air Citroen C4 2005 2.G Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 259 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 253

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

B1BP304D

Tools.

[1]Flywheel setting peg: (-).0194.C

[2]Camshaft setting peg Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 253

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

B1BP304D

Tools.

[1]Flywheel setting peg: (-).0194.C

[2]Camshaft setting peg](/img/9/4138/w960_4138-258.png)

Downloaded from www.Manualslib.com manuals search engine 253

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

B1BP304D

Tools.

[1]Flywheel setting peg: (-).0194.C

[2]Camshaft setting peg: (-).0194.B

[3] Crankshaft setting peg: (-).0194.A

Checking and setting the timing.

Removing.

Raise and support the vehicle, wheels hanging.

Disconnect the positive and negative terminals of the battery.

Remove:

- The front RH wheel.

- The front RH splash-shield.

- The accessories drive belt

(see corresponding operation).

Uncouple:

- The fuel supply unions (1).

- The air/air heat exchanger inlet and outlet pipes (3).

- The exhaust line

(at the flexible pipe).

Disconnect the connecter at «a».

Remove and move aside the power steering fluid reservoir (6).

Uncouple, plug and move aside the tube (2).

Support the engine with a roller jack equipped with a block.

Remove the engine supports(4)and (5).

XSARA PICASSO

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 253

Page 264 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 258

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting (continued).

Refit tool [1]at «b».

Remove the screw (10).

Refit: Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 258

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting (continued).

Refit tool [1]at «b».

Remove the screw (10).

Refit:](/img/9/4138/w960_4138-263.png)

Downloaded from www.Manualslib.com manuals search engine 258

ENGINECHECKING AND SETTING THE VALVE TIMING

Engines: 9HZ - 9HY

Refitting (continued).

Refit tool [1]at «b».

Remove the screw (10).

Refit:

- The upper timing cover (12).

- The lower timing cover (11).

- The accessories drive pulley (9).

- The screw (10).

Tightening torque

- Screw (10)Pre-tighten to: 3 ± 0,3 m.daN.

Angular tighten: 180° ± 5°.

Remove tool [1].

Refit:

- The engine support (8), tighten to 5,5 ± 0,4 m.daN.

- The engine support (4), tighten to 6,1 ± 0,6 m.daN.

- The engine support (5), tighten to 2,5 ± 0,2 m.daN.

- The electrical harness (7).

- The power steering fluid reservoir (6).

XSARA PICASSO

Disengage the jack from under the engine.

Couple:

- The tube (2).

- The exhaust line, tighten the clip to 2,5 ± 0,3 m.daN.

- The fuel unions (1).

- The air/air heat exchanger inlet and outlet pipes (3).

Connect the connector at «a».

Refit:

- The accessories drive belt

(see corresponding operation).

- The front RH splash-shield (see corresponding operation).

- The front RH wheel, tighten to 9 ± 1 m.daN.

Reconnect the positive and negative terminals of the battery.

IMPERATIVE: Perform the operations that are necessary following

a reconnection of the battery

(see corresponding operation).

Angl.-t2-page240-282-2005 9/01/06 10:16 Page 258

Page 290 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 284

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2]Pressure gauge for testing boost pr Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 284

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2]Pressure gauge for testing boost pr](/img/9/4138/w960_4138-289.png)

Downloaded from www.Manualslib.com manuals search engine 284

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2]Pressure gauge for testing boost pressure: 4073-T.A Toolkit 4073-T

IMPERATIV: Respect the safety and cleanliness specific to high pressure diesel injection

engines.

Remove the air filter duct.

Link tool [1]in series, downstream of the injectors, between the fuel high pressure pump and the

fuel filter at «a»and «b».

WARNING: Any checking of pressure downstream of the fuel filter is prohibited.

Switch on the ignition.

Check the pressure :

Vacuum measured by the pressure gauge [2]:

Vacuum Observations

10 ± 0,5 cmHgEngine driven by the starter motor.

