tow CITROEN C3 PICASSO 2017 Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2017, Model line: C3 PICASSO, Model: CITROEN C3 PICASSO 2017Pages: 292, PDF Size: 8.23 MB

Page 151 of 292

149

C3Picasso_en_Chap10_verification_ed01-2015

Parking brake

If excessive travel or a loss of

effectiveness of this system is

noticed, the parking brake must be

checked, even between two services.

Manual gearbox

The gearbox does not require any

maintenance (no oil change).

Refer to the manufacturer's service

schedule for the checking interval for

this component.For information on checking brake

disc wear, contact a CITROËN dealer

or a qualified workshop.

Brake disc wear

Brake wear depends on the style

of driving, particularly in the case

of vehicles used in town, over short

distances. It may be necessary to have

the condition of the brakes checked,

even between vehicle services.

Brake pads

The gearbox does not require any

maintenance (no oil change).

Refer to the manufacturer's service

schedule for details of the checking

interval for this component.

Electronic gearboxOnly use products recommended by

CITROËN or products of equivalent

quality and specification.

In order to optimise the operation of

units as important as those in the

braking system, CITROËN selects and

offers very specific products.

After washing the vehicle, dampness,

or in wintry conditions, ice can form

on the brake discs and pads: braking

efficiency may be reduced. Make light

brake applications to dry and defrost

the brakes.

Checking this system must be done by a

CITROËN dealer or a qualified workshop.

Unless there is a leak in the circuit, a drop in

the brake fluid level indicates that the brake

pads are worn.

10

Checks

Page 153 of 292

151

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

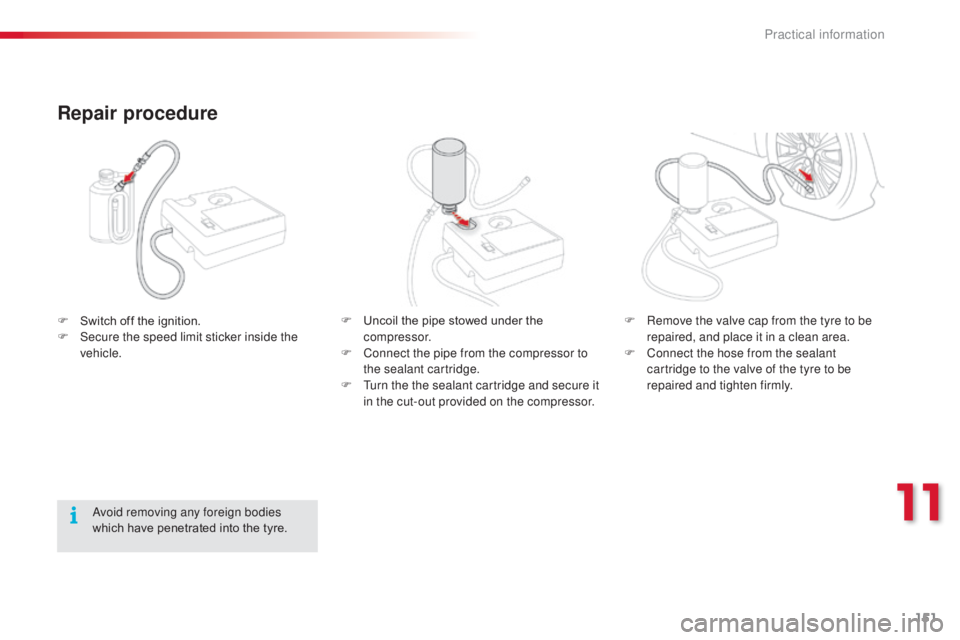

F Switch off the ignition.

F S ecure the speed limit sticker inside the

vehicle. F

U ncoil the pipe stowed under the

compressor.

F

C

onnect the pipe from the compressor to

the sealant cartridge.

F

T

urn the the sealant cartridge and secure it

in the cut-out provided on the compressor.

Avoid removing any foreign bodies

which have penetrated into the tyre. F

R emove the valve cap from the tyre to be

repaired, and place it in a clean area.

F

C

onnect the hose from the sealant

cartridge to the valve of the tyre to be

repaired and tighten firmly.

