Comfort CHRYSLER VOYAGER 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 70 of 2339

BUSHING - LEAF SPRING

FRONT

REMOVAL

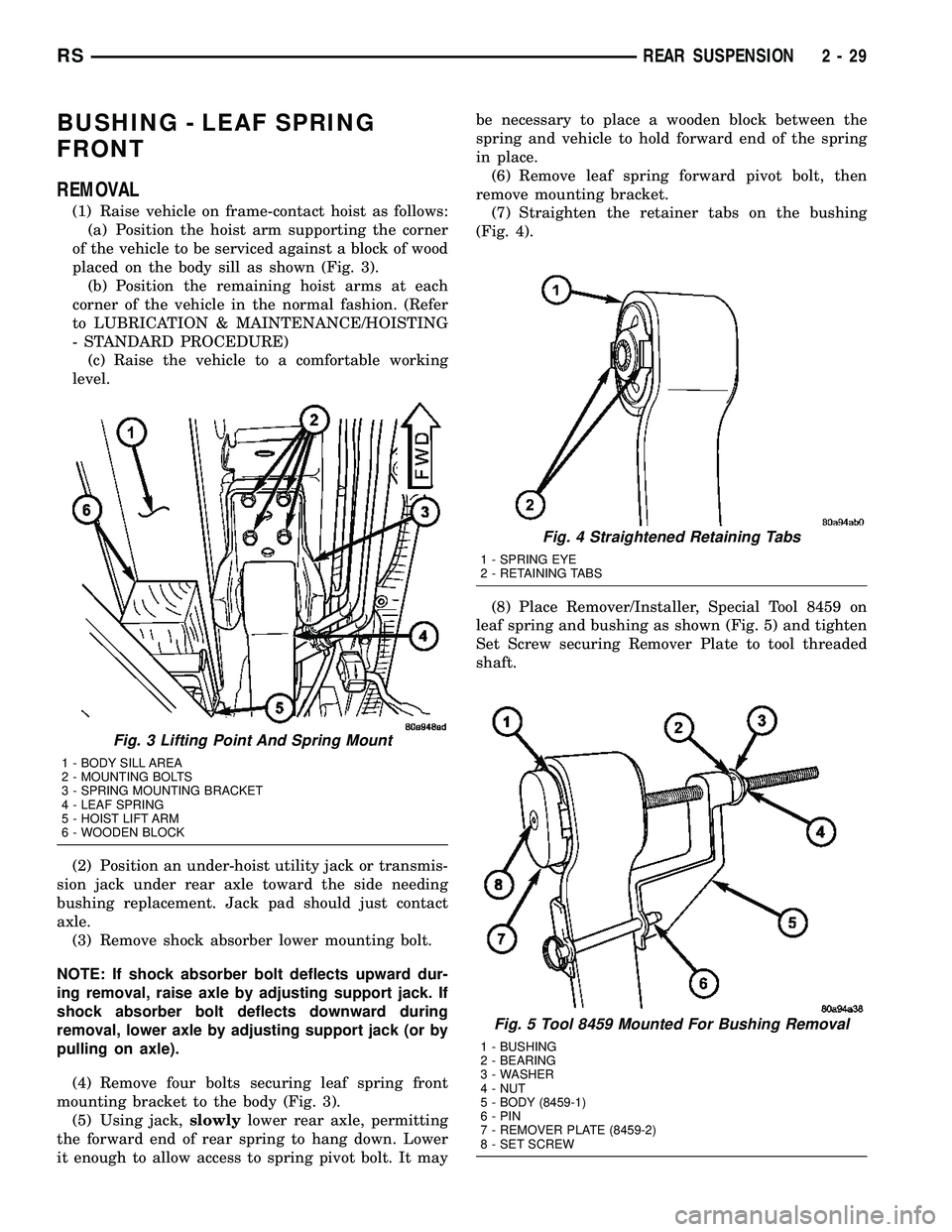

(1) Raise vehicle on frame-contact hoist as follows:

(a) Position the hoist arm supporting the corner

of the vehicle to be serviced against a block of wood

placed on the body sill as shown (Fig. 3).

(b) Position the remaining hoist arms at each

corner of the vehicle in the normal fashion. (Refer

to LUBRICATION & MAINTENANCE/HOISTING

- STANDARD PROCEDURE)

(c) Raise the vehicle to a comfortable working

level.

(2) Position an under-hoist utility jack or transmis-

sion jack under rear axle toward the side needing

bushing replacement. Jack pad should just contact

axle.

(3) Remove shock absorber lower mounting bolt.

NOTE: If shock absorber bolt deflects upward dur-

ing removal, raise axle by adjusting support jack. If

shock absorber bolt deflects downward during

removal, lower axle by adjusting support jack (or by

pulling on axle).

(4) Remove four bolts securing leaf spring front

mounting bracket to the body (Fig. 3).

(5) Using jack,slowlylower rear axle, permitting

the forward end of rear spring to hang down. Lower

it enough to allow access to spring pivot bolt. It maybe necessary to place a wooden block between the

spring and vehicle to hold forward end of the spring

in place.

(6) Remove leaf spring forward pivot bolt, then

remove mounting bracket.

