hub Citroen C4 2005 2.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 265 of 462

![Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 259

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: WJY

Tools.

[1]Pliers for remving plastic pins: 7504-T or (-).1311

[2]Flywheel peg: 701 Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 259

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: WJY

Tools.

[1]Pliers for remving plastic pins: 7504-T or (-).1311

[2]Flywheel peg: 701](/img/9/4138/w960_4138-264.png)

Downloaded from www.Manualslib.com manuals search engine 259

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: WJY

Tools.

[1]Pliers for remving plastic pins: 7504-T or (-).1311

[2]Flywheel peg: 7014-T.J or (-).0188 Y

[3]Injection pump setting peg Ø 6 mm : (-).0188 H

[4]Screw H M8 : (-).0188 E

[5]Belt retaining pin: (-).0188 K

[6] Square for adjusting belt tension: (-).0188 J1

[7] Belt tension measuring instrument, with digital display: SEEM CTG 105.5M

Checking the timing.

Peg the flywheel, using tool [2].

Peg the camshaft hub, using tool [4].

Peg the injection pump hub, using tool[3].

IMPERATIVE: If the pegging proves impossible, repeat the setting of the timing.

B1BP2FTC

B1EP16PD

XSARA

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 259

Page 267 of 462

![Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 261

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: WJY

Setting the timing (continued).

Peg the camshaft hub, using tool[4].

Peg the injec Citroen C4 2005 2.G User Guide Downloaded from www.Manualslib.com manuals search engine 261

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: WJY

Setting the timing (continued).

Peg the camshaft hub, using tool[4].

Peg the injec](/img/9/4138/w960_4138-266.png)

Downloaded from www.Manualslib.com manuals search engine 261

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: WJY

Setting the timing (continued).

Peg the camshaft hub, using tool[4].

Peg the injection pump hub, using tool[3].

Slacken screws (5)and (6).

Slacken screw (9)of the tensioner roller (8).

Remove the timing belt.

Refitting.

Retighten screws (5)and (6) by hand.

Turn the pinions (10)and(7)clockwise in order to place them at end of slots.

Fit the timing belt on the crankshaft.

Hold the belt, using tool [5].

Position the timing belt in the following sequence:

- Guide roller (11).

- Injection pump pinion (7).

- Camshaft pinion (10).

- Coolant pump pinion (12).

- Tensioner roller (8).