20 ± 0,5 cmHgEngine running under full load

60 ± 0,5 cmHgSupply circuit obstructed

(full tank strainer, piping, fuel filter)

B1CP0GFD

Engines: 9HX - 9HY - 9HZ

C4

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 284

Page 291 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 285

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Pressure gauge for testing boost Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 285

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Pressure gauge for testing boost](/img/9/4138/w960_4138-290.png)

Downloaded from www.Manualslib.com manuals search engine 285

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Tools.

[1] Ø 10 mm low pressure connector: 4215-T

[2] Pressure gauge for testing boost pressure: 4073-T.A Toolkit 4073-T

IMPERATIVE: Respect the safety and cleanliness specific to high pressure diesel injection

engines.

Remove the air filter duct.

Link tool [1]in series, downstream of the injectors, between the fuel high pressure pump and the

fuel filter at «a»and «b».

WARNING: Any checking of pressure downstream of the fuel filter is prohibited.

Switch on the ignition.

ESSENTIAL: Check that the tool [2] is clean.

Check the negative pressure according to the table below:

Vacuum Observations

10 ± 05 cmhgEngine driven by the starter motor

20 ± 20 cmhgEngine running under full load

60 ± 05 cmhgSupply circuit obstructed

(full tank strainer, piping, fuel filter

B1BP2PHC

Engines: 9HZ - 9HY

XSARA PICASSO

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 285

Page 299 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 293

INJECTION

CHECKS: TURBO PRESSURE

Tools.

[1] Pressure gauge for checking the turbo pressure: 4073-T Toolkit 4073-T

[2]Pressure take-off exte Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 293

INJECTION

CHECKS: TURBO PRESSURE

Tools.

[1] Pressure gauge for checking the turbo pressure: 4073-T Toolkit 4073-T

[2]Pressure take-off exte](/img/9/4138/w960_4138-298.png)

Downloaded from www.Manualslib.com manuals search engine 293

INJECTION

CHECKS: TURBO PRESSURE

Tools.

[1] Pressure gauge for checking the turbo pressure: 4073-T Toolkit 4073-T

[2]Pressure take-off extension: 8607-T.A

[3]Pressure take-off union and hose: 8607-T.B

[4] Sleeve for checking the turbo pressure: 4185-T

[5]Adaptor sleeve: 4219-T

IMPERATIVE: Respect the safety and cleanliness specific to high pressure diesel injection

engines.

Preliminary operation.

Slacken the clip (1).

Uncouple the air duct (2).

Connect the tool [1]on tool [2]and the tool [3]on tool [2].

Positioning on the vehicle.

Insert the tools [4]and [5]between the air duct (2)and the turbo air cooler outlet at «a».

Connect the tool [3]on tool [4].

Position the tool [1]inside the vehicle.

Start the engine.

Accelerate to 4000 rpm.

The value should be: 1 ± 0,2.

Return the vehicle to conformity.

Remove tools [1], [2], [3], [4]and [5].

Recouple the air duct (2)on the turbo air cooler.

Tighten the clip (1).

B1BP356C

B1HP1ZXC

Engine: RHR

C4

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 293

Page 302 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 296

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Vacuum pump:

- Connect the tool [1]onto the va Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 296

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Vacuum pump:

- Connect the tool [1]onto the va](/img/9/4138/w960_4138-301.png)

Downloaded from www.Manualslib.com manuals search engine 296

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Vacuum pump:

- Connect the tool [1]onto the vacuum pump (1).

- Start the engine.

- Wait 30 seconds.

The vacuum value should be 0.9 ± 0.1 barat idle.

B1HP1K8D

Engines: 8HX - 8HZ

XSARA

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 296

Page 303 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 297

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Checks.

Vacuum pump.

Connect the tool [1]into t Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 297

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Checks.

Vacuum pump.

Connect the tool [1]into t](/img/9/4138/w960_4138-302.png)

Downloaded from www.Manualslib.com manuals search engine 297

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Checks.