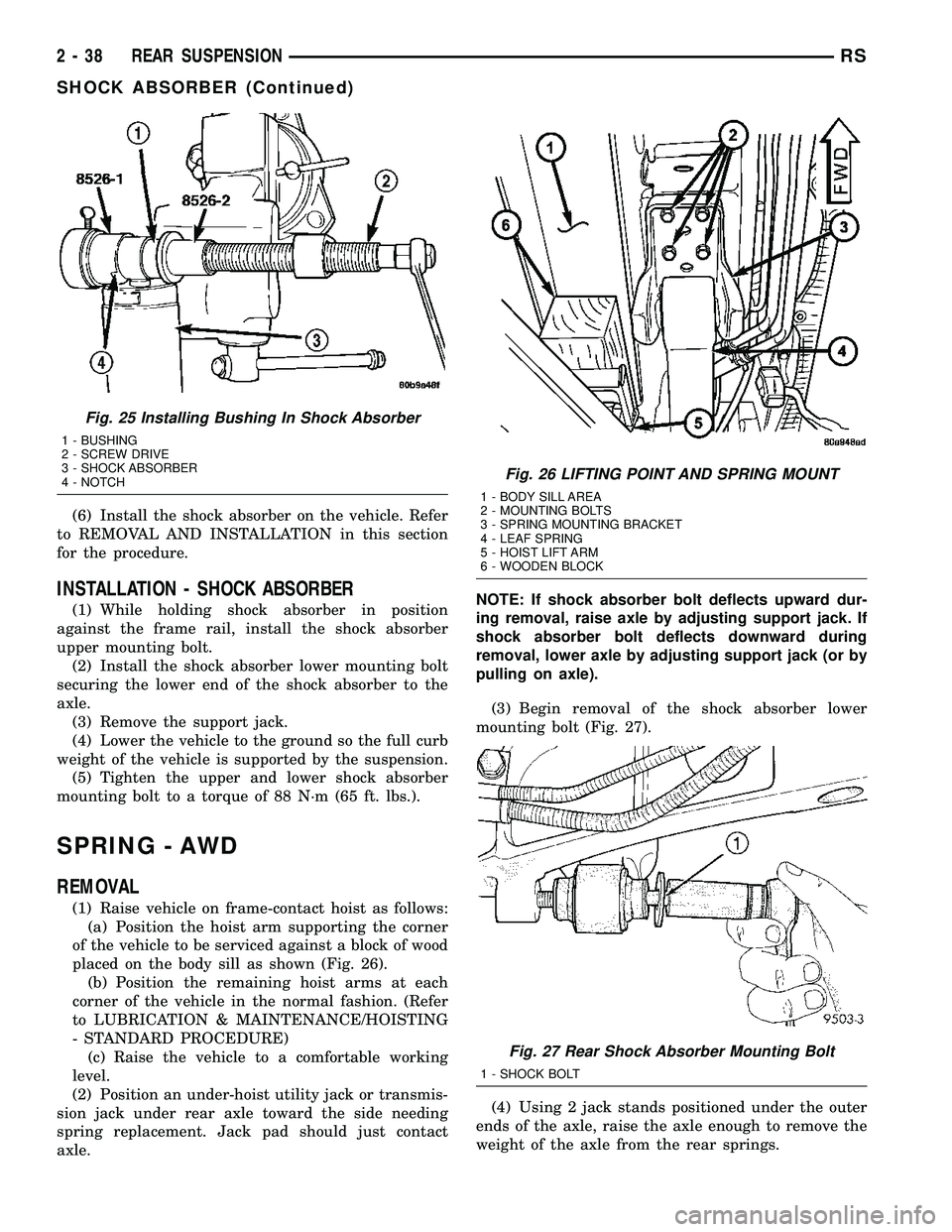

(7) Straighten the retainer tabs on the bushing

(Fig. 4).

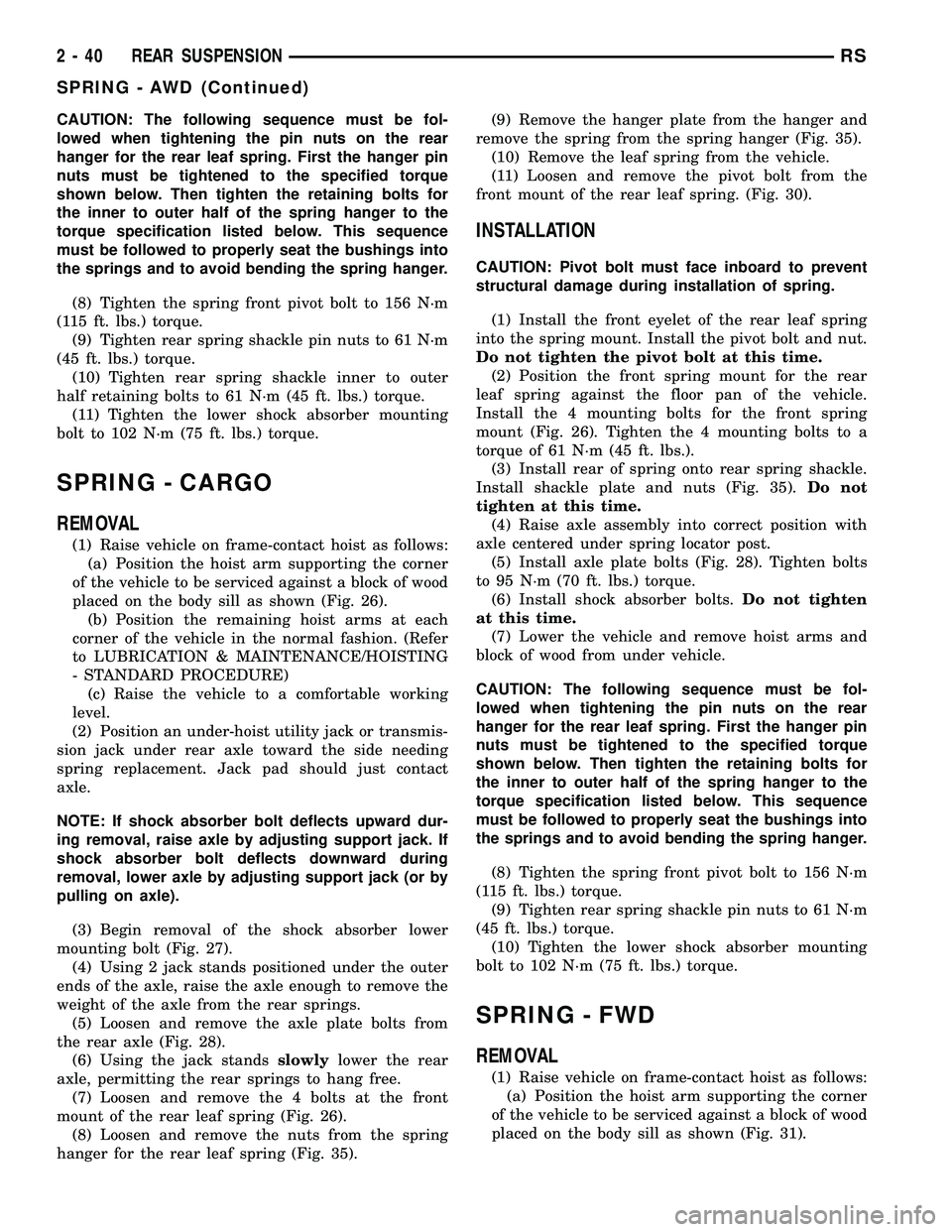

(8) Place Remover/Installer, Special Tool 8459 on

leaf spring and bushing as shown (Fig. 5) and tighten

Set Screw securing Remover Plate to tool threaded

shaft.

