side Citroen C2 2004 1.G Service Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2004, Model line: C2, Model: Citroen C2 2004 1.GPages: 523, PDF Size: 10.32 MB

Page 492 of 523

Downloaded from www.Manualslib.com manuals search engine 488

ELECTRICAL

SYSTEM

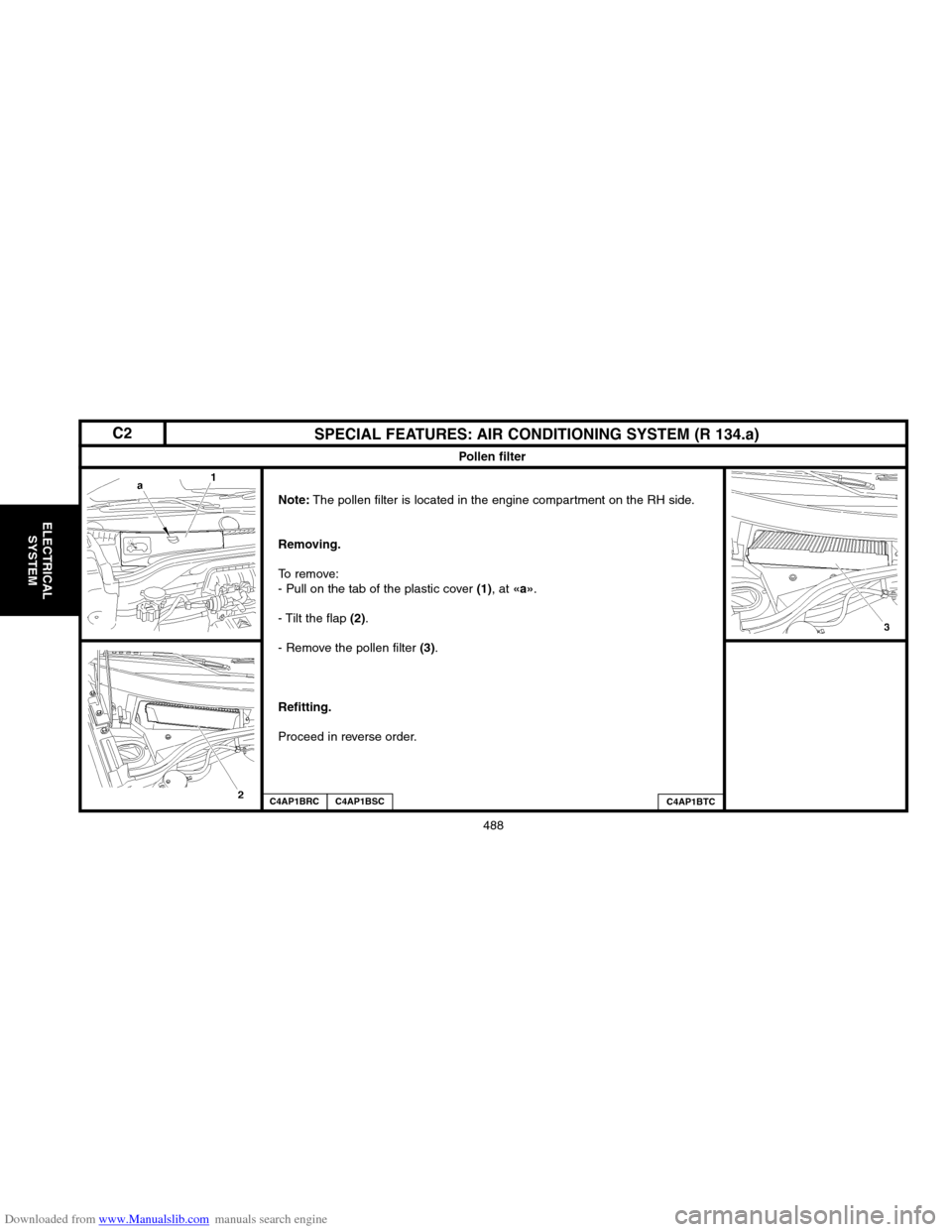

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Pollen filter

Note:

The pollen filter is located in the engine compartment on the RH side.