Vacuum pump.

Connect the tool [1]into the vacuum pump (1).

Start the engine.

The vacuum value should be 0.9 ± 0.1 barat idle

(after 30 secondsof operation).

NOTE:The exhaust gas recycling valve is not linked to the air supply circuit.

The exhaust gas recycling electrovalve is controlled by the engine ECU.

Turbocharging pressure regulation valve.

Connect the tool [1]on the valve (2).

Apply a vacuum of approx. 0.8 bar.

Rod "a"should move 6 ± 2 mm.B1HP1UGC

B1HP22RC

Engine: 9HX

C4

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 297

Page 304 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 298

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Checks.

Vacuum pump.

Connect the tool [1]into t Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 298

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Checks.

Vacuum pump.

Connect the tool [1]into t](/img/9/4138/w960_4138-303.png)

Downloaded from www.Manualslib.com manuals search engine 298

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

Checks.

Vacuum pump.

Connect the tool [1]into the vacuum pump (1).

Start the engine.

Wait 30 seconds.

The vacuum value should be 0.9 ± 0.1 barat idle.

NOTE:The exhaust gas recycling valve is not linked to the air supply circuit.

The exhaust gas recycling electrovalve is controlled by the engine ECU.

Turbocharging pressure regulation valve.

Connect the tool [1]on the valve (2)

(tube identified by the colour grey).

Apply a vacuum of approx. 0.8 bar.

Rod "a"should move 12 ± 2 mm.

B1HP1UGC

B1HP1UHC

Engines: 9HY - 9HZ

C4

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 298

Page 305 of 462

![Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 299

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

B1BP33ZC

B1BP340C

Engine: RHR

B1BP341C

B1BP342C

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16 Citroen C4 2005 2.G Repair Manual Downloaded from www.Manualslib.com manuals search engine 299

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

B1BP33ZC

B1BP340C

Engine: RHR

B1BP341C

B1BP342C

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16](/img/9/4138/w960_4138-304.png)

Downloaded from www.Manualslib.com manuals search engine 299

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

B1BP33ZC

B1BP340C

Engine: RHR

B1BP341C

B1BP342C

Tool.

[1]Manual pressure-vacuum pump: FACOM DA 16

IMPERATIVE: Respect the safety and cleanliness specific to high pressure diesel

injection engines.

WARNING: After switching off the ignition, wait 15 minutes before disconnecting

the battery

(to guarantee memorisation of the initialisations of the different ECUS).

Checking the vacuum source

(vacuum pump).

Connect the tool [1] on the take-off «a».

Start the engine.

The value should be: 1 ± 0,2.

Turbocharging pressure electrovalve.

Connect the tool [1]on the vacuum supply «b»of the electrovalve (1).

Start the engine.

The value should be: 1 ± 0,2.

Cold air circuit electrovalve.

Connect the tool [1]on the vacuum supply «c»of the electrovalve (2).

Start the engine.

The value should be: 1 ± 0,2.

Warm air circuit electrovalve.

Connect the tool [1]on the vacuum supply «d»of the electrovalve (3).

Start the engine.

The value should be: 1 ± 0,2.

