Citroen C3 2017 2.G Owner's Manual

Manufacturer: CITROEN, Model Year: 2017, Model line: C3, Model: Citroen C3 2017 2.GPages: 450, PDF Size: 10.11 MB

Page 221 of 450

219

B618_en_Chap07_info-pratiques_ed01-2016

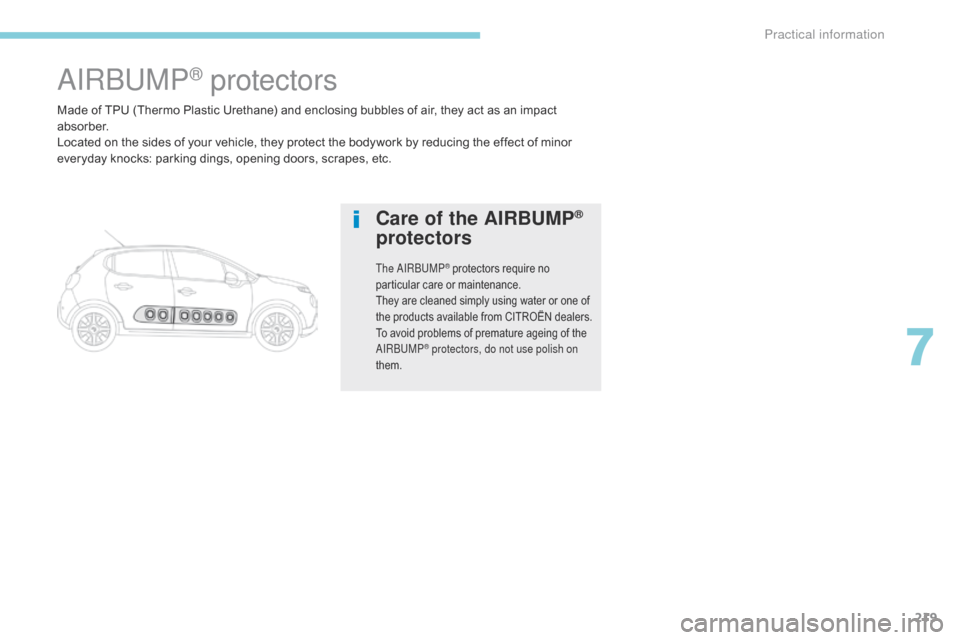

Made of TPU (Thermo Plastic Urethane) and enclosing bubbles of air, they act as an impact

a b s o r b e r.

Located on the sides of your vehicle, they protect the bodywork by reducing the effect of minor

everyday knocks: parking dings, opening doors, scrapes, etc.

AIRBUMP® protectors

Care of the AIRBUMP®

protectors

The AIRBUMP® protectors require no

particular care or maintenance.

They are cleaned simply using water or one of

the products available from CITROËN dealers.

To avoid problems of premature ageing of the

AIRBUMP

® protectors, do not use polish on

them.

7

Practical information

Page 222 of 450

220

B618_en_Chap08_En-cas-de-panne_ed01-2016

Warning triangle

The triangle can be stored on the rear face of

the boot, secured by straps.

Assembling the triangle

As a safety precaution, before leaving your

vehicle to set up and install the triangle, switch

on the hazard warning lamps and put on your

high visibility vest.Refer to the instructions provided with the

triangle.

Positioning the triangle

Running out of fuel

(Diesel)

On vehicles fitted with Diesel engines, the fuel

system must be primed if you run out of fuel. For more information on Misfuel

prevention (Diesel) , refer to the

corresponding section.

If the engine does not start first

time, don't keep trying, but start the

procedure again from the beginning.

BlueHDi engines

F Fill the fuel tank with at least five litres of Diesel.

F

S

witch on the ignition (without starting the

engine).

F

W

ait around 6 seconds and switch off the

ignition.

F

R

epeat the operation 10 times.

F

O

perate the starter to run the engine.

F

P

lace the triangle behind the vehicle, as

required by local legislation.

Other HDi engines

(except BlueHDi version)

F A dd at least five litres of Diesel fuel to the

tank.

F

O

pen the bonnet.

F

I

f necessary, unclip the styling cover for

access to the priming pump.

F

S

queeze and release the priming pump

repeatedly until resistance is felt (there

may be resistance at the first press).

F

O

perate the starter to start the engine

(if the engine does not start at the first

attempt, wait around 15 seconds before

trying again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again

then start the engine.

F

R

efit the styling cover and clip it in place.

F

C

lose the bonnet.

