CITROEN C1 2017 Owners Manual

Manufacturer: CITROEN, Model Year: 2017, Model line: C1, Model: CITROEN C1 2017Pages: 269, PDF Size: 7.63 MB

Page 151 of 269

149

C1_en_Chap07_info-pratiques_ed01-2016

Theô brakeô fluidô levelô shouldô beô closeô to ô the ô "MA X" ô mark. ô If ô it ô is ô not, ô check ô

t

he ô brake ô pad ô wear.

Brake fluid level

Changing the fluid

Referô toô theô manufacturer'sô serviceô scheduleô for ô details ô of ô the ô interval ô for ô this ô operation.

Fluid specification

Theô brakeô fluidô mustô conformô toô theô manufacturer'sô r ecommendations.

Topping-up the engine oil

Oil grade

Theô oil ô must ô be ô the ô correct ô grade ô for ô your ô

e

ngine ô and ô conform ô to ô the ô manufacturer's ô

r

ecommendations.

Refer

ô to ô the ô under-bonnet ô view ô for ô the ô location ô

o

f ô the ô oil ô filler ô cap ô on ô your ô vehicle.

F

U

nscrew the filler cap for access to the

filler

ô orifice.

F

ô

P

our ô in ô the ô oil ô in ô small ô quantities, ô avoiding ô

s

pills ô onto ô the ô engine ô (risk ô of ô fire).

F

ô

W

ait ô a ô few ô minutes ô before ô checking ô the ô

l

evel ô again ô using ô the ô dipstick.

F

ô

T

op-up ô again ô if ô necessary.

F

ô

A

fter ô checking ô and ô topping ô up, ô carefully ô

r

efit ô the ô oil ô filler ô cap ô and ô the ô dipstick ô to ô its ô

h

ousing.

Engine oil change

Referô toô theô manufacturer'sô serviceô scheduleô for ô details ô of ô the ô interval ô for ô this ô operation.

In

ô order ô to ô maintain ô the ô reliability ô of ô the ô engine ô

a

nd ô emissions ô control ô system, ô never ô use ô

a

dditives ô in ô the ô engine ô oil.

7

Practical information

Page 152 of 269

150

C1_en_Chap07_info-pratiques_ed01-2016

Avoidô prolongedô contactô ofô usedô oilô orô fluids ô with ô the ô skin.

Most

ô of ô these ô fluids ô are ô harmful ô to ô

h

ealth ô or ô indeed ô very ô corrosive.

Do

ô not ô discard ô used ô oil ô or ô fluids ô into ô

s

ewers ô or ô onto ô the ô ground.

Take

ô used ô oil ô to ô a ô CITROûN ô dealer ô or ô

a

ô qualified ô workshop ô (France) ô or ô to ô an ô

a

uthorised ô waste ô disposal ô site.

Used products

Fluid specification

Forô optimumô cleaningô andô toô avoidô freezing,ô this ô fluid ô must ô not ô be ô topped ô up ô or ô replaced ô

w

ith ô plain ô water.

In

ô

w

intry ô

c

onditions, ô

i

t ô

i

s ô

r

ecommended ô

t

hat ô

y

ou ô

u

se ô an ô ethyl ô alcohol ô or ô methanol ô based ô fluid.

Screenwash fluid level

Topô upô theô levelô whenô necessary.

Coolant level

Theô coolantô levelô mustô be:

- ô b etween ô the ô "FULL " or "F"

ô and ô

"LO

W" or " L"

ô marks ô for ô VTi ô 68 ô

a

nd ô VTi ô 68 ô S&S ô engines,

In

ô

addition, ô as ô the ô cooling ô system ô is ô pressurised,

ô w

ait

ô

at

ô

least ô one ô hour ô after ô switching ô off ô the

ô e

ngine

ô

before ô carrying ô out ô any ô work.

To

ô

avoid

ô

any ô risk ô of ô scalding, ô unscrew ô the ô cap

ô b

y

ô

two

ô

turns ô to ô allow ô the ô pressure ô to ô drop. ô When

ô t

he

ô

pressure ô has ô dropped, ô remove ô the ô cap ô and

ô t

op

ô

up

ô

the

ô level.

