ignition Citroen C3 RHD 2017 2.G Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2017, Model line: C3 RHD, Model: Citroen C3 RHD 2017 2.GPages: 442, PDF Size: 9.75 MB

Page 207 of 442

205

After topping up the oil, the check when

switching on the ignition with the oil

level indicator in the instrument panel

is not valid during the 30 minutes after

topping up.

Topping up the engine oil level

The location of the oil filler cap is shown in the

corresponding underbonnet layout view.

F

U

nscrew the oil filler cap to reveal the filler

aperture.

F

A

dd oil in small quantities, avoiding any

spills on engine components (risk of fire).

F

W

ait a few minutes before checking the

level again using the dipstick.

F

A

dd more oil if necessary.

F

A

fter checking the level, carefully refit the

oil filler cap and the dipstick in its tube.

Engine oil change

Refer to the manufacturer's service schedule

for details of the interval for this operation.

In order to maintain the reliability of the engine

and emission control system, never use

additives in the engine oil. The brake fluid level should be close

to the "MA X" mark. If it is not, check

the brake pad wear.

Brake fluid level

Changing the fluid

Refer to the manufacturer's service schedule

for details of the interval for this operation.

Fluid specification

The brake fluid must conform to the

manufacturer's recommendations.

7

Practical information

Page 214 of 442

212

Recommendations on storage

Never store bottles of AdBlue® in your

vehicle.

Procedure

Park the vehicle

F Switch off the ignition and remove the key from the switch to switch off the engine.

or

F

W

ith Keyless Entry and Starting, press the

" START/STOP " button to switch off the

engine.

AdBlue

® freezes at about -11°C and

deteriorates above 25°C. It is recommended

that bottles be stored in a cool area and

protected from direct sunlight .

Under these conditions, the fluid can be kept

for at least a year .

If the additive has frozen, it can be used once it

has completely thawed out. Before topping up, ensure that the vehicle is

parked on a flat and level sur face.

In wintry conditions, ensure that the

temperature of the vehicle is above -11°C.

Otherwise the AdBlue

® may be frozen and

so cannot be poured into its tank. Park your

vehicle in a warmer area for a few hours to

allow the top-up to be carried out.

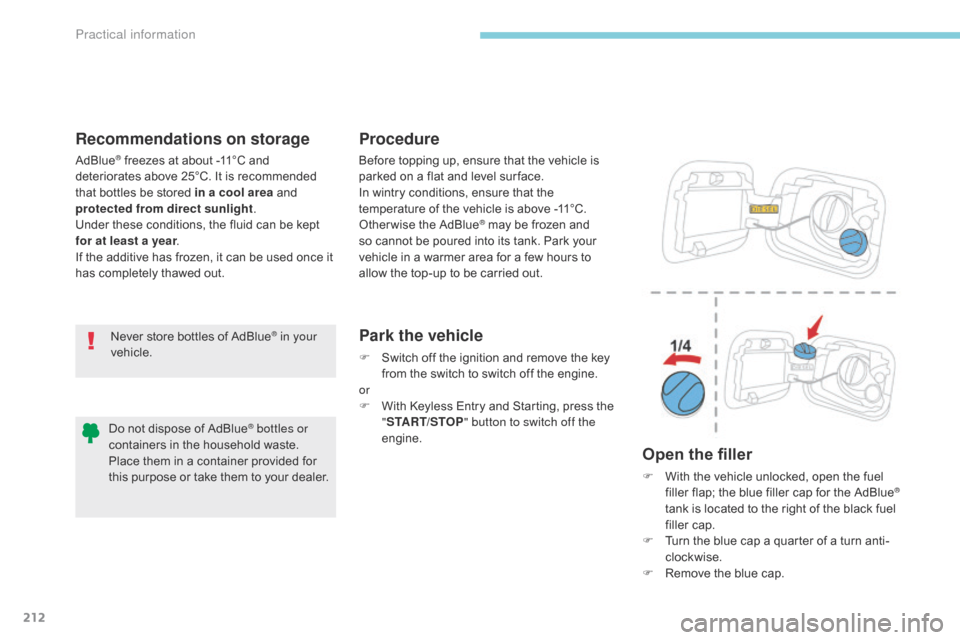

Open the filler

F With the vehicle unlocked, open the fuel filler flap; the blue filler cap for the AdBlue®

tank is located to the right of the black fuel

filler cap.

