wheel CHRYSLER VOYAGER 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 120 of 2339

Follow pressure bleeder manufacturer's instruc-

tions for use of pressure bleeding equipment.

(1) Install the Adapter Master Cylinder Pressure

Bleed Cap, Special Tool 6921 on the fluid reservoir of

the master cylinder (Fig. 2). Attach the fluid hose

from the pressure bleeder to the fitting on Special

Tool 6921.

(2) Attach a clear plastic hose to the bleeder screw

at one wheel and feed the hose into a clear jar con-

taining fresh brake fluid.

(3) Open the left rear wheel bleeder screw at least

one full turnor more to obtain an adequate flow of

brake fluid.

CAUTION: ªJust crackingº the bleeder screw often

restricts fluid flow, allowing only a slow, weak fluid

discharge of fluid. This practice will NOT get all the

air out. Make sure the bleeder is opened at least 1

full turn when bleeding.

(4) After 4 to 8 ounces of brake fluid has been bled

through the hydraulic system, and an air-free flow is

maintained in the hose and jar, this will indicate a

good bleed of the hydraulic system has been

obtained.

(5) Repeat the procedure at all the other remain-

ing bleeder screws.

(6) Check pedal travel. If pedal travel is excessive

or has not been improved, enough fluid has not

passed through the system to expel all the trapped

air. Be sure to monitor the fluid level in the pressure

bleeder, so it stays at a proper level so air will not

enter the brake system through the master cylinder.

(7) Perform a final adjustment of the rear brake

shoes (when applicable), then test drive vehicle to be

sure brakes are operating correctly and that pedal is

solid.SPECIFICATIONS

BRAKE FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

ABS ICU Mounting Bolts To

Bracket11 Ð 9 7

ABS ICU Mounting

Bracket-To-Cradle Bolts28 21 250

ABS CAB-To-HCU Mounting

Screws2Ð17

ABS Wheel Speed Sensor

Head Mounting Bolt - Front13 Ð 115

ABS Wheel Speed Sensor

Head Mounting Bolt - Rear10 Ð 90

Adjustable Pedal Position

Sensor Mounting Screws7.5 66 Ð

Adjustable Pedal Module

Mounting Screws2.0 15 Ð

Brake Tube Nuts 17 Ð 145

Brake Hose Intermediate

Bracket Bolt12 Ð 105

Brake Hose-To-Caliper

Mounting Bolt47 35 Ð

Disc Brake Caliper Guide

Pin Bolts35 26 Ð

Disc Brake Caliper Bleeder

Screw15 Ð 125

Drum Brake Wheel Cylinder

Mounting Bolts8Ð75

Drum Brake Wheel Cylinder

Mounting Bleeder screw10 Ð 80

Drum Brake Support Plate

Mounting Bolts130 95 Ð

Junction Block (Non-ABS

Brakes) Mounting Bolts28 21 250

Master Cylinder Mounting

Nuts25 19 225

Power Brake Booster

Mounting Nuts28 21 250

Proportioning Valve

Mounting Bolts54 40 Ð

Proportioning Valve Axle

Bracket Mounting Bolt20 Ð 175

Parking Brake Lever (Pedal)

Mounting Bolts And Nut28 21 250

Wheel Mounting (Lug) Nuts 135 100 Ð

Fig. 2 Tool 6921 Installed On Master Cylinder

1 - SPECIAL TOOL 6921

2 - FLUID RESERVOIR

RSBRAKES - BASE5-9

BRAKES - BASE (Continued)