Fluid specification

Theô coolantô mustô conformô toô theô ma nufacturer'sô r ecommendations.

The cooling fan may star t after switching

off the engine: take care with ar ticles and

clothing that might be caught by the fan

blades. - ô

b

etween ô the ô "

MIN " ô and ô "

MAX " ô marks ô for ô

t

he ô PureTech ô 82 ô engine.

When ô the ô engine ô is ô warm, ô the ô temperature ô of ô

t

he ô coolant ô is ô regulated ô by ô the ô fan.

Practical information

Page 153 of 269

151

C1_en_Chap07_info-pratiques_ed01-2016

Checks

12 V battery

Theô batteryô doesô notô requireô anyô maintenance.

H owever, ô check ô regularly ô that ô the ô terminalsô a

re ô correctly ô tightened ô (versions ô without ô quick

ô r

elease ô terminals) ô and ô that ô the ô connections

ô a

re ô clean.Referô toô theô manufacturer'sô service ô schedule ô for ô details ô of ô the ô

r

eplacement ô intervals ô for ô these ô

c

omponents.

Air filter and passenger compartment filter

Replaceô theô oilô filterô eachô timeô theô e ngine ô oil ô is ô changed.

Refer

ô to ô the ô manufacturer's ô

s

ervice ô schedule ô for ô details ô of ô

t

he ô replacement ô interval ô for ô this ô

c

omponent.

Oil filter

Unlessô other wiseô indicated,ô checkô theseô componentsô inô accordanceô withô theô manufacturer'sô serviceô scheduleô andô accordingô toô yourô engine.

O ther wise, ô have ô them ô checked ô by ô a ô CITROûN ô dealer ô or ô a ô qualified ô workshop.

Depending

ô on ô the ô environment ô (e.g. ô dusty ô

a

tmosphere) ô and ô the ô use ô of ô the ô vehicle ô

(e.g.

ô city ô driving), ô replace them twice as often

if necessary .

A

ô clogged ô passenger ô compartment ô filter ô may ô

h

ave ô an ô adverse ô effect ô on ô the ô per formance ô

o

f ô the ô air ô conditioning ô system ô and ô generate ô

u

ndesirable

ô o

dours.

When

ô carrying ô out ô any ô operation ô on ô the ô

12

ô V ô battery, ô refer ô to ô the ô corresponding ô section ô

f

or ô details ô of ô the ô precautions ô to ô be ô taken ô before ô

s

tarting ô work.

Manual gearbox

Theô gearboxô doesô notô requireô anyô maintenance ô (no ô oil ô change).

Refer

ô to ô the ô manufacturer's ô service ô

s

chedule ô for ô the ô checking ô interval ô for ô

t

his

ô c

omponent.

Clutch

Theô clutchô isô operatedô mechanicallyô andô requiresô r egularô a djustment.

Refer

ô to ô the ô manufacturer's ô service ô schedule ô

f

or ô information ô on ô when ô the ô adjustment ô should ô

beô c

hecked.In

ô the ô event ô of ô an ô operating ô fault ô

(

difficulty ô moving ô off, ô for ô example), ô

c

ontact ô a ô CITROûN ô dealer ô or ô a ô

q

ualified

ô w

orkshop.

Versions

ô

equipped

ô

with

ô

Stop

ô

&

ô

Start

ô

are

ô

f

itted

ô

with

ô

a

ô

12

ô

V

ô

lead-acid

ô

battery

ô

of

ô

s

pecific

ô t

echnology

ô a

nd

ô s

pecification.

Its

ô

replacement

ô

should

ô

be

ô

carried

ô

out

ô

o

nly

ô

by

ô

a

ô

CITROûN

ô

dealer

ô

or

ô

a

ô

qualified

ô w

orkshop.

7

Practical information

Page 154 of 269

152

C1_en_Chap07_info-pratiques_ed01-2016

ETG gearbox

Theô ETGô gearboxô doesô notô requireô any ô maintenance ô (no ô oil ô change).

