window CHRYSLER VOYAGER 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 1784 of 2339

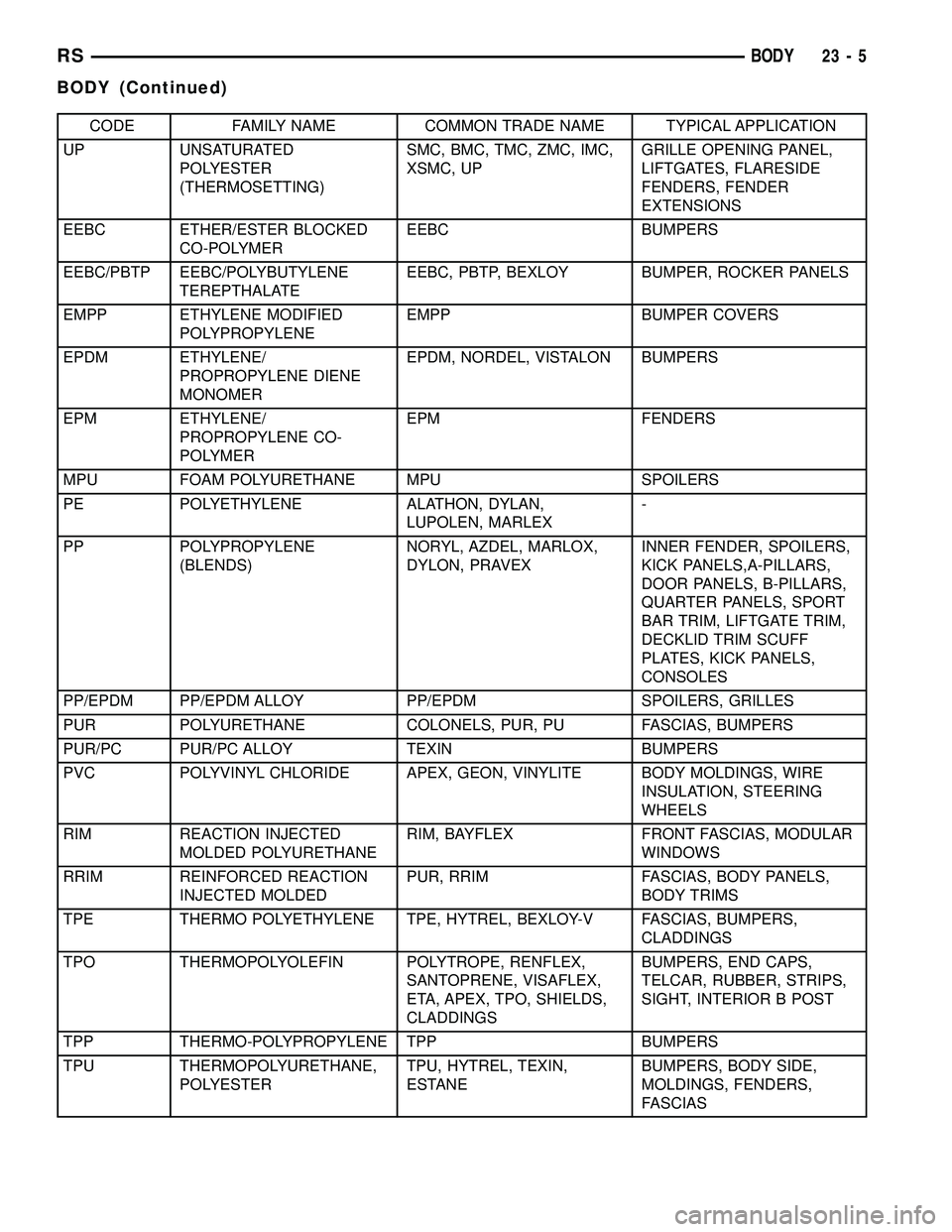

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

UP UNSATURATED

POLYESTER

(THERMOSETTING)SMC, BMC, TMC, ZMC, IMC,

XSMC, UPGRILLE OPENING PANEL,

LIFTGATES, FLARESIDE

FENDERS, FENDER

EXTENSIONS

EEBC ETHER/ESTER BLOCKED

CO-POLYMEREEBC BUMPERS

EEBC/PBTP EEBC/POLYBUTYLENE

TEREPTHALATEEEBC, PBTP, BEXLOY BUMPER, ROCKER PANELS

EMPP ETHYLENE MODIFIED

POLYPROPYLENEEMPP BUMPER COVERS

EPDM ETHYLENE/

PROPROPYLENE DIENE

MONOMEREPDM, NORDEL, VISTALON BUMPERS

EPM ETHYLENE/

PROPROPYLENE CO-

POLYMEREPM FENDERS

MPU FOAM POLYURETHANE MPU SPOILERS

PE POLYETHYLENE ALATHON, DYLAN,

LUPOLEN, MARLEX-

PP POLYPROPYLENE

(BLENDS)NORYL, AZDEL, MARLOX,

DYLON, PRAVEXINNER FENDER, SPOILERS,

KICK PANELS,A-PILLARS,

DOOR PANELS, B-PILLARS,

QUARTER PANELS, SPORT

BAR TRIM, LIFTGATE TRIM,

DECKLID TRIM SCUFF

PLATES, KICK PANELS,

CONSOLES

PP/EPDM PP/EPDM ALLOY PP/EPDM SPOILERS, GRILLES

PUR POLYURETHANE COLONELS, PUR, PU FASCIAS, BUMPERS

PUR/PC PUR/PC ALLOY TEXIN BUMPERS

PVC POLYVINYL CHLORIDE APEX, GEON, VINYLITE BODY MOLDINGS, WIRE

INSULATION, STEERING

WHEELS

RIM REACTION INJECTED

MOLDED POLYURETHANERIM, BAYFLEX FRONT FASCIAS, MODULAR

WINDOWS

RRIM REINFORCED REACTION

INJECTED MOLDEDPUR, RRIM FASCIAS, BODY PANELS,

BODY TRIMS

TPE THERMO POLYETHYLENE TPE, HYTREL, BEXLOY-V FASCIAS, BUMPERS,

CLADDINGS

TPO THERMOPOLYOLEFIN POLYTROPE, RENFLEX,

SANTOPRENE, VISAFLEX,

ETA, APEX, TPO, SHIELDS,

CLADDINGSBUMPERS, END CAPS,

TELCAR, RUBBER, STRIPS,

SIGHT, INTERIOR B POST

TPP THERMO-POLYPROPYLENE TPP BUMPERS

TPU THERMOPOLYURETHANE,

POLYESTERTPU, HYTREL, TEXIN,

ESTANEBUMPERS, BODY SIDE,

MOLDINGS, FENDERS,

FASCIAS

RSBODY23-5

BODY (Continued)

Page 1793 of 2339

DOOR - FRONT

TABLE OF CONTENTS

page page

APPLIQUE