B1EP16PDB1EP1EDCB1EP132C

XSARA

B1EP1EEC

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 261

Page 268 of 462

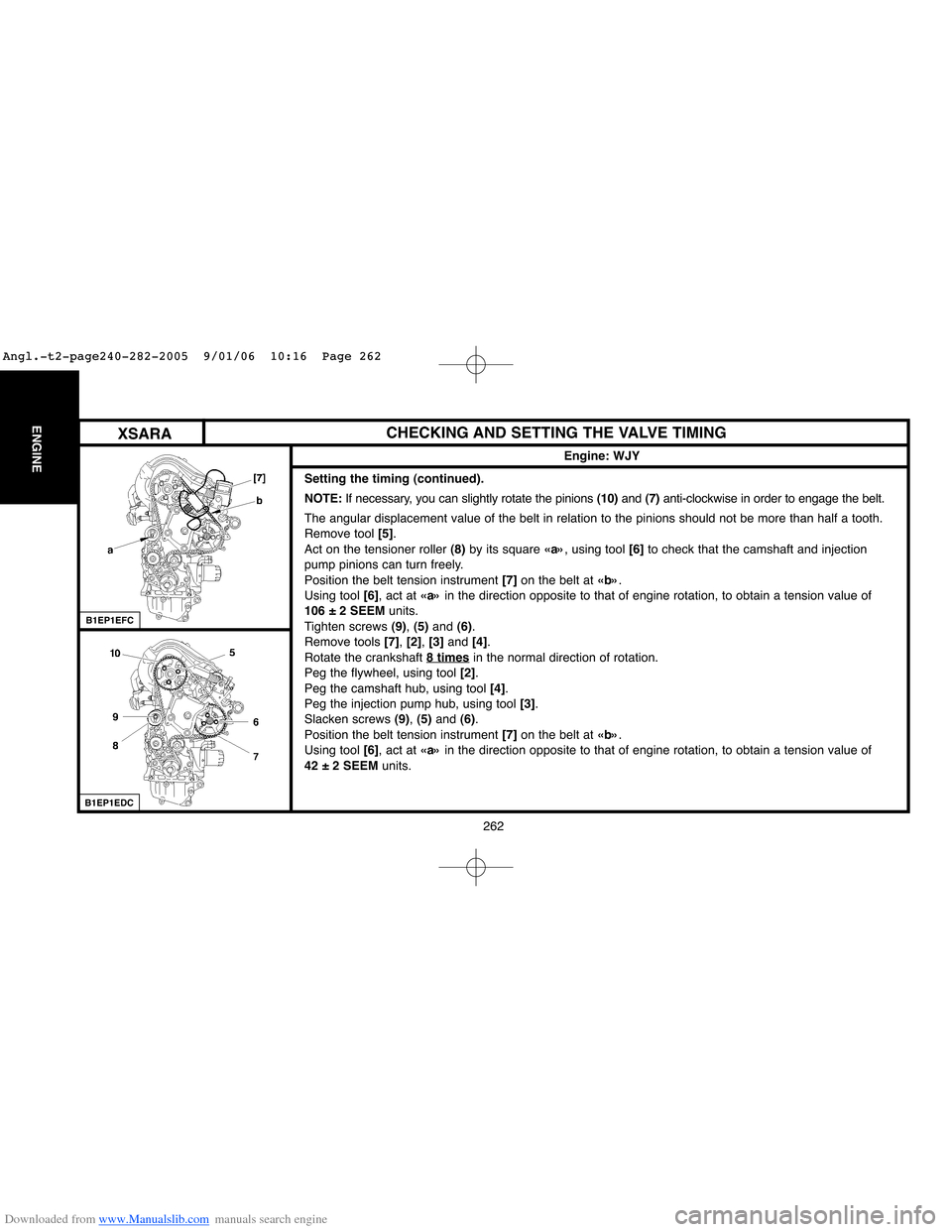

Downloaded from www.Manualslib.com manuals search engine 262

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: WJY

B1EP1EDC

Setting the timing (continued).

NOTE:If necessary, you can slightly rotate the pinions (10)and (7)anti-clockwise in order to engage the belt.

The angular displacement value of the belt in relation to the pinions should not be more than half a tooth.

Remove tool [5].

Act on the tensioner roller (8)by its square «a», using tool [6]to check that the camshaft and injection

pump pinions can turn freely.

Position the belt tension instrument [7]on the belt at «b».

Using tool [6], act at «a»in the direction opposite to that of engine rotation, to obtain a tension value of

106 ± 2 SEEMunits.

Tighten screws (9), (5) and (6).

Remove tools [7], [2], [3]and [4].

Rotate the crankshaft 8 times

in the normal direction of rotation.

Peg the flywheel, using tool [2].

Peg the camshaft hub, using tool [4].

Peg the injection pump hub, using tool [3].

Slacken screws (9), (5)and (6).

Position the belt tension instrument [7]on the belt at «b».

Using tool [6], act at «a»in the direction opposite to that of engine rotation, to obtain a tension value of

42 ± 2 SEEMunits.

B1EP1EFC

XSARA

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 262

Page 269 of 462

Downloaded from www.Manualslib.com manuals search engine 263

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: WJY

Setting the timing (continued).

Tighten:

- Screw (9)to 2.1 ± 0.2 m.daN.

- Screws (5)to 2,3 ± 0.2 m.daN.

- Screws (6)to 2,3 ± 0.2 m.daN.

- Remove and refit tool [7].

- The tension value should be between 38 and 46 SEEMunits.

- Remove tools [7], [2], [3]and [4].

- Turn the crankshaft 2 times

in the normal direction of rotation.

- Peg the flywheel, using the peg [2].

- Visually check the peggings of the camshaft and injection pump.

ESSENTIAL: Visually check that the offsets between the holes of

the camshaft and injection pump hubs and the corresponding

pegging holes are not more than 1 mm. If necessary, recommence

the procedure for fitting the timing belt.

XSARA

Setting the timing (continued).

Remove the peg [2].

Remove the screw (4)and the washer.

Refit the lower cover (3).

Refit the intermediate cover (2).

Refit the upper cover (1).

Remove the RH engine support.

Take away the workshop hoist.

Remove the plugs and recouple the diesel fuel delivery and return

hoses.

Refit the accessories drive belt

(see corresponding operation).

Refit the RH lower splash-shield.

Disengage 5th gear.

Connect the battery.