F

T

urn the blue cap a quarter of a turn anti-

clockwise.

F

R

emove the blue cap.

Do not dispose of AdBlue

® bottles or

containers in the household waste.

Place them in a container provided for

this purpose or take them to your dealer.

Practical information

Page 215 of 442

213

To p u p

F Obtain a bottle of AdBlue®. After first

checking the use-by date , read carefully

the instructions on use on the label before

pouring the contents of the bottle into your

vehicle's AdBlue

® tank.

Important : if your vehicle's AdBlue

®

tank is completely empty

- which is

confirmed by the alert messages and

the impossibility of starting the engine

-

you must add at least 4 litres and no

more than 10 litres. If any fluid is spilt or splashed, wash

immediately with cold water or wipe with

a damp cloth.

If the fluid has crystallised, clean it off

using a sponge and hot water.

Important:

when topping up after

running out of AdBlue , signalled

by the message " To p up AdBlue:

starting impossible ", you must wait for

about 5 minutes before switching the

ignition on again, without opening the

driver's door, unlocking the vehicle,

introducing the remote control key

into the ignition switch, or placing

the Keyless Entr y and Star ting

electronic key inside the vehicle.

Switch on the ignition, then wait for

10 seconds before starting the engine.

F

A

fter emptying the bottle, wipe away any

spillage around the tank filler using a damp

cloth.

Refit the filler cap

F Refit the blue cap and turn it a quarter of a turn clockwise, to its stop.

F

C

lose the filler flap.

7

Practical information

Page 217 of 442

215

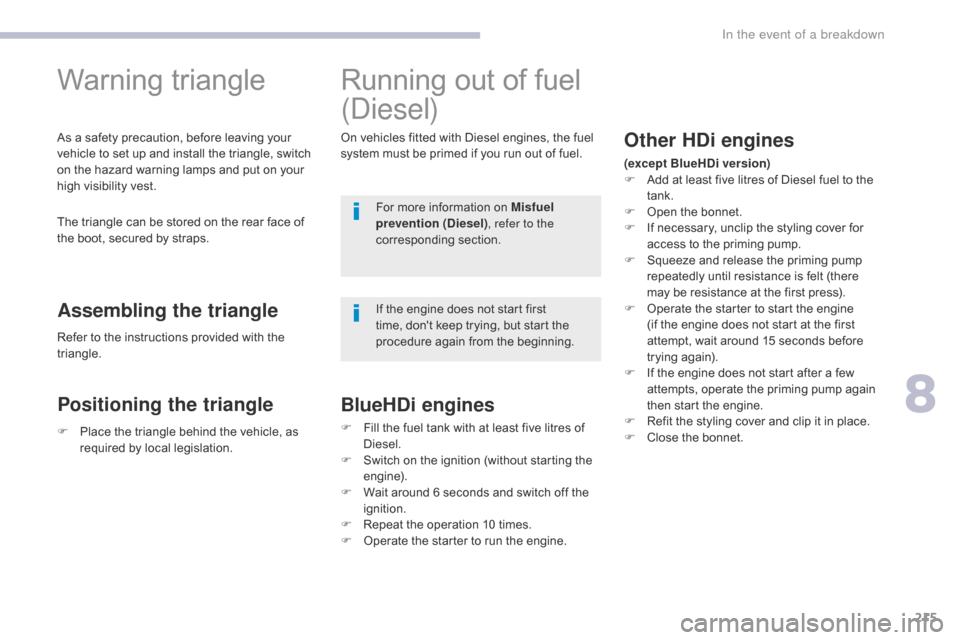

Warning triangle

The triangle can be stored on the rear face of

the boot, secured by straps.