Repair procedure

11

Practical information

Page 154 of 292

152

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

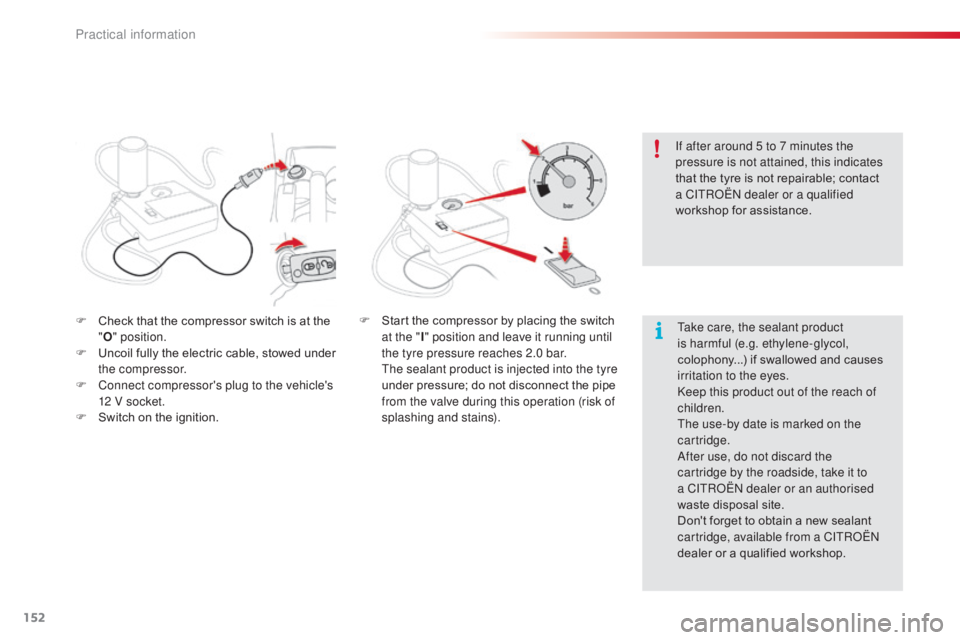

F Check that the compressor switch is at the "O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

F

C

onnect compressor's plug to the vehicle's

12 V socket.

F

S

witch on the ignition. Take care, the sealant product

is harmful (e.g. ethylene-glycol,

colophony...) if swallowed and causes

irritation to the eyes.

Keep this product out of the reach of

children.

The use-by date is marked on the

cartridge.

After use, do not discard the

cartridge by the roadside, take it to

a CITROËN

dealer or an authorised

waste disposal site.

Don't forget to obtain a new sealant

cartridge, available from a CITROËN

dealer or a qualified workshop.

F

S tart the compressor by placing the switch

at the " I" position and leave it running until

the tyre pressure reaches 2.0 bar.

T

he sealant product is injected into the tyre

under pressure; do not disconnect the pipe

from the valve during this operation (risk of

splashing and stains). If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a CITROËN dealer or a qualified

workshop for assistance.