REMOVAL.............................14

INSTALLATION.........................14

CHECK STRAP

REMOVAL.............................15

INSTALLATION.........................15

DOOR

REMOVAL.............................15

INSTALLATION.........................15

DOOR GLASS

REMOVAL.............................16

INSTALLATION.........................17

FRAME CLOSEOUT MOLDING

REMOVAL ± A-PILLAR-HEADER, OR B-PILLAR . 17

INSTALLATION ± A-PILLAR-HEADER, OR

B-PILLAR............................17

HINGE

REMOVAL.............................17

INSTALLATION.........................18

LATCH

REMOVAL.............................18

INSTALLATION.........................18

LATCH STRIKER

REMOVAL.............................19INSTALLATION.........................19

LOCK CYLINDER

REMOVAL.............................19

INSTALLATION.........................19

TRIM PANEL

REMOVAL.............................20

INSTALLATION.........................20

WATERSHIELD

REMOVAL.............................21

INSTALLATION.........................21

WINDOW CRANK

REMOVAL.............................21

INSTALLATION.........................21

EXTERIOR HANDLE

REMOVAL.............................21

INSTALLATION.........................22

WINDOW REGULATOR - POWER

REMOVAL.............................22

INSTALLATION.........................22

WINDOW REGULATOR - MANUAL

REMOVAL.............................22

INSTALLATION.........................23

APPLIQUE

REMOVAL

(1) Roll door glass down.

(2) Remove outer door belt molding.

(3) Disengage clips holding front edge of applique

to door frame.

(4) Remove applique from vehicle (Fig. 1).

INSTALLATION

(1) Position applique on vehicle.

(2) Hook rear edge of applique over rear edge of

door frame and seat applique bottom edge on sheet

metal.

(3) Engage clips to hold front edge of applique to

door frame.

(4) Install outer door belt molding.