Fig. 3 Lifting Point And Spring Mount

1 - BODY SILL AREA

2 - MOUNTING BOLTS

3 - SPRING MOUNTING BRACKET

4 - LEAF SPRING

5 - HOIST LIFT ARM

6 - WOODEN BLOCK

Fig. 4 Straightened Retaining Tabs

1 - SPRING EYE

2 - RETAINING TABS

Fig. 5 Tool 8459 Mounted For Bushing Removal

1 - BUSHING

2 - BEARING

3 - WASHER

4 - NUT

5 - BODY (8459-1)

6 - PIN

7 - REMOVER PLATE (8459-2)

8 - SET SCREW

RSREAR SUSPENSION2-29

Page 79 of 2339

(6) Install the shock absorber on the vehicle. Refer

to REMOVAL AND INSTALLATION in this section

for the procedure.

INSTALLATION - SHOCK ABSORBER

(1) While holding shock absorber in position

against the frame rail, install the shock absorber

upper mounting bolt.

(2) Install the shock absorber lower mounting bolt

securing the lower end of the shock absorber to the

axle.

(3) Remove the support jack.

(4) Lower the vehicle to the ground so the full curb

weight of the vehicle is supported by the suspension.

(5) Tighten the upper and lower shock absorber

mounting bolt to a torque of 88 N´m (65 ft. lbs.).

SPRING - AWD

REMOVAL

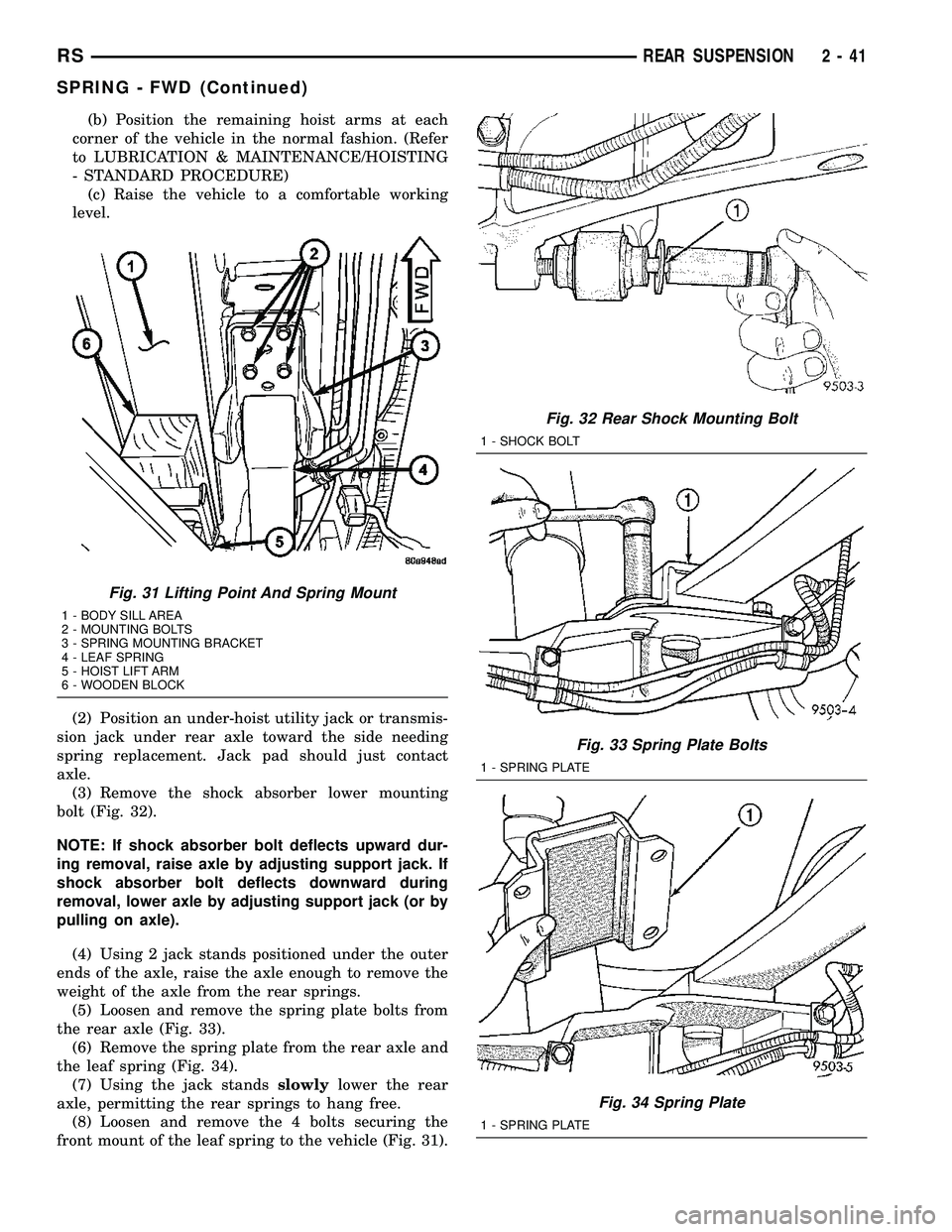

(1) Raise vehicle on frame-contact hoist as follows:

(a) Position the hoist arm supporting the corner

of the vehicle to be serviced against a block of wood

placed on the body sill as shown (Fig. 26).

(b) Position the remaining hoist arms at each

corner of the vehicle in the normal fashion. (Refer

to LUBRICATION & MAINTENANCE/HOISTING

- STANDARD PROCEDURE)

(c) Raise the vehicle to a comfortable working

level.

(2) Position an under-hoist utility jack or transmis-

sion jack under rear axle toward the side needing

spring replacement. Jack pad should just contact

axle.NOTE: If shock absorber bolt deflects upward dur-

ing removal, raise axle by adjusting support jack. If

shock absorber bolt deflects downward during

removal, lower axle by adjusting support jack (or by

pulling on axle).

(3) Begin removal of the shock absorber lower

mounting bolt (Fig. 27).

(4) Using 2 jack stands positioned under the outer

ends of the axle, raise the axle enough to remove the

weight of the axle from the rear springs.

Fig. 25 Installing Bushing In Shock Absorber

1 - BUSHING

2 - SCREW DRIVE

3 - SHOCK ABSORBER

4 - NOTCH

Fig. 26 LIFTING POINT AND SPRING MOUNT

1 - BODY SILL AREA

2 - MOUNTING BOLTS

3 - SPRING MOUNTING BRACKET

4 - LEAF SPRING

5 - HOIST LIFT ARM

6 - WOODEN BLOCK

Fig. 27 Rear Shock Absorber Mounting Bolt

1 - SHOCK BOLT

2 - 38 REAR SUSPENSIONRS

SHOCK ABSORBER (Continued)

Page 81 of 2339

CAUTION: The following sequence must be fol-

lowed when tightening the pin nuts on the rear

hanger for the rear leaf spring. First the hanger pin

nuts must be tightened to the specified torque

shown below. Then tighten the retaining bolts for

the inner to outer half of the spring hanger to the

torque specification listed below. This sequence

must be followed to properly seat the bushings into

the springs and to avoid bending the spring hanger.