Refer

ô to ô the ô manufacturer's ô service ô

s

chedule ô for ô information ô on ô when ô this ô

u

nit ô should ô be ô checked.

Brake

ô wear ô depends ô on ô the ô style ô

o

f ô driving, ô particularly ô in ô the ô case ô

o

f ô vehicles ô used ô in ô town, ô over ô short ô

d

istances. ô It ô may ô be ô necessary ô to ô

Brake pads

Forô informationô onô checkingô brakeô disc ô wear, ô contact ô a ô CITROûN ô dealer ô

o

r ô a ô qualified ô workshop.

Brake disc wearOnlyô useô productsô recommendedô byô CITROûN ô or ô products ô of ô equivalent ô

q

uality

ô an

d

ô sp

ecification.

In

ô order ô to ô optimise ô the ô operation ô of ô

u

nits ô as ô important ô as ô those ô in ô the ô

b

raking ô system, ô CITROûN ô selects ô and ô

o

ffers ô very ô specific ô products.

After

ô washing ô the ô vehicle, ô dampness, ô

o

r ô in ô wintry ô conditions, ô ice ô can ô form ô

o

n ô the ô brake ô discs ô and ô pads: ô braking ô

e

fficiency ô may ô be ô reduced. ô Make ô light ô

b

rake ô applications ô to ô dry ô and ô defrost ô

t

he ô brakes.

Parking brake

Ifô excessiveô travelô orô aô lossô ofô effectiveness ô of ô this ô system ô is ô

n

oticed, ô the ô parking ô brake ô must ô be ô

c

hecked,

ô e

ven

ô b

etween

ô t

woô services.

Checking

ô

this ô system ô must ô be ô done ô by ô a ô

C

ITROûN

ô dealer ô or ô a ô qualified ô workshop.

have

ô

the

ô

condition

ô

of

ô

the

ô

brakes

ô

checked,

ô

even

ô

b

etween

ô v

ehicle

ô s

ervices.

Unless

ô

there

ô

is

ô

a

ô

leak

ô

in

ô

the

ô

circuit,

ô

a

ô

drop

ô

in

ô

t

he

ô

brake

ô

fluid

ô

level

ô

indicates

ô

that

ô

the

ô

brake

ô

p

ads

ô

are

ô

worn. To

ô avoid ô damaging ô the ô electrical ô units, ô

n

ever use ô a ô high ô pressure ô jet ô wash ô in ô

t

he ô engine ô compartment.

Practical information

Page 155 of 269

153

C1_en_Chap08_en-cas-pannes_ed01-2016

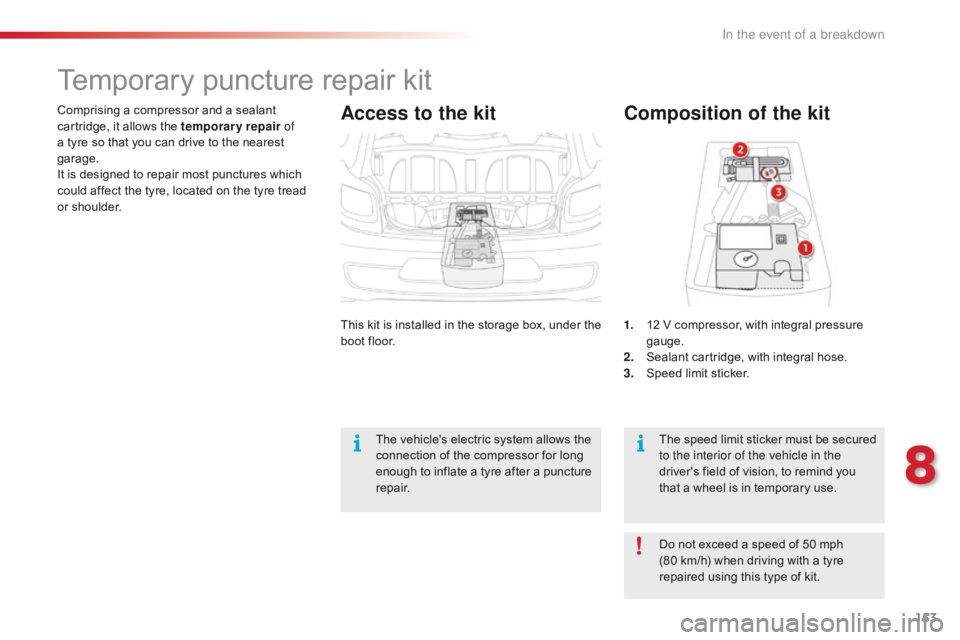

Comprisingô aô compressorô andô aô sealantô cartridge, ô it ô allows ô the ô temporary repair of