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 263

Page 313 of 462

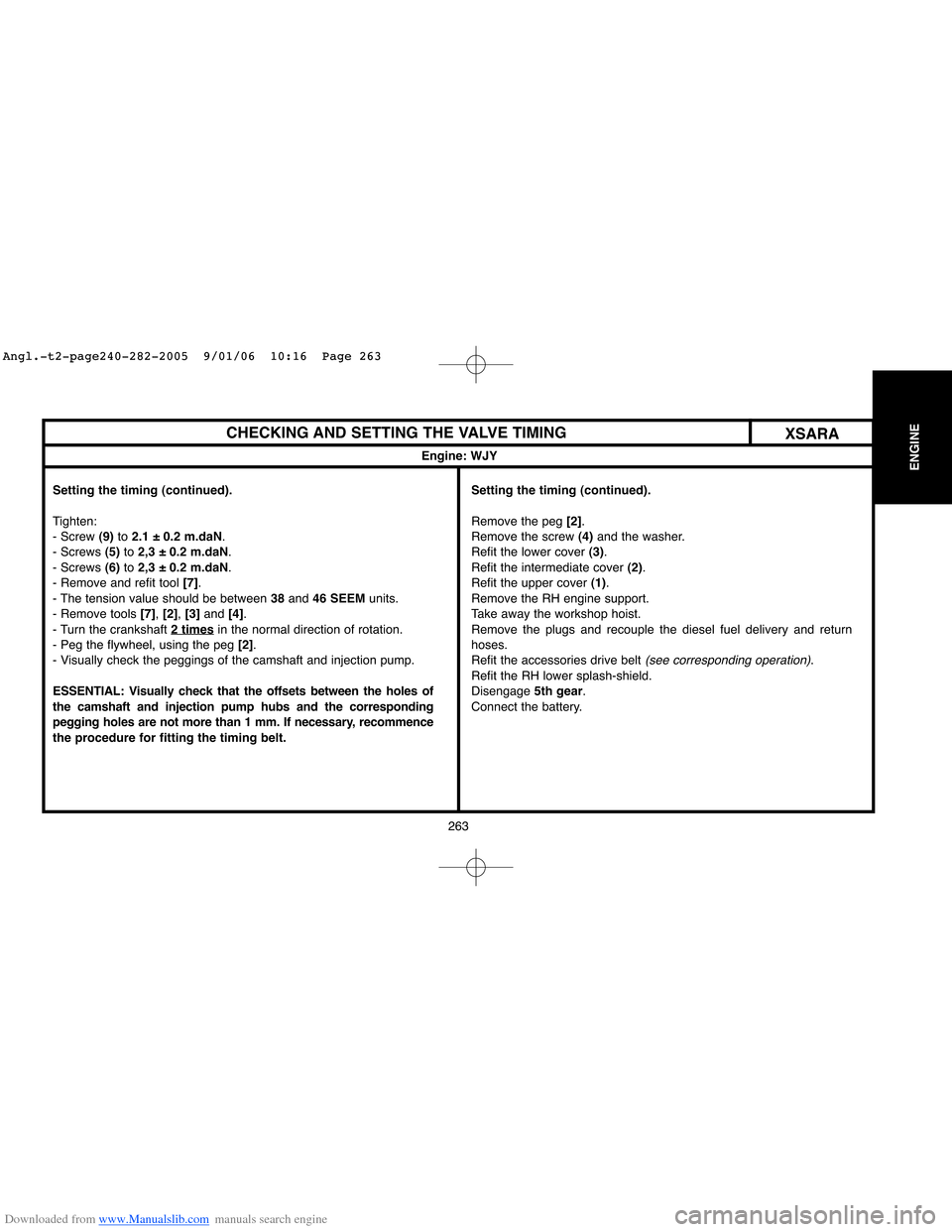

Downloaded from www.Manualslib.com manuals search engine 307

CLUTCH

GEARBOX

TRANSMISSION

CLUTCH SPECIFICATIONS

Engine type KFU NFU RFN RFK

Gearbox type MA5/L MA5/N BE4/5N BE4R/5S

SupplierSACHS VALEO VALEO VALEO

Mechanism/type200 MF 3850 200 CPX 3850 230 DNG 5100 230 DNG 5100

Hub discSAE 24/48-18Z 11 RX 11 R 14X 11 R 14X

Ø of lining. ext/int200/134 200/137 228.6/155 228.6/155

Quality of liningF810 DS 810 DS 810 DS 810 DS

ET3J4 TU5JP EW10J4 EW10J4S

Petrol

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 307