Removing.

To remove:

� Pull on the tab of the plastic cover (1), at «a».

� Tilt the flap

(2).

� Remove the pollen filter

(3).

Refitting.

Proceed in reverse order.

C4AP1BRCC4AP1BSCC4AP1BTC

C2

Page 493 of 523

Downloaded from www.Manualslib.com manuals search engine 489

ELECTRICAL

SYSTEM

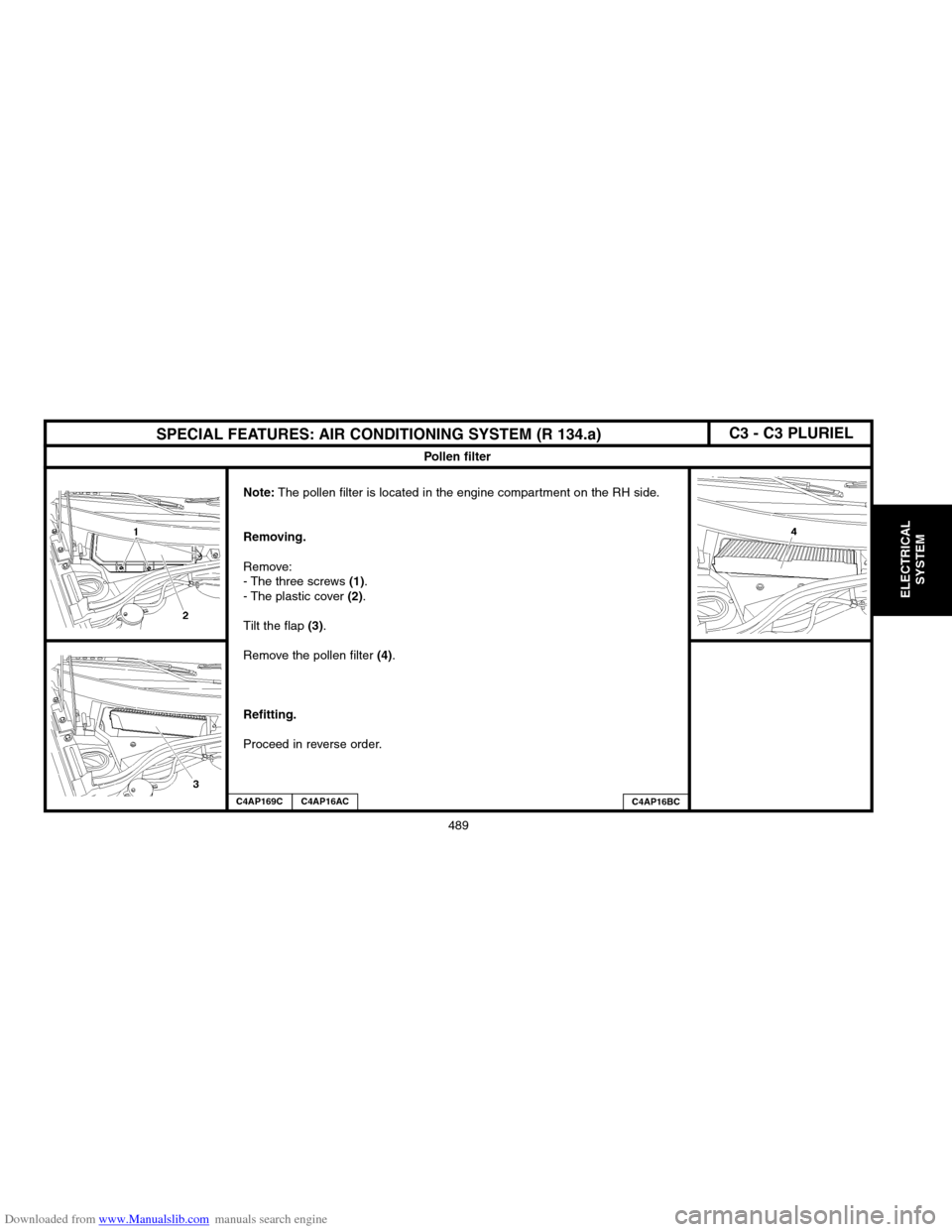

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Pollen filter

Note:

The pollen filter is located in the engine compartment on the RH side.