C4

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 299

Page 306 of 462

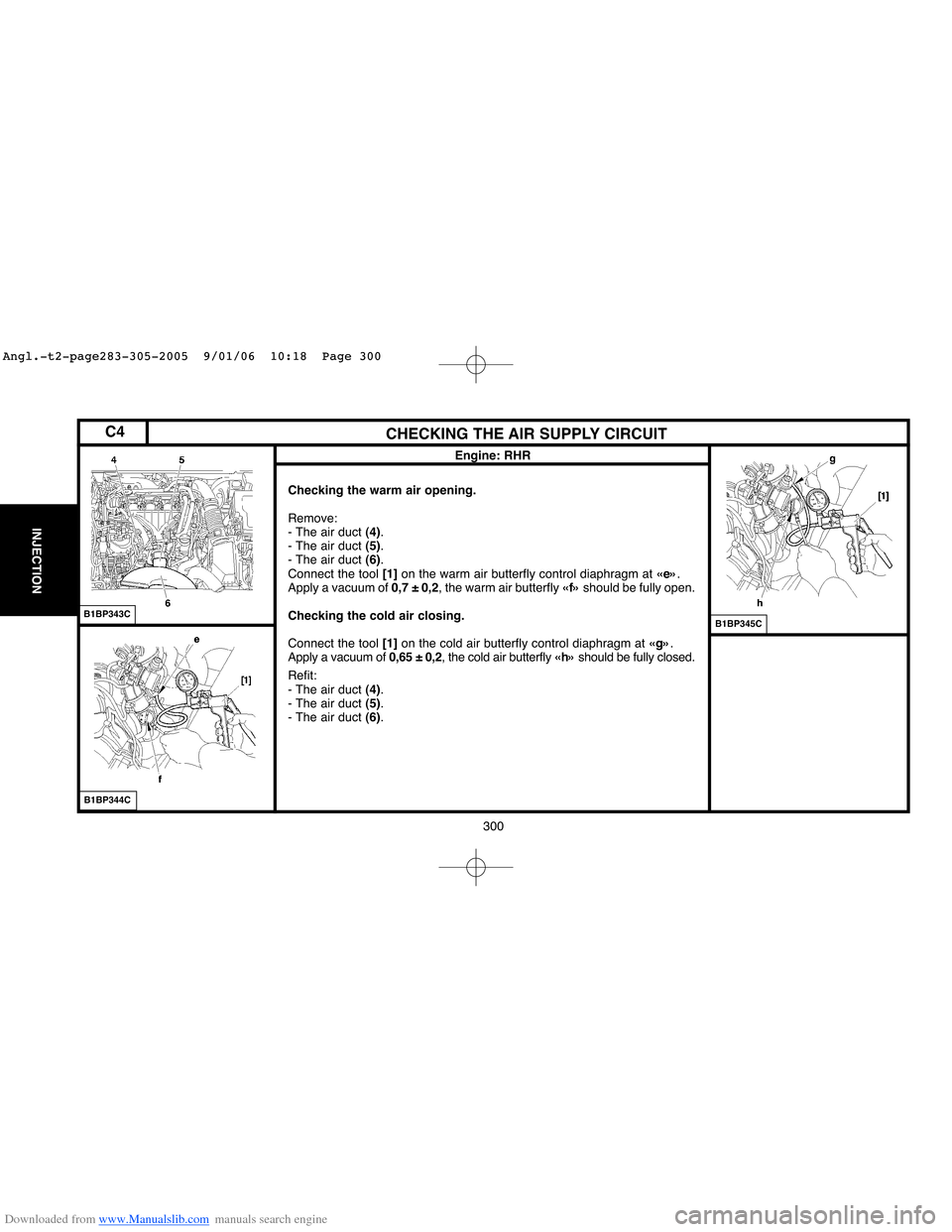

Downloaded from www.Manualslib.com manuals search engine 300

INJECTION

CHECKING THE AIR SUPPLY CIRCUIT

B1BP343C

B1BP344C

Engine: RHR

B1BP345C

Checking the warm air opening.

Remove:

- The air duct (4).

- The air duct (5).

- The air duct (6).

Connect the tool [1]on the warm air butterfly control diaphragm at «e».

Apply a vacuum of 0,7 ± 0,2, the warm air butterfly «f»should be fully open.

Checking the cold air closing.

Connect the tool [1]on the cold air butterfly control diaphragm at «g».

Apply a vacuum of 0,65 ± 0,2, the cold air butterfly «h»should be fully closed.

Refit:

- The air duct (4).

- The air duct (5).

- The air duct (6).

C4

Angl.-t2-page283-305-2005 9/01/06 10:18 Page 300