In the event of a breakdown

Page 223 of 450

221

B618_en_Chap08_En-cas-de-panne_ed01-2016

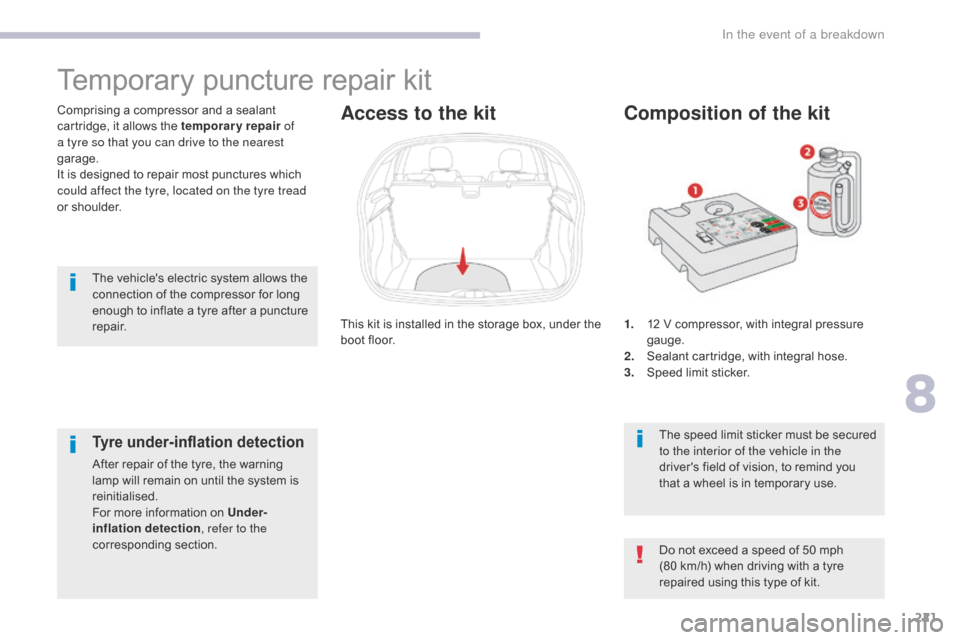

1. 12 V compressor, with integral pressure gauge.

2.

S

ealant cartridge, with integral hose.

3.

S

peed limit sticker.

Composition of the kit

The speed limit sticker must be secured

to the interior of the vehicle in the

driver's field of vision, to remind you

that a wheel is in temporary use.

The vehicle's electric system allows the

connection of the compressor for long

enough to inflate a tyre after a puncture

repair.

This kit is installed in the storage box, under the

boot floor.

Comprising a compressor and a sealant

cartridge, it allows the temporary repair

of

a tyre so that you can drive to the nearest

garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

Temporary puncture repair kit

Access to the kit

Do not exceed a speed of 50 mph

(80 km/h) when driving with a tyre

repaired using this type of kit.

Tyre under-inflation detection

After repair of the tyre, the warning

lamp will remain on until the system is

reinitialised.

For more information on Under-

inflation detection , refer to the

corresponding section.

8

In the event of a breakdown

Page 224 of 450

222

B618_en_Chap08_En-cas-de-panne_ed01-2016

F Switch off the ignition.

F S ecure the speed limit sticker inside the

vehicle.

Repair procedure

Avoid removing any foreign bodies

which have penetrated into the tyre. F

T

urn the sealant cartridge and secure it in

the cut-out provided on the compressor. F

R

emove the valve cap from the tyre to be

repaired, and place it in a clean area.

F

C

onnect the hose from the sealant

cartridge to the valve of the tyre to be

repaired and tighten firmly.

F

U

ncoil the pipe stowed under the

compressor.

F

C

onnect the pipe from the compressor to

the sealant cartridge.