23 - 14 DOOR - FRONTRS

Page 1796 of 2339

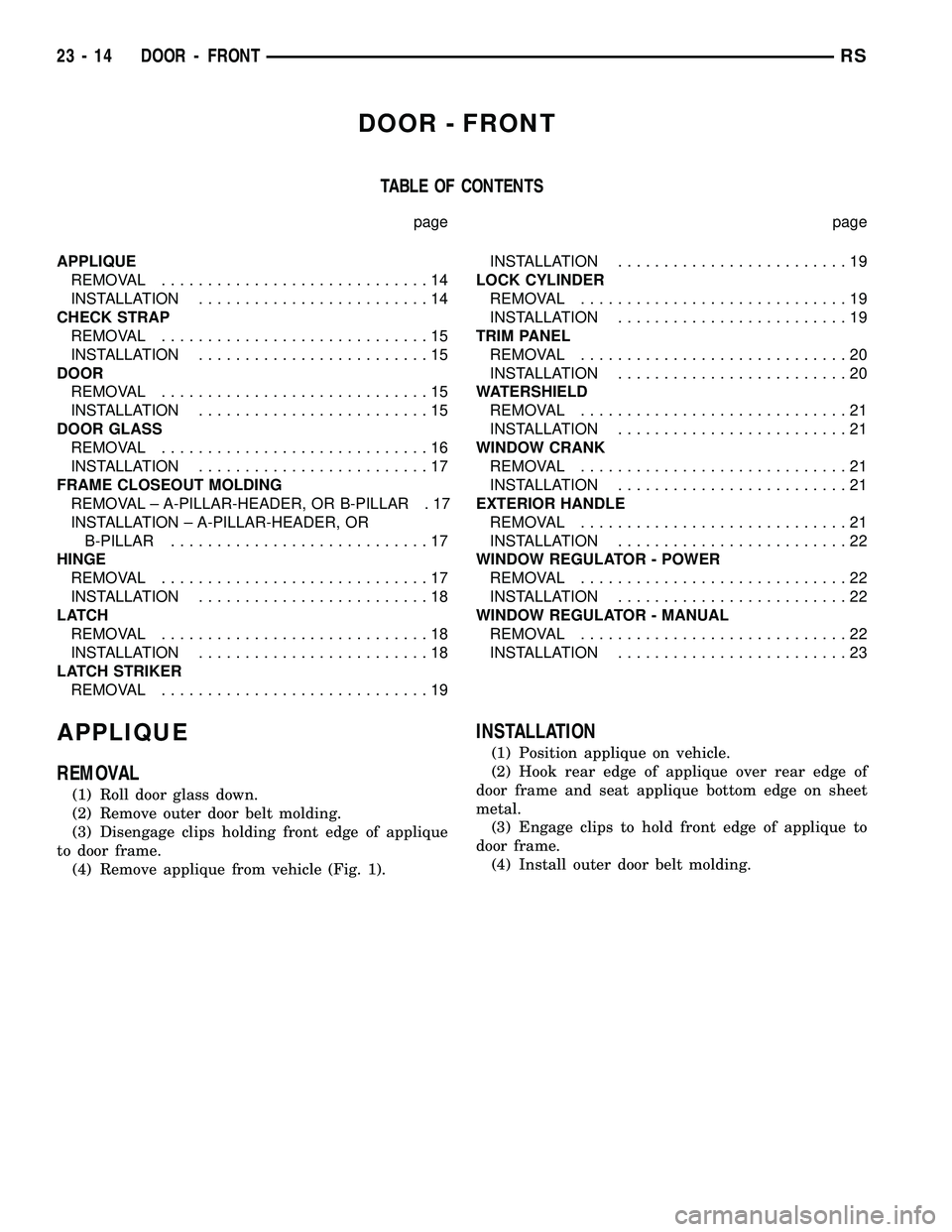

(3) Position glass to gain access to front and rear

regulator lift plates through front and rear access

holes in door panel.

(4) Loosen two screws on regulator clamping glass

(Fig. 6).

(5) Remove glass from regulator lift plates.

(6) Disengage glass from glass run weatherstrip.

(7) Insert front of glass between glass run channel

and outer door panel.

(8) Lift glass upward and out of exterior side of

the opening at top of door (Fig. 7).

(9) Remove glass from vehicle.

INSTALLATION

(1) Ensure clamp opening is set to 6 mm (0.2 in.)

front and rear (Fig. 6).

(2) Place glass in window opening with front

inserted between run channel and outer door panel

(Fig. 7).

(3) Lower glass downward into door.

(4) Insert ends of glass into glass run weatherstrip

channels at front and rear of door.

(5) Place glass in position on regulator lift plates.

(6) Roll glass up to level to tie down two glass

clamps and fasten.

(7) Install inner belt molding.(Refer to 23 - BODY/

WEATHERSTRIP/SEALS/FRONT DOOR INNER

BELT MOLDING - INSTALLATION)

(8) Verify door glass operation and fit.

(9) Install watershield. (Refer to 23 - BODY/DOOR

- FRONT/WATERSHIELD - INSTALLATION)

FRAME CLOSEOUT MOLDING

REMOVAL ± A-PILLAR-HEADER, OR B-PILLAR

(1) Roll door glass down.

(2) Using a hook tool, pull front door frame close-

out molding from window frame channel.

(3) Remove closeout molding from vehicle.

INSTALLATION ± A-PILLAR-HEADER, OR

B-PILLAR

(1) Position closeout molding in window frame.

(2) Insert closeout molding into window frame

channel starting at the corners and working inward.

(3) Verify door glass operation.

HINGE

REMOVAL

(1) Release front door latch and open door.

(2) Mark hinge foot print on both door and pillar

to aid when installing door.

(3) Support door on suitable lifting device.

(4) Remove bolts attaching front door to door

hinge.

(5) Remove bolts attaching hinge to pillar.

(6) Remove door hinge from vehicle.

Fig. 6 FRONT DOOR GLASS CLIPS

1 - DOOR GLASS

2 - REGULATOR GLASS CLAMP ASSEMBLY

3 - GLASS LIFT PLATE

Fig. 7 FRONT DOOR GLASS

1 - DOOR GLASS

2 - FRONT DOOR

3 - GLASS RUN CHANNEL

RSDOOR - FRONT23-17

DOOR GLASS (Continued)

Page 1799 of 2339

TRIM PANEL

REMOVAL

(1) Remove the plug and remove screw attaching

door pull cup to inner door panel.

(2) Remove switch bezel and disconnect power win-

dow/memory switch.

(3) Remove screws attaching trim panel to door

from below map pocket.

(4) If equipped, remove window crank. (Refer to 23

- BODY/DOOR - FRONT/WINDOW CRANK -

REMOVAL)

(5) Remove screw holding door trim to door panel

from behind inside latch release handle.