(8) Tighten the spring front pivot bolt to 156 N´m

(115 ft. lbs.) torque.

(9) Tighten rear spring shackle pin nuts to 61 N´m

(45 ft. lbs.) torque.

(10) Tighten rear spring shackle inner to outer

half retaining bolts to 61 N´m (45 ft. lbs.) torque.

(11) Tighten the lower shock absorber mounting

bolt to 102 N´m (75 ft. lbs.) torque.

SPRING - CARGO

REMOVAL

(1) Raise vehicle on frame-contact hoist as follows:

(a) Position the hoist arm supporting the corner

of the vehicle to be serviced against a block of wood

placed on the body sill as shown (Fig. 26).

(b) Position the remaining hoist arms at each

corner of the vehicle in the normal fashion. (Refer

to LUBRICATION & MAINTENANCE/HOISTING

- STANDARD PROCEDURE)

(c) Raise the vehicle to a comfortable working

level.

(2) Position an under-hoist utility jack or transmis-

sion jack under rear axle toward the side needing

spring replacement. Jack pad should just contact

axle.

NOTE: If shock absorber bolt deflects upward dur-

ing removal, raise axle by adjusting support jack. If

shock absorber bolt deflects downward during

removal, lower axle by adjusting support jack (or by

pulling on axle).

(3) Begin removal of the shock absorber lower

mounting bolt (Fig. 27).

(4) Using 2 jack stands positioned under the outer

ends of the axle, raise the axle enough to remove the

weight of the axle from the rear springs.

(5) Loosen and remove the axle plate bolts from

the rear axle (Fig. 28).

(6) Using the jack standsslowlylower the rear

axle, permitting the rear springs to hang free.

(7) Loosen and remove the 4 bolts at the front

mount of the rear leaf spring (Fig. 26).

(8) Loosen and remove the nuts from the spring

hanger for the rear leaf spring (Fig. 35).(9) Remove the hanger plate from the hanger and

remove the spring from the spring hanger (Fig. 35).

(10) Remove the leaf spring from the vehicle.

(11) Loosen and remove the pivot bolt from the

front mount of the rear leaf spring. (Fig. 30).

INSTALLATION

CAUTION: Pivot bolt must face inboard to prevent

structural damage during installation of spring.

(1) Install the front eyelet of the rear leaf spring

into the spring mount. Install the pivot bolt and nut.

Do not tighten the pivot bolt at this time.

(2) Position the front spring mount for the rear

leaf spring against the floor pan of the vehicle.

Install the 4 mounting bolts for the front spring

mount (Fig. 26). Tighten the 4 mounting bolts to a

torque of 61 N´m (45 ft. lbs.).

(3) Install rear of spring onto rear spring shackle.

Install shackle plate and nuts (Fig. 35).Do not

tighten at this time.

(4) Raise axle assembly into correct position with

axle centered under spring locator post.

(5) Install axle plate bolts (Fig. 28). Tighten bolts

to 95 N´m (70 ft. lbs.) torque.

(6) Install shock absorber bolts.Do not tighten

at this time.

(7) Lower the vehicle and remove hoist arms and

block of wood from under vehicle.

CAUTION: The following sequence must be fol-

lowed when tightening the pin nuts on the rear

hanger for the rear leaf spring. First the hanger pin

nuts must be tightened to the specified torque

shown below. Then tighten the retaining bolts for

the inner to outer half of the spring hanger to the

torque specification listed below. This sequence

must be followed to properly seat the bushings into

the springs and to avoid bending the spring hanger.

(8) Tighten the spring front pivot bolt to 156 N´m

(115 ft. lbs.) torque.

(9) Tighten rear spring shackle pin nuts to 61 N´m

(45 ft. lbs.) torque.

(10) Tighten the lower shock absorber mounting

bolt to 102 N´m (75 ft. lbs.) torque.

SPRING - FWD

REMOVAL

(1) Raise vehicle on frame-contact hoist as follows:

(a) Position the hoist arm supporting the corner

of the vehicle to be serviced against a block of wood

placed on the body sill as shown (Fig. 31).

2 - 40 REAR SUSPENSIONRS

SPRING - AWD (Continued)

Page 82 of 2339

(b) Position the remaining hoist arms at each

corner of the vehicle in the normal fashion. (Refer

to LUBRICATION & MAINTENANCE/HOISTING

- STANDARD PROCEDURE)

(c) Raise the vehicle to a comfortable working

level.

(2) Position an under-hoist utility jack or transmis-

sion jack under rear axle toward the side needing

spring replacement. Jack pad should just contact

axle.

(3) Remove the shock absorber lower mounting

bolt (Fig. 32).

NOTE: If shock absorber bolt deflects upward dur-

ing removal, raise axle by adjusting support jack. If

shock absorber bolt deflects downward during

removal, lower axle by adjusting support jack (or by

pulling on axle).

(4) Using 2 jack stands positioned under the outer

ends of the axle, raise the axle enough to remove the

weight of the axle from the rear springs.

(5) Loosen and remove the spring plate bolts from

the rear axle (Fig. 33).

(6) Remove the spring plate from the rear axle and

the leaf spring (Fig. 34).

(7) Using the jack standsslowlylower the rear

axle, permitting the rear springs to hang free.

(8) Loosen and remove the 4 bolts securing the

front mount of the leaf spring to the vehicle (Fig. 31).