Assembling the triangle

As a safety precaution, before leaving your

vehicle to set up and install the triangle, switch

on the hazard warning lamps and put on your

high visibility vest.Refer to the instructions provided with the

triangle.

Positioning the triangle

Running out of fuel

(Diesel)

On vehicles fitted with Diesel engines, the fuel

system must be primed if you run out of fuel. For more information on Misfuel

prevention (Diesel) , refer to the

corresponding section.

If the engine does not start first

time, don't keep trying, but start the

procedure again from the beginning.

BlueHDi engines

F Fill the fuel tank with at least five litres of Diesel.

F

S

witch on the ignition (without starting the

engine).

F

W

ait around 6 seconds and switch off the

ignition.

F

R

epeat the operation 10 times.

F

O

perate the starter to run the engine.

F

P

lace the triangle behind the vehicle, as

required by local legislation.

Other HDi engines

(except BlueHDi version)

F A dd at least five litres of Diesel fuel to the

tank.

F

O

pen the bonnet.

F

I

f necessary, unclip the styling cover for

access to the priming pump.

F

S

queeze and release the priming pump

repeatedly until resistance is felt (there

may be resistance at the first press).

F

O

perate the starter to start the engine

(if the engine does not start at the first

attempt, wait around 15 seconds before

trying again).

F

I

f the engine does not start after a few

attempts, operate the priming pump again

then start the engine.

F

R

efit the styling cover and clip it in place.

F

C

lose the bonnet.

8

In the event of a breakdown

Page 219 of 442

217

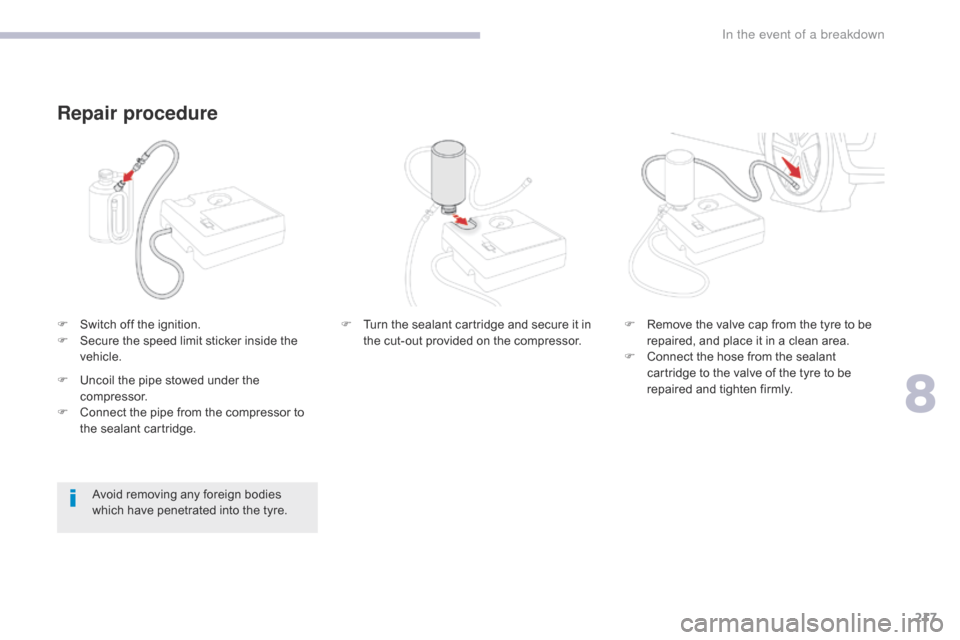

F Switch off the ignition.

F S ecure the speed limit sticker inside the

vehicle.

Repair procedure

Avoid removing any foreign bodies

which have penetrated into the tyre. F

T

urn the sealant cartridge and secure it in

the cut-out provided on the compressor. F

R

emove the valve cap from the tyre to be

repaired, and place it in a clean area.

F

C

onnect the hose from the sealant

cartridge to the valve of the tyre to be

repaired and tighten firmly.

F

U

ncoil the pipe stowed under the

compressor.

F

C

onnect the pipe from the compressor to

the sealant cartridge.