Page 314 of 462

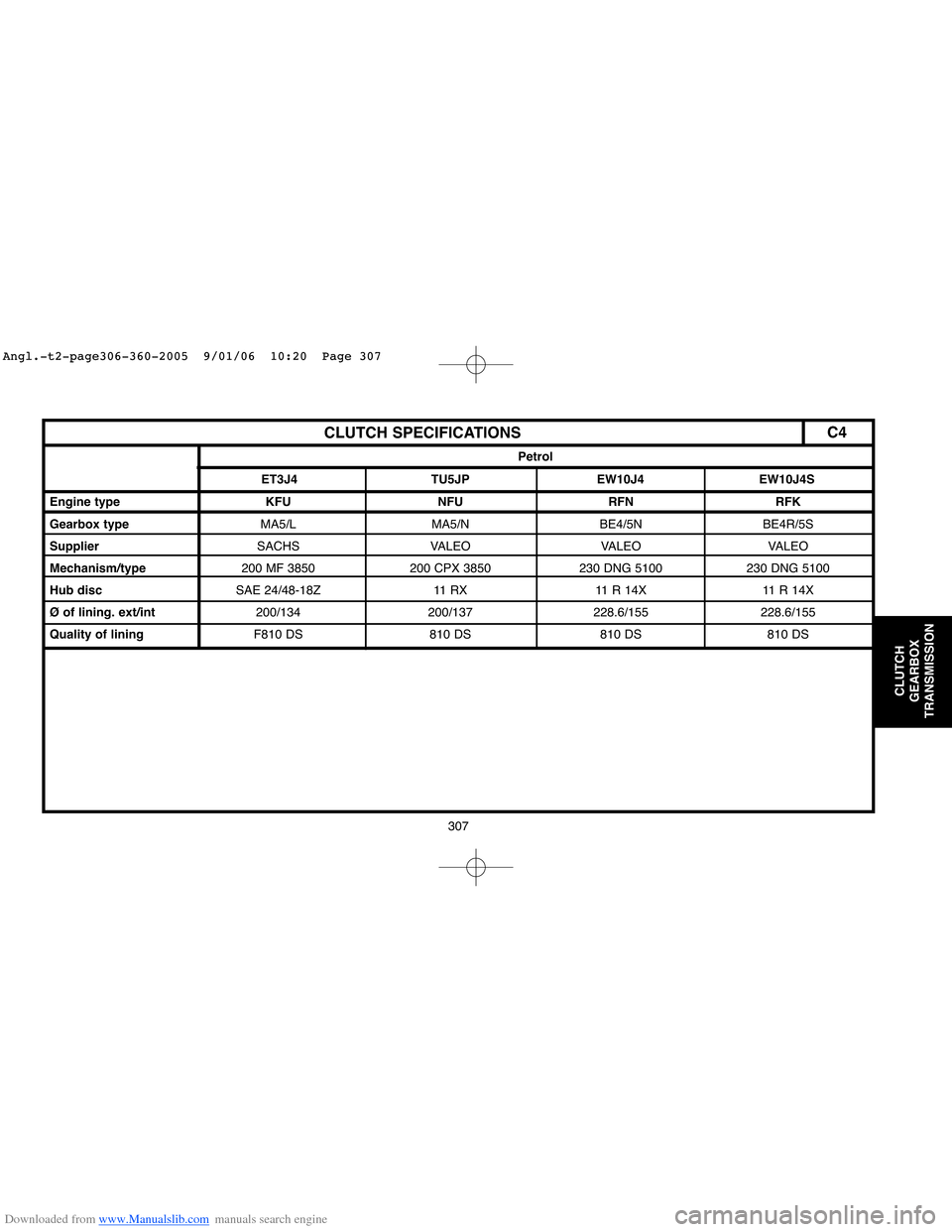

Downloaded from www.Manualslib.com manuals search engine 308

CLUTCH

GEARBOX

TRANSMISSION

CLUTCH SPECIFICATIONS

Engine type 9HY (*) 9HZ (*) 9HX RHR (**)

Gearbox type BE4/5L ML6C

SupplierLUK

Mechanism/type235 P 4800 235 P 7400

Hub disc

Ø of lining. ext/int234/165 235/150

Quality of lining810 DS

NOTE: (*) DVAR: Equipped with a Double Damping Flywheel with springs in the radial position in relation to the axis of the crankshaft.

NOTE: (**) DVA: Equipped with a Double Damping Flywheel with springs arranged concentrically.