(6) Disengage clips attaching door trim to door

frame around perimeter of panel.

(7) Lift trim panel upward to disengage flange

from inner belt molding at top of door.

(8) Tilt top of trim panel away from door to gain

access to latch linkage.

(9) Disengage clip attaching linkage rod to inside

latch release handle (Fig. 12).

(10) Separate linkage rod from latch handle.

(11) Disconnect the power door switch, courtesy

lamp electrical connectors.

(12) Remove front door trim panel from vehicle.

INSTALLATION

(1) Hold top of trim panel away from door to gain

access to latch linkage.

(2) Place linkage rod in position on latch handle.

(3) Engage clip to hold linkage rod to inside latch

release handle.

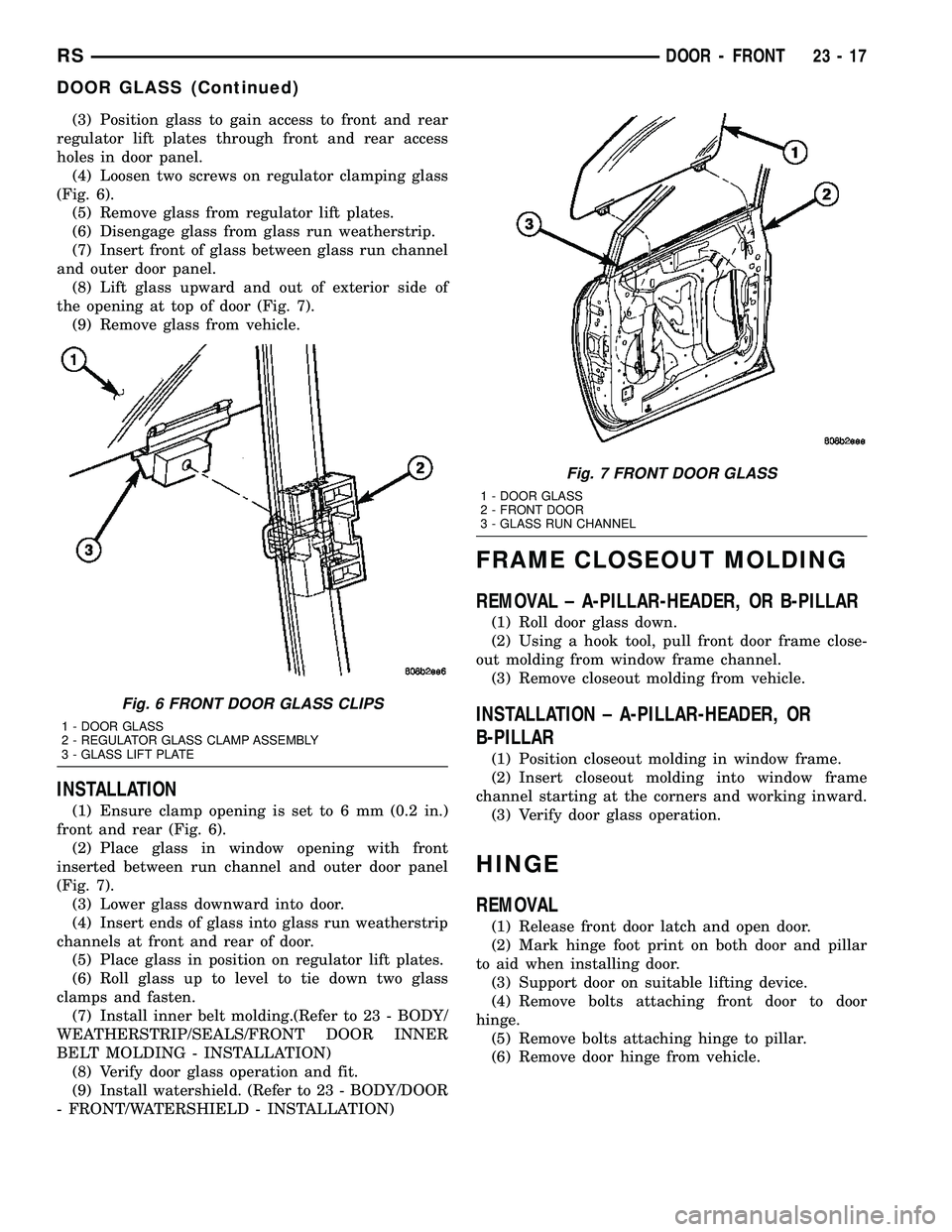

Fig. 11 OUTSIDE DOOR HANDLE

1 - CLIP

2 - LOCK CYLINDER

3 - KEY CYLINDER TO LATCH LINK

4 - OUTSIDE HANDLE TO LATCH LINK5 - LOCK KNOB LINK

6 - FRONT DOOR

7 - KEY POSITION SWITCH

8 - OUTSIDE HANDLE

Fig. 12 INSIDE DOOR HANDLE LINKAGE

1 - DOOR LATCH HANDLE

2 - DOOR TRIM

3 - LATCH LINKAGE

4 - CLIP

5 - MEMORY SEAT SWITCH

23 - 20 DOOR - FRONTRS

LOCK CYLINDER (Continued)

Page 1800 of 2339

(4) Place front door trim panel in position on door.