Practical information

Page 155 of 292

153

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

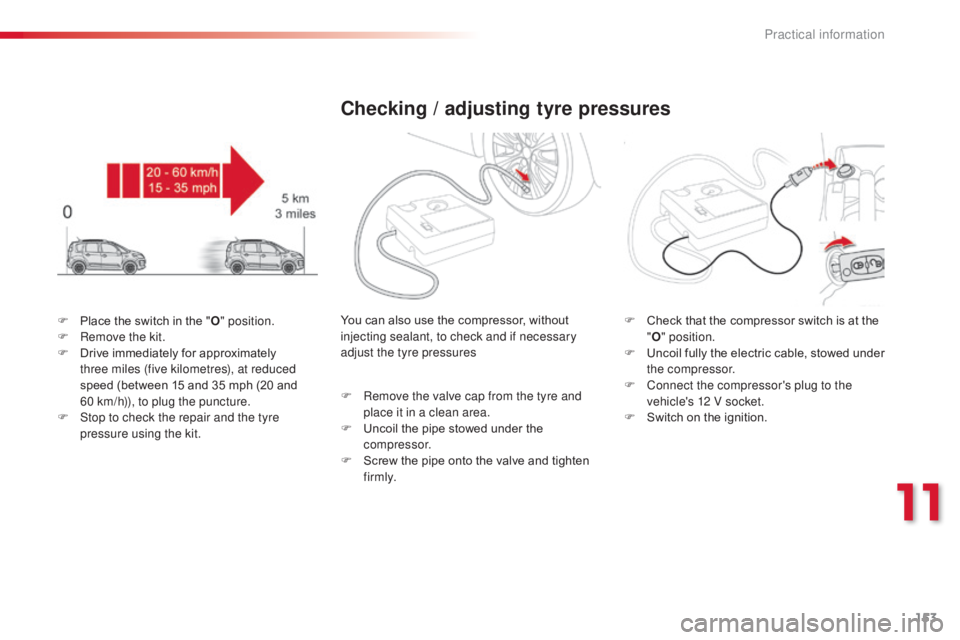

F Place the switch in the "O" position.

F R emove the kit.

F

D

rive immediately for approximately

three miles (five kilometres), at reduced

speed (between 15 and 35 mph (20 and

60

km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

pressure using the kit.

Checking / adjusting tyre pressures

You can also use the compressor, without

injecting sealant, to check and if necessary

adjust the tyre pressures

F

R

emove the valve cap from the tyre and

place it in a clean area.

F

U

ncoil the pipe stowed under the

compressor.

F

S

crew the pipe onto the valve and tighten

f i r m l y. F

C heck that the compressor switch is at the

" O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

F

C

onnect the compressor's plug to the

vehicle's 12 V socket.

F

S

witch on the ignition.

11

Practical information

Page 156 of 292

154

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

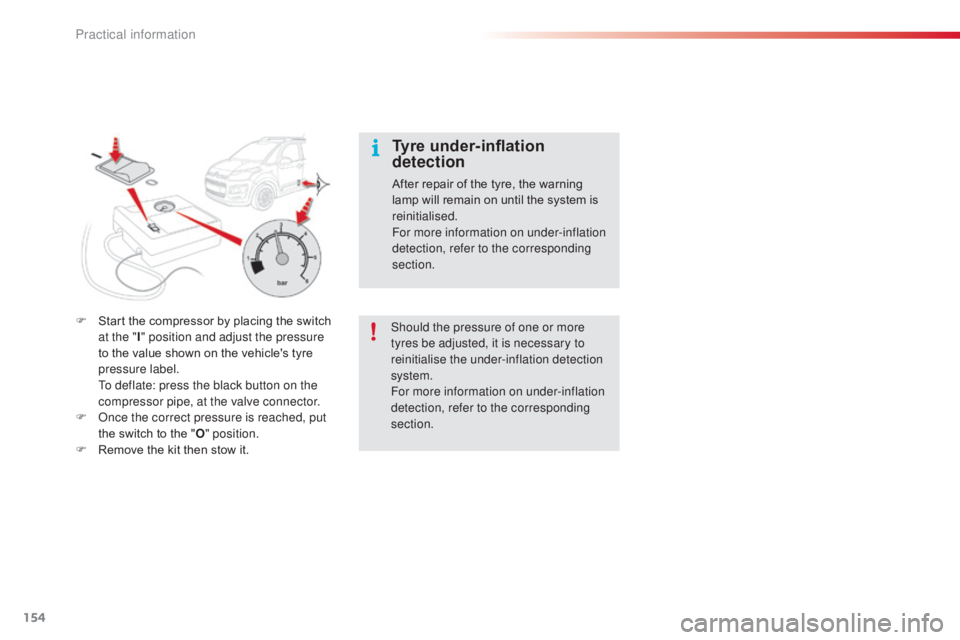

F Start the compressor by placing the switch at the " I" position and adjust the pressure

to the value shown on the vehicle's tyre

pressure label.

T

o deflate: press the black button on the

compressor pipe, at the valve connector.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

Tyre under-inflation

detection

After repair of the tyre, the warning

lamp will remain on until the system is

reinitialised.