Fig. 31 Lifting Point And Spring Mount

1 - BODY SILL AREA

2 - MOUNTING BOLTS

3 - SPRING MOUNTING BRACKET

4 - LEAF SPRING

5 - HOIST LIFT ARM

6 - WOODEN BLOCK

Fig. 32 Rear Shock Mounting Bolt

1 - SHOCK BOLT

Fig. 33 Spring Plate Bolts

1 - SPRING PLATE

Fig. 34 Spring Plate

1 - SPRING PLATE

RSREAR SUSPENSION2-41

SPRING - FWD (Continued)

Page 83 of 2339

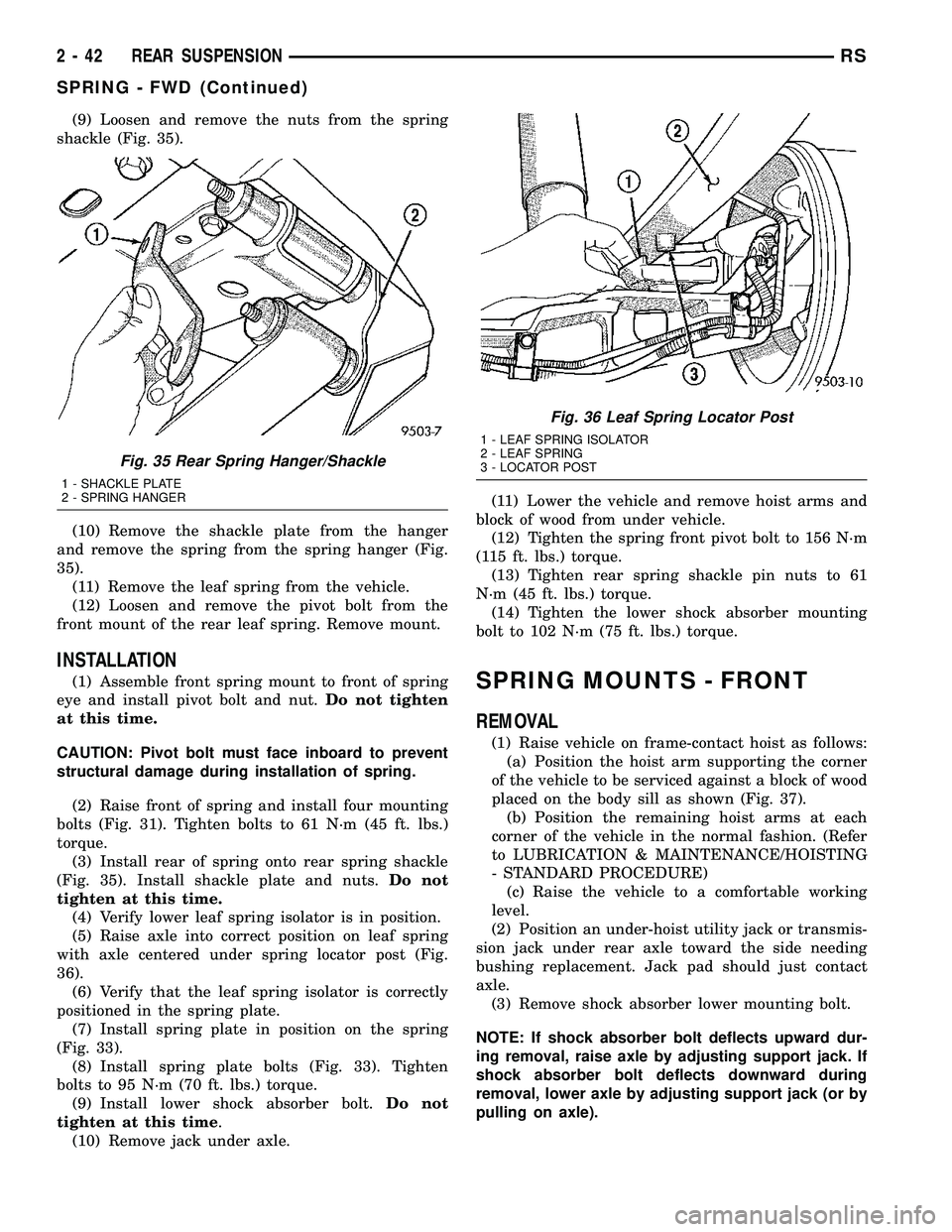

(9) Loosen and remove the nuts from the spring

shackle (Fig. 35).

(10) Remove the shackle plate from the hanger

and remove the spring from the spring hanger (Fig.

35).

(11) Remove the leaf spring from the vehicle.

(12) Loosen and remove the pivot bolt from the

front mount of the rear leaf spring. Remove mount.

INSTALLATION

(1) Assemble front spring mount to front of spring

eye and install pivot bolt and nut.Do not tighten

at this time.

CAUTION: Pivot bolt must face inboard to prevent

structural damage during installation of spring.

(2) Raise front of spring and install four mounting

bolts (Fig. 31). Tighten bolts to 61 N´m (45 ft. lbs.)

torque.

(3) Install rear of spring onto rear spring shackle

(Fig. 35). Install shackle plate and nuts.Do not

tighten at this time.

(4) Verify lower leaf spring isolator is in position.