DV6TED4 DV6ATED4 DW10BTED4

Diesel

C4

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 308

Page 315 of 462

Downloaded from www.Manualslib.com manuals search engine CLUTCH

GEARBOX

TRANSMISSION

309

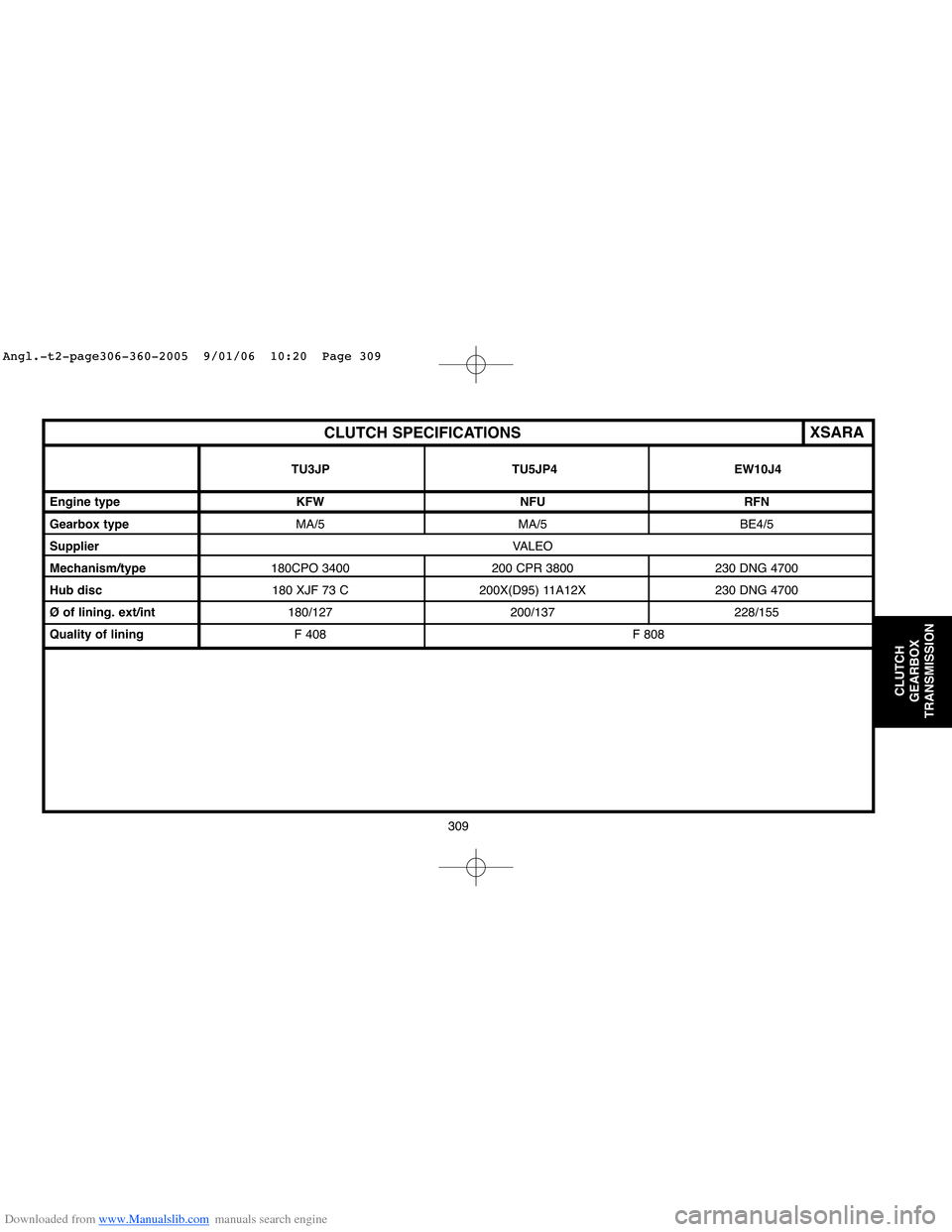

CLUTCH SPECIFICATIONS

Engine type KFW NFU RFN

Gearbox type MA/5 MA/5 BE4/5

SupplierVALEO

Mechanism/type180CPO 3400 200 CPR 3800 230 DNG 4700

Hub disc180 XJF 73 C 200X(D95) 11A12X 230 DNG 4700

Ø of lining. ext/int180/127 200/137 228/155