Page 124 of 2339

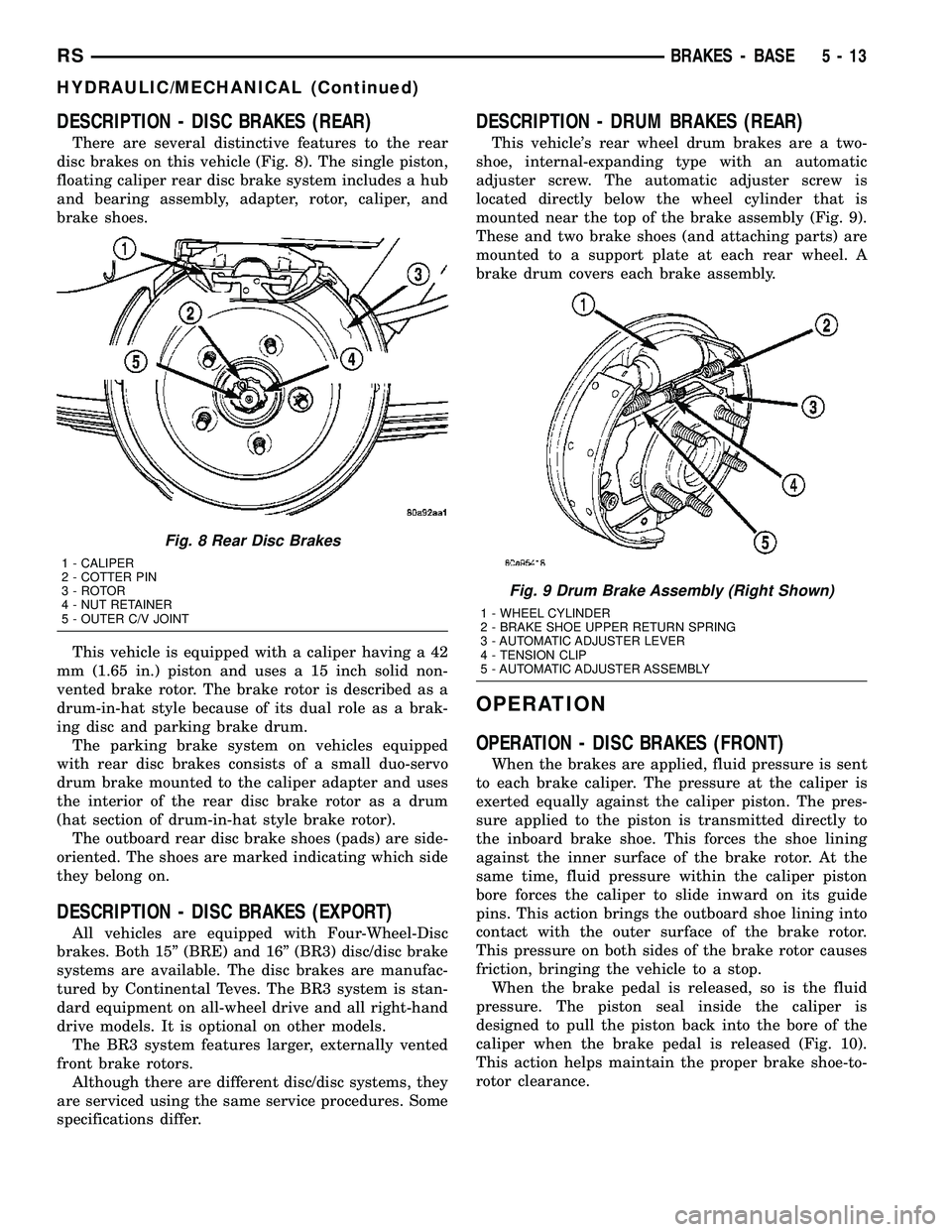

DESCRIPTION - DISC BRAKES (REAR)

There are several distinctive features to the rear

disc brakes on this vehicle (Fig. 8). The single piston,

floating caliper rear disc brake system includes a hub

and bearing assembly, adapter, rotor, caliper, and

brake shoes.

This vehicle is equipped with a caliper having a 42

mm (1.65 in.) piston and uses a 15 inch solid non-

vented brake rotor. The brake rotor is described as a

drum-in-hat style because of its dual role as a brak-

ing disc and parking brake drum.

The parking brake system on vehicles equipped

with rear disc brakes consists of a small duo-servo

drum brake mounted to the caliper adapter and uses

the interior of the rear disc brake rotor as a drum

(hat section of drum-in-hat style brake rotor).

The outboard rear disc brake shoes (pads) are side-

oriented. The shoes are marked indicating which side

they belong on.

DESCRIPTION - DISC BRAKES (EXPORT)

All vehicles are equipped with Four-Wheel-Disc

brakes. Both 15º (BRE) and 16º (BR3) disc/disc brake

systems are available. The disc brakes are manufac-

tured by Continental Teves. The BR3 system is stan-

dard equipment on all-wheel drive and all right-hand

drive models. It is optional on other models.

The BR3 system features larger, externally vented

front brake rotors.

Although there are different disc/disc systems, they

are serviced using the same service procedures. Some

specifications differ.

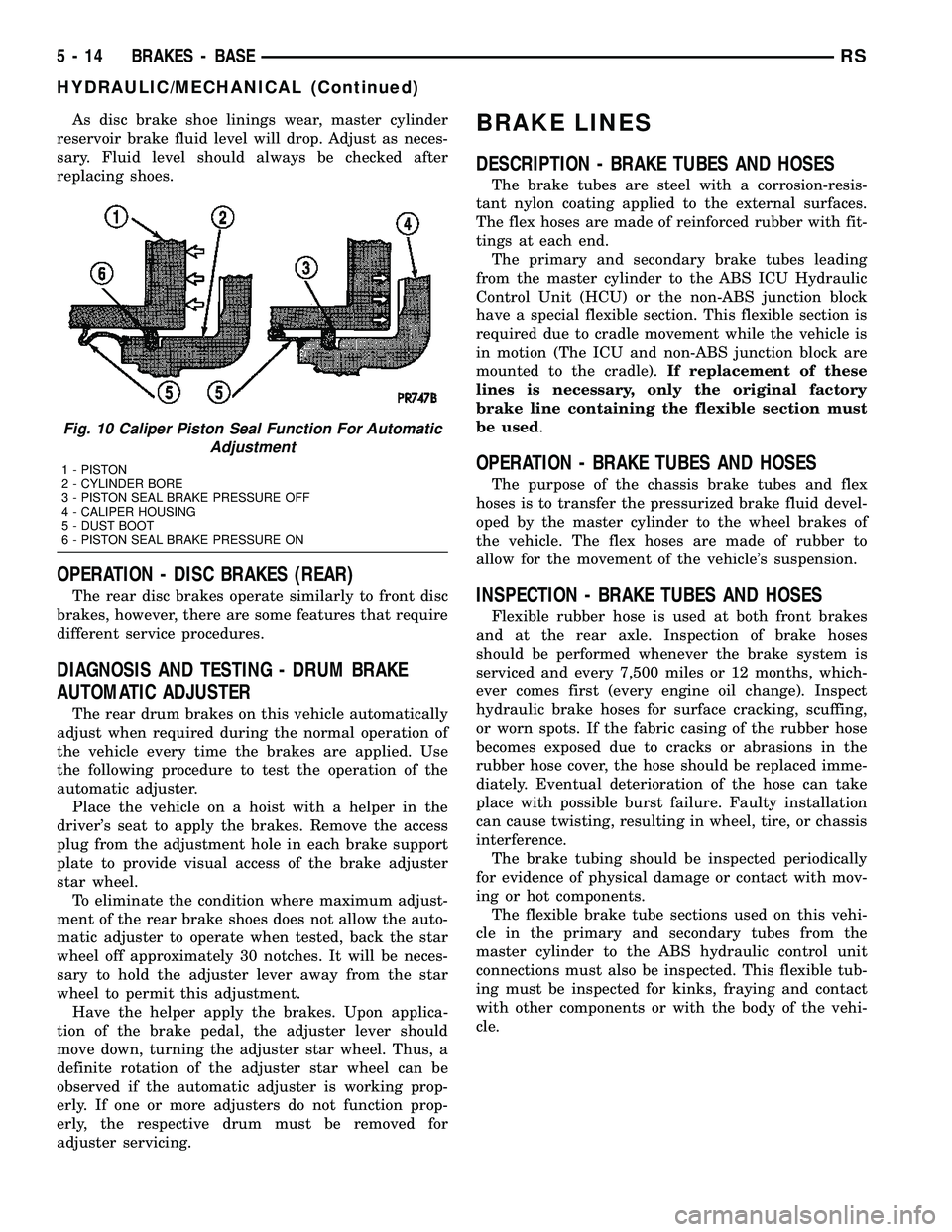

DESCRIPTION - DRUM BRAKES (REAR)

This vehicle's rear wheel drum brakes are a two-

shoe, internal-expanding type with an automatic

adjuster screw. The automatic adjuster screw is

located directly below the wheel cylinder that is

mounted near the top of the brake assembly (Fig. 9).