8

In the event of a breakdown

Page 220 of 442

218

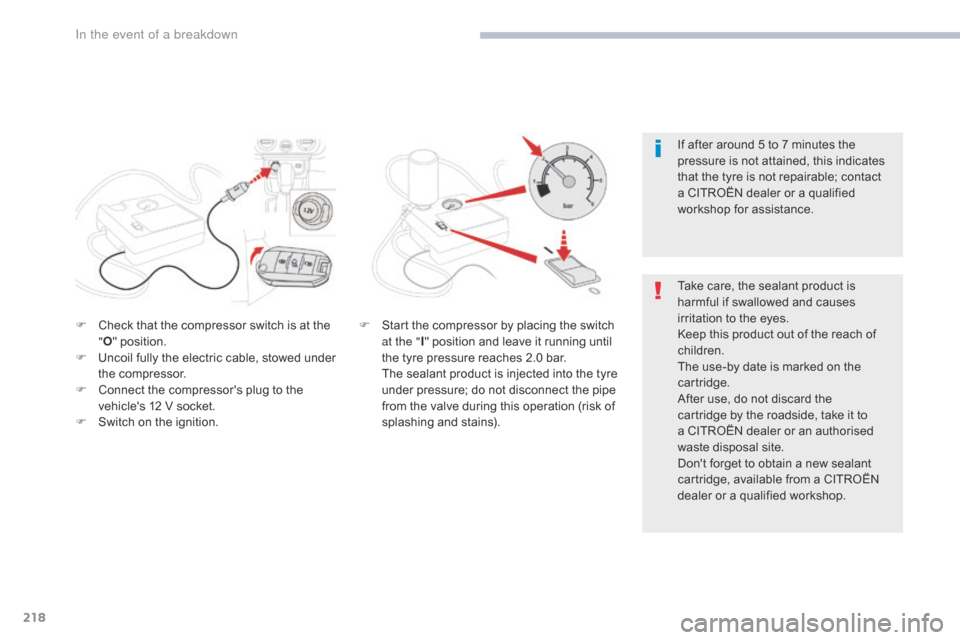

F Check that the compressor switch is at the "O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

F

C

onnect the compressor's plug to the

vehicle's 12 V socket.

F

S

witch on the ignition. If after around 5 to 7 minutes the

pressure is not attained, this indicates

that the tyre is not repairable; contact

a CITROËN dealer or a qualified

workshop for assistance.

F S tart the compressor by placing the switch

at the " I" position and leave it running until

the tyre pressure reaches 2.0 bar.

T

he sealant product is injected into the tyre

under pressure; do not disconnect the pipe

from the valve during this operation (risk of

splashing and stains). Take care, the sealant product is

harmful if swallowed and causes

irritation to the eyes.

Keep this product out of the reach of

children.

The use-by date is marked on the

cartridge.

After use, do not discard the

cartridge by the roadside, take it to

a CITROËN

dealer or an authorised

waste disposal site.

Don't forget to obtain a new sealant

cartridge, available from a CITROËN

dealer or a qualified workshop.