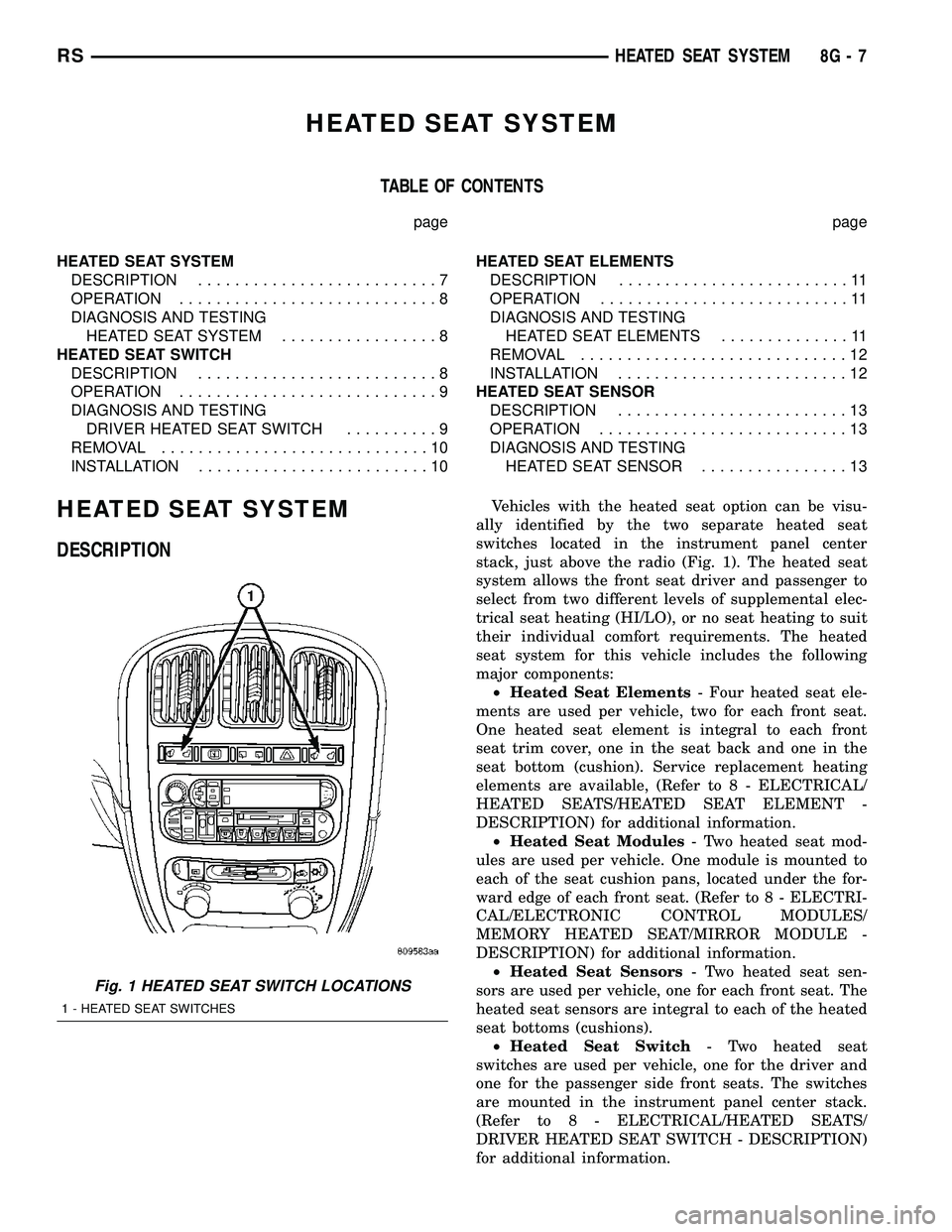

(5) Raise axle into correct position on leaf spring

with axle centered under spring locator post (Fig.

36).

(6) Verify that the leaf spring isolator is correctly

positioned in the spring plate.

(7) Install spring plate in position on the spring

(Fig. 33).

(8) Install spring plate bolts (Fig. 33). Tighten

bolts to 95 N´m (70 ft. lbs.) torque.

(9) Install lower shock absorber bolt.Do not

tighten at this time.

(10) Remove jack under axle.(11) Lower the vehicle and remove hoist arms and

block of wood from under vehicle.

(12) Tighten the spring front pivot bolt to 156 N´m

(115 ft. lbs.) torque.

(13) Tighten rear spring shackle pin nuts to 61

N´m (45 ft. lbs.) torque.

(14) Tighten the lower shock absorber mounting

bolt to 102 N´m (75 ft. lbs.) torque.SPRING MOUNTS - FRONT

REMOVAL

(1) Raise vehicle on frame-contact hoist as follows:

(a) Position the hoist arm supporting the corner

of the vehicle to be serviced against a block of wood

placed on the body sill as shown (Fig. 37).

(b) Position the remaining hoist arms at each

corner of the vehicle in the normal fashion. (Refer

to LUBRICATION & MAINTENANCE/HOISTING

- STANDARD PROCEDURE)

(c) Raise the vehicle to a comfortable working

level.

(2) Position an under-hoist utility jack or transmis-

sion jack under rear axle toward the side needing

bushing replacement. Jack pad should just contact

axle.

(3) Remove shock absorber lower mounting bolt.

NOTE: If shock absorber bolt deflects upward dur-

ing removal, raise axle by adjusting support jack. If

shock absorber bolt deflects downward during

removal, lower axle by adjusting support jack (or by

pulling on axle).

Fig. 35 Rear Spring Hanger/Shackle

1 - SHACKLE PLATE

2 - SPRING HANGER

Fig. 36 Leaf Spring Locator Post

1 - LEAF SPRING ISOLATOR

2 - LEAF SPRING

3 - LOCATOR POST

2 - 42 REAR SUSPENSIONRS

SPRING - FWD (Continued)

