head Citroen C4 2005 2.G Owner's Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 145 of 462

Downloaded from www.Manualslib.com manuals search engine 139

ENGINE

SPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Cylinder head

5 Camshaft bearing cap cover screws (*) 1 ± 0,1

6 Coolant outlet housing fixing 2 ± 0,2

Camshaft bearing cap cover studs (*)

7Pre-tightening (the 26 screws Ø 6)0,5

Tightening (the 26 screws Ø 6)1 ± 0,1

8 Inlet valve cover screws (*) (19 screws) 0,9 ± 0,1

Engine: RHR

B1DP1LCP

C4

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 139

Page 146 of 462

Downloaded from www.Manualslib.com manuals search engine 140

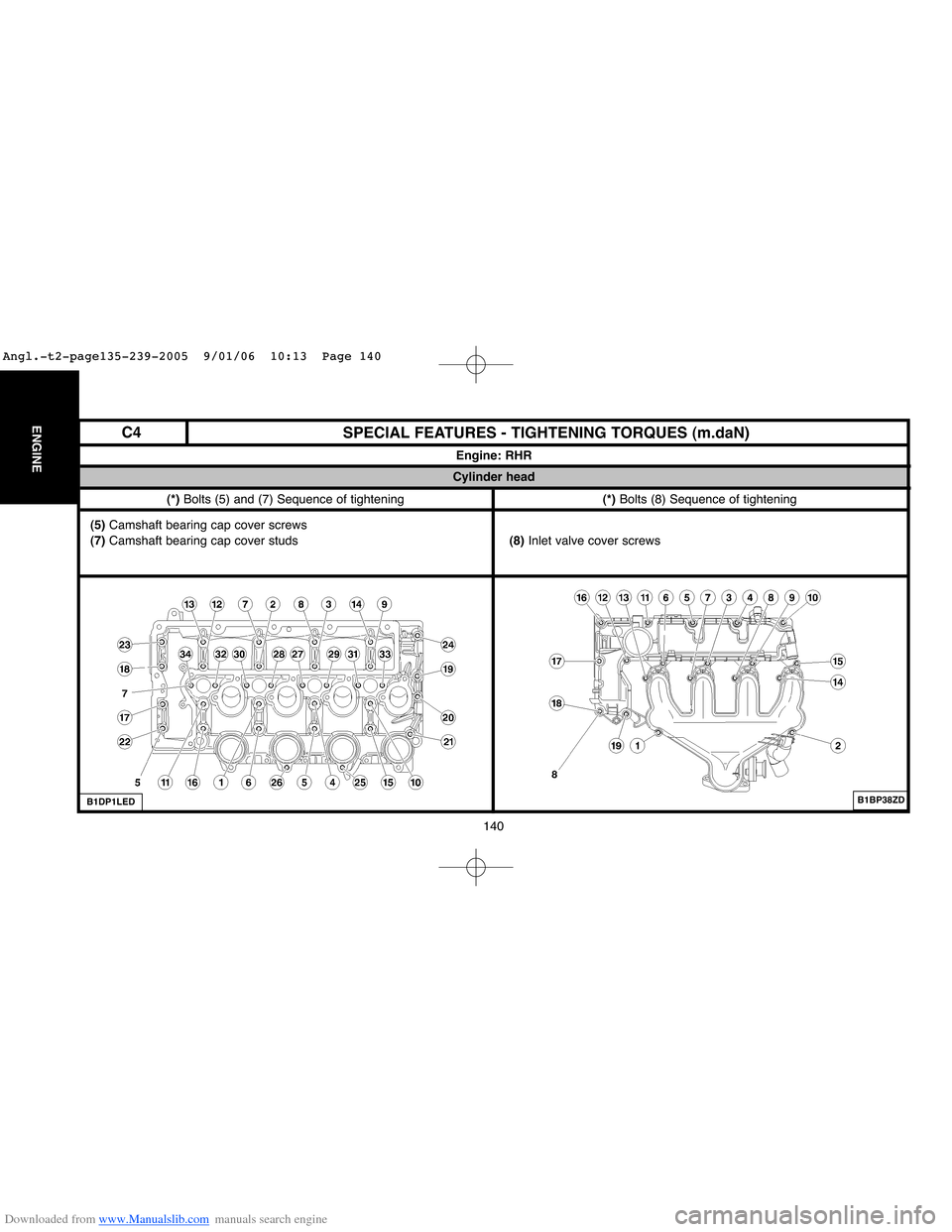

ENGINESPECIAL FEATURES - TIGHTENING TORQUES (m.daN)