In the event of a breakdown

Page 221 of 442

219

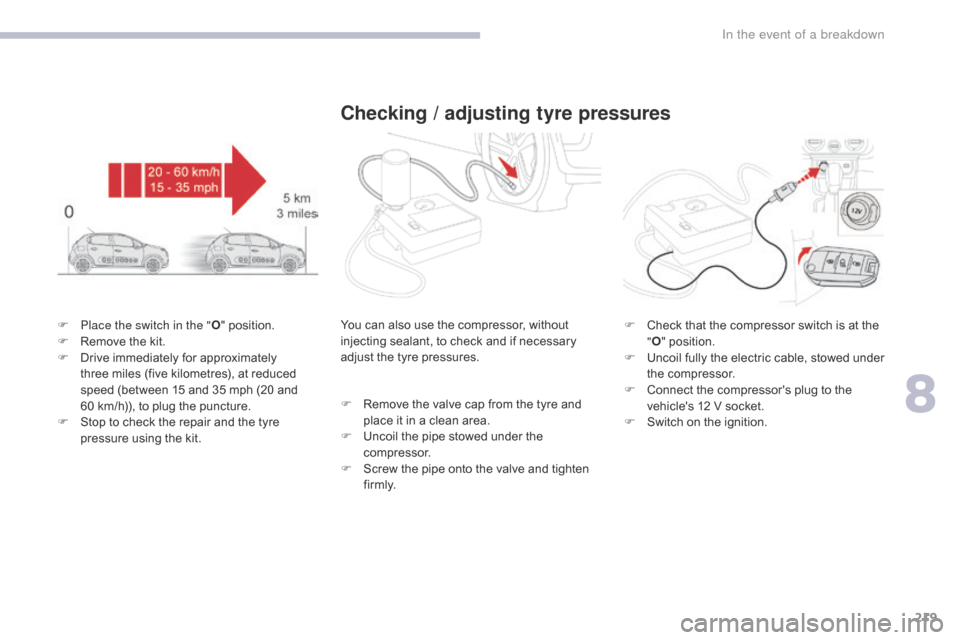

F Place the switch in the "O" position.

F R emove the kit.

F

D

rive immediately for approximately

three miles (five kilometres), at reduced

speed (between 15 and 35 mph (20 and

60

km/h)), to plug the puncture.

F

S

top to check the repair and the tyre

pressure using the kit.

Checking / adjusting tyre pressures

You can also use the compressor, without

injecting sealant, to check and if necessary

adjust the tyre pressures.

F

R

emove the valve cap from the tyre and

place it in a clean area.

F

U

ncoil the pipe stowed under the

compressor.

F

S

crew the pipe onto the valve and tighten

f i r m l y. F

C heck that the compressor switch is at the

" O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

F

C

onnect the compressor's plug to the

vehicle's 12 V socket.

F

S

witch on the ignition.

8

In the event of a breakdown

Page 226 of 442

224

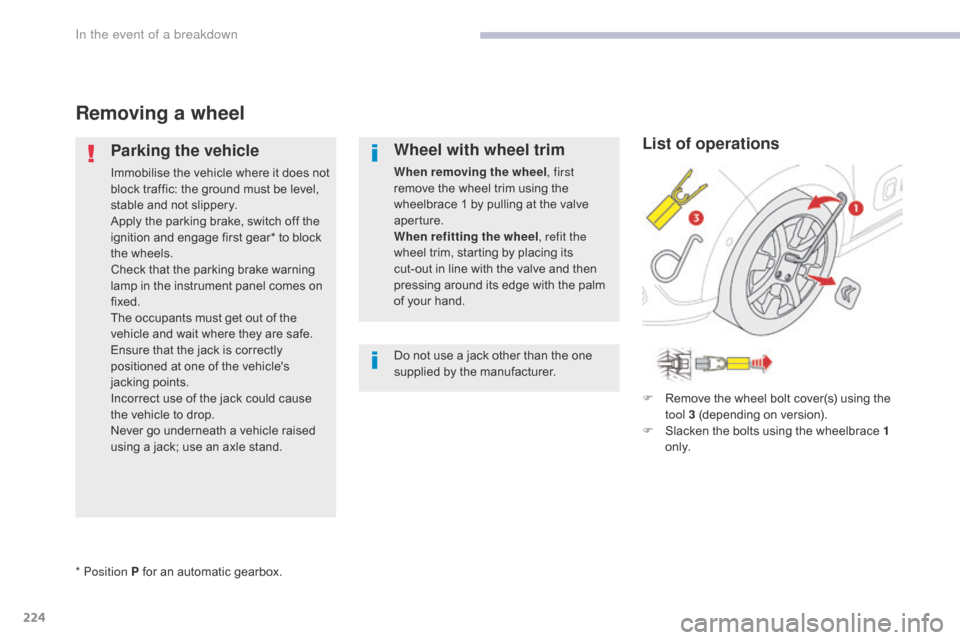

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does not

block traffic: the ground must be level,

stable and not slippery.

