooler hoses

from the left side of the cooling module (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER

LINES - REMOVAL).

(7) Disconnect the A/C discharge line and the A/C

liquid line from the A/C condenser (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

DISCHARGE LINE - REMOVAL) and (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

LIQUID LINE - REMOVAL).

(8) Install plugs in, or tape over the opened refrig-

erant line fittings and the condenser ports.

(9) Remove the two screws that secure the top of

the mounting bracket on each side of the A/C con-

denser to the cooling module.

(10) Lift the A/C condenser, transmission oil cooler,

and mounting brackets as an assembly far enough to

disengage the lower mounting brackets from the rub-

ber isolators located on each side of the cooling mod-

ule.

(11) Remove the A/C condenser, transmission oil

cooler, and mounting brackets from the vehicle as an

assembly.

(12) Place the assembly on a workbench and

remove the two screws that secure each mounting

bracket to the A/C condenser.

(13) Remove the one screw that secures the left

mounting bracket to the side of the transmission oil

cooler.

(14) Remove the left mounting bracket from the

side of the A/C condenser and transmission oil cooler.

(15) Remove the A/C condenser from the right

mounting bracket and transmission oil cooler.

INSTALLATION

2.4L/3.3L/3.8L ENGINES

NOTE: If the A/C condenser is being replaced, add

50 milliliters (1.7 fluid ounce) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the A/C compressor in the

vehicle.

NOTE: Be certain that each of the radiator and con-

denser air seals are reinstalled in their proper loca-

tions. These air seals are required for proper A/C

and engine cooling system operation.

Fig. 10 Radiator Sight Shield ± Typical

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSPLUMBING - FRONT24-77

A/C CONDENSER (Continued)

Page 2229 of 2339

(1) Position the A/C condenser into the engine

compartment.

(2) Carefully lower the A/C condenser straight

down to engage the lower mounting brackets to the

radiator.

(3) Engage the upper A/C condenser mounting

brackets to the radiator. Be sure that the upper

retaining clips are fully engaged to the upper mount-

ing brackets.

(4) Remove the tape or plugs from the opened

refrigerant line fittings and the condenser ports.

(5) Connect the A/C discharge line and the A/C liq-

uid line to the A/C condenser (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C

DISCHARGE LINE - INSTALLATION) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

A/C LIQUID LINE - INSTALLATION).

(6) Connect the transmission oil cooler lines to the

A/C Condenser. Be sure that the quick-connect fit-

tings are fully engaged to the cooler tapping block

(Refer to 7 - COOLING/TRANSMISSION - STAN-

DARD PROCEDURE - TRANSMISSION COOLING).

(7) Position the hood latch onto the front of the

radiator closure panel crossmember.

(8) Install the two screws that secure the hood

latch to the crossmember. Check and adjust the hoodlatch as required. Tighten the bolts to 14 N´m (123

in. lbs.).

(9) Position the radiator sight shield onto the radi-

ator closure panel crossmember.

(10) Install the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

Tighten the screws to 2 N´m (17 in. lbs.).

(11) Install the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber. Tighten the screws to 6 N´m (53 in. lbs.).

(12) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(13) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

2.5L/2.8L DIESEL ENGINES

NOTE: If the A/C condenser is being replaced, add

50 milliliters (1.7 fluid ounce) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the A/C compressor in the

vehicle.

NOTE: Be certain that each of the radiator and con-

denser air seals are reinstalled in their proper loca-

tions. These air seals are required for proper A/C

and engine cooling system operation.