Engine: RHR

B1DP1LED

(*) Bolts (5) and (7) Sequence of tightening(*) Bolts (8) Sequence of tightening

Cylinder head

(5) Camshaft bearing cap cover screws

(7) Camshaft bearing cap cover studs(8) Inlet valve cover screws

B1BP38ZD

C4

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 140

Page 154 of 462

Downloaded from www.Manualslib.com manuals search engine 148

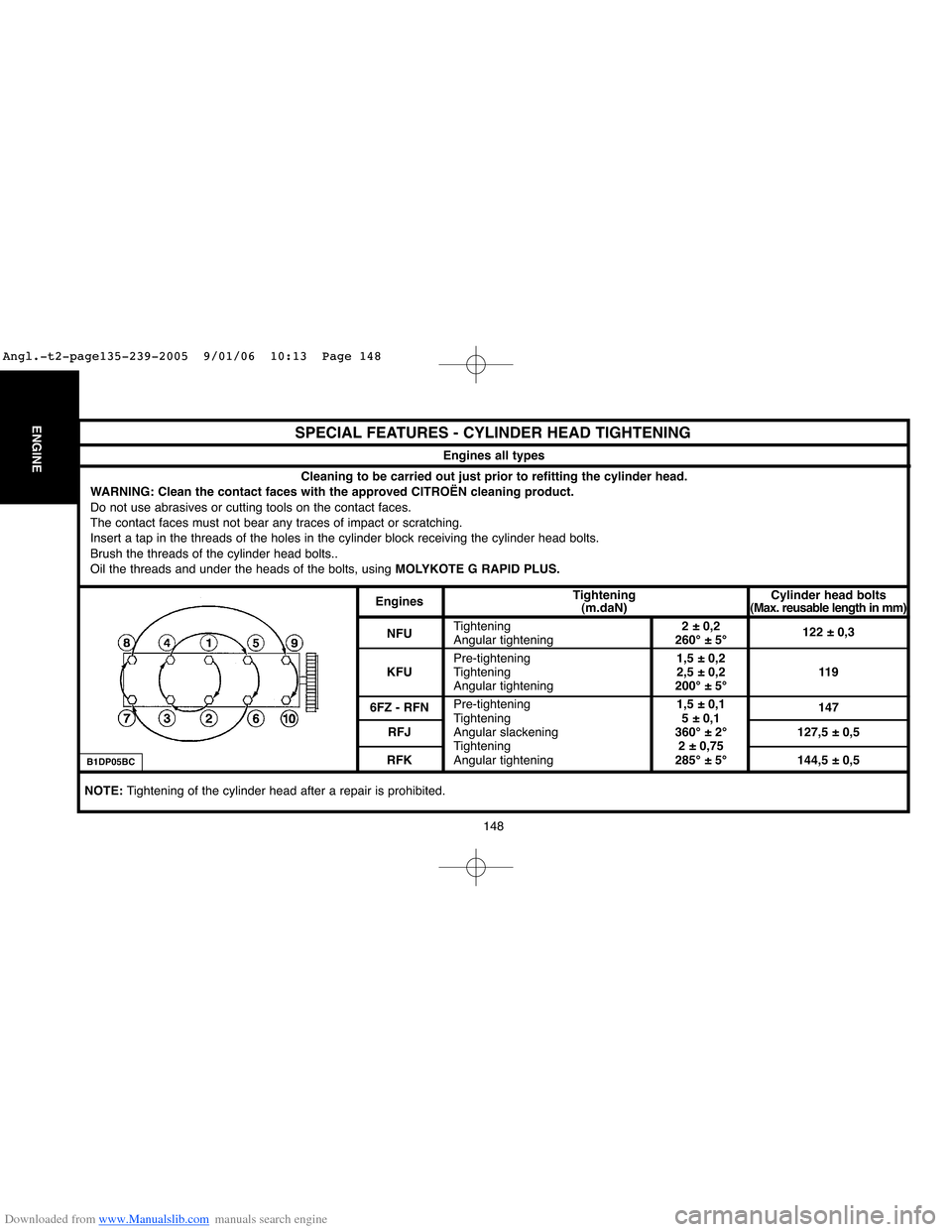

ENGINESPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

B1DP05BC

Cleaning to be carried out just prior to refitting the cylinder head.

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts..

Oil the threads and under the heads of the bolts, usingMOLYKOTE G RAPID PLUS.

EnginesTightening Cylinder head bolts

(m.daN)(Max. reusable length in mm)

NFUTightening2 ± 0,2

Angular tightening260° ± 5°122 ± 0,3

Pre-tightening1,5 ± 0,2

KFUTightening2,5 ± 0,2 119

Angular tightening200° ± 5°

6FZ - RFNPre-tightening1,5 ± 0,1

147

Tightening5 ± 0,1

RFJAngular slackening360° ± 2° 127,5 ± 0,5

Tightening2 ± 0,75

RFKAngular tightening285° ± 5° 144,5 ± 0,5

NOTE: Tightening of the cylinder head after a repair is prohibited.