Apply the parking brake, switch off the

ignition and engage first gear* to block

the wheels.

Check that the parking brake warning

lamp in the instrument panel comes on

fixed.

The occupants must get out of the

vehicle and wait where they are safe.

Ensure that the jack is correctly

positioned at one of the vehicle's

jacking points.

Incorrect use of the jack could cause

the vehicle to drop.

Never go underneath a vehicle raised

using a jack; use an axle stand.

Wheel with wheel trim

When removing the wheel, first

remove the wheel trim using the

wheelbrace 1 by pulling at the valve

aperture.

When refitting the wheel , refit the

wheel trim, starting by placing its

cut-out in line with the valve and then

pressing around its edge with the palm

of your hand.

Do not use a jack other than the one

supplied by the manufacturer.

* Position P for an automatic gearbox. F

R

emove the wheel bolt cover(s) using the

tool 3 (depending on version).

F

S

lacken the bolts using the wheelbrace 1

o n l y.

List of operations

In the event of a breakdown

Page 238 of 442

236

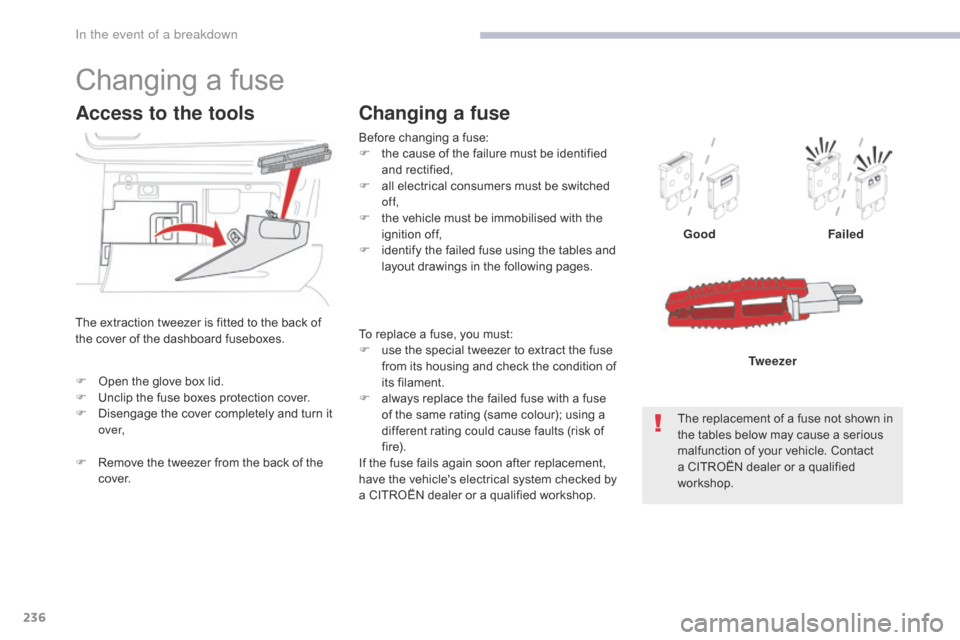

To replace a fuse, you must:

F u se the special tweezer to extract the fuse

from its housing and check the condition of

its filament.

F

a

lways replace the failed fuse with a fuse

of the same rating (same colour); using a

different rating could cause faults (risk of

f i r e).

If the fuse fails again soon after replacement,

have the vehicle's electrical system checked by

a CITROËN dealer or a qualified workshop. Good

Failed

The replacement of a fuse not shown in

the tables below may cause a serious

malfunction of your vehicle. Contact

a CITROËN dealer or a qualified

workshop. Tw e e z e r

Changing a fuse

Changing a fuse

Before changing a fuse:

F

t he cause of the failure must be identified

and rectified,

F

a

ll electrical consumers must be switched

of f,

F

t

he vehicle must be immobilised with the

ignition off,

F

i

dentify the failed fuse using the tables and

layout drawings in the following pages.

The extraction tweezer is fitted to the back of

the cover of the dashboard fuseboxes.

Access to the tools

F Open the glove box lid.