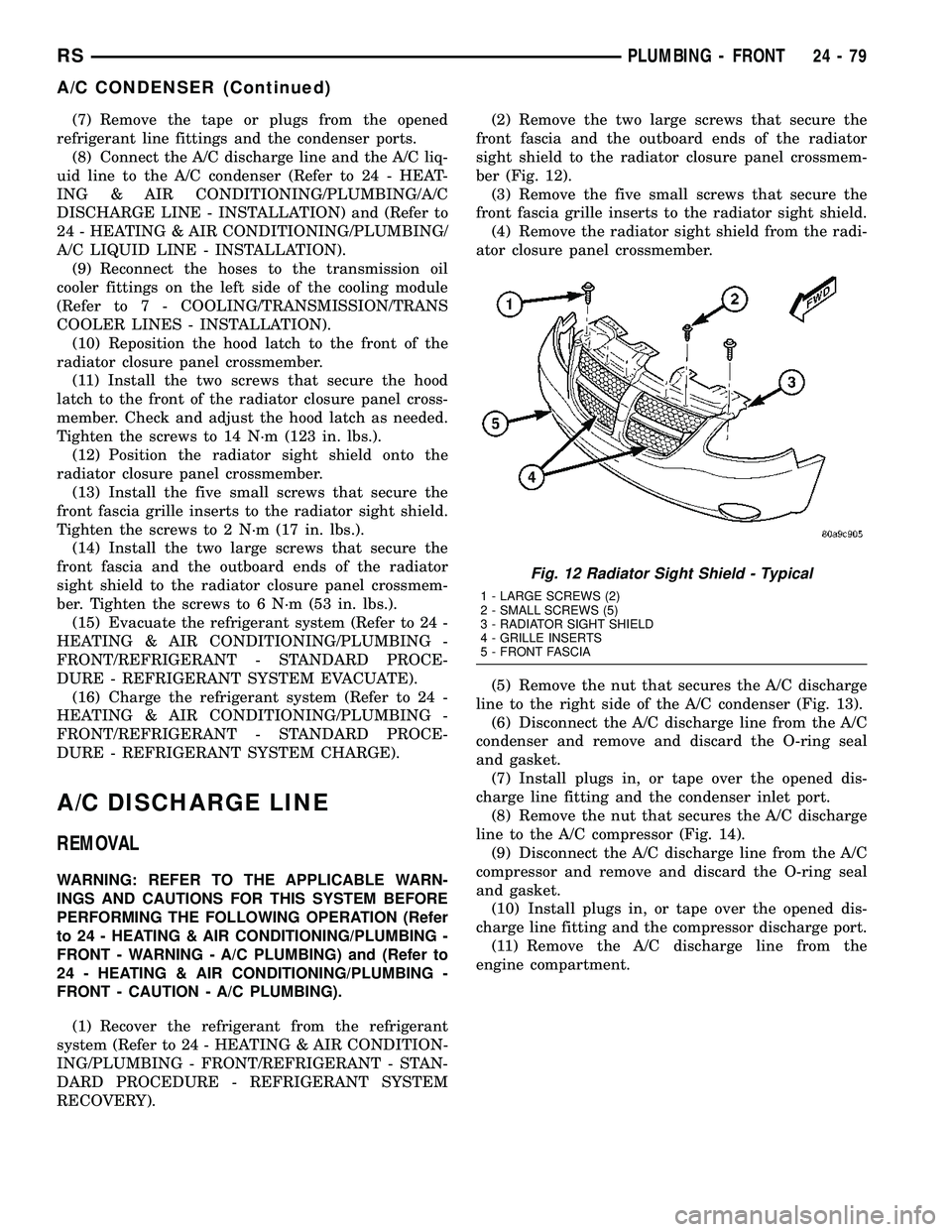

(1) Position the A/C condenser onto the right

mounting bracket and transmission oil cooler unit.

(2) Position the left mounting bracket onto the side

of the A/C condenser and transmission oil cooler.

(3) Install the screw that secures the left mounting

bracket to the side of the transmission oil cooler.

Tighten the screw to 5 N´m (45 in. lbs.).

(4) Install the two screws that secure each mount-

ing bracket to the sides of the A/C condenser. Tighten

the screws to 5 N´m (45 in. lbs.).

NOTE: Verify that the A/C condenser isolators are

all installed and positioned correctly.

(5) Position the A/C condenser, transmission oil

cooler, and mounting brackets into the vehicle as an

assembly. Be certain that the lower mounting brack-

ets are engaged into the rubber isolators located on

each side of the cooling module.