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 148

Page 155 of 462

Downloaded from www.Manualslib.com manuals search engine 149

ENGINE

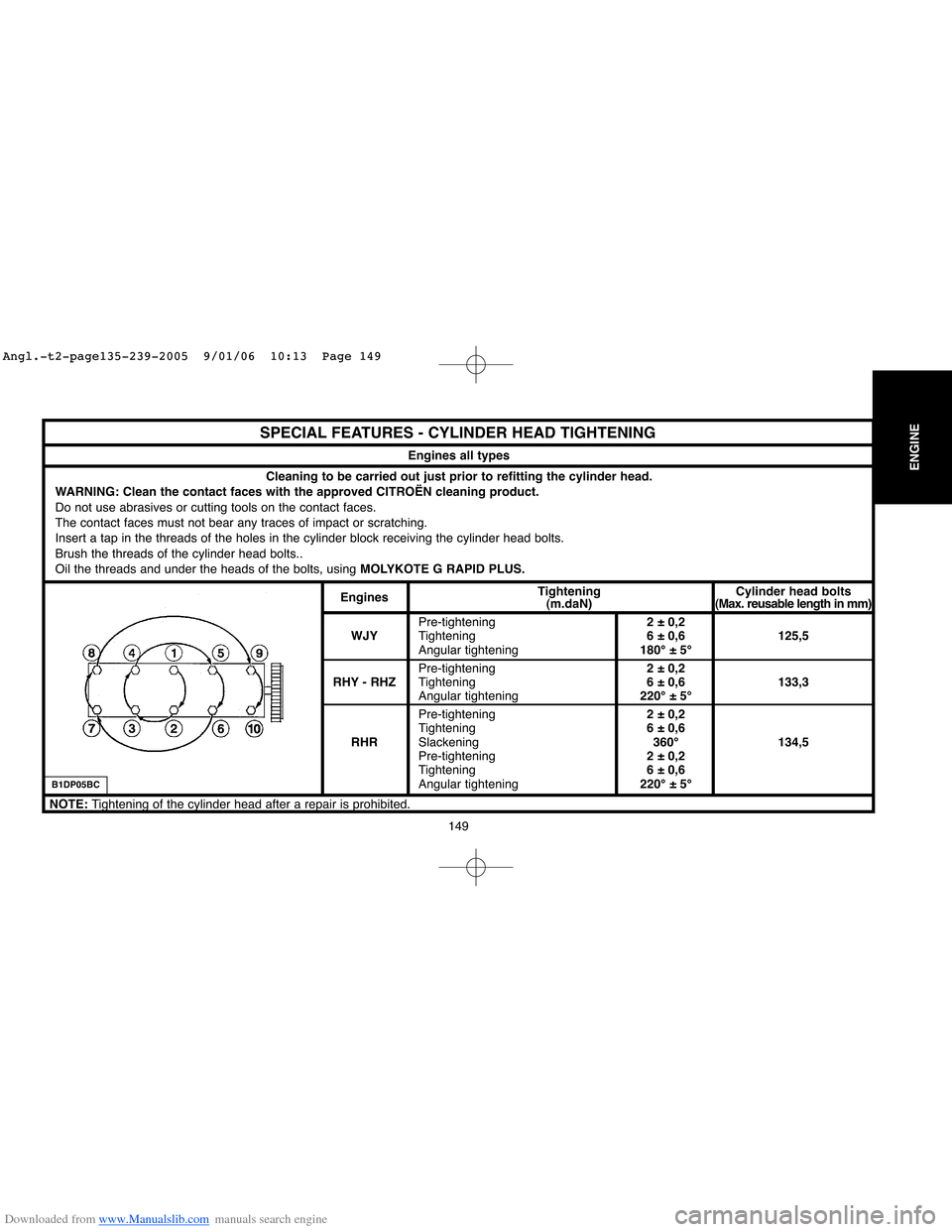

SPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

B1DP05BC

Cleaning to be carried out just prior to refitting the cylinder head.

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts..

Oil the threads and under the heads of the bolts, using MOLYKOTE G RAPID PLUS.

EnginesTightening Cylinder head bolts

(m.daN)(Max. reusable length in mm)

Pre-tightening2 ± 0,2

WJYTightening6 ± 0,6 125,5

Angular tightening180° ± 5°

Pre-tightening2 ± 0,2

RHY - RHZTightening6 ± 0,6 133,3

Angular tightening220° ± 5°

Pre-tightening2 ± 0,2

Tightening6 ± 0,6

RHRSlackening360° 134,5

Pre-tightening2 ± 0,2

Tightening6 ± 0,6

Angular tightening220° ± 5°

NOTE: Tightening of the cylinder head after a repair is prohibited.