These and two brake shoes (and attaching parts) are

mounted to a support plate at each rear wheel. A

brake drum covers each brake assembly.

OPERATION

OPERATION - DISC BRAKES (FRONT)

When the brakes are applied, fluid pressure is sent

to each brake caliper. The pressure at the caliper is

exerted equally against the caliper piston. The pres-

sure applied to the piston is transmitted directly to

the inboard brake shoe. This forces the shoe lining

against the inner surface of the brake rotor. At the

same time, fluid pressure within the caliper piston

bore forces the caliper to slide inward on its guide

pins. This action brings the outboard shoe lining into

contact with the outer surface of the brake rotor.

This pressure on both sides of the brake rotor causes

friction, bringing the vehicle to a stop.

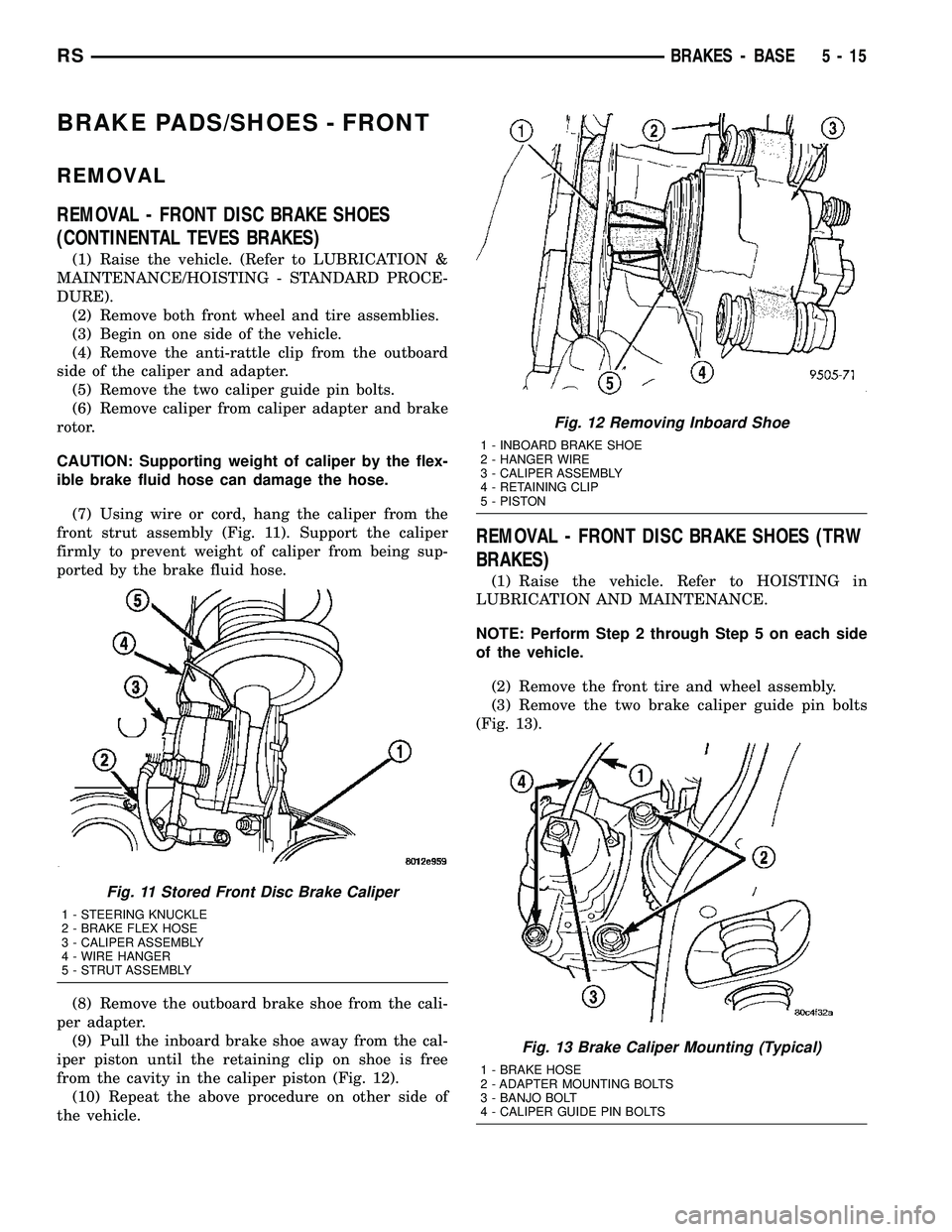

When the brake pedal is released, so is the fluid

pressure. The piston seal inside the caliper is

designed to pull the piston back into the bore of the

caliper when the brake pedal is released (Fig. 10).

This action helps maintain the proper brake shoe-to-

rotor clearance.

Fig. 8 Rear Disc Brakes

1 - CALIPER

2 - COTTER PIN

3 - ROTOR

4 - NUT RETAINER

5 - OUTER C/V JOINT

Fig. 9 Drum Brake Assembly (Right Shown)

1 - WHEEL CYLINDER

2 - BRAKE SHOE UPPER RETURN SPRING

3 - AUTOMATIC ADJUSTER LEVER

4 - TENSION CLIP

5 - AUTOMATIC ADJUSTER ASSEMBLY

RSBRAKES - BASE5-13

HYDRAULIC/MECHANICAL (Continued)

Page 125 of 2339

As disc brake shoe linings wear, master cylinder

reservoir brake fluid level will drop. Adjust as neces-

sary. Fluid level should always be checked after

replacing shoes.

OPERATION - DISC BRAKES (REAR)

The rear disc brakes operate similarly to front disc

brakes, however, there are some features that require

different service procedures.

DIAGNOSIS AND TESTING - DRUM BRAKE

AUTOMATIC ADJUSTER

The rear drum brakes on this vehicle automatically

adjust when required during the normal operation of

the vehicle every time the brakes are applied. Use

the following procedure to test the operation of the

automatic adjuster.

Place the vehicle on a hoist with a helper in the

driver's seat to apply the brakes. Remove the access

plug from the adjustment hole in each brake support

plate to provide visual access of the brake adjuster

star wheel.