(6) Install the two screws that secure the top of

the mounting bracket on each side of the A/C con-

denser to the cooling module. Tighten the screws to 5

N´m (45 in. lbs.).

Fig. 11 A/C Condenser ± 2.5L/2.8L Diesel Engines

1 - BOLT (2)

2 - LOWER MOUNT ISOLATOR (2)

3 - A/C CONDENSER

24 - 78 PLUMBING - FRONTRS

A/C CONDENSER (Continued)

Page 2230 of 2339

(7) Remove the tape or plugs from the opened

refrigerant line fittings and the condenser ports.

(8) Connect the A/C discharge line and the A/C liq-

uid line to the A/C condenser (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C

DISCHARGE LINE - INSTALLATION) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING/

A/C LIQUID LINE - INSTALLATION).

(9) Reconnect the hoses to the transmission oil

cooler fittings on the left side of the cooling module

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER LINES - INSTALLATION).

(10) Reposition the hood latch to the front of the

radiator closure panel crossmember.

(11) Install the two screws that secure the hood

latch to the front of the radiator closure panel cross-

member. Check and adjust the hood latch as needed.

Tighten the screws to 14 N´m (123 in. lbs.).

(12) Position the radiator sight shield onto the

radiator closure panel crossmember.

(13) Install the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

Tighten the screws to 2 N´m (17 in. lbs.).

(14) Install the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber. Tighten the screws to 6 N´m (53 in. lbs.).

(15) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(16) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

A/C DISCHARGE LINE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/REFRIGERANT - STAN-

DARD PROCEDURE - REFRIGERANT SYSTEM

RECOVERY).(2) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 12).

(3) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(4) Remove the radiator sight shield from the radi-

ator closure panel crossmember.

(5) Remove the nut that secures the A/C discharge

line to the right side of the A/C condenser (Fig. 13).

(6) Disconnect the A/C discharge line from the A/C

condenser and remove and discard the O-ring seal

and gasket.

(7) Install plugs in, or tape over the opened dis-

charge line fitting and the condenser inlet port.

(8) Remove the nut that secures the A/C discharge

line to the A/C compressor (Fig. 14).

(9) Disconnect the A/C discharge line from the A/C

compressor and remove and discard the O-ring seal

and gasket.

(10) Install plugs in, or tape over the opened dis-

charge line fitting and the compressor discharge port.

(11) Remove the A/C discharge line from the

engine compartment.

Fig. 12 Radiator Sight Shield - Typical

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSPLUMBING - FRONT24-79

A/C CONDENSER (Continued)