Page 352 of 2339

HEATED SEAT SYSTEM

TABLE OF CONTENTS

page page

HEATED SEAT SYSTEM

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING

HEATED SEAT SYSTEM.................8

HEATED SEAT SWITCH

DESCRIPTION..........................8

OPERATION............................9

DIAGNOSIS AND TESTING

DRIVER HEATED SEAT SWITCH..........9

REMOVAL.............................10

INSTALLATION.........................10HEATED SEAT ELEMENTS

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING

HEATED SEAT ELEMENTS..............11

REMOVAL.............................12

INSTALLATION.........................12

HEATED SEAT SENSOR

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING

HEATED SEAT SENSOR................13

HEATED SEAT SYSTEM

DESCRIPTION

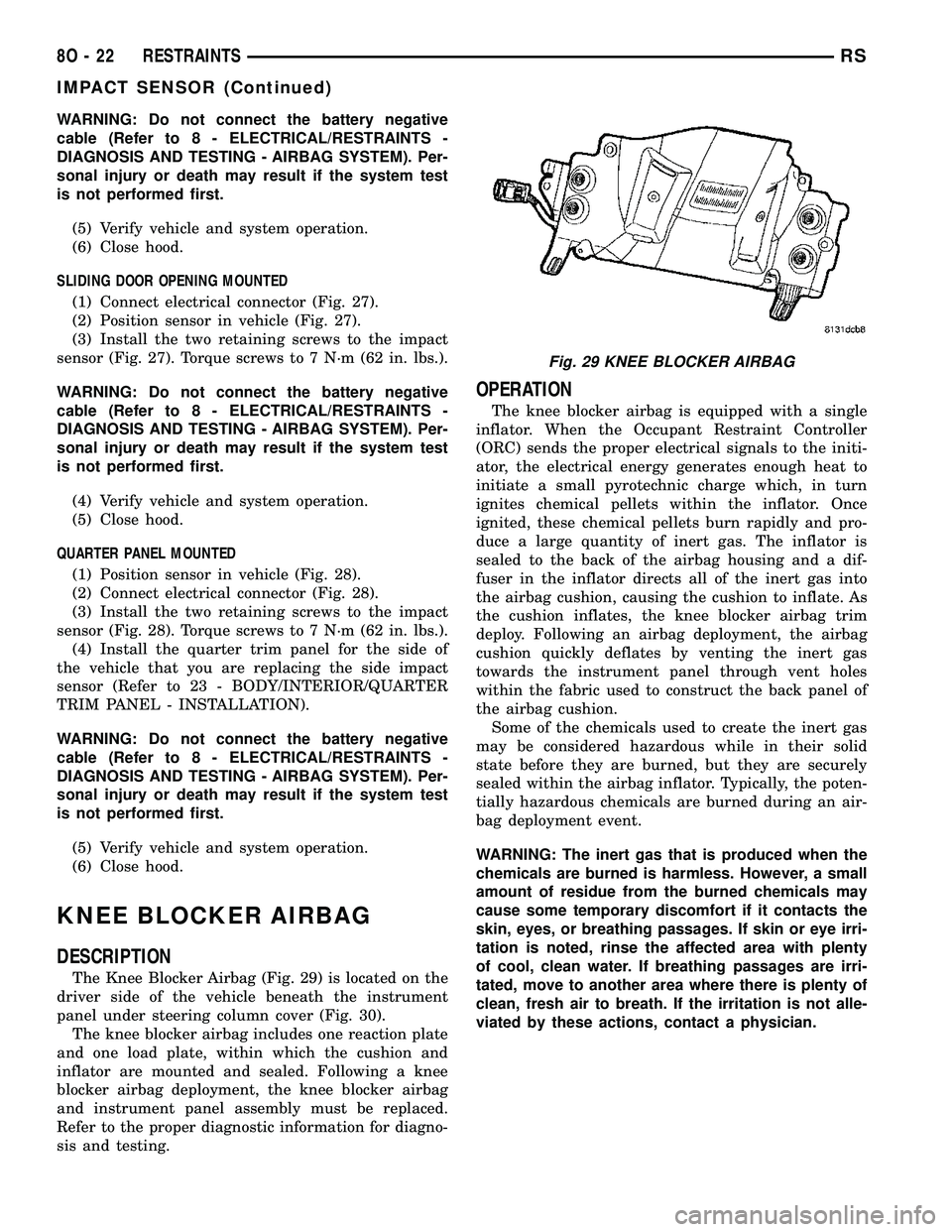

Vehicles with the heated seat option can be visu-

ally identified by the two separate heated seat

switches located in the instrument panel center

stack, just above the radio (Fig. 1). The heated seat

system allows the front seat driver and passenger to

select from two different levels of supplemental elec-

trical seat heating (HI/LO), or no seat heating to suit

their individual comfort requirements. The heated

seat system for this vehicle includes the following

major components:

²Heated Seat Elements- Four heated seat ele-

ments are used per vehicle, two for each front seat.

One heated seat element is integral to each front

seat trim cover, one in the seat back and one in the

seat bottom (cushion). Service replacement heating

elements are available, (Refer to 8 - ELECTRICAL/

HEATED SEATS/HEATED SEAT ELEMENT -

DESCRIPTION) for additional information.

²Heated Seat Modules- Two heated seat mod-

ules are used per vehicle. One module is mounted to

each of the seat cushion pans, located under the for-

ward edge of each front seat. (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/

MEMORY HEATED SEAT/MIRROR MODULE -

DESCRIPTION) for additional information.

²Heated Seat Sensors- Two heated seat sen-

sors are used per vehicle, one for each front seat. The

heated seat sensors are integral to each of the heated

seat bottoms (cushions).

²Heated Seat Switch- Two heated seat

switches are used per vehicle, one for the driver and

one for the passenger side front seats. The switches

are mounted in the instrument panel center stack.

(Refer to 8 - ELECTRICAL/HEATED SEATS/

DRIVER HEATED SEAT SWITCH - DESCRIPTION)

for additional information.

Fig. 1 HEATED SEAT SWITCH LOCATIONS

1 - HEATED SEAT SWITCHES

RSHEATED SEAT SYSTEM8G-7

Page 454 of 2339

POWER SEAT SYSTEM

TABLE OF CONTENTS

page page

POWER SEAT SYSTEM

DESCRIPTION

POWER SEAT SYSTEM................31

MEMORY SYSTEM....................32

OPERATION

POWER SEAT SYSTEM................32

MEMORY SYSTEM....................33

DIAGNOSIS AND TESTING

POWER SEAT SYSTEM................33

MEMORY SYSTEM....................33

SEAT SWITCH

DESCRIPTION.........................34

OPERATION...........................34

DIAGNOSIS AND TESTING

DRIVER SEAT SWITCH.................34

REMOVAL.............................36INSTALLATION.........................36

MEMORY SWITCH

DESCRIPTION.........................36

OPERATION...........................36

DIAGNOSIS AND TESTING

MEMORY SWITCH....................37

REMOVAL.............................37

INSTALLATION.........................37

POWER SEAT TRACK

DESCRIPTION.........................37

OPERATION...........................38

DIAGNOSIS AND TESTING

POWER SEAT TRACK..................38

REMOVAL.............................38

INSTALLATION.........................39

POWER SEAT SYSTEM

DESCRIPTION

POWER SEAT SYSTEM

The power seat system option allows the driver

and front seat passenger to electrically adjust their

seating positions for optimum control and comfort.

The driver side power front seat can be adjusted in

eight different directions: up, down, front up, front

down, rear up, rear down, forward, rearward and

recliner forward and rearward. The passenger side

power front seat can be adjusted in four different

directions: forward, rearward and recliner forward

and rearward.

The power seat system receives battery current

through a 40 amp fuse in the Integrated Power Mod-

ule (IPM) and a 30 amp circuit breaker under the

seat so that the power seats remain operational,

regardless of the ignition switch position.

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS (Fig. 1). BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

The eight-way driver side power seat is also avail-

able with the heated seat and/or memory seat sys-

tem. The memory seat system automatically

positions the power seat for two different drivers.

Fig. 1 IDENTIFYING A SIDE AIRBAG EQUIPPED

SEAT

1 - AIRBAG LABEL

RSPOWER SEAT SYSTEM8N-31

Page 509 of 2339

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

SLIDING DOOR OPENING MOUNTED

(1) Connect electrical connector (Fig. 27).

(2) Position sensor in vehicle (Fig. 27).

(3) Install the two retaining screws to the impact

sensor (Fig. 27). Torque screws to 7 N´m (62 in. lbs.).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(4) Verify vehicle and system operation.

(5) Close hood.

QUARTER PANEL MOUNTED

(1) Position sensor in vehicle (Fig. 28).

(2) Connect electrical connector (Fig. 28).

(3) Install the two retaining screws to the impact

sensor (Fig. 28). Torque screws to 7 N´m (62 in. lbs.).

(4) Install the quarter trim panel for the side of

the vehicle that you are replacing the side impact

sensor (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

KNEE BLOCKER AIRBAG

DESCRIPTION

The Knee Blocker Airbag (Fig. 29) is located on the

driver side of the vehicle beneath the instrument

panel under steering column cover (Fig. 30).