To eliminate the condition where maximum adjust-

ment of the rear brake shoes does not allow the auto-

matic adjuster to operate when tested, back the star

wheel off approximately 30 notches. It will be neces-

sary to hold the adjuster lever away from the star

wheel to permit this adjustment.

Have the helper apply the brakes. Upon applica-

tion of the brake pedal, the adjuster lever should

move down, turning the adjuster star wheel. Thus, a

definite rotation of the adjuster star wheel can be

observed if the automatic adjuster is working prop-

erly. If one or more adjusters do not function prop-

erly, the respective drum must be removed for

adjuster servicing.

BRAKE LINES

DESCRIPTION - BRAKE TUBES AND HOSES

The brake tubes are steel with a corrosion-resis-

tant nylon coating applied to the external surfaces.

The flex hoses are made of reinforced rubber with fit-

tings at each end.

The primary and secondary brake tubes leading

from the master cylinder to the ABS ICU Hydraulic

Control Unit (HCU) or the non-ABS junction block

have a special flexible section. This flexible section is

required due to cradle movement while the vehicle is

in motion (The ICU and non-ABS junction block are

mounted to the cradle).If replacement of these

lines is necessary, only the original factory

brake line containing the flexible section must

be used.

OPERATION - BRAKE TUBES AND HOSES

The purpose of the chassis brake tubes and flex

hoses is to transfer the pressurized brake fluid devel-

oped by the master cylinder to the wheel brakes of

the vehicle. The flex hoses are made of rubber to

allow for the movement of the vehicle's suspension.

INSPECTION - BRAKE TUBES AND HOSES

Flexible rubber hose is used at both front brakes

and at the rear axle. Inspection of brake hoses

should be performed whenever the brake system is

serviced and every 7,500 miles or 12 months, which-

ever comes first (every engine oil change). Inspect

hydraulic brake hoses for surface cracking, scuffing,

or worn spots. If the fabric casing of the rubber hose

becomes exposed due to cracks or abrasions in the

rubber hose cover, the hose should be replaced imme-

diately. Eventual deterioration of the hose can take

place with possible burst failure. Faulty installation

can cause twisting, resulting in wheel, tire, or chassis

interference.

The brake tubing should be inspected periodically

for evidence of physical damage or contact with mov-

ing or hot components.

The flexible brake tube sections used on this vehi-

cle in the primary and secondary tubes from the

master cylinder to the ABS hydraulic control unit

connections must also be inspected. This flexible tub-

ing must be inspected for kinks, fraying and contact

with other components or with the body of the vehi-

cle.

Fig. 10 Caliper Piston Seal Function For Automatic

Adjustment

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

5 - 14 BRAKES - BASERS

HYDRAULIC/MECHANICAL (Continued)

Page 126 of 2339

BRAKE PADS/SHOES - FRONT

REMOVAL

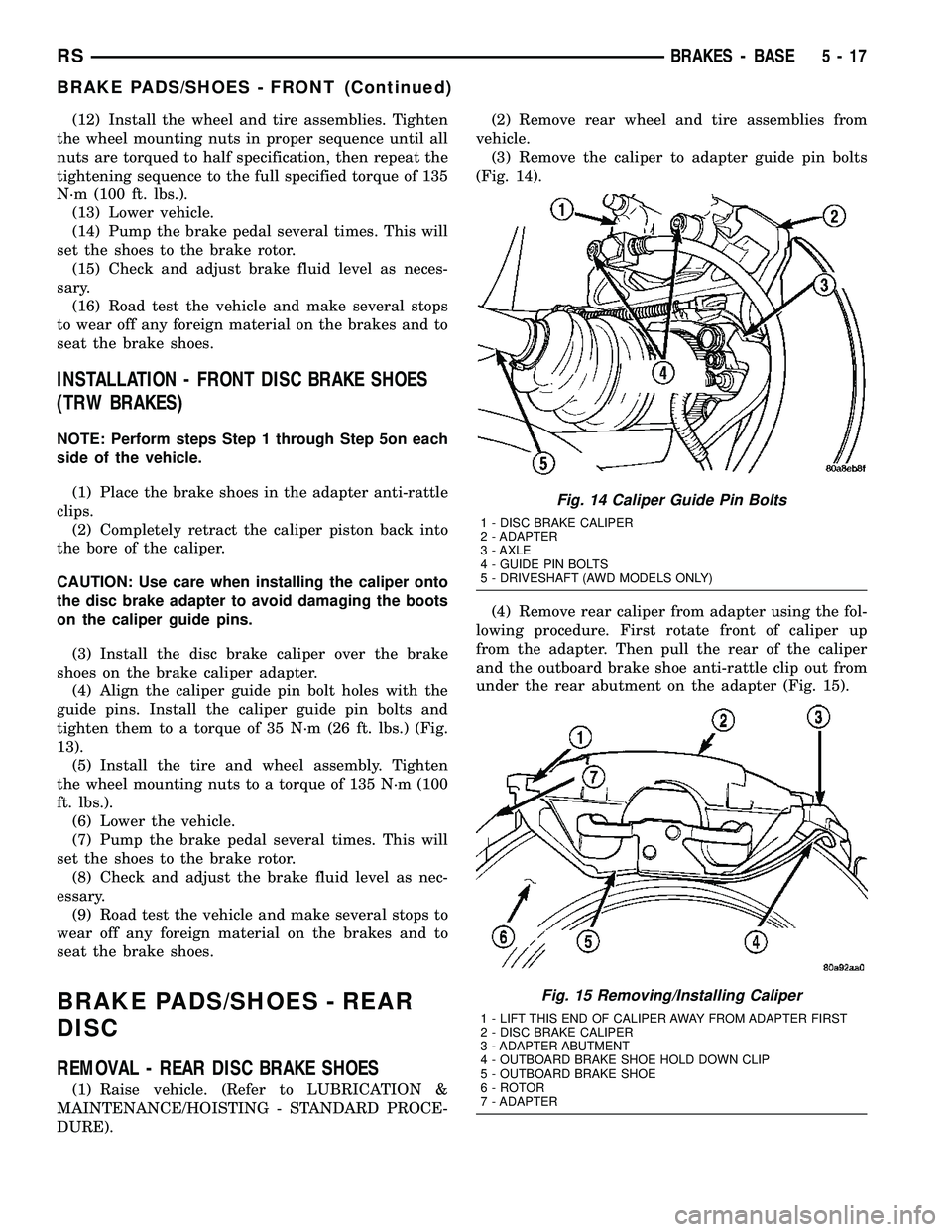

REMOVAL - FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES)

(1) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(2) Remove both front wheel and tire assemblies.