Page 2332 of 2339

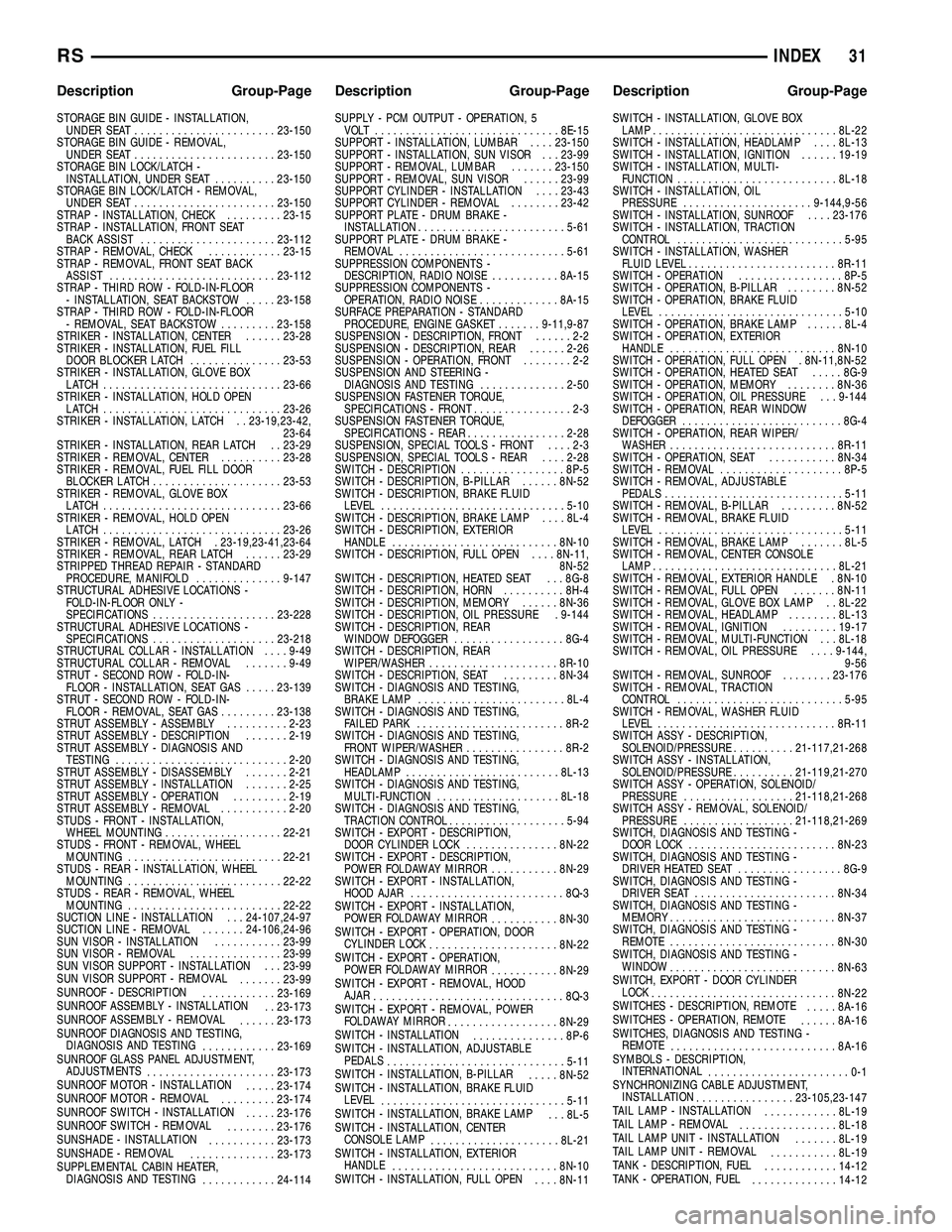

STORAGE BIN GUIDE - INSTALLATION,UNDER SEAT ....................... 23-150

STORAGE BIN GUIDE - REMOVAL, UNDER SEAT ....................... 23-150

STORAGE BIN LOCK/LATCH - INSTALLATION, UNDER SEAT ..........23-150

STORAGE BIN LOCK/LATCH - REMOVAL, UNDER SEAT ....................... 23-150

STRAP - INSTALLATION, CHECK .........23-15

STRAP - INSTALLATION, FRONT SEAT BACK ASSIST ...................... 23-112

STRAP - REMOVAL, CHECK ............23-15

STRAP - REMOVAL, FRONT SEAT BACK ASSIST ........................... 23-112

STRAP - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACKSTOW .....23-158

STRAP - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACKSTOW .........23-158