(5) Install trim panel into inner belt molding at

top of door.

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

(11) Install screws to attach accessary switch

panel to door trim.

(12) Install screw cover into switch panel.

(13) If equipped, install window crank.

(14) If equipped, install screws to attach trim

panel to door inside map pocket.

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

(19) Install switch bezel.

WATERSHIELD

REMOVAL

(1) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Remove the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the water dam. Replace as necessary.

(2) Place the shield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Install the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - INSTALLATION)

(4) Install door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

WINDOW CRANK

REMOVAL

(1) Using a window crank removal tool, disengage

clip attaching window crank to regulator shaft (Fig.

13).

NOTE: Wrap a shop towel around the window crank

to catch the clip when it springs out.

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Place the clip on to the window crank handle.

(2) Position window crank to regulator shaft.

(3) Push window crank onto regulator shaft to

engage retaining clip.

EXTERIOR HANDLE

REMOVAL

(1) Roll door glass up.

(2) Remove the watershield as necessary to gain

access to the outside door handle. (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL)

(3) Through access hole at rear of inner door

panel, disconnect Vehicle Theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch (Fig. 11).

(6) Remove latch linkage from latch.

Fig. 13 WINDOW CRANK - TYPICAL

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

RSDOOR - FRONT23-21

TRIM PANEL (Continued)

Page 1801 of 2339

(7) Disengage clip holding door lock linkage to

door latch.

(8) Remove lock linkage from latch.

(9) Remove nuts holding outside door handle to

door outer panel.

(10) Remove outside door handle from vehicle.

INSTALLATION

If outside door handle replacement is necessary,

transfer lock cylinder from the original handle to the

new one.

(1) Place outside door handle in position on vehi-

cle.

(2) Install nuts attaching outside door handle to

door outer panel (Fig. 11). Tighten nuts to 6 N´m (50

in. lbs.).

(3) Insert lock linkage into door latch.

(4) Engage clip to hold door lock linkage to latch.

(5) Insert latch linkage into door latch.

(6) Engage clip to hold door latch linkage to latch.

(7) Install push-in fasteners to hold VTSS switch

harness to inner door reinforcement bar, if equipped.

(8) Connect VTSS switch connector into door har-

ness, if equipped.

(9) Verify door latch operation.

(10) Install sound shield and door trim panel.