a

ô tyre ô so ô that ô you ô can ô drive ô to ô the ô nearest ô

g

arage.

It

ô is ô designed ô to ô repair ô most ô punctures ô which ô

c

ould ô affect ô the ô tyre, ô located ô on ô the ô tyre ô tread ô

o

r ô shoulder.

Temporaryô pu nctureô r epairô k it

Composition of the kit

1.ô 12ô V ô compressor, ô with ô integral ô pressure ô ga

uge.

2.

ô S

ealant ô cartridge, ô with ô integral ô hose.

3.

ô S

peed ô limit ô sticker.

The

ô speed ô limit ô sticker ô must ô be ô secured ô

t

o the interior of the vehicle in the

driver's

ô field ô of ô vision, ô to ô remind ô you ô

t

hat ô a ô wheel ô is ô in ô temporary ô use.

This

ô k

it

ô i

s

ô i

nstalled

ô i

n

ô t

he

ô s

torage

ô b

ox,

ô u

nder

ô t

he

ô b

oot

ô

floor.

The

ô

vehicle's

ô

electric

ô

system

ô

allows

ô

the

ô

c

onnection

ô

of

ô

the

ô

compressor

ô

for

ô

long

ô

e

nough

ô

to

ô

inflate

ô

a

ô

tyre

ô

after

ô

a

ô

puncture

ô

r

epair. Do

ô not ô exceed ô a ô speed ô of ô 50 ô mph ô

(

80ô km/h) ô when ô driving ô with ô a ô tyre ô

r

epaired ô using ô this ô type ô of ô kit.

Access to the kit

8

In the event of a breakdown

Page 156 of 269

154

C1_en_Chap08_en-cas-pannes_ed01-2016

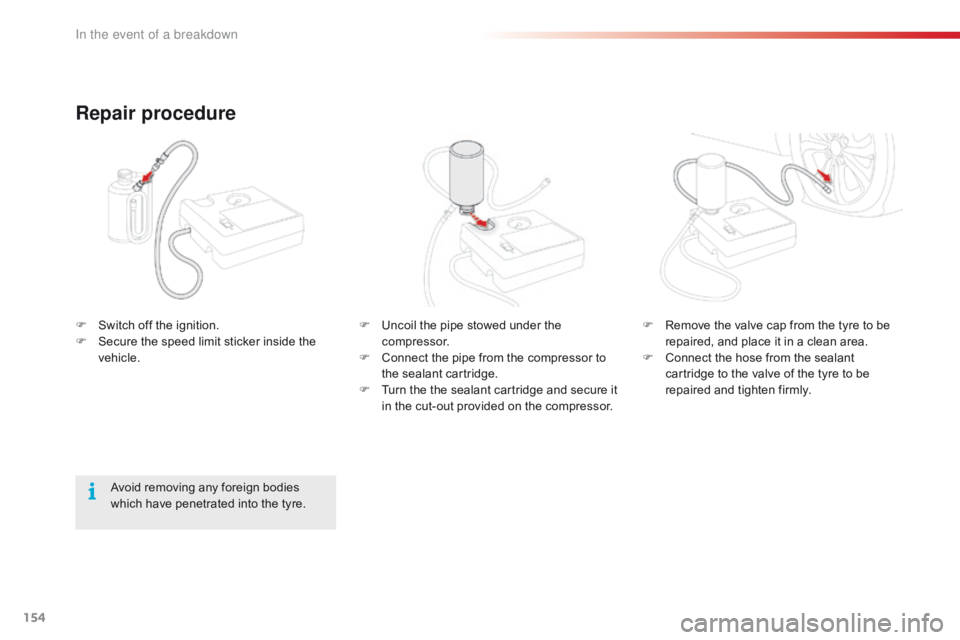

Fô Uncoilô the ô pipe ô stowed ô under ô the ô c

ompressor.