STRIKER - INSTALLATION, CENTER ......23-28

STRIKER - INSTALLATION, FUEL FILL DOOR BLOCKER LATCH ...............23-53

STRIKER - INSTALLATION, GLOVE BOX LATCH ............................. 23-66

STRIKER - INSTALLATION, HOLD OPEN LATCH ............................. 23-26

STRIKER - INSTALLATION, LATCH . . 23-19,23-42, 23-64

STRIKER - INSTALLATION, REAR LATCH . . 23-29

STRIKER - REMOVAL, CENTER ..........23-28

STRIKER - REMOVAL, FUEL FILL DOOR BLOCKER LATCH ..................... 23-53

STRIKER - REMOVAL, GLOVE BOX LATCH ............................. 23-66

STRIKER - REMOVAL, HOLD OPEN LATCH ............................. 23-26

STRIKER - REMOVAL, LATCH . 23-19,23-41,23-64

STRIKER - REMOVAL, REAR LATCH ......23-29

STRIPPED THREAD REPAIR - STANDARD PROCEDURE, MANIFOLD ..............9-147

STRUCTURAL ADHESIVE LOCATIONS - FOLD-IN-FLOOR ONLY -

SPECIFICATIONS .................... 23-228

STRUCTURAL ADHESIVE LOCATIONS - SPECIFICATIONS .................... 23-218

STRUCTURAL COLLAR - INSTALLATION ....9-49

STRUCTURAL COLLAR - REMOVAL .......9-49

STRUT - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION, SEAT GAS .....23-139