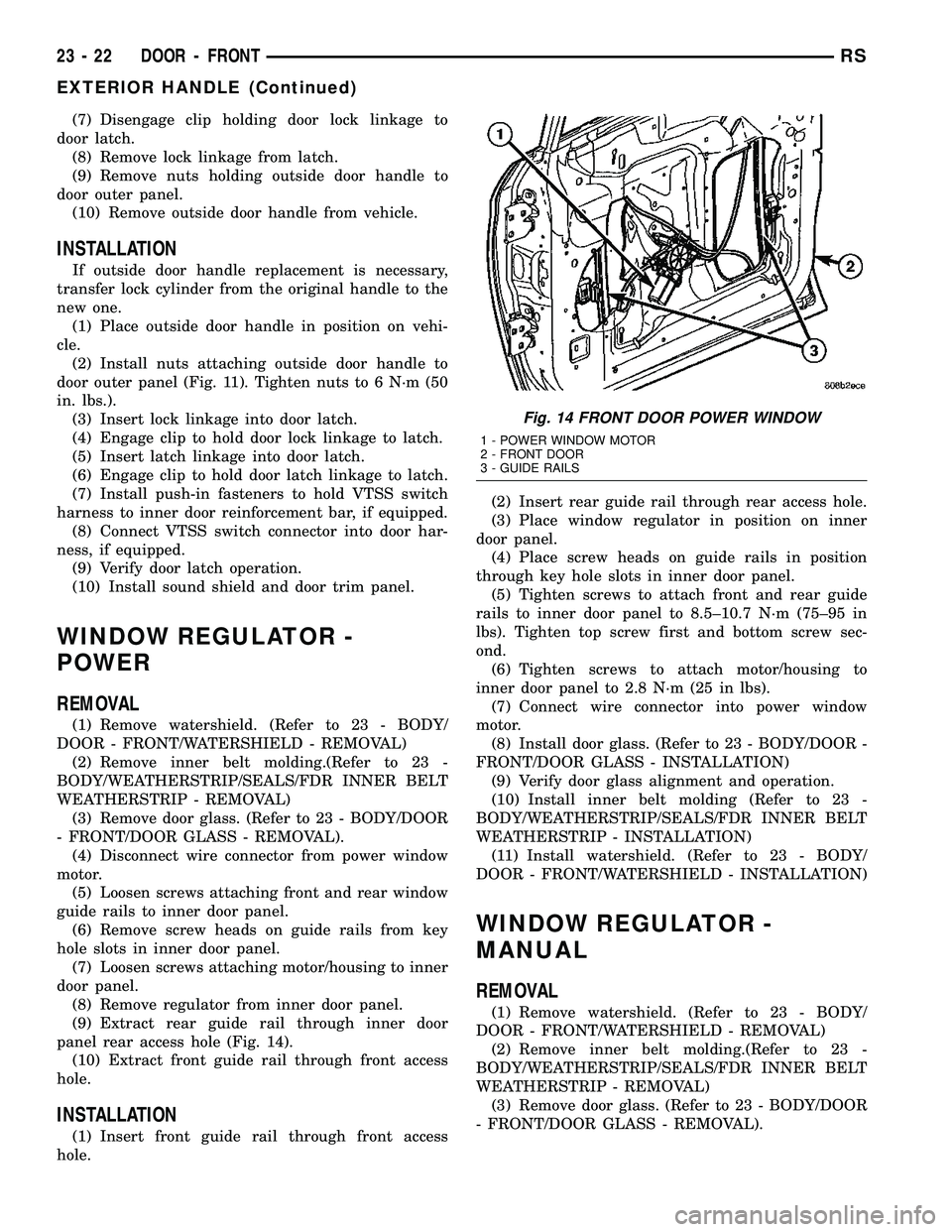

WINDOW REGULATOR -

POWER

REMOVAL

(1) Remove watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - REMOVAL)

(2) Remove inner belt molding.(Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - REMOVAL)

(3) Remove door glass. (Refer to 23 - BODY/DOOR

- FRONT/DOOR GLASS - REMOVAL).

(4) Disconnect wire connector from power window

motor.

(5) Loosen screws attaching front and rear window

guide rails to inner door panel.

(6) Remove screw heads on guide rails from key

hole slots in inner door panel.

(7) Loosen screws attaching motor/housing to inner

door panel.

(8) Remove regulator from inner door panel.

(9) Extract rear guide rail through inner door

panel rear access hole (Fig. 14).

(10) Extract front guide rail through front access

hole.

INSTALLATION

(1) Insert front guide rail through front access

hole.(2) Insert rear guide rail through rear access hole.

(3) Place window regulator in position on inner

door panel.

(4) Place screw heads on guide rails in position

through key hole slots in inner door panel.

(5) Tighten screws to attach front and rear guide

rails to inner door panel to 8.5±10.7 N´m (75±95 in

lbs). Tighten top screw first and bottom screw sec-

ond.

(6) Tighten screws to attach motor/housing to

inner door panel to 2.8 N´m (25 in lbs).

(7) Connect wire connector into power window

motor.

(8) Install door glass. (Refer to 23 - BODY/DOOR -

FRONT/DOOR GLASS - INSTALLATION)

(9) Verify door glass alignment and operation.

(10) Install inner belt molding (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - INSTALLATION)

(11) Install watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - INSTALLATION)

WINDOW REGULATOR -

MANUAL

REMOVAL

(1) Remove watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - REMOVAL)

(2) Remove inner belt molding.(Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - REMOVAL)

(3) Remove door glass. (Refer to 23 - BODY/DOOR

- FRONT/DOOR GLASS - REMOVAL).

Fig. 14 FRONT DOOR POWER WINDOW

1 - POWER WINDOW MOTOR

2 - FRONT DOOR

3 - GUIDE RAILS

23 - 22 DOOR - FRONTRS

EXTERIOR HANDLE (Continued)