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 149

Page 156 of 462

Downloaded from www.Manualslib.com manuals search engine 150

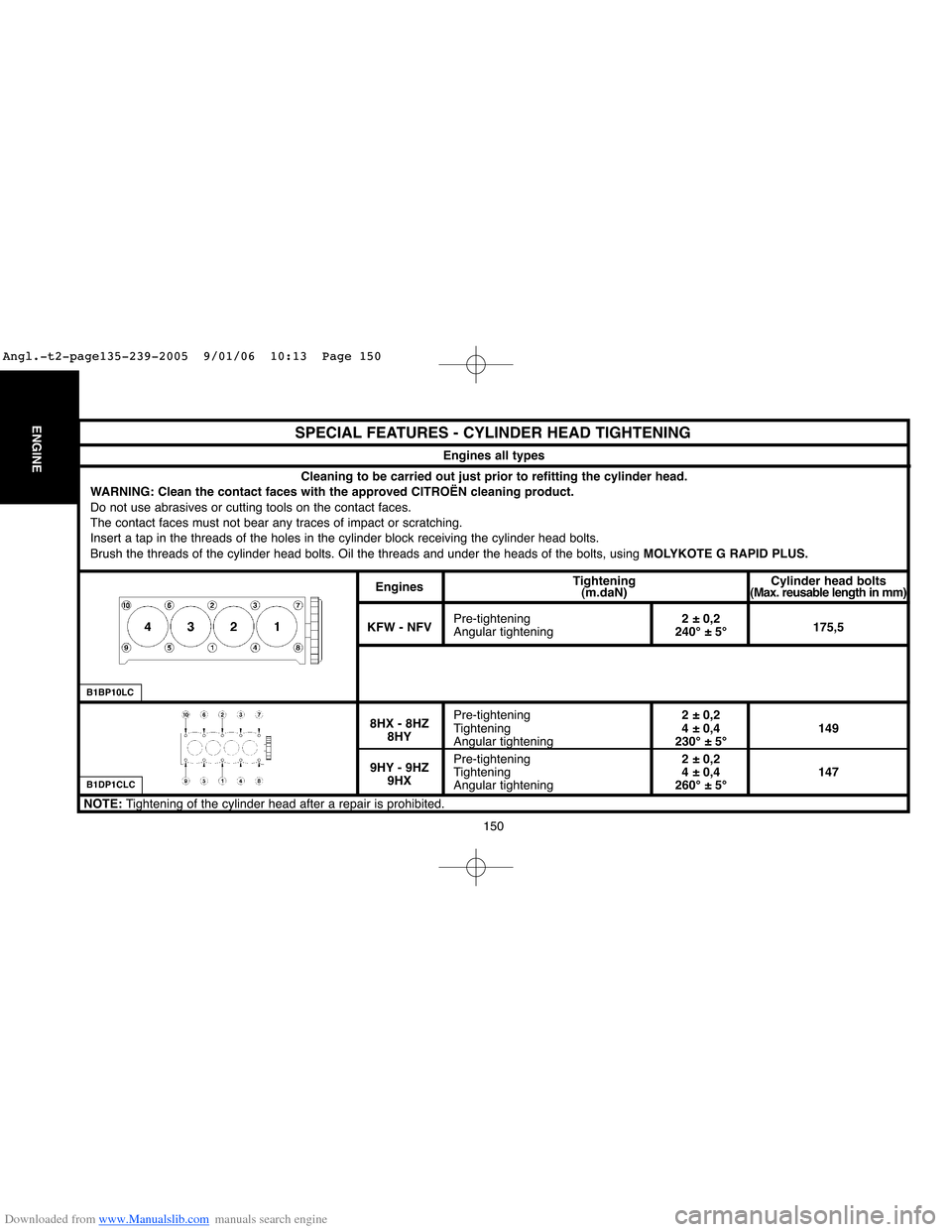

ENGINESPECIAL FEATURES - CYLINDER HEAD TIGHTENING

Engines all types

B1DP1CLC

Cleaning to be carried out just prior to refitting the cylinder head.

WARNING: Clean the contact faces with the approved CITROËN cleaning product.

Do not use abrasives or cutting tools on the contact faces.

The contact faces must not bear any traces of impact or scratching.

Insert a tap in the threads of the holes in the cylinder block receiving the cylinder head bolts.

Brush the threads of the cylinder head bolts. Oil the threads and under the heads of the bolts, using MOLYKOTE G RAPID PLUS.

EnginesTightening Cylinder head bolts

(m.daN)(Max. reusable length in mm)

Pre-tightening2 ± 0,2

KFW - NFV

Angular tightening240° ± 5°175,5

Pre-tightening2 ± 0,2

8HX - 8HZ

Tightening4 ± 0,4 149

8HY

Angular tightening230° ± 5°

Pre-tightening2 ± 0,2

9HY - 9HZ

Tightening4 ± 0,4 147

9HX

Angular tightening260° ± 5°

NOTE: Tightening of the cylinder head after a repair is prohibited.