For more information on under-inflation

detection, refer to the corresponding

section.

Should the pressure of one or more

tyres be adjusted, it is necessary to

reinitialise the under-inflation detection

system.

For more information on under-inflation

detection, refer to the corresponding

section.

Practical information

Page 157 of 292

155

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

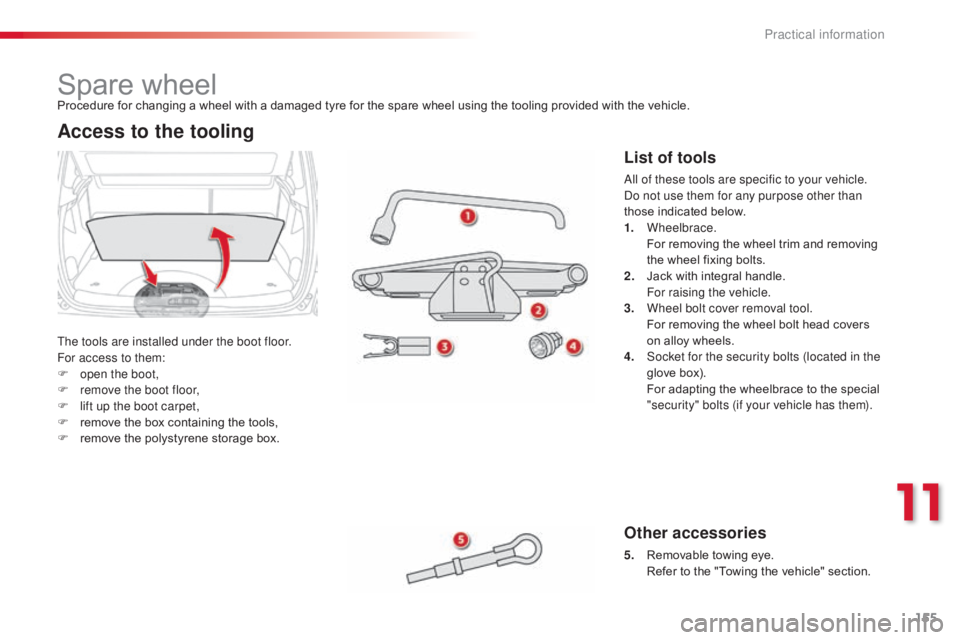

Spare wheel

The tools are installed under the boot floor.

For access to them:

F

o

pen the boot,

F

r

emove the boot floor,

F

l

ift up the boot carpet,

F

r

emove the box containing the tools,

F

r

emove the polystyrene storage box.

Other accessories

5. Removable towing eye. R

efer to the "Towing the vehicle" section.

Access to the tooling

Procedure for changing a wheel with a damaged tyre for the spare wheel using the tooling provided with the vehicle.

List of tools

All of these tools are specific to your vehicle.

Do not use them for any purpose other than

those indicated below.

1.

Wheelbrace.

F

or removing the wheel trim and removing

the wheel fixing bolts.

2.

J

ack with integral handle.

F

or raising the vehicle.

3.

W

heel bolt cover removal tool.

F

or removing the wheel bolt head covers

on alloy wheels.

4.

S

ocket for the security bolts (located in the

glove box).

F

or adapting the wheelbrace to the special

"security" bolts (if your vehicle has them).