Quality of liningF 408 F 808

TU3JP TU5JP4 EW10J4

XSARA

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 309

Page 316 of 462

Downloaded from www.Manualslib.com manuals search engine 310

CLUTCH

GEARBOX

TRANSMISSION

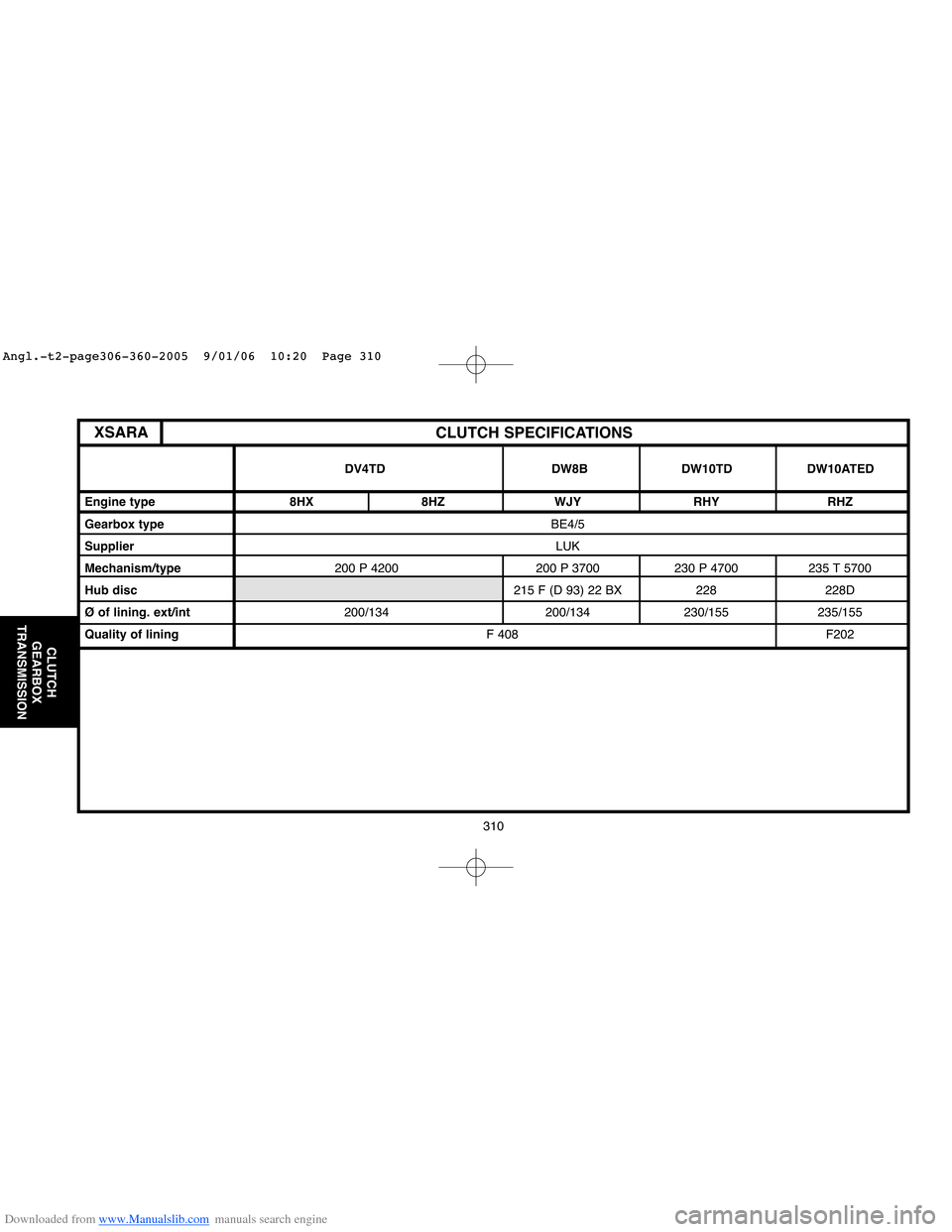

CLUTCH SPECIFICATIONS

Engine type 8HX 8HZ WJY RHY RHZ

Gearbox type BE4/5

SupplierLUK

Mechanism/type200 P 4200 200 P 3700 230 P 4700 235 T 5700

Hub disc215 F (D 93) 22 BX 228 228D

Ø of lining. ext/int200/134 200/134 230/155 235/155