Page 1802 of 2339

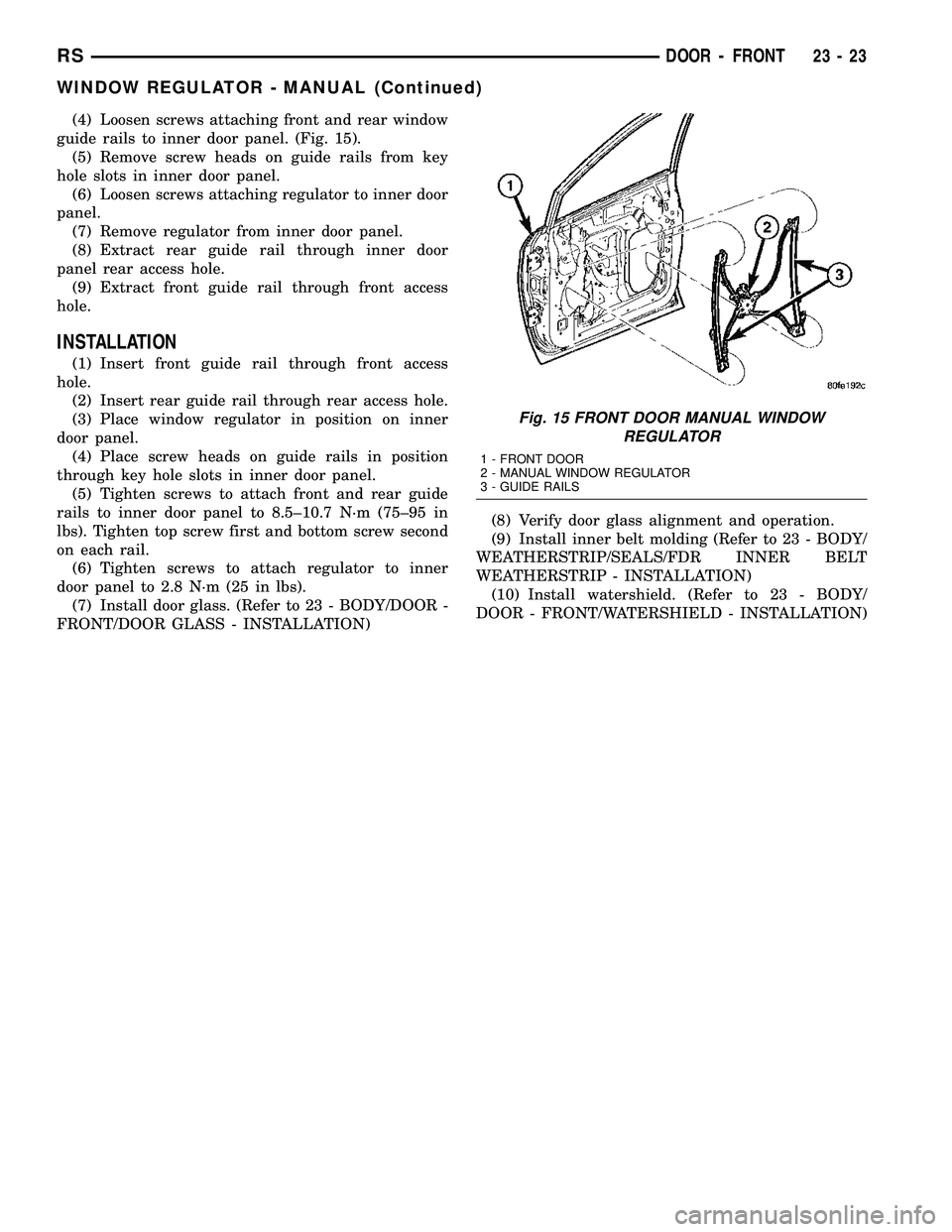

(4) Loosen screws attaching front and rear window

guide rails to inner door panel. (Fig. 15).

(5) Remove screw heads on guide rails from key

hole slots in inner door panel.

(6) Loosen screws attaching regulator to inner door

panel.

(7) Remove regulator from inner door panel.

(8) Extract rear guide rail through inner door

panel rear access hole.

(9) Extract front guide rail through front access

hole.

INSTALLATION

(1) Insert front guide rail through front access

hole.

(2) Insert rear guide rail through rear access hole.

(3) Place window regulator in position on inner

door panel.

(4) Place screw heads on guide rails in position

through key hole slots in inner door panel.

(5) Tighten screws to attach front and rear guide

rails to inner door panel to 8.5±10.7 N´m (75±95 in

lbs). Tighten top screw first and bottom screw second

on each rail.

(6) Tighten screws to attach regulator to inner

door panel to 2.8 N´m (25 in lbs).

(7) Install door glass. (Refer to 23 - BODY/DOOR -

FRONT/DOOR GLASS - INSTALLATION)(8) Verify door glass alignment and operation.

(9) Install inner belt molding (Refer to 23 - BODY/

WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - INSTALLATION)

(10) Install watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - INSTALLATION)

Fig. 15 FRONT DOOR MANUAL WINDOW

REGULATOR

1 - FRONT DOOR

2 - MANUAL WINDOW REGULATOR

3 - GUIDE RAILS

RSDOOR - FRONT23-23

WINDOW REGULATOR - MANUAL (Continued)

Page 1821 of 2339

INSTALLATION

(1) Place striker in position on vehicle.

(2) Align striker to outline mark on sill.

(3) Install screws attaching striker to sill. Tighten

screws to 28 N´m (21 ft. lbs.) torque.

(4) Verify liftgate alignment and operation.

LIFTGATE

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Release liftgate latch and open liftgate.

(3) Remove liftgate upper frame molding.

(4) Remove screws attaching liftgate wire connec-

tor to rear header.

(5) Disconnect liftgate wire harness from body

wire harness.

(6) Disconnect rear window washer hose from

spray nozzle.

(7) Support liftgate on a suitable lifting device.

(8) Disconnect power liftgate link, if equipped.

(9) Remove screws attaching support cylinders to

liftgate.

(10) Remove bolts attaching liftgate hinge to roof

header (Fig. 4).

(11) With assistance, remove liftgate from vehicle.

INSTALLATION

(1) With assistance, place liftgate in position on

vehicle.

(2) Install bolts attaching liftgate hinge to roof

header. Tighten bolts to 33 N´m (24 ft. lbs.) torque.

(3) Install screws attaching support cylinders to

liftgate. Tighten bolts to 28 N´m (21 ft. lbs.) torque.(4) Reconnect power liftgate link, if equipped.

(5) Remove lifting device from under liftgate.

(6) Connect liftgate wire harness into body wire

harness.

(7) Install screws attaching wire connector to rear

header.

(8) Connect rear window washer hose onto spray

nozzle.

(9) Install liftgate upper frame molding.

(10) Install battery negative cable.

(11) Verify liftgate alignment. The liftgate should

have a gap to adjacent panels and fit flush across the

gaps. The gap is; (Refer to 23 - BODY/BODY STRUC-

TURE/GAP AND FLUSH - SPECIFICATIONS).