11

Practical information

Page 159 of 292

157

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

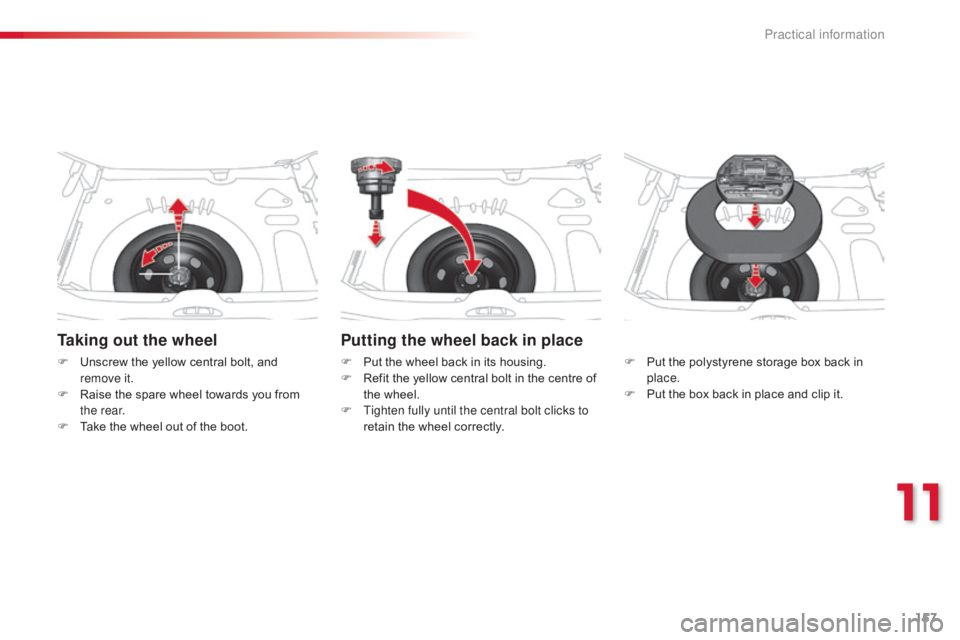

Taking out the wheel

F Unscrew the yellow central bolt, and remove it.

F

R

aise the spare wheel towards you from

the rear.

F

T

ake the wheel out of the boot.

Putting the wheel back in place

F Put the wheel back in its housing.

F R efit the yellow central bolt in the centre of

the wheel.

F

T

ighten fully until the central bolt clicks to

retain the wheel correctly. F

P ut the polystyrene storage box back in

place.

F

P

ut the box back in place and clip it.

11

Practical information

Page 162 of 292

160

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

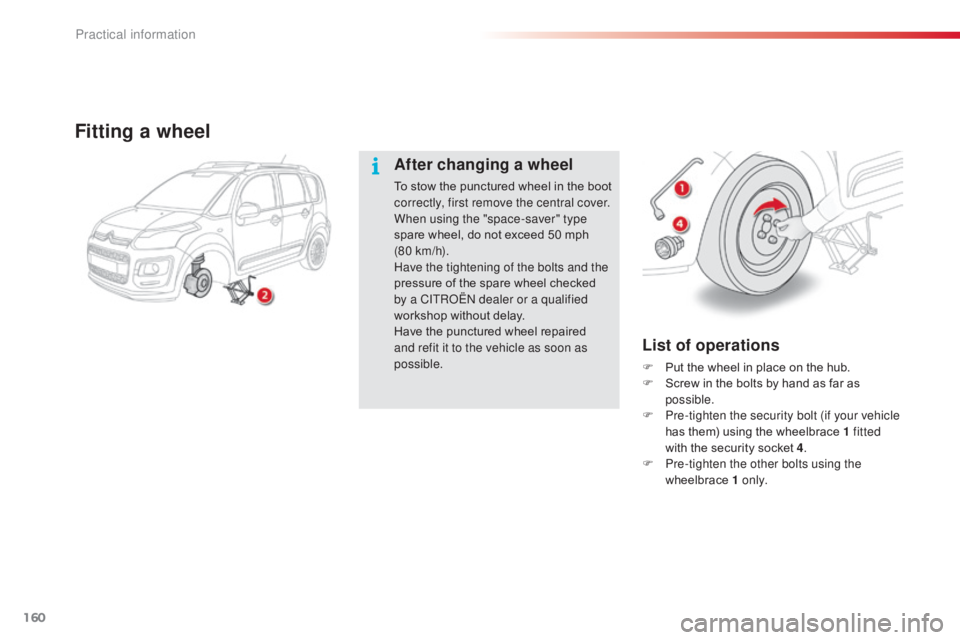

List of operations

F Put the wheel in place on the hub.

F S crew in the bolts by hand as far as

possible.

F

P

re-tighten the security bolt (if your vehicle

has them) using the wheelbrace 1 fitted

with the security socket 4 .

F

P

re-tighten the other bolts using the

wheelbrace 1 o n l y.