Quality of liningF 408 F202

DV4TD DW8B DW10TD DW10ATED

XSARA

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 310

Page 317 of 462

Downloaded from www.Manualslib.com manuals search engine 311

CLUTCH

GEARBOX

TRANSMISSION

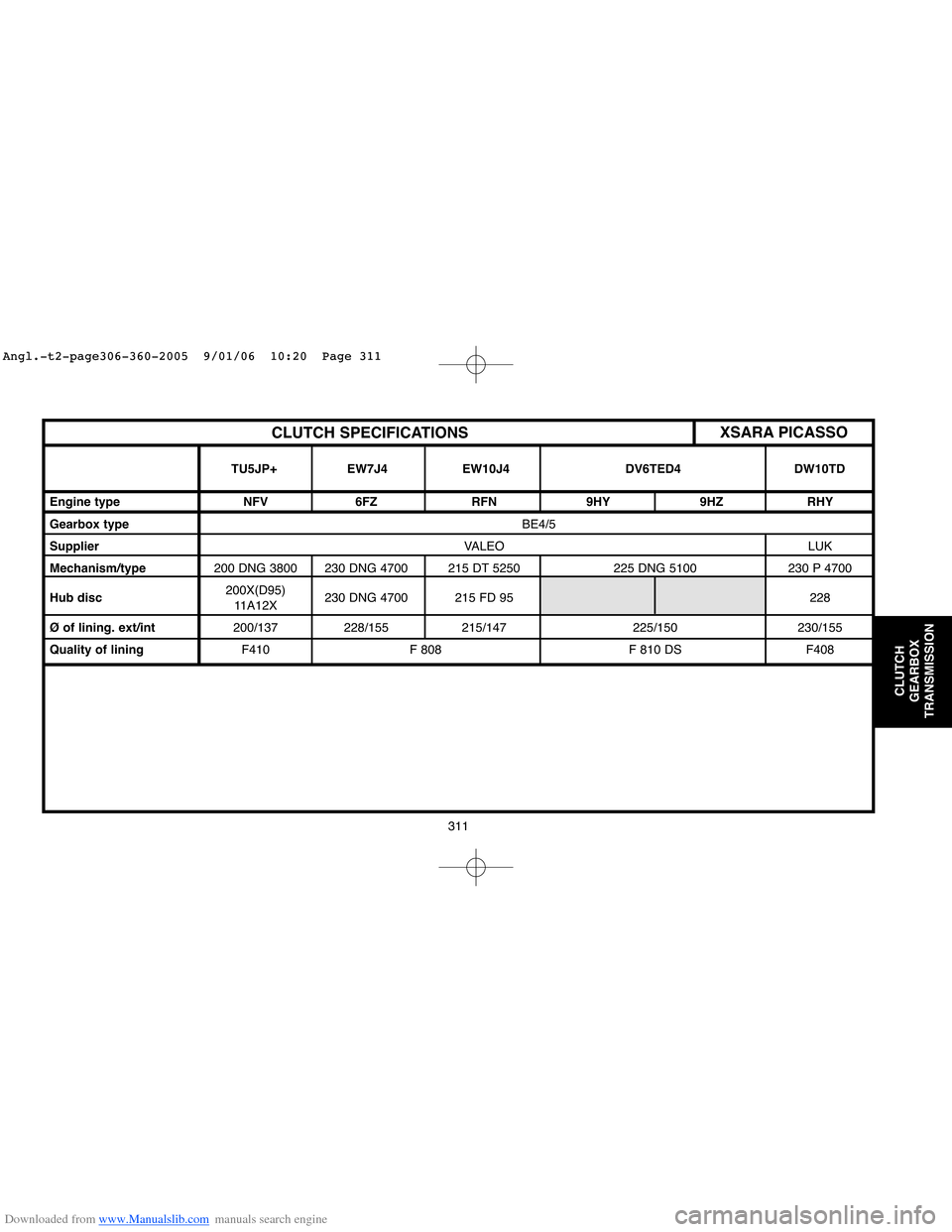

CLUTCH SPECIFICATIONS

Engine type NFV 6FZ RFN 9HY 9HZ RHY

Gearbox type BE4/5

SupplierVALEO LUK

Mechanism/type200 DNG 3800 230 DNG 4700 215 DT 5250 225 DNG 5100 230 P 4700

Hub disc200X(D95)