In the event of a breakdown

Page 225 of 450

223

B618_en_Chap08_En-cas-de-panne_ed01-2016

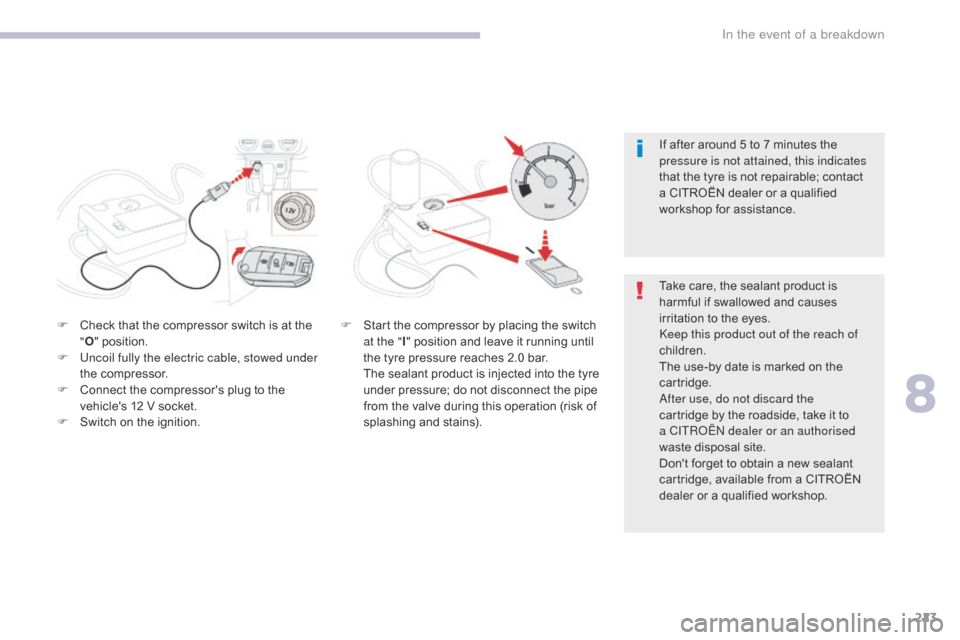

F Check that the compressor switch is at the "O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

F

C

onnect the compressor's plug to the

vehicle's 12 V socket.

F

S

witch on the ignition. If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a CITROËN dealer or a qualified

workshop for assistance.

F S tart the compressor by placing the switch

at the " I" position and leave it running until

the tyre pressure reaches 2.0 bar.

T

he sealant product is injected into the tyre

under pressure; do not disconnect the pipe

from the valve during this operation (risk of

splashing and stains). Take care, the sealant product is

harmful if swallowed and causes

irritation to the eyes.

Keep this product out of the reach of

children.

The use-by date is marked on the

cartridge.

After use, do not discard the

cartridge by the roadside, take it to

a CITROËN

dealer or an authorised

waste disposal site.

Don't forget to obtain a new sealant

cartridge, available from a CITROËN

dealer or a qualified workshop.

8

In the event of a breakdown

Page 226 of 450

224

B618_en_Chap08_En-cas-de-panne_ed01-2016

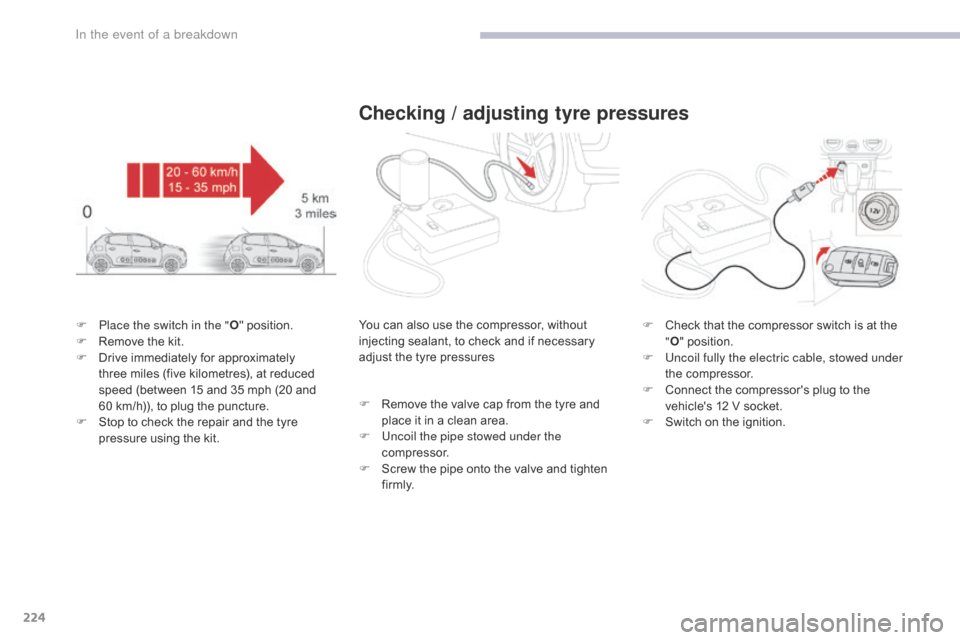

F Place the switch in the "O" position.

F R emove the kit.

F

D

rive immediately for approximately

three miles (five kilometres), at reduced

speed (between 15 and 35 mph (20 and

60

km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

pressure using the kit.

Checking / adjusting tyre pressures

You can also use the compressor, without

injecting sealant, to check and if necessary

adjust the tyre pressures

F

R

emove the valve cap from the tyre and

place it in a clean area.