B1BP10LC

Angl.-t2-page135-239-2005 9/01/06 10:13 Page 150

Page 214 of 462

Downloaded from www.Manualslib.com manuals search engine 208

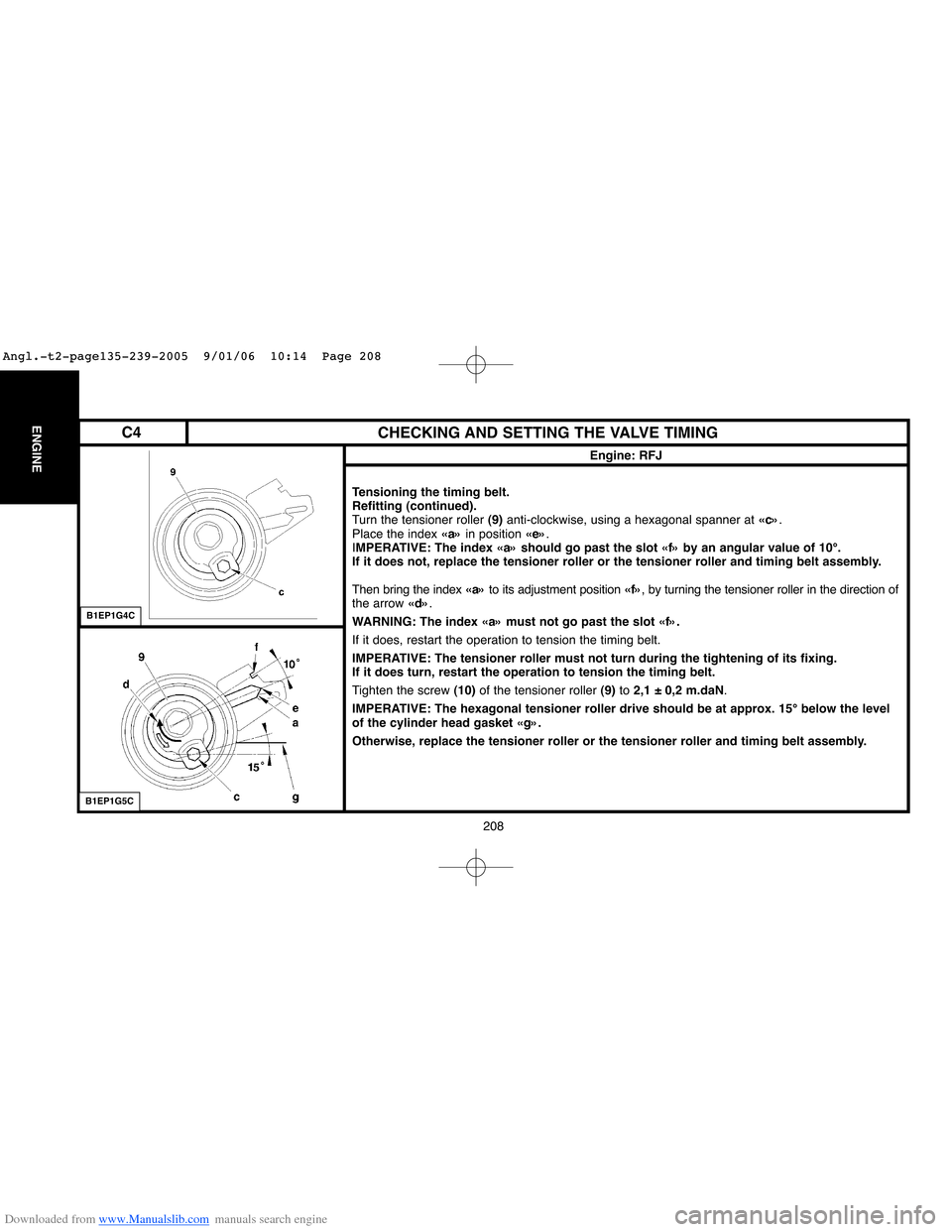

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFJ

Tensioning the timing belt.

Refitting (continued).

Turn the tensioner roller (9)anti-clockwise, using a hexagonal spanner at «c».

Place the index «a»in position «e».

IMPERATIVE: The index «a» should go past the slot «f» by an angular value of 10°.

If it does not, replace the tensioner roller or the tensioner roller and timing belt assembly.

Then bring the index «a»to its adjustment position «f», by turning the tensioner roller in the direction of

the arrow «d».

WARNING: The index «a» must not go past the slot «f».

If it does, restart the operation to tension the timing belt.

IMPERATIVE: The tensioner roller must not turn during the tightening of its fixing.

If it does turn, restart the operation to tension the timing belt.

Tighten the screw (10)of the tensioner roller (9)to 2,1 ± 0,2 m.daN.

IMPERATIVE: The hexagonal tensioner roller drive should be at approx. 15° below the level

of the cylinder head gasket «g».

Otherwise, replace the tensioner roller or the tensioner roller and timing belt assembly.