F U nclip the fuse boxes protection cover.

F

D

isengage the cover completely and turn it

ove r,

F

R

emove the tweezer from the back of the

c ove r.

In the event of a breakdown

Page 246 of 442

244

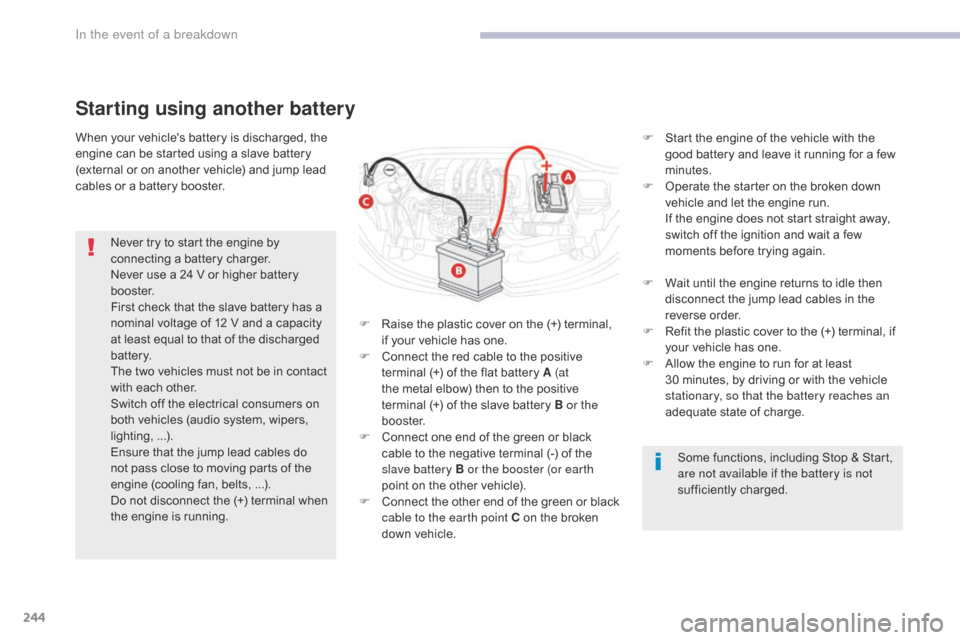

When your vehicle's battery is discharged, the

engine can be started using a slave battery

(external or on another vehicle) and jump lead

cables or a battery booster.

Starting using another battery

F Raise the plastic cover on the (+) terminal, if your vehicle has one.

F

C

onnect the red cable to the positive

terminal (+) of the flat battery A (at

the metal elbow) then to the positive

terminal

(+) of the slave battery B or the

b o o s t e r.

F

C

onnect one end of the green or black

cable to the negative terminal (-) of the

slave battery B or the booster (or earth

point on the other vehicle).

F

C

onnect the other end of the green or black

cable to the earth point C on the broken

down vehicle. F

S

tart the engine of the vehicle with the

good battery and leave it running for a few

minutes.

F

O

perate the starter on the broken down

vehicle and let the engine run.

I

f the engine does not start straight away,

switch off the ignition and wait a few

moments before trying again.

Never try to start the engine by

connecting a battery charger.

Never use a 24 V or higher battery

b o o s t e r.

First check that the slave battery has a

nominal voltage of 12 V and a capacity

at least equal to that of the discharged

battery.

The two vehicles must not be in contact

with each other.

Switch off the electrical consumers on

both vehicles (audio system, wipers,

lighting,

...

).

Ensure that the jump lead cables do

not pass close to moving parts of the

engine (cooling fan, belts,

...).

Do not disconnect the (+) terminal when

the engine is running. F

W

ait until the engine returns to idle then

disconnect the jump lead cables in the

reverse order.

F R efit the plastic cover to the (+) terminal, if

your vehicle has one.

F

A

llow the engine to run for at least

30

minutes, by driving or with the vehicle

stationary, so that the battery reaches an

adequate state of charge.

Some functions, including Stop & Start,

are not available if the battery is not

sufficiently charged.

In the event of a breakdown