Removing.

Remove:

� The three screws (1).

� The plastic cover (2).

Tilt the flap

(3).

Remove the pollen filter

(4).

Refitting.

Proceed in reverse order.

C4AP169CC4AP16ACC4AP16BC

C3 � C3 PLURIEL

Page 498 of 523

![Citroen C2 2004 1.G Service Manual Downloaded from www.Manualslib.com manuals search engine 494

AIRCONAIRCON

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Changing the filtering/drying cartridge

Tools.

[1]

Charge station :(accord Citroen C2 2004 1.G Service Manual Downloaded from www.Manualslib.com manuals search engine 494

AIRCONAIRCON

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Changing the filtering/drying cartridge

Tools.

[1]

Charge station :(accord](/img/9/4135/w960_4135-497.png)

Downloaded from www.Manualslib.com manuals search engine 494

AIRCONAIRCON

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Changing the filtering/drying cartridge

Tools.

[1]

Charge station :(according to workshop equipment)[2]TORX adaptor: TORX 70 FACOM

Removing.

Depressurise the aircon circuit, using tool [1].

Uncouple the hose

(2).

Remove:

� The air filter assembly

(3).

� The nuts (1).

Protect the radiator harness with strong cardboard cut to the dimensions of the radiator.

Move aside the cooling fan.

Remove:

� The screws

(4).

� The brackets (5).