(3) Begin on one side of the vehicle.

(4) Remove the anti-rattle clip from the outboard

side of the caliper and adapter.

(5) Remove the two caliper guide pin bolts.

(6) Remove caliper from caliper adapter and brake

rotor.

CAUTION: Supporting weight of caliper by the flex-

ible brake fluid hose can damage the hose.

(7) Using wire or cord, hang the caliper from the

front strut assembly (Fig. 11). Support the caliper

firmly to prevent weight of caliper from being sup-

ported by the brake fluid hose.

(8) Remove the outboard brake shoe from the cali-

per adapter.

(9) Pull the inboard brake shoe away from the cal-

iper piston until the retaining clip on shoe is free

from the cavity in the caliper piston (Fig. 12).

(10) Repeat the above procedure on other side of

the vehicle.

REMOVAL - FRONT DISC BRAKE SHOES (TRW

BRAKES)

(1) Raise the vehicle. Refer to HOISTING in

LUBRICATION AND MAINTENANCE.

NOTE: Perform Step 2 through Step 5 on each side

of the vehicle.

(2) Remove the front tire and wheel assembly.

(3) Remove the two brake caliper guide pin bolts

(Fig. 13).

Fig. 11 Stored Front Disc Brake Caliper

1 - STEERING KNUCKLE

2 - BRAKE FLEX HOSE

3 - CALIPER ASSEMBLY

4 - WIRE HANGER

5 - STRUT ASSEMBLY

Fig. 12 Removing Inboard Shoe

1 - INBOARD BRAKE SHOE

2 - HANGER WIRE

3 - CALIPER ASSEMBLY

4 - RETAINING CLIP

5 - PISTON

Fig. 13 Brake Caliper Mounting (Typical)

1 - BRAKE HOSE

2 - ADAPTER MOUNTING BOLTS

3 - BANJO BOLT

4 - CALIPER GUIDE PIN BOLTS

RSBRAKES - BASE5-15

Page 128 of 2339

(12) Install the wheel and tire assemblies. Tighten

the wheel mounting nuts in proper sequence until all

nuts are torqued to half specification, then repeat the

tightening sequence to the full specified torque of 135

N´m (100 ft. lbs.).

(13) Lower vehicle.

(14) Pump the brake pedal several times. This will

set the shoes to the brake rotor.

(15) Check and adjust brake fluid level as neces-

sary.

(16) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoes.

INSTALLATION - FRONT DISC BRAKE SHOES

(TRW BRAKES)

NOTE: Perform steps Step 1 through Step 5on each

side of the vehicle.

(1) Place the brake shoes in the adapter anti-rattle

clips.

(2) Completely retract the caliper piston back into

the bore of the caliper.

CAUTION: Use care when installing the caliper onto

the disc brake adapter to avoid damaging the boots

on the caliper guide pins.

(3) Install the disc brake caliper over the brake

shoes on the brake caliper adapter.

(4) Align the caliper guide pin bolt holes with the

guide pins. Install the caliper guide pin bolts and

tighten them to a torque of 35 N´m (26 ft. lbs.) (Fig.

13).

(5) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(6) Lower the vehicle.

(7) Pump the brake pedal several times. This will

set the shoes to the brake rotor.

(8) Check and adjust the brake fluid level as nec-

essary.

(9) Road test the vehicle and make several stops to

wear off any foreign material on the brakes and to

seat the brake shoes.

BRAKE PADS/SHOES - REAR

DISC

REMOVAL - REAR DISC BRAKE SHOES

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).(2) Remove rear wheel and tire assemblies from

vehicle.

(3) Remove the caliper to adapter guide pin bolts

(Fig. 14).

(4) Remove rear caliper from adapter using the fol-

lowing procedure. First rotate front of caliper up

from the adapter. Then pull the rear of the caliper

and the outboard brake shoe anti-rattle clip out from

under the rear abutment on the adapter (Fig. 15).

Fig. 14 Caliper Guide Pin Bolts

1 - DISC BRAKE CALIPER

2 - ADAPTER

3 - AXLE

4 - GUIDE PIN BOLTS

5 - DRIVESHAFT (AWD MODELS ONLY)

Fig. 15 Removing/Installing Caliper

1 - LIFT THIS END OF CALIPER AWAY FROM ADAPTER FIRST

2 - DISC BRAKE CALIPER

3 - ADAPTER ABUTMENT

4 - OUTBOARD BRAKE SHOE HOLD DOWN CLIP

5 - OUTBOARD BRAKE SHOE

6 - ROTOR

7 - ADAPTER

RSBRAKES - BASE5-17

BRAKE PADS/SHOES - FRONT (Continued)