F

ô

C

onnect ô the ô pipe ô from ô the ô compressor ô to ô

t

he ô sealant ô cartridge.

F

ô

T

urn ô the ô the ô sealant ô cartridge ô and ô secure ô it ô

i

n ô the ô cut-out ô provided ô on ô the ô compressor.

Repair procedure

Avoidô removingô anyô foreignô bodiesô which ô have ô penetrated ô into ô the ô tyre. F

ô

R

emove ô the ô valve ô cap ô from ô the ô tyre ô to ô be ô

r

epaired, ô and ô place ô it ô in ô a ô clean ô area.

F ô

C

onnect ô the ô hose ô from ô the ô sealant ô

c

artridge ô to ô the ô valve ô of ô the ô tyre ô to ô be ô

r

epaired ô and ô tighten ô firmly.

F

ô

S

witch ô off ô the ô ignition.

F

ô

S

ecure ô the ô speed ô limit ô sticker ô inside ô the ô

v

ehicle.

In the event of a breakdown

Page 157 of 269

155

C1_en_Chap08_en-cas-pannes_ed01-2016

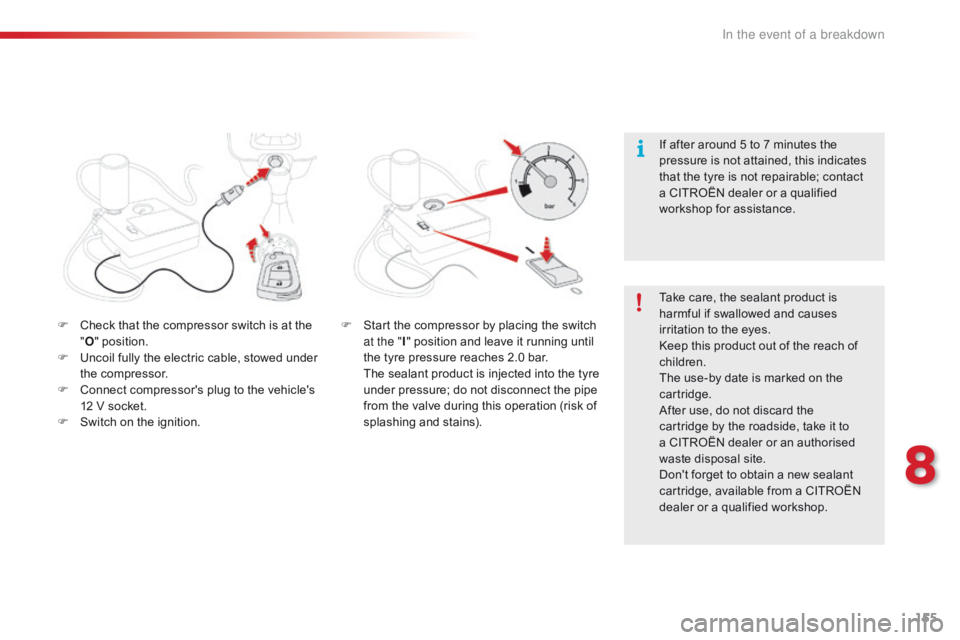

Fô Checkô that ô the ô compressor ô switch ô is ô at ô the ô "O "

ô position.

F

ô

U

ncoil ô fully ô the ô electric ô cable, ô stowed ô under ô

t

he ô compressor.

F

ô

C

onnect ô compressor's ô plug ô to ô the ô vehicle's ô

1

2 ô V ô socket.

F

ô

S

witch ô on ô the ô ignition. Take

ô care, ô the ô sealant ô product ô is ô h

armful ô if ô swallowed ô and ô causes ô i

rritation ô to ô the ô eyes.

Keep

ô this ô product ô out ô of ô the ô reach ô of ô

c

hildren.