B1EP1G4C

B1EP1G5C

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 208

Page 221 of 462

Downloaded from www.Manualslib.com manuals search engine 215

ENGINE

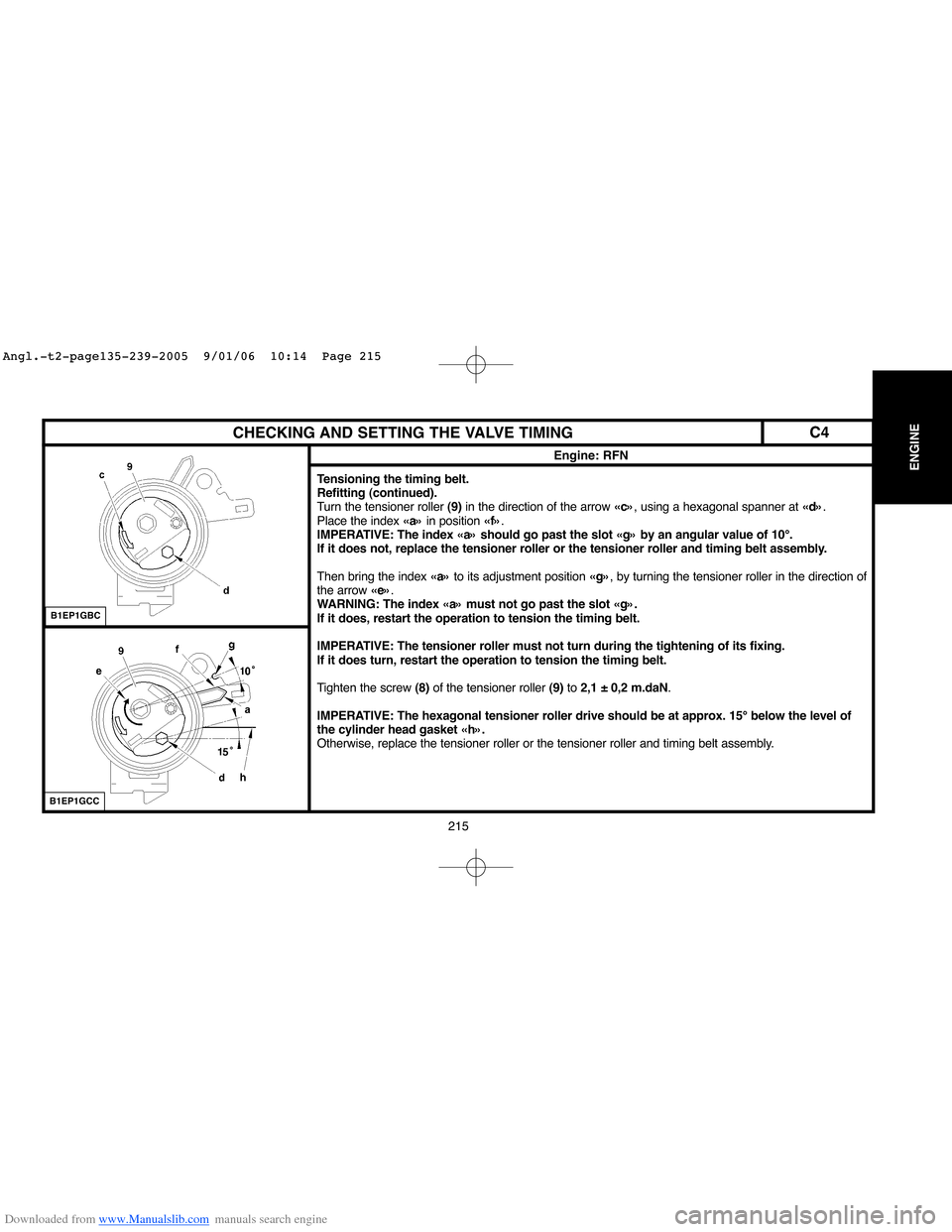

CHECKING AND SETTING THE VALVE TIMING

Engine: RFN

Tensioning the timing belt.

Refitting (continued).

Turn the tensioner roller (9)in the direction of the arrow «c», using a hexagonal spanner at «d».

Place the index «a»in position «f».

IMPERATIVE: The index «a» should go past the slot «g» by an angular value of 10°.

If it does not, replace the tensioner roller or the tensioner roller and timing belt assembly.

Then bring the index «a»to its adjustment position «g», by turning the tensioner roller in the direction of

the arrow «e».

WARNING: The index «a» must not go past the slot «g».

If it does, restart the operation to tension the timing belt.

IMPERATIVE: The tensioner roller must not turn during the tightening of its fixing.

If it does turn, restart the operation to tension the timing belt.

Tighten the screw (8)of the tensioner roller (9)to 2,1 ± 0,2 m.daN.

IMPERATIVE: The hexagonal tensioner roller drive should be at approx. 15° below the level of

the cylinder head gasket «h».

Otherwise, replace the tensioner roller or the tensioner roller and timing belt assembly.