Page 129 of 2339

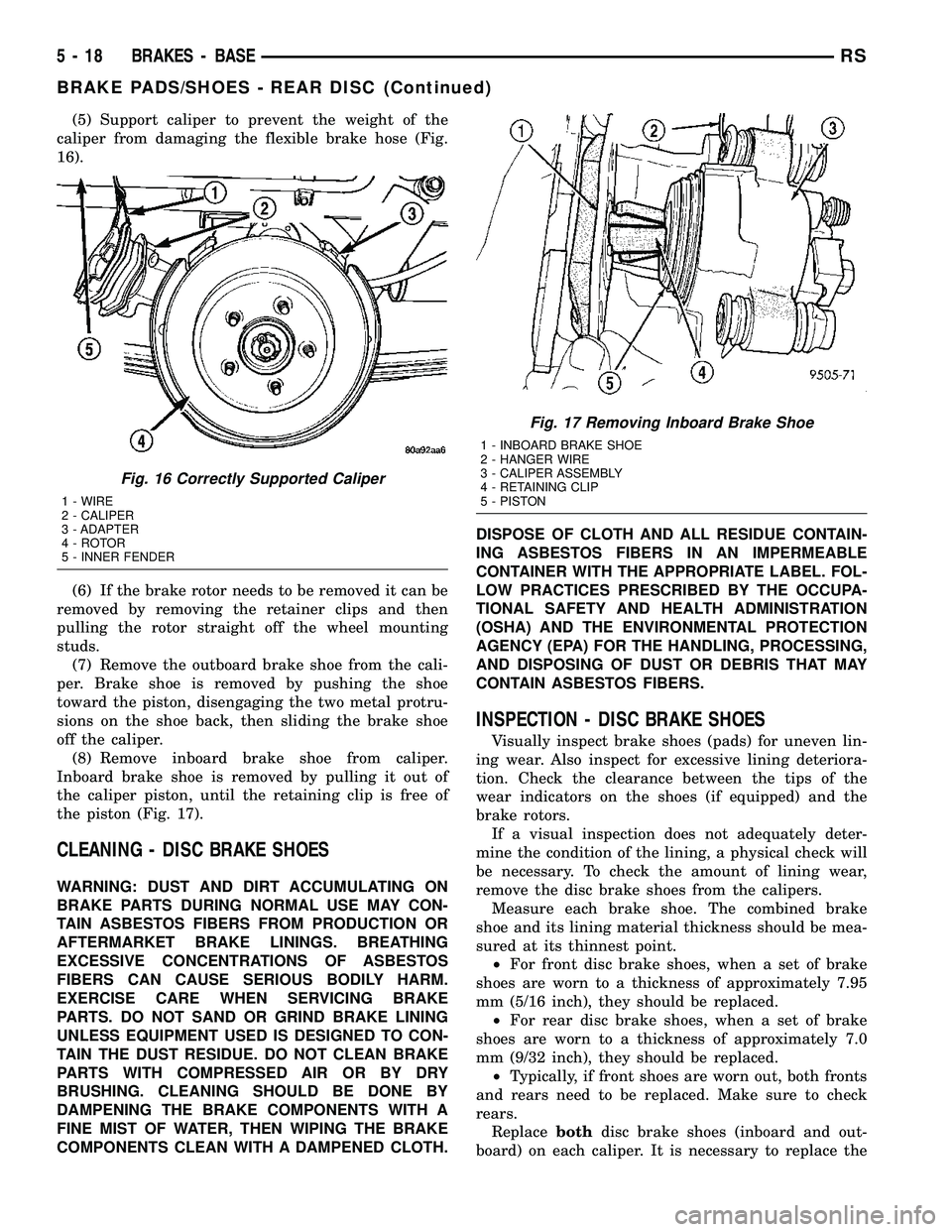

(5) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

16).

(6) If the brake rotor needs to be removed it can be

removed by removing the retainer clips and then

pulling the rotor straight off the wheel mounting

studs.

(7) Remove the outboard brake shoe from the cali-

per. Brake shoe is removed by pushing the shoe

toward the piston, disengaging the two metal protru-

sions on the shoe back, then sliding the brake shoe

off the caliper.

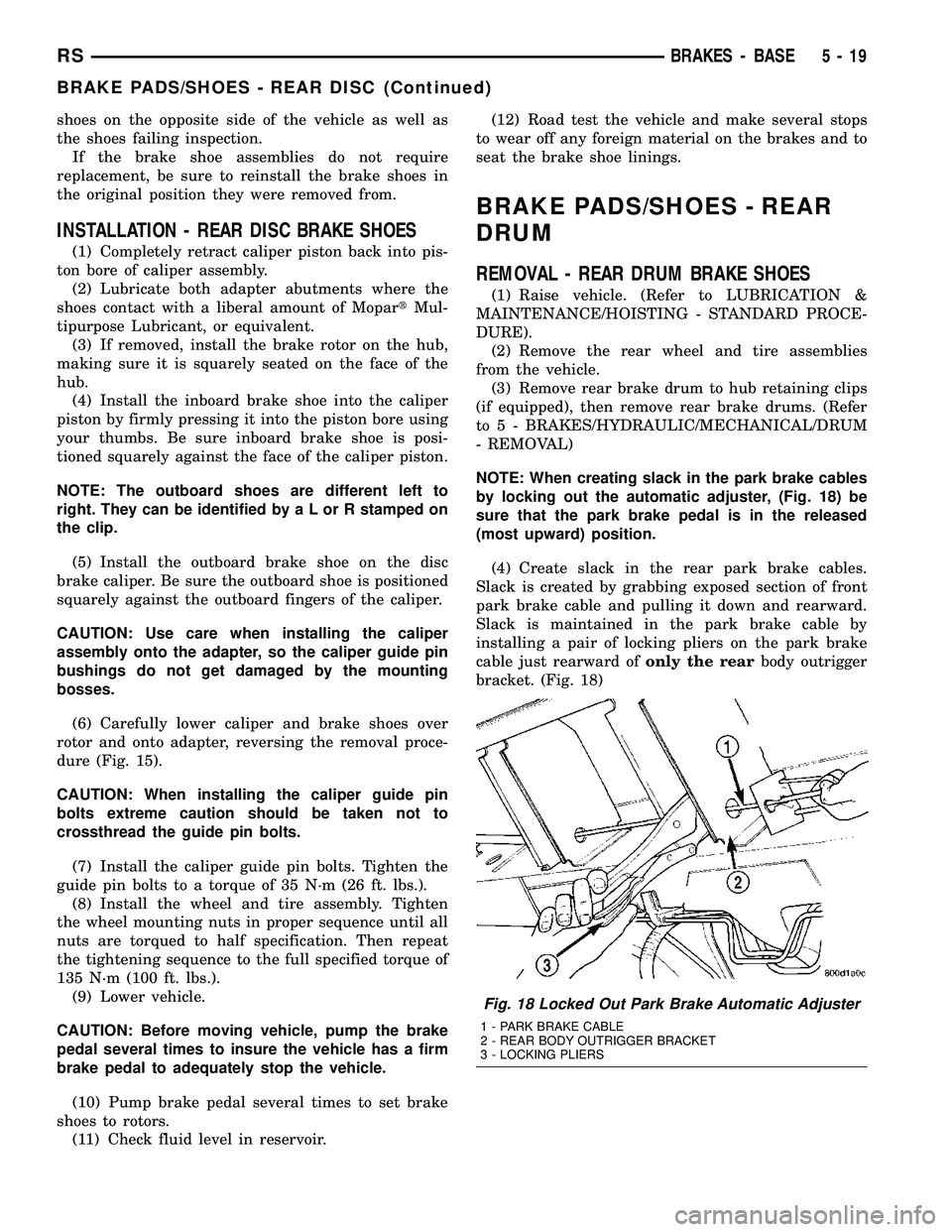

(8) Remove inboard brake shoe from caliper.