The

ô use-by ô date ô is ô marked ô on ô the ô

c

artridge.

After

ô use, ô do ô not ô discard ô the ô

c

artridge ô by ô the ô roadside, ô take ô it ô to ô

a

ô CITROûNô dealer ô or ô an ô authorised ô

w

aste ô disposal ô site.

Don't

ô forget ô to ô obtain ô a ô new ô sealant ô

c

artridge, ô available ô from ô a ô CITROûN ô

d

ealer ô or ô a ô qualified ô workshop.

If

ô after ô around ô 5 ô to ô 7 ô minutes ô the ô

p

ressure ô is ô not ô attained, ô this ô indicates ô

t

hat ô the ô tyre ô is ô not ô repairable; ô contact ô

a

ô CITROûN ô dealer ô or ô a ô qualified ô

w

orkshop ô for ô assistance.

F ô S tart ô the ô compressor ô by ô placing ô the ô switch ô a

t the "I"

ô position ô and ô leave ô it ô running ô until ô

t

he ô tyre ô pressure ô reaches ô 2.0 ô bar.

ô T

he ô sealant ô product ô is ô injected ô into ô the ô tyre ô

u

nder ô pressure; ô do ô not ô disconnect ô the ô pipe ô

f

rom ô the ô valve ô during ô this ô operation ô (risk ô of ô

sp

lashing

ô an

d

ô s

tains).

8

In the event of a breakdown

Page 158 of 269

156

C1_en_Chap08_en-cas-pannes_ed01-2016

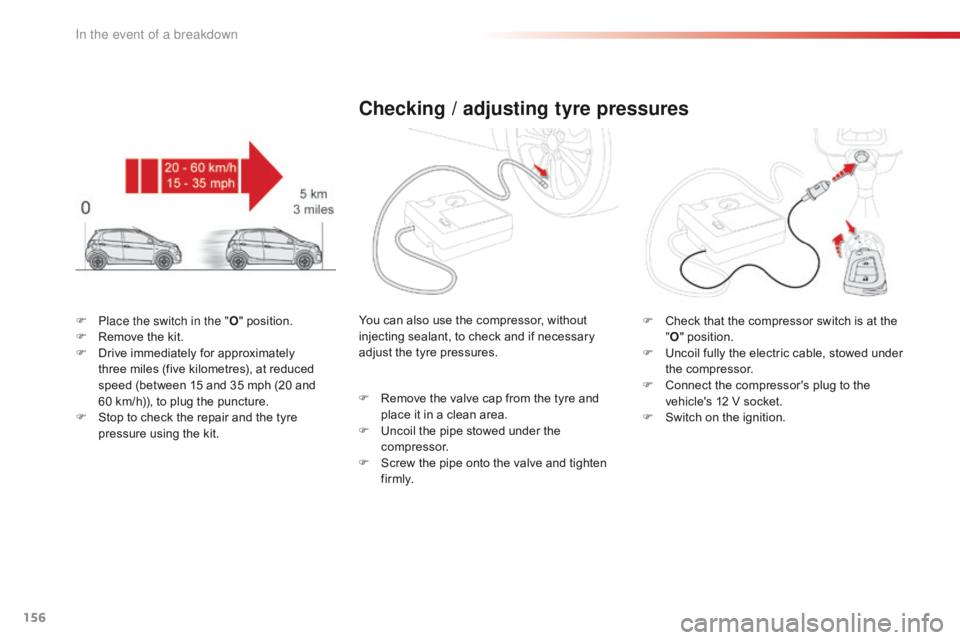

F Place the switch in the "O" ô position.

F ô R emove ô the ô kit.

F

ô

D

rive ô immediately ô for ô approximately ô

t

hree ô miles ô (five ô kilometres), ô at ô reduced ô

s

peed ô (between ô 15 ô and ô 35 ô mph ô (20 ô and ô

6

0ô km/h)), ô to ô plug ô the ô puncture.

F

ô

S

top ô to ô check ô the ô repair ô and ô the ô tyre ô

p

ressure ô using ô the ô kit.