F

U

ncoil the pipe stowed under the

compressor.

F

S

crew the pipe onto the valve and tighten

f i r m l y. F

C heck that the compressor switch is at the

" O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

F

C

onnect the compressor's plug to the

vehicle's 12 V socket.

F

S

witch on the ignition.

In the event of a breakdown

Page 227 of 450

225

B618_en_Chap08_En-cas-de-panne_ed01-2016

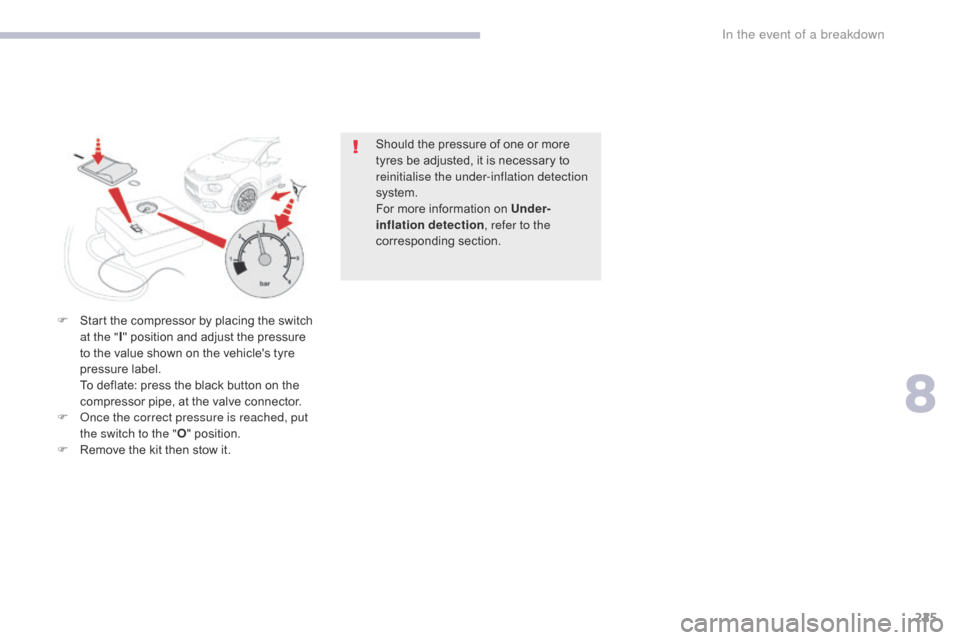

Should the pressure of one or more

tyres be adjusted, it is necessary to

reinitialise the under-inflation detection

system.

For more information on Under-

inflation detection, refer to the

corresponding section.

F

S

tart the compressor by placing the switch

at the " I" position and adjust the pressure

to the value shown on the vehicle's tyre

pressure label.

T

o deflate: press the black button on the

compressor pipe, at the valve connector.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

8

In the event of a breakdown

Page 228 of 450

226

B618_en_Chap08_En-cas-de-panne_ed01-2016

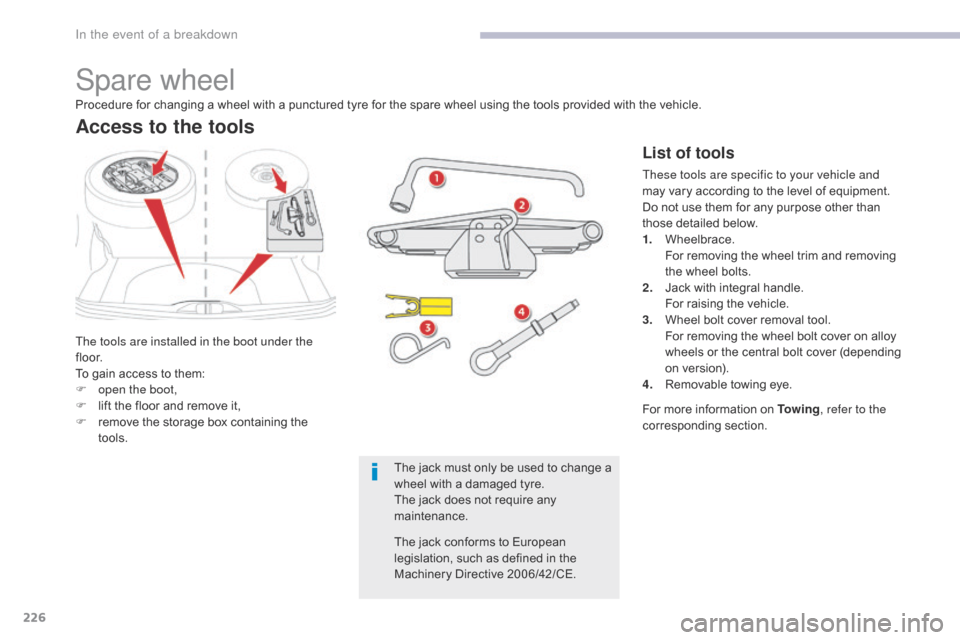

Spare wheel

The tools are installed in the boot under the

f l o o r.