B1EP1GBC

B1EP1GCC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 215

Page 228 of 462

Downloaded from www.Manualslib.com manuals search engine 222

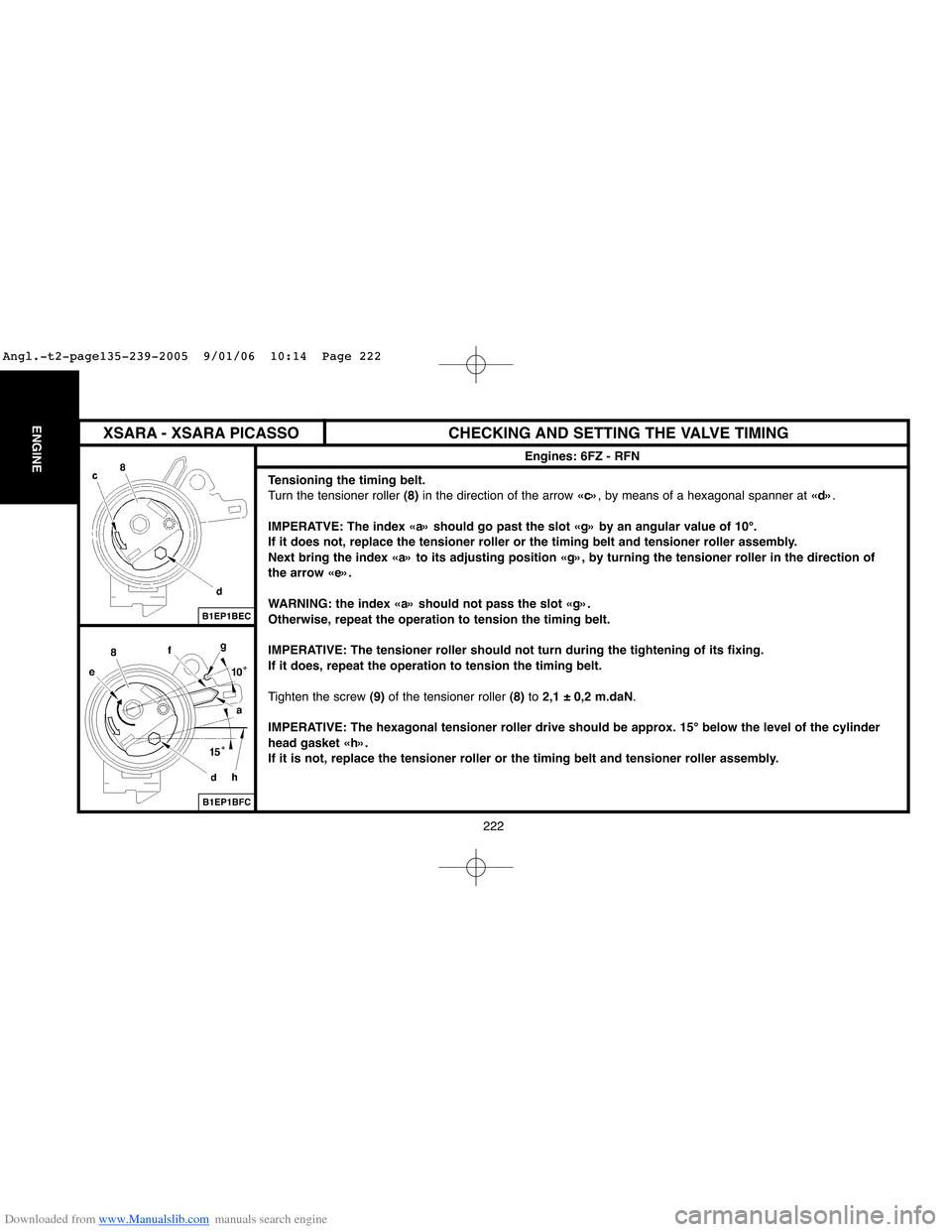

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 6FZ - RFN

Tensioning the timing belt.

Turn the tensioner roller (8)in the direction of the arrow «c», by means of a hexagonal spanner at «d».

IMPERATVE: The index «a» should go past the slot «g» by an angular value of 10°.

If it does not, replace the tensioner roller or the timing belt and tensioner roller assembly.

Next bring the index «a» to its adjusting position «g», by turning the tensioner roller in the direction of

the arrow «e».

WARNING: the index «a» should not pass the slot «g».

Otherwise, repeat the operation to tension the timing belt.

IMPERATIVE: The tensioner roller should not turn during the tightening of its fixing.

If it does, repeat the operation to tension the timing belt.

Tighten the screw (9)of the tensioner roller (8)to 2,1 ± 0,2 m.daN.

IMPERATIVE: The hexagonal tensioner roller drive should be approx. 15° below the level of the cylinder

head gasket «h».

If it is not, replace the tensioner roller or the timing belt and tensioner roller assembly.