Checking / adjusting tyre pressures

Fô Checkô that ô the ô compressor ô switch ô is ô at ô the ô "O "

ô position.

F

ô

U

ncoil ô fully ô the ô electric ô cable, ô stowed ô under ô

t

he ô compressor.

F

ô

C

onnect ô the ô compressor's ô plug ô to ô the ô

v

ehicle's ô 12 ô V ô socket.

F

ô

S

witch ô on ô the ô ignition.

You

ô

can

ô

also

ô

use

ô

the

ô

compressor,

ô

without

ô i

njecting

ô

sealant,

ô

to

ô

check

ô

and

ô

if

ô

necessary

ô

a

djust

ô

the

ô

tyre

ô

pressures.

F

ô

R

emove

ô

the

ô

valve

ô

cap

ô

from

ô

the

ô

tyre

ô

and

ô

p

lace

ô

it

ô

in

ô

a

ô

clean

ô

area.

F

ô

U

ncoil

ô

the

ô

pipe

ô

stowed

ô

under

ô

the

ô

c

ompressor.

F

ô

S

crew

ô

the

ô

pipe

ô

onto

ô

the

ô

valve

ô

and

ô

tighten

ô

f

i r m l y.

In the event of a breakdown

Page 159 of 269

157

C1_en_Chap08_en-cas-pannes_ed01-2016

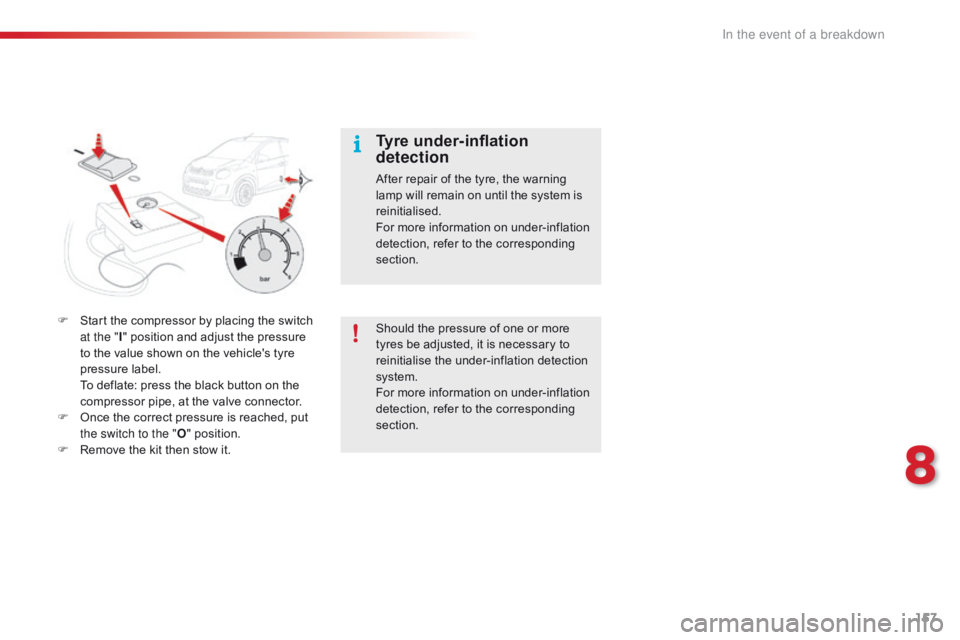

Shouldô theô pressureô ofô oneô orô moreô tyres ô be ô adjusted, ô it ô is ô necessary ô to ô

r

einitialise ô the ô under-inflation ô detection ô

s

ystem.

For

ô more ô information ô on ô under-inflation ô

d

etection, ô refer ô to ô the ô corresponding ô

s

ection.

Tyre under-inflation

detection

Afterô repairô ofô theô tyre,ô theô warningô lamp ô will ô remain ô on ô until ô the ô system ô is ô

r

einitialised.

For

ô more ô information ô on ô under-inflation ô

d

etection, ô refer ô to ô the ô corresponding ô

s

ection.