To gain access to them:

F

o

pen the boot,

F

l

ift the floor and remove it,

F

r

emove the storage box containing the

tools.

Access to the tools

List of tools

These tools are specific to your vehicle and

may vary according to the level of equipment.

Do not use them for any purpose other than

those detailed below.

1.

W

heelbrace.

F

or removing the wheel trim and removing

the wheel bolts.

2.

J

ack with integral handle.

F

or raising the vehicle.

3.

W

heel bolt cover removal tool.

F

or removing the wheel bolt cover on alloy

wheels or the central bolt cover (depending

on version).

4.

R

emovable towing eye.

Procedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

For more information on To w i n g, refer to the

corresponding section.

The jack must only be used to change a

wheel with a damaged tyre.

The jack does not require any

maintenance.

The jack conforms to European

legislation, such as defined in the

Machinery Directive 2006/42/CE.

In the event of a breakdown

Page 229 of 450

227

B618_en_Chap08_En-cas-de-panne_ed01-2016

Taking out the wheel

F Unclip the tool storage box (standard spare wheel).

F

U

nscrew the central nut.

F

R

emove the fixing parts (nut and bolt).

F

R

aise the spare wheel towards you from

the rear.

F

T

ake the wheel out of the boot.

The spare wheel is installed in the boot under

the floor.

Depending on engine, the spare wheel is

a standard wheel or the space-saver type

(BlueHDi).

Access to the spare wheel

8

In the event of a breakdown

Page 230 of 450

228

B618_en_Chap08_En-cas-de-panne_ed01-2016

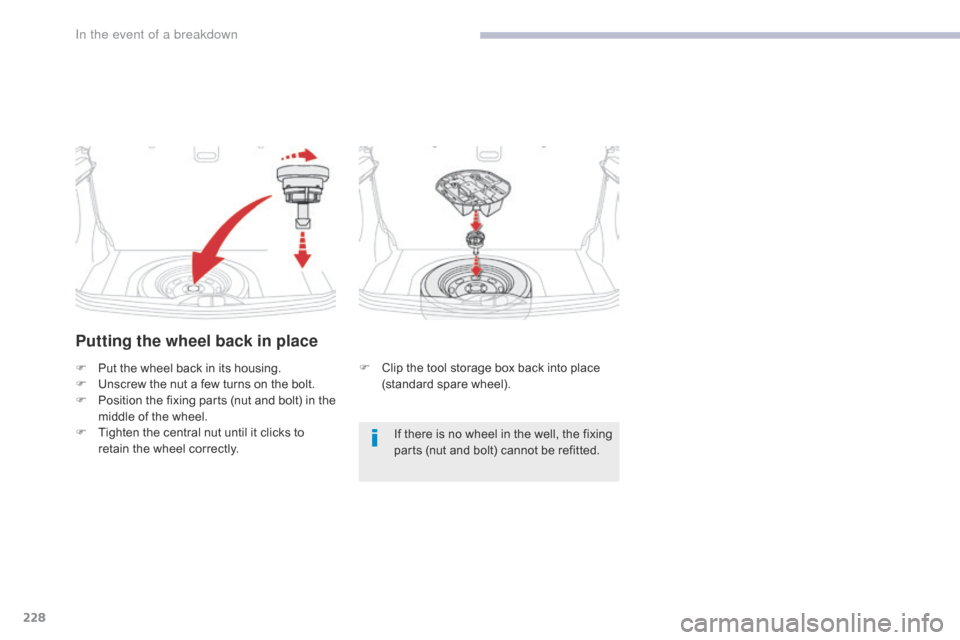

Putting the wheel back in place

F Put the wheel back in its housing.

F U nscrew the nut a few turns on the bolt.

F

P

osition the fixing parts (nut and bolt) in the

middle of the wheel.

F

T

ighten the central nut until it clicks to

retain the wheel correctly. F

C lip the tool storage box back into place

(standard spare wheel).

If there is no wheel in the well, the fixing

parts (nut and bolt) cannot be refitted.

In the event of a breakdown