Inboard brake shoe is removed by pulling it out of

the caliper piston, until the retaining clip is free of

the piston (Fig. 17).

CLEANING - DISC BRAKE SHOES

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

INSPECTION - DISC BRAKE SHOES

Visually inspect brake shoes (pads) for uneven lin-

ing wear. Also inspect for excessive lining deteriora-

tion. Check the clearance between the tips of the

wear indicators on the shoes (if equipped) and the

brake rotors.

If a visual inspection does not adequately deter-

mine the condition of the lining, a physical check will

be necessary. To check the amount of lining wear,

remove the disc brake shoes from the calipers.

Measure each brake shoe. The combined brake

shoe and its lining material thickness should be mea-

sured at its thinnest point.

²For front disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.95

mm (5/16 inch), they should be replaced.

²For rear disc brake shoes, when a set of brake

shoes are worn to a thickness of approximately 7.0

mm (9/32 inch), they should be replaced.

²Typically, if front shoes are worn out, both fronts

and rears need to be replaced. Make sure to check

rears.

Replacebothdisc brake shoes (inboard and out-

board) on each caliper. It is necessary to replace the

Fig. 16 Correctly Supported Caliper

1 - WIRE

2 - CALIPER

3 - ADAPTER

4 - ROTOR

5 - INNER FENDER

Fig. 17 Removing Inboard Brake Shoe

1 - INBOARD BRAKE SHOE

2 - HANGER WIRE

3 - CALIPER ASSEMBLY

4 - RETAINING CLIP

5 - PISTON

5 - 18 BRAKES - BASERS

BRAKE PADS/SHOES - REAR DISC (Continued)

Page 130 of 2339

shoes on the opposite side of the vehicle as well as

the shoes failing inspection.

If the brake shoe assemblies do not require

replacement, be sure to reinstall the brake shoes in

the original position they were removed from.

INSTALLATION - REAR DISC BRAKE SHOES

(1) Completely retract caliper piston back into pis-

ton bore of caliper assembly.

(2) Lubricate both adapter abutments where the

shoes contact with a liberal amount of MopartMul-

tipurpose Lubricant, or equivalent.

(3) If removed, install the brake rotor on the hub,

making sure it is squarely seated on the face of the

hub.

(4) Install the inboard brake shoe into the caliper

piston by firmly pressing it into the piston bore using

your thumbs. Be sure inboard brake shoe is posi-

tioned squarely against the face of the caliper piston.

NOTE: The outboard shoes are different left to

right. They can be identified by a L or R stamped on

the clip.

(5) Install the outboard brake shoe on the disc

brake caliper. Be sure the outboard shoe is positioned

squarely against the outboard fingers of the caliper.

CAUTION: Use care when installing the caliper

assembly onto the adapter, so the caliper guide pin

bushings do not get damaged by the mounting

bosses.

(6) Carefully lower caliper and brake shoes over

rotor and onto adapter, reversing the removal proce-

dure (Fig. 15).

CAUTION: When installing the caliper guide pin

bolts extreme caution should be taken not to

crossthread the guide pin bolts.

(7) Install the caliper guide pin bolts. Tighten the

guide pin bolts to a torque of 35 N´m (26 ft. lbs.).

(8) Install the wheel and tire assembly. Tighten

the wheel mounting nuts in proper sequence until all

nuts are torqued to half specification. Then repeat

the tightening sequence to the full specified torque of

135 N´m (100 ft. lbs.).

(9) Lower vehicle.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop the vehicle.

(10) Pump brake pedal several times to set brake

shoes to rotors.

(11) Check fluid level in reservoir.(12) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoe linings.

BRAKE PADS/SHOES - REAR

DRUM

REMOVAL - REAR DRUM BRAKE SHOES

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(2) Remove the rear wheel and tire assemblies

from the vehicle.

(3) Remove rear brake drum to hub retaining clips

(if equipped), then remove rear brake drums. (Refer

to 5 - BRAKES/HYDRAULIC/MECHANICAL/DRUM

- REMOVAL)

NOTE: When creating slack in the park brake cables

by locking out the automatic adjuster, (Fig. 18) be

sure that the park brake pedal is in the released

(most upward) position.

(4) Create slack in the rear park brake cables.

Slack is created by grabbing exposed section of front

park brake cable and pulling it down and rearward.

Slack is maintained in the park brake cable by

installing a pair of locking pliers on the park brake

cable just rearward ofonly the rearbody outrigger

bracket. (Fig. 18)

Fig. 18 Locked Out Park Brake Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

RSBRAKES - BASE5-19

BRAKE PADS/SHOES - REAR DISC (Continued)

Page 132 of 2339

(8) Remove the tension clip (Fig. 23) attaching the

upper return spring to the automatic adjuster assem-

bly.

(9) Remove the brake shoe to brake shoe upper

return spring (Fig. 24).(10) Remove the trailing brake shoe assembly to

brake support plate hold down spring and pin (Fig.

25) from the brake shoe assembly.

(11) Remove the trailing brake shoe assembly from

the brake support plate, park brake actuating lever

and park brake actuating strut (Fig. 26). Remove the

automatic adjuster assembly from the leading brake

shoe.