STRUT - SECOND ROW - FOLD-IN- FLOOR - REMOVAL, SEAT GAS .........23-138

STRUT ASSEMBLY - ASSEMBLY ..........2-23

STRUT ASSEMBLY - DESCRIPTION .......2-19

STRUT ASSEMBLY - DIAGNOSIS AND TESTING ............................ 2-20

STRUT ASSEMBLY - DISASSEMBLY .......2-21

STRUT ASSEMBLY - INSTALLATION .......2-25

STRUT ASSEMBLY - OPERATION .........2-19

STRUT ASSEMBLY - REMOVAL ...........2-20

STUDS - FRONT - INSTALLATION, WHEEL MOUNTING ................... 22-21

STUDS - FRONT - REMOVAL, WHEEL MOUNTING ......................... 22-21

STUDS - REAR - INSTALLATION, WHEEL MOUNTING ......................... 22-22

STUDS - REAR - REMOVAL, WHEEL MOUNTING ......................... 22-22

SUCTION LINE - INSTALLATION . . . 24-107,24-97

SUCTION LINE - REMOVAL .......24-106,24-96

SUN VISOR - INSTALLATION ...........23-99

SUN VISOR - REMOVAL ...............23-99

SUN VISOR SUPPORT - INSTALLATION . . . 23-99

SUN VISOR SUPPORT - REMOVAL .......23-99

SUNROOF - DESCRIPTION ............23-169

SUNROOF ASSEMBLY - INSTALLATION . . 23-173

SUNROOF ASSEMBLY - REMOVAL ......23-173

SUNROOF DIAGNOSIS AND TESTING, DIAGNOSIS AND TESTING ............23-169

SUNROOF GLASS PANEL ADJUSTMENT, ADJUSTMENTS ..................... 23-173

SUNROOF MOTOR - INSTALLATION .....23-174

SUNROOF MOTOR - REMOVAL .........23-174

SUNROOF SWITCH - INSTALLATION .....23-176

SUNROOF SWITCH - REMOVAL ........23-176

SUNSHADE - INSTALLATION ...........23-173

SUNSHADE - REMOVAL ..............23-173

SUPPLEMENTAL CABIN HEATER, DIAGNOSIS AND TESTING ............24-114SUPPLY - PCM OUTPUT - OPERATION, 5

VOLT .............................. 8E-15

SUPPORT - INSTALLATION, LUMBAR ....23-150

SUPPORT - INSTALLATION, SUN VISOR . . . 23-99

SUPPORT - REMOVAL, LUMBAR .......23-150

SUPPORT - REMOVAL, SUN VISOR ......23-99

SUPPORT CYLINDER - INSTALLATION ....23-43

SUPPORT CYLINDER - REMOVAL ........23-42

SUPPORT PLATE - DRUM BRAKE - INSTALLATION ........................ 5-61

SUPPORT PLATE - DRUM BRAKE - REMOVAL ........................... 5-61

SUPPRESSION COMPONENTS - DESCRIPTION, RADIO NOISE ...........8A-15

SUPPRESSION COMPONENTS - OPERATION, RADIO NOISE .............8A-15

SURFACE PREPARATION - STANDARD PROCEDURE, ENGINE GASKET .......9-11,9-87

SUSPENSION - DESCRIPTION, FRONT ......2-2

SUSPENSION - DESCRIPTION, REAR ......2-26

SUSPENSION - OPERATION, FRONT ........2-2

SUSPENSION AND STEERING - DIAGNOSIS AND TESTING ..............2-50

SUSPENSION FASTENER TORQUE, SPECIFICATIONS - FRONT ................2-3

SUSPENSION FASTENER TORQUE, SPECIFICATIONS - REAR ................2-28

SUSPENSION, SPECIAL TOOLS - FRONT ....2-3

SUSPENSION, SPECIAL TOOLS - REAR ....2-28

SWITCH - DESCRIPTION .................8P-5

SWITCH - DESCRIPTION, B-PILLAR ......8N-52

SWITCH - DESCRIPTION, BRAKE FLUID LEVEL .............................. 5-10

SWITCH - DESCRIPTION, BRAKE LAMP ....8L-4

SWITCH - DESCRIPTION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - DESCRIPTION, FULL OPEN ....8N-11,

8N-52

SWITCH - DESCRIPTION, HEATED SEAT . . . 8G-8

SWITCH - DESCRIPTION, HORN ..........8H-4

SWITCH - DESCRIPTION, MEMORY ......8N-36

SWITCH - DESCRIPTION, OIL PRESSURE . 9-144

SWITCH - DESCRIPTION, REAR WINDOW DEFOGGER .................. 8G-4

SWITCH - DESCRIPTION, REAR WIPER/WASHER ..................... 8R-10

SWITCH - DESCRIPTION, SEAT .........8N-34

SWITCH - DIAGNOSIS AND TESTING, BRAKE LAMP ........................ 8L-4

SWITCH - DIAGNOSIS AND TESTING, FAILED PARK ........................ 8R-2

SWITCH - DIAGNOSIS AND TESTING, FRONT WIPER/WASHER ................8R-2

SWITCH - DIAGNOSIS AND TESTING, HEADLAMP ......................... 8L-13

SWITCH - DIAGNOSIS AND TESTING, MULTI-FUNCTION .................... 8L-18

SWITCH - DIAGNOSIS AND TESTING, TRACTION CONTROL ................... 5-94

SWITCH - EXPORT - DESCRIPTION, DOOR CYLINDER LOCK ...............8N-22

SWITCH - EXPORT - DESCRIPTION, POWER FOLDAWAY MIRROR ...........8N-29

SWITCH - EXPORT - INSTALLATION, HOOD AJAR ......................... 8Q-3

SWITCH - EXPORT - INSTALLATION, POWER FOLDAWAY MIRROR ...........8N-30

SWITCH - EXPORT - OPERATION, DOOR CYLINDER LOCK ..................... 8N-22

SWITCH - EXPORT - OPERATION, POWER FOLDAWAY MIRROR ...........8N-29

SWITCH - EXPORT - REMOVAL, HOOD AJAR ............................... 8Q-3

SWITCH - EXPORT - REMOVAL, POWER FOLDAWAY MIRROR .................. 8N-29

SWITCH - INSTALLATION ...............8P-6

SWITCH - INSTALLATION, ADJUSTABLE PEDALS ............................. 5-11

SWITCH - INSTALLATION, B-PILLAR .....8N-52

SWITCH - INSTALLATION, BRAKE FLUID LEVEL .............................. 5-11

SWITCH - INSTALLATION, BRAKE LAMP . . . 8L-5

SWITCH - INSTALLATION, CENTER CONSOLE LAMP ..................... 8L-21

SWITCH - INSTALLATION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - INSTALLATION, FULL OPEN ....8N-11 SWITCH - INSTALLATION, GLOVE BOX

LAMP .............................. 8L-22

SWITCH - INSTALLATION, HEADLAMP ....8L-13

SWITCH - INSTALLATION, IGNITION ......19-19

SWITCH - INSTALLATION, MULTI- FUNCTION .......................... 8L-18

SWITCH - INSTALLATION, OIL PRESSURE ..................... 9-144,9-56

SWITCH - INSTALLATION, SUNROOF ....23-176

SWITCH - INSTALLATION, TRACTION CONTROL ........................... 5-95

SWITCH - INSTALLATION, WASHER FLUID LEVEL ........................ 8R-11

SWITCH - OPERATION .................8P-5

SWITCH - OPERATION, B-PILLAR ........8N-52

SWITCH - OPERATION, BRAKE FLUID LEVEL .............................. 5-10

SWITCH - OPERATION, BRAKE LAMP ......8L-4

SWITCH - OPERATION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - OPERATION, FULL OPEN . 8N-11,8N-52