F

ô

S

tart

ô

the

ô

compressor

ô

by

ô

placing

ô

the

ô

switch

ô

a

t the " I"

ô

position

ô

and

ô

adjust

ô

the

ô

pressure

ô

t

o

ô

the

ô

value

ô

shown

ô

on

ô

the

ô

vehicle's

ô

tyre

ô

p

ressure

ô

label.

ô T

o

ô

deflate:

ô

press

ô

the

ô

black

ô

button

ô

on

ô

the

ô

c

ompressor

ô

pipe,

ô

at

ô

the

ô

valve

ô

connector.

F

ô

O

nce

ô

the

ô

correct

ô

pressure

ô

is

ô

reached,

ô

put

ô

t

he switch to the " O"

ô

position.

F

ô

R

emove

ô

the

ô

kit

ô

then

ô

stow

ô

it.

8

In the event of a breakdown

Page 160 of 269

158

C1_en_Chap08_en-cas-pannes_ed01-2016

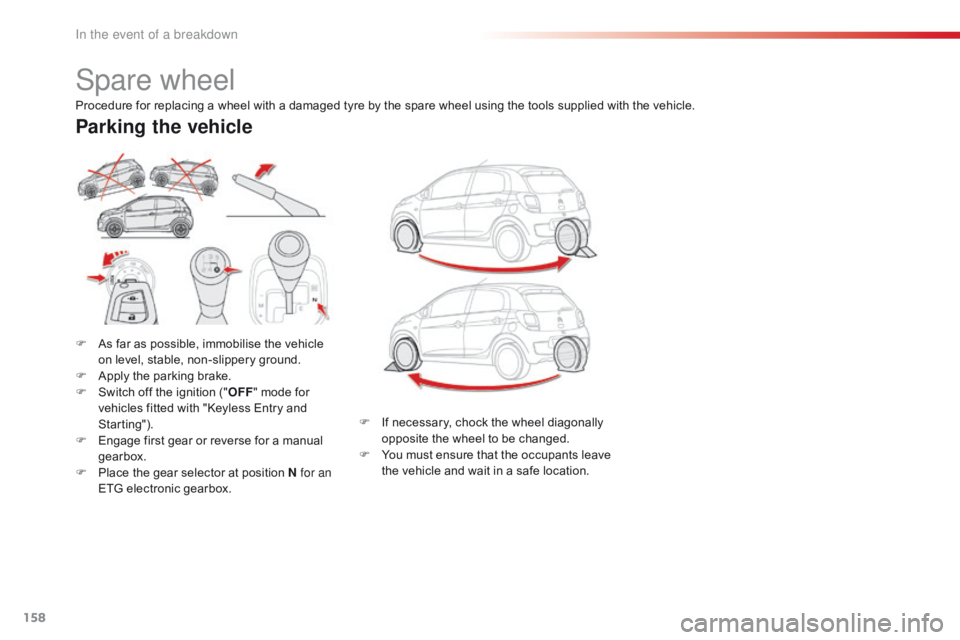

Spare wheel

Fô Asô far ô as ô possible, ô immobilise ô the ô vehicle ô o

n ô level, ô stable, ô non-slippery ô ground.

F

ô

A

pply ô the ô parking ô brake.

F

ô

S

witch ô off ô the ô ignition ô ("OFF "

ô mode ô for ô

v

ehicles ô fitted ô with ô "Keyless ô Entry ô and ô

S

tarting").

F

ô

E

ngage ô first ô gear ô or ô reverse ô for ô a ô manual ô

g

earbox.

F

ô

P

lace ô the ô gear ô selector ô at ô position ô N for an

ETG

ô electronic ô gearbox.

Parking the vehicle

Procedureô forô replacingô aô wheelô withô aô damagedô tyreô byô theô spareô wheelô usingô theô toolsô suppliedô withô theô vehicle.

F ô

I

f ô necessary, ô chock ô the ô wheel ô diagonally ô

o

pposite ô the ô wheel ô to ô be ô changed.

F

ô

Y

ou ô must ô ensure ô that ô the ô occupants ô leave ô

t

he ô vehicle ô and ô wait ô in ô a ô safe ô location.

In the event of a breakdown