B1EP1BEC

B1EP1BFC

XSARA - XSARA PICASSO

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 222

Page 236 of 462

Downloaded from www.Manualslib.com manuals search engine 230

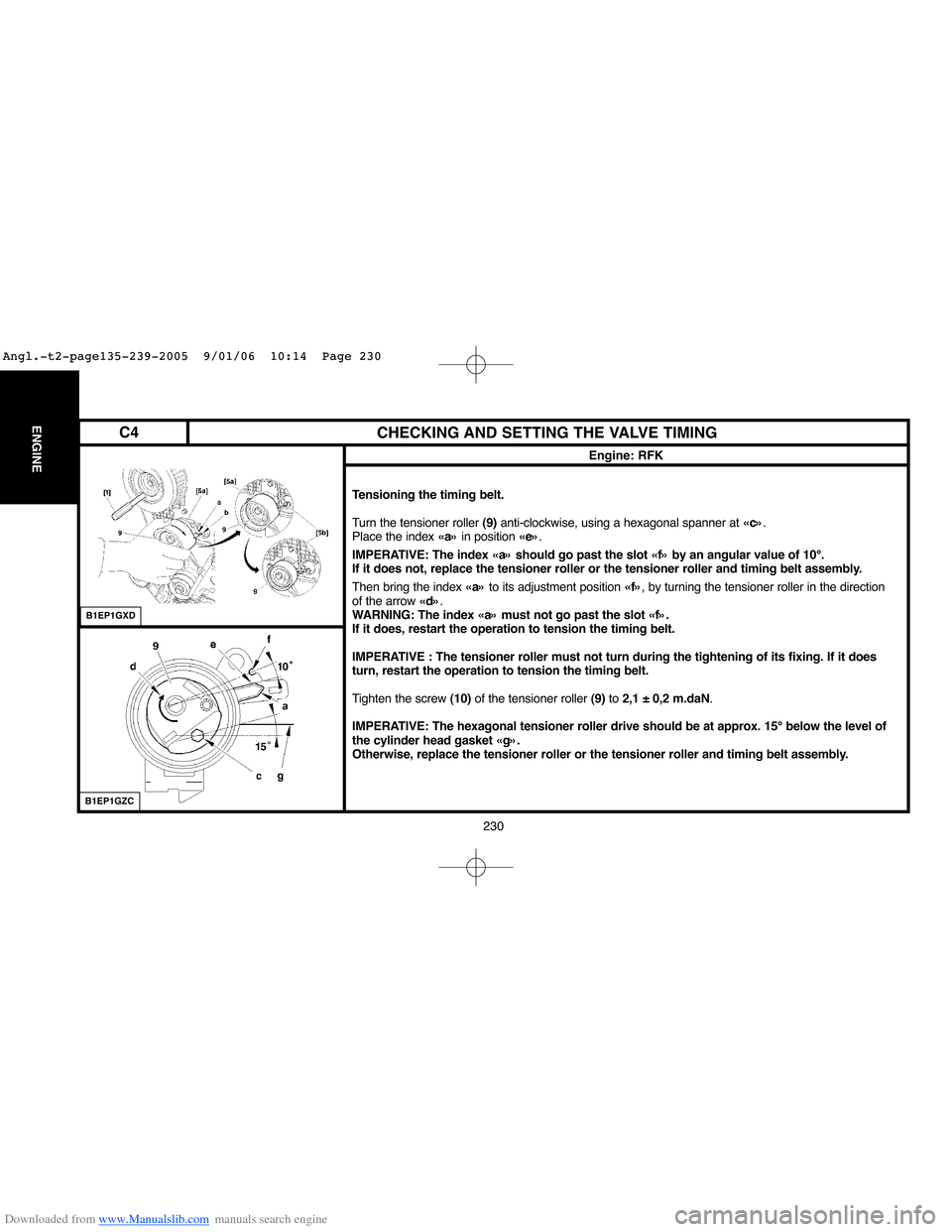

ENGINECHECKING AND SETTING THE VALVE TIMING

Engine: RFK

Tensioning the timing belt.

Turn the tensioner roller (9)anti-clockwise, using a hexagonal spanner at «c».

Place the index «a»in position «e».

IMPERATIVE: The index «a» should go past the slot «f» by an angular value of 10°.

If it does not, replace the tensioner roller or the tensioner roller and timing belt assembly.

Then bring the index «a»to its adjustment position «f», by turning the tensioner roller in the direction

of the arrow «d».

WARNING: The index «a» must not go past the slot «f».

If it does, restart the operation to tension the timing belt.

IMPERATIVE : The tensioner roller must not turn during the tightening of its fixing. If it does

turn, restart the operation to tension the timing belt.

Tighten the screw (10)of the tensioner roller (9)to 2,1 ± 0,2 m.daN.

IMPERATIVE: The hexagonal tensioner roller drive should be at approx. 15° below the level of

the cylinder head gasket «g».

Otherwise, replace the tensioner roller or the tensioner roller and timing belt assembly.

B1EP1GXD

B1EP1GZC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 230

Page 277 of 462

![Citroen C4 2005 2.G Owners Guide Downloaded from www.Manualslib.com manuals search engine 271

ENGINE

CHECKING THE VALVE TIMING

Engine: RHR

Tools.

[1] Kit of plugs: (-).0188.T

[2] Double flywheel setting peg: (-).0188.X Toolkit 0188-T Citroen C4 2005 2.G Owners Guide Downloaded from www.Manualslib.com manuals search engine 271

ENGINE

CHECKING THE VALVE TIMING

Engine: RHR

Tools.

[1] Kit of plugs: (-).0188.T

[2] Double flywheel setting peg: (-).0188.X Toolkit 0188-T](/img/9/4138/w960_4138-276.png)

Downloaded from www.Manualslib.com manuals search engine 271

ENGINE

CHECKING THE VALVE TIMING

Engine: RHR

Tools.

[1] Kit of plugs: (-).0188.T

[2] Double flywheel setting peg: (-).0188.X Toolkit 0188-T

[3]Camshaft setting peg: (-).0188.M

IMPERATIVE: Respect the safety and cleanliness requirements specific to High pressure Diesel

injection (HDi) engine versions.

Remove the engine cover and the battery.

Disconnect the negative terminal of the battery.

Raise and support the front of the vehicle.

Remove the under-engine sound-deadening and the front RH splash-shield.

Uncouple, plug and move aside, using tool [1], the fuel supply and fuel return pipes..

Suspend the engine, using a workshop hoist.

Remove the engine support bracket and the engine support.

Move aside the electrical harness (1).

Remove:

- The camshaft position sensor.

- The inlet cylinder head cover (2).

- The upper timing cover screws.

- The upper timing cover (3).

B1EP1GFC

C4

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 271