SWITCH - OPERATION, HEATED SEAT .....8G-9

SWITCH - OPERATION, MEMORY ........8N-36

SWITCH - OPERATION, OIL PRESSURE . . . 9-144

SWITCH - OPERATION, REAR WINDOW DEFOGGER .......................... 8G-4

SWITCH - OPERATION, REAR WIPER/ WASHER ........................... 8R-11

SWITCH - OPERATION, SEAT ...........8N-34

SWITCH - REMOVAL .................... 8P-5

SWITCH - REMOVAL, ADJUSTABLE PEDALS ............................. 5-11

SWITCH - REMOVAL, B-PILLAR .........8N-52

SWITCH - REMOVAL, BRAKE FLUID LEVEL .............................. 5-11

SWITCH - REMOVAL, BRAKE LAMP .......8L-5

SWITCH - REMOVAL, CENTER CONSOLE LAMP .............................. 8L-21

SWITCH - REMOVAL, EXTERIOR HANDLE . 8N-10

SWITCH - REMOVAL, FULL OPEN .......8N-11

SWITCH - REMOVAL, GLOVE BOX LAMP . . 8L-22

SWITCH - REMOVAL, HEADLAMP ........8L-13

SWITCH - REMOVAL, IGNITION .........19-17

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-18

SWITCH - REMOVAL, OIL PRESSURE ....9-144,

9-56

SWITCH - REMOVAL, SUNROOF ........23-176

SWITCH - REMOVAL, TRACTION CONTROL ........................... 5-95

SWITCH - REMOVAL, WASHER FLUID LEVEL ............................. 8R-11

SWITCH ASSY - DESCRIPTION, SOLENOID/PRESSURE ..........21-117,21-268

SWITCH ASSY - INSTALLATION, SOLENOID/PRESSURE ..........21-119,21-270

SWITCH ASSY - OPERATION, SOLENOID/ PRESSURE .................. 21-118,21-268

SWITCH ASSY - REMOVAL, SOLENOID/ PRESSURE .................. 21-118,21-269

SWITCH, DIAGNOSIS AND TESTING - DOOR LOCK ........................ 8N-23

SWITCH, DIAGNOSIS AND TESTING - DRIVER HEATED SEAT .................8G-9

SWITCH, DIAGNOSIS AND TESTING - DRIVER SEAT ....................... 8N-34

SWITCH, DIAGNOSIS AND TESTING - MEMORY ........................... 8N-37

SWITCH, DIAGNOSIS AND TESTING - REMOTE ........................... 8N-30

SWITCH, DIAGNOSIS AND TESTING - WINDOW ........................... 8N-63

SWITCH, EXPORT - DOOR CYLINDER LOCK .............................. 8N-22

SWITCHES - DESCRIPTION, REMOTE .....8A-16

SWITCHES - OPERATION, REMOTE ......8A-16

SWITCHES, DIAGNOSIS AND TESTING - REMOTE ........................... 8A-16

SYMBOLS - DESCRIPTION, INTERNATIONAL .......................0-1

SYNCHRONIZING CABLE ADJUSTMENT, INSTALLATION ................ 23-105,23-147

TAIL LAMP - INSTALLATION ............8L-19

TAIL LAMP - REMOVAL ................8L-18

TAIL LAMP UNIT - INSTALLATION .......8L-19

TAIL LAMP UNIT - REMOVAL ...........8L-19

TANK - DESCRIPTION, FUEL ............14-12

TANK - OPERATION, FUEL ..............14-12

RS INDEX31

Description Group-Page Description Group-Page Description Group-Page