B1BP23FCB1BP23GC

XSARA PICASSO

Page 499 of 523

Downloaded from www.Manualslib.com manuals search engine 495

AIRCON

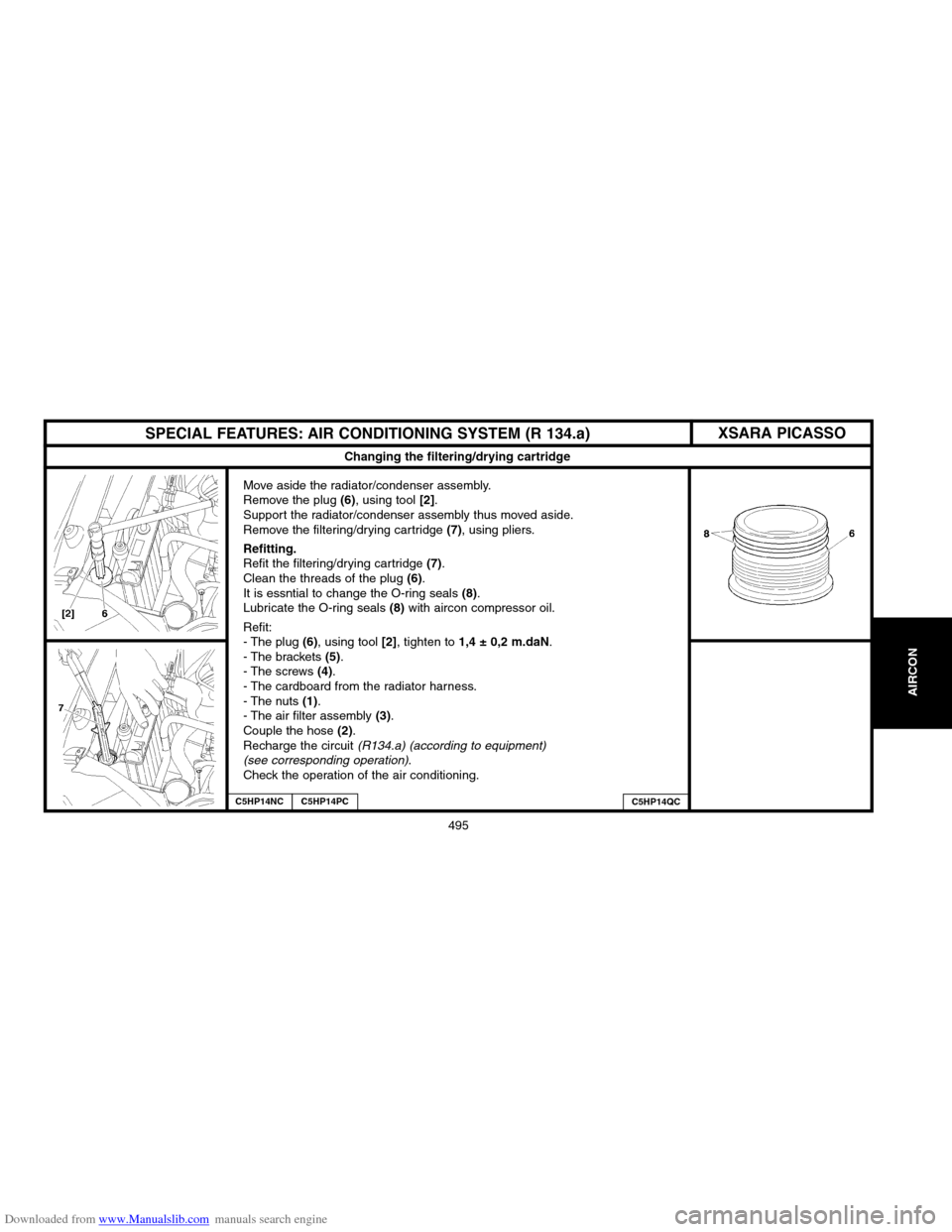

SPECIAL FEATURES: AIR CONDITIONING SYSTEM (R 134.a)

Changing the filtering/drying cartridge

Move aside the radiator/condenser assembly.

Remove the plug (6), using tool [2].

Support the radiator/condenser assembly thus moved aside.

Remove the filtering/drying cartridge

(7), using pliers.

Refitting.Refit the filtering/drying cartridge (7).

Clean the threads of the plug (6).

It is essntial to change the O�ring seals (8).

Lubricate the O�ring seals (8)with aircon compressor oil.

Refit:

� The plug

(6), using tool [2], tighten to 1,4 ±0,2 m.daN.

� The brackets (5).

� The screws (4).

� The cardboard from the radiator harness.

� The nuts

(1).

� The air filter assembly (3).

Couple the hose (2).

Recharge the circuit (R134.a) (according to equipment)

(see corresponding operation).

Check the operation of the air conditioning.

C5HP14NCC5HP14PCC5HP14QC

XSARA PICASSO

Page 502 of 523

Downloaded from www.Manualslib.com manuals search engine 498

AIRCONAIRCON

AIR CONDITIONING SYSTEM R 134.a

Testing procedure

Conditions inside the vehicle.

Positions of the air conditioning controls:

Maximum cold.

Maximum blower power.

Air distribution on

«ventilation»with the air vents open.

Position the air inlet flap to outside air.

WARNING:For RFTA (1), disconnect the air inlet motor connector, first

ensuring that it is in the outside air position.

(1) RFTA= Fully automatic air conditioning.

Test procedure.When all these conditions are met, proceed in the following order:

� Measure the temperature in the workshop approx. one metre in front of

the vehicle’s air inlet grille.

� Start the engine

(without the air conditioning, or the blower, operating)and wait for the cooling fan slow speed to trigger (should the engine tem�

perature not rise sufficiently, it is permissable to increase the engine

speed to 2000 rpm)

.

� Once it is sufficiently hot in the engine compartment, return the engine

to idle and commence the test.Switch on the air conditioning and adjust the engine speed to

2500 rpm.

In an ambient temperature of 40°C, the engine speed will be brought

down to 2000 rpm, in order for the pressure safety threshold to cut off the

compressor.

For further temperatures/pressures: see Tables and Graphs on following

pages

221, 222 and 226.

After

3 minutesof operation, note down the following 3 parameters:

� The temperature of the blown air coming out of the 2 central air vents

(take the average).

� The high pressure, via the intermediary of the clickfit union (at the

pressure reducer inlet).

� The low pressure, via the intermediary of the clickfit union (at the pressure

reducer outlet).NOTE:The low and high pressures are absolute pressures.

When measuring the blown air temperatures, avoid any contact between

the thermocouple and the air vents.

At the conclusion of the test involving vehicles with

«RFTA»

ALL TYPES