230 DNG 4700 215 FD 95 228

11A12X

Ø of lining. ext/int200/137 228/155 215/147 225/150 230/155

Quality of liningF410 F 808 F 810 DS F408

TU5JP+ EW7J4 EW10J4 DV6TED4 DW10TD

XSARA PICASSO

Angl.-t2-page306-360-2005 9/01/06 10:20 Page 311

Page 371 of 462

Downloaded from www.Manualslib.com manuals search engine 365

AXLES

SUSPENSION

STEERING

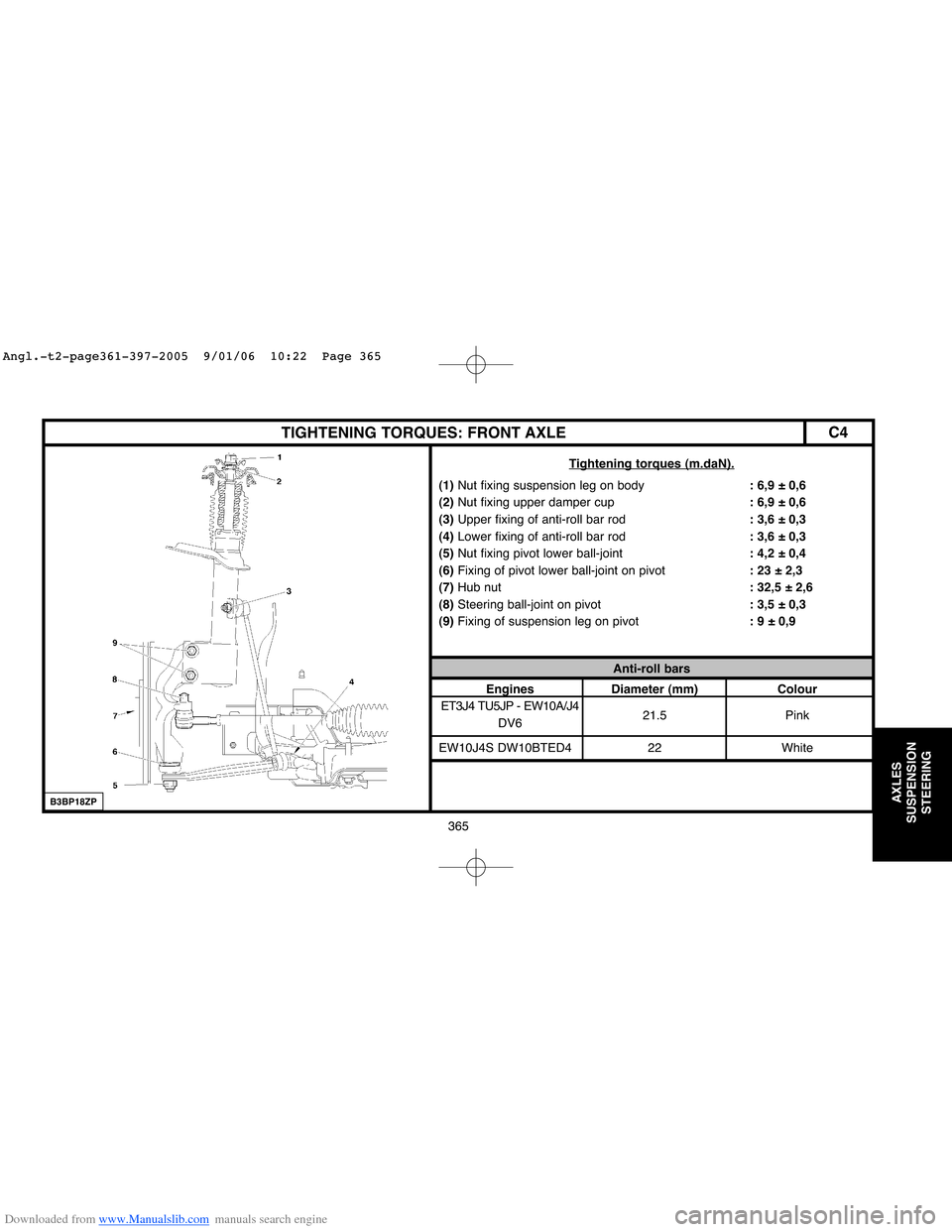

C4TIGHTENING TORQUES: FRONT AXLE

Tightening torques (m.daN).

(1)Nut fixing suspension leg on body: 6,9 ± 0,6

(2) Nut fixing upper damper cup: 6,9 ± 0,6

(3)Upper fixing of anti-roll bar rod: 3,6 ± 0,3

(4)Lower fixing of anti-roll bar rod: 3,6 ± 0,3

(5)Nut fixing pivot lower ball-joint: 4,2 ± 0,4

(6)Fixing of pivot lower ball-joint on pivot: 23 ± 2,3

(7)Hub nut: 32,5 ± 2,6

(8)Steering ball-joint on pivot: 3,5 ± 0,3

(9)Fixing of suspension leg on pivot: 9 ± 0,9

Anti-roll bars

Engines Diameter (mm) Colour

ET3J4 TU5JP - EW10A/J4

DV621.5 Pink

EW10J4S DW10BTED4 22 White

B3BP18ZP

Angl.-t2-page361-397-2005 9/01/06 10:22 Page 365