²8.0 mm 2.5 to the rear fascia,

²8.0 mm 2.0 to the roof,

²2.0 mm 0.5 mm to the aperture.

LOCK CYLINDER

REMOVAL

(1) Remove the liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL)

(2) Disconnect the electrical connector.

(3) Disconnect the latch rod.

(4) Rotate plastic lock cylinder nut one quarter

turn and remove nut and spring washer.

(5) Remove the lock cylinder from the liftgate.

INSTALLATION

(1) Install lock cylinder into liftgate.

(2) Install the plastic lock cylinder lock nut, spring

washer and rotate one quarter turn.

(3) Connect the electrical connector.

(4) Connect the latch rod.

(5) Install the trim panel. (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION)

(6) Verify lock cylinder operation.

SUPPORT CYLINDER

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Support liftgate on a suitable lifting device in

the full open position.

(3) Pull liftgate opening weatherstrip from D-pillar

flange next to prop assembly end pivot.

(4) Remove bolt attaching end pivot to D-pillar

(Fig. 5).

(5) Remove bolt attaching prop assembly to lift-

gate.

(6) Remove prop assembly from vehicle.

Fig. 4 LIFTGATE

1 - HINGE

2 - ROOF

3 - NET HOLE OR SLOT

23 - 42 DECKLID/HATCH/LIFTGATE/TAILGATERS

LATCH STRIKER (Continued)

Page 1870 of 2339

HEADLINER

REMOVAL

(1) Remove sun visors and vanity mirrors.

(2) Remove sun visor center supports.

(3) If equipped, remove coat hooks.

(4) If equipped, remove roof rail modules.

(5) Remove A-pillar trim covers. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - REMOVAL).

(6) Remove B-pillar upper trim covers (Fig. 20).

(Refer to 23 - BODY/INTERIOR/B-PILLAR UPPER

TRIM - REMOVAL).

(7) Remove C-pillar upper trim covers (Fig. 21).

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

REMOVAL).

(8) Remove D-pillar trim covers. (Refer to 23 -

BODY/INTERIOR/RIGHT D-PILLAR TRIM PANEL -

REMOVAL) and (Refer to 23 - BODY/INTERIOR/

LEFT D-PILLAR TRIM PANEL - REMOVAL).

(9) Remove liftgate opening header trim.

(10) If equipped, remove overhead console screws.

(11) If equipped, remove reading lamps.

(12) Remove dome lamp.

(13) Remove push in locking fasteners attaching

headlining to rear roof header and roof bows (Fig.

22).(14) Remove wiring connections.

(15) Remove headlining from roof (Fig. 23), (Fig.

24), (Fig. 25), and (Fig. 26).

(16) Extract headlining through liftgate opening.

Fig. 20 HEADLINER AT B-PILLAR

1 - FRONT AND SLIDING DOOR WEATHERSTRIP SEAL

2 - B-PILLAR UPPER TRIM PANEL

Fig. 21 HEADLINER AT C-PILLAR

1 - SLIDING DOOR WEATHERSTRIP

2 - C-PILLAR UPPER TRIM PANEL

3 - REAR QUARTER WINDOW OPENING WEATHERSTRIP

Fig. 22 HEADLINER PUSH PINS

RSINTERIOR23-91

Page 1940 of 2339

STATIONARY GLASS

TABLE OF CONTENTS

page page

WINDSHIELD

DESCRIPTION........................161

WARNING

WINDSHIELD SAFETY PRECAUTIONS....161

REMOVAL............................161

INSTALLATION........................162

SLIDING DOOR GLASS

REMOVAL............................163INSTALLATION........................163

QUARTER WINDOW

REMOVAL............................164

INSTALLATION........................164

LIFTGATE GLASS

REMOVAL............................164

INSTALLATION........................164

WINDSHIELD

DESCRIPTION

The windshield is attached to the window frame

with urethane adhesive. The urethane adhesive is

applied cold and seals the surface area between the

window opening and the glass. The primer adheres

the urethane adhesive to the windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the

structural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficult

to cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

WARNING

WINDSHIELD SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, PVC (VINYL) PRIMER AND

PINCH WELD (FENCE) PRIMER PROVIDED BY THE

ADHESIVE MANUFACTURER. IF NOT, STRUCTURAL

INTEGRITY COULD BE COMPROMISED.

DAIMLERCHRYSLER DOES NOT RECOMMEND

GLASS ADHESIVE BY BRAND. TECHNICIANS

SHOULD REVIEW PRODUCT LABELS AND TECHNI-

CAL DATA SHEETS, AND USE ONLY ADHESIVESTHAT THEIR MANUFACTURES WARRANT WILL

RESTORE A VEHICLE TO THE REQUIREMENTS OF

FMVSS 212. TECHNICIANS SHOULD ALSO INSURE

THAT PRIMERS AND CLEANERS ARE COMPATIBLE

WITH THE PARTICULAR ADHESIVE USED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

REMOVAL

WINDSHIELD REMOVAL ± EXTERIOR METHOD

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

(1) Remove inside rear view mirror.

(2) Remove windshield wiper arms.

(3) Remove cowl cover.

RSSTATIONARY GLASS23 - 161