Fig. 23 Tension Clip Attachment To Adjuster

1 - WHEEL CYLINDER

2 - BRAKE SHOE UPPER RETURN SPRING

3 - AUTOMATIC ADJUSTER LEVER

4 - TENSION CLIP

5 - AUTOMATIC ADJUSTER ASSEMBLY

Fig. 24 Brake Shoe Upper Return Spring

1 - BRAKE SHOE RETURN SPRING

2 - LEADING BRAKE SHOE

3 - TRAILING BRAKE SHOE

Fig. 25 Trailing Brake Shoe Hold Down Spring And

Pin

1 - BRAKE SUPPORT PLATE

2 - HOLD DOWN SPRING AND PIN

3 - TRAILING BRAKE SHOE

Fig. 26 Trailing Brake Shoe Removal/Installation

1 - BRAKE SUPPORT PLATE

2 - LEADING BRAKE SHOE

3 - PARK BRAKE ACTUATING LEVER

4 - PARK BRAKE ACTUATING STRUT

5 - TRAILING BRAKE SHOE

RSBRAKES - BASE5-21

BRAKE PADS/SHOES - REAR DRUM (Continued)

Page 133 of 2339

(12) Remove the leading brake shoe assembly to

brake support plate hold down spring and pin (Fig.

27) from the brake shoe. Remove the leading brake

shoe from the brake support plate.

(13) Remove the park brake actuator (Fig. 28)

from the leading brake shoe and transfer to the

replacement brake shoe.INSPECTION - REAR DRUM BRAKE SHOE

LINING

(1) Remove the tire and wheel assembly from the

vehicle

(2) Remove the rear brake adjusting hole plug

found in the brake support.

(3) Insert a thin screwdriver into brake adjusting

hole to hold the adjusting lever away from the

notches on the adjusting screw star wheel.

(4) Insert Tool C-3784 into brake adjusting hole

and engage notches of brake adjusting screw star

wheel. Release brake by prying down with adjusting

tool.

(5) Remove the rear brake drum from the rear hub

and bearing assembly. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DRUM - REMOVAL)

(6) Inspect brake lining for wear, shoe alignment,

and or contamination from grease or brake fluid.

INSTALLATION - REAR DRUM BRAKE SHOES

(1) Lubricate the eight shoe contact areas on the

support plate and anchor, (Fig. 29) using the

required special MopartBrake Lubricant or equiva-

lent.

(2) Install leading brake shoe on brake support

plate. Install the leading brake shoe hold down

spring and pin (Fig. 27) on the brake shoe.

Fig. 27 Leading Brake Shoe Hold Down Spring And

Pin

1 - PARK BRAKE ACTUATING LEVER

2 - BRAKE SUPPORT PLATE

3 - LEADING BRAKE SHOE

4 - HOLD DOWN SPRING AND PIN

Fig. 28 Park Brake Actuator Plate

1 - RETAINING CLIP

2 - BRAKE SHOE ASSEMBLY

3 - ACTUATOR PLATE

Fig. 29 Brake Support Plate Contact Areas

1 - REAR BRAKE SUPPORT PLATE

5 - 22 BRAKES - BASERS

BRAKE PADS/SHOES - REAR DRUM (Continued)

Page 134 of 2339

(3) Install the park brake actuator strut (Fig. 30)

on the leading brake shoe. Then install the park

brake actuator lever on the strut (Fig. 30).

(4) Install the automatic adjuster screw on the

leading brake shoe. Then install the trailing brake

shoe on the park brake actuating lever and park

brake actuating strut (Fig. 26). Position trailing

brake shoe on brake support plate.

(5) Install the brake shoe hold down pin and

spring on the trailing brake shoe (Fig. 25).

(6) Install the brake shoe to brake shoe upper

return spring (Fig. 24).

CAUTION: When installing the tension clip on the

automatic adjuster, it must be located on only the

threaded area of the adjuster assembly (Fig. 23). If it

is located on a non-threaded area of the adjuster, the

function of the automatic adjuster will be affected.

(7)Install the tension clip (Fig. 23) attaching the

upper return spring to the automatic adjuster assembly.

(8)Install the brake shoe to brake shoe lower return

springs on the brake shoes (Fig. 21) and (Fig. 22).

(9) Install automatic adjustment lever on the lead-

ing brake shoe of the rear brake assembly (Fig. 20).

(10) Install the actuating spring on the automatic

adjustment lever and leading brake shoe assembly

(Fig. 19).

(11) Verify that the automatic adjuster lever has

positive contact with the star wheel on the automatic

adjuster assembly.

(12) When all components of both rear brake

assemblies are correctly and fully installed, remove

the locking pliers from the front park brake cable.(13) Adjust brake shoes assemblies so as not to

interfere with brake drum installation.

(14) Install the rear brake drums on the hubs.

(15) Adjust rear brake shoes.

(16) Install the wheel and tire assembly.

(17) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 135 N´m (100 ft. lbs.).

(18) Lower the vehicle.

(19) Push the parking brake lever (pedal) to the

floor once and release pedal. This will automatically

remove the slack from and correctly adjust the park-

ing brake cables.

(20) Road test vehicle. The automatic adjuster will

continue the brake adjustment during the road test

of the vehicle.

ADJUSTMENTS

ADJUSTMENT - REAR DRUM BRAKE SHOES

NOTE: Normally, self-adjusting drum brakes do not

require manual brake shoe adjustment. Although, in

the event of a brake shoe replacement, it is advis-

able to make the initial adjustment manually to

speed up the adjusting time.

NOTE: Before raising the vehicle, verify the parking

brake lever is fully released.

(1) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(2) Remove rubber plug from rear brake adjusting

hole in the rear brake support plate.

(3) Insert a thin screwdriver through the adjusting

hole in the support plate and against the star wheel

of the adjusting screw. Move handle of the tool down-

ward, rotating the star wheel until a slight drag is

felt when tire and wheel assembly is rotated.

(4) Insert a second thin screwdriver or piece of

welding rod into brake adjusting hole and push the

adjusting lever out of engagement with the star

wheel.Care should be taken so as not to bend

adjusting lever or distort lever spring.

(5) While holding the adjusting lever out of

engagement, back off the star wheel just enough to

ensure a free wheel with no brake shoe drag.

(6) Repeat the above adjustment at the other rear

wheel.

(7) Install the adjusting hole rubber plugs back in

the rear brake support plates.

(8) Lower the vehicle.

Fig. 30 Park Brake Components Assembled On

Leading Brake Shoe

1 - PARK BRAKE CABLE

2 - LEADING BRAKE SHOE

3 - PARK BRAKE ACTUATING STRUT

4 - PARK BRAKE ACTUATING LEVER

5 - BRAKE SUPPORT PLATE

RSBRAKES - BASE5-23

BRAKE PADS/SHOES - REAR DRUM (Continued)