The knee blocker airbag includes one reaction plate

and one load plate, within which the cushion and

inflator are mounted and sealed. Following a knee

blocker airbag deployment, the knee blocker airbag

and instrument panel assembly must be replaced.

Refer to the proper diagnostic information for diagno-

sis and testing.

OPERATION

The knee blocker airbag is equipped with a single

inflator. When the Occupant Restraint Controller

(ORC) sends the proper electrical signals to the initi-

ator, the electrical energy generates enough heat to

initiate a small pyrotechnic charge which, in turn

ignites chemical pellets within the inflator. Once

ignited, these chemical pellets burn rapidly and pro-

duce a large quantity of inert gas. The inflator is

sealed to the back of the airbag housing and a dif-

fuser in the inflator directs all of the inert gas into

the airbag cushion, causing the cushion to inflate. As

the cushion inflates, the knee blocker airbag trim

deploy. Following an airbag deployment, the airbag

cushion quickly deflates by venting the inert gas

towards the instrument panel through vent holes

within the fabric used to construct the back panel of

the airbag cushion.

Some of the chemicals used to create the inert gas

may be considered hazardous while in their solid

state before they are burned, but they are securely

sealed within the airbag inflator. Typically, the poten-

tially hazardous chemicals are burned during an air-

bag deployment event.

WARNING: The inert gas that is produced when the

chemicals are burned is harmless. However, a small

amount of residue from the burned chemicals may

cause some temporary discomfort if it contacts the

skin, eyes, or breathing passages. If skin or eye irri-

tation is noted, rinse the affected area with plenty

of cool, clean water. If breathing passages are irri-

tated, move to another area where there is plenty of

clean, fresh air to breath. If the irritation is not alle-

viated by these actions, contact a physician.

Fig. 29 KNEE BLOCKER AIRBAG

8O - 22 RESTRAINTSRS

IMPACT SENSOR (Continued)

Page 1174 of 2339

8W-97 POWER DISTRIBUTION SYSTEM

TABLE OF CONTENTS

page page

POWER DISTRIBUTION SYSTEM

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........1

INTEGRATED POWER MODULE

DESCRIPTION..........................1

OPERATION............................2

REMOVAL.............................2

INSTALLATION..........................2IOD FUSE

DESCRIPTION..........................3

OPERATION............................3

POWER OUTLET

DESCRIPTION..........................3

OPERATION............................3

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET . . 3

REMOVAL.............................4

INSTALLATION..........................4

POWER DISTRIBUTION

SYSTEM

DESCRIPTION

The power distribution system for this vehicle con-

sists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Outlets

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Bus bars

²Cartridge fuses

²Circuit splice blocks

²Flashers

²Fusible links

²Relays

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide theelectrical current needed to operate many accessories

that the vehicle owner may choose to have installed.

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

INTEGRATED POWER MODULE

DESCRIPTION

The Integrated Power Module (IPM) is a combina-

tion of the Power Distribution Center (PDC) and the

Front Control Module (FCM). The IPM is located in

the engine compartment, next to the battery. (Fig. 1).

The PDC mates directly with the FCM to form the

IPM. The PDC is a printed circuit board based mod-

ule that contains fuses and relays, while the FCM

contains the electronics controlling the IPM and

other functions. This IPM connects directly to the

battery positive through a four pin connector. The

ground connection is through two other connectors.

Terminal Pick Kit 6680

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-1

Page 1948 of 2339

SUNROOF

TABLE OF CONTENTS

page page

SUNROOF

DESCRIPTION........................169

DIAGNOSIS AND TESTING

SUNROOF DIAGNOSIS AND TESTING....169

DRAIN TUBE

REMOVAL............................172

INSTALLATION........................172

GLASS PANEL

REMOVAL............................173

INSTALLATION........................173

ADJUSTMENTS

SUNROOF GLASS PANEL ADJUSTMENT . . 173

SUNROOF ASSEMBLY

REMOVAL............................173

INSTALLATION........................173

SUNSHADE

REMOVAL............................173INSTALLATION........................173

WIND DEFLECTOR

REMOVAL............................174

INSTALLATION........................174

WATER CHANNEL

REMOVAL............................174

INSTALLATION........................174

SUNROOF MOTOR

REMOVAL............................174

INSTALLATION........................174

ADJUSTMENTS

ADJUSTMENT.......................175

SUNROOF SWITCH

REMOVAL............................176

INSTALLATION........................176

SUNROOF

DESCRIPTION

WARNING: Keep fingers and other body parts out

of sunroof opening at all times.

The sun roof features consists of: (Fig. 1)

²Sun roof glass

²Sun roof sun shade

The sunroof power sliding glass panel and sun-

shade can be positioned anywhere along its travel,

rearward of glass panel front edge.

The sunroof is electrically operated from a switch

located in the overhead console. To operate the sun-

roof the ignition switch must be in the Accessory or

On/Run position. Both switchs are a rocker style

design that open or close the sunroof. When pressing

and releasing the open button once, the sunroof will

express open to the comfort stop and the wind deflec-

tor will raise. If the button is pressed a second time,

the sunroof will continue to open to full travel unless

the button is released, at which time it will stop in

that position. Pressing and holding the close button

will close the sunroof. If the close button is released

before the glass fully closes, the sunroof will stop in

that position. The vent switch operates in a similar

manor. The sunroof will also operate for up to fifteen

minutes after the ignition key is turned off for cus-

tomer comfort and convenance while parking.

DIAGNOSIS AND TESTING

SUNROOF DIAGNOSIS AND TESTING

Refer to Sunroof Diagnostic Chart for possible

causes. Before beginning sunroof diagnostics verify

that all other power accessories are in proper operat-

ing condition. If not, a common electrical problem

may exist. Refer to Wiring Diagrams, in this publica-

tion for circuit, splice and component descriptions.

Check the condition of the circuit protection (20 amp

circuit breaker in the Junction Block). Inspect all

wiring connector pins for proper engagement and

continuity. Check for battery voltage at the power

sunroof controller, refer to Wiring Diagrams, for cir-

cuit information. If battery voltage of more than 10

volts is detected at the controller, proceed with the

following tests (the controller will not operate at less

than 10 volts).

Before beginning diagnosis for wind noise or water

leaks, verify that the problem was not caused by

releasing the control switch before the sunroof was

fully closed. The sunroof module has a water-man-

agement system. If however, the sunroof glass is in a

partial closed position, high pressure water may be

forced beyond the water management system bound-

aries and onto the headlining.

RSSUNROOF23 - 169