Fitting a wheel

After changing a wheel

To stow the punctured wheel in the boot

correctly, first remove the central cover.

When using the "space-saver" type

spare wheel, do not exceed 50 mph

(80

km/h).

Have the tightening of the bolts and the

pressure of the spare wheel checked

by a CITROËN dealer or a qualified

workshop without delay.

Have the punctured wheel repaired

and refit it to the vehicle as soon as

possible.

Practical information

Page 163 of 292

161

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

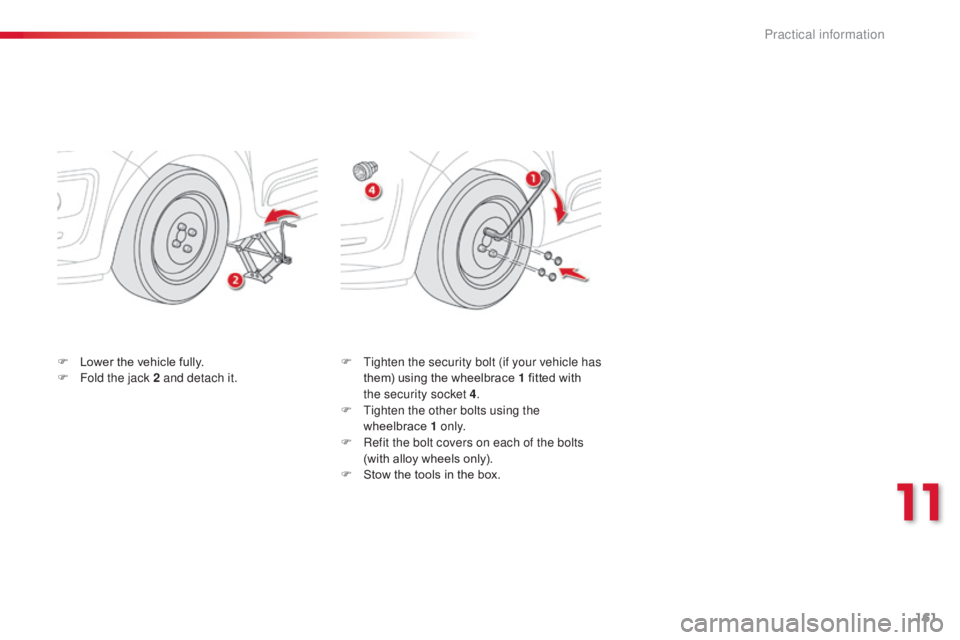

F Tighten the security bolt (if your vehicle has them) using the wheelbrace 1 fitted with

the security socket 4 .

F

T

ighten the other bolts using the

wheelbrace 1 o n l y.

F

R

efit the bolt covers on each of the bolts

(with alloy wheels only).

F

S

tow the tools in the box.

F

L

ower the vehicle fully.

F

F

old the jack 2 and detach it.

11

Practical information

Page 172 of 292

170

C3Picasso_en_Chap11_informations-pratiques_ed01-2015

Changing a bulbProcedure for replacing a faulty bulb with a new bulb.1.

D

irection indicators (H21W amber).

2.

D

ipped beam headlamps (H7-55W).

3.

M

ain beam headlamps (H1-55W).

4.

S

idelamps (W5W).

5.

F

oglamps (PSX24W).

6.

L

ED daytime running lamps.

Front lampsThe headlamps are fitted with

polycarbonate glass with a protective

coating:

F

d

o not clean them using a dr y

or abrasive cloth, nor with a

detergent or solvent product,

F

u

se a sponge and soapy water or a

pH neutral product,

F

w

hen using a high pressure washer

on persistent marks, do not keep

the lance directed towards the

lamps or their edges for too long,

so as not to damage their protective

coating and seals. Changing a bulb should only be done

after the headlamp has been switched

off for several minutes (risk of serious

burns).

F

D

o not touch the bulb directly with

your fingers, use a lint-free cloth.

It is imperative to use only anti-

ultraviolet (UV) type bulbs to avoid

damaging the headlamp.

Always replace a failed bulb with a

new bulb with the same type and

specification.

Practical information