ash Citroen C4 2005 2.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C4, Model: Citroen C4 2005 2.GPages: 462, PDF Size: 10.48 MB

Page 44 of 462

Downloaded from www.Manualslib.com manuals search engine 38

GENERAL

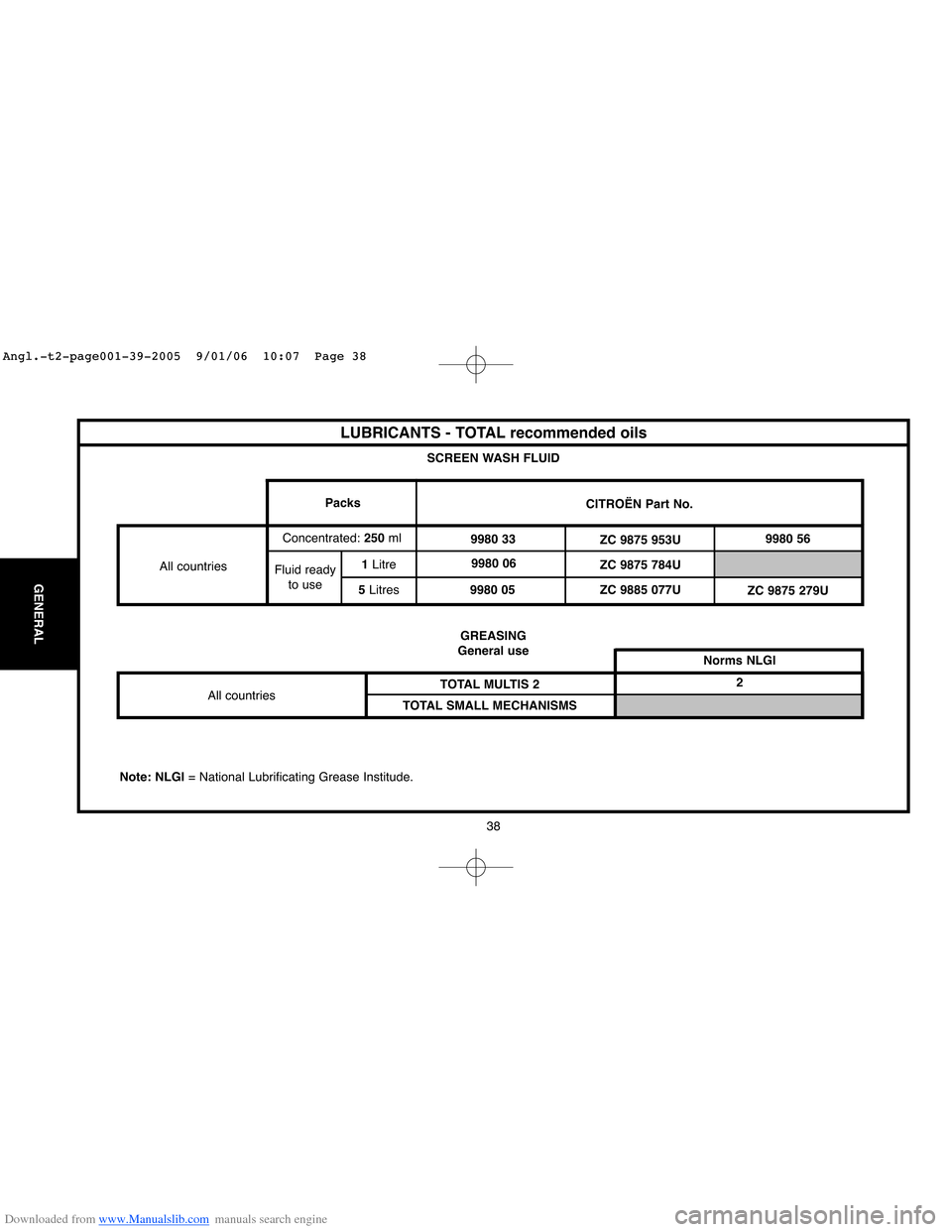

SCREEN WASH FLUID

GREASING

General use

All countriesConcentrated: 250ml

Fluid ready

to use9980 33

9980 06

9980 05ZC 9875 953U

ZC 9875 784U

ZC 9885 077U9980 56

ZC 9875 279U Packs

CITROËN Part No.

LUBRICANTS - TOTAL recommended oils

1Litre

5Litres

Norms NLGI

2

TOTAL MULTIS 2

TOTAL SMALL MECHANISMS All countries

Note: NLGI= National Lubrificating Grease Institude.

Angl.-t2-page001-39-2005 9/01/06 10:07 Page 38

Page 162 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 156

ENGINE

B1BP2LSC

B1BP2LTC

AUXILIARY EQUIPMENT DRIVE BELT

Engines: KFU - NFU

Tools.

[1]Pliers for removing plastic pegs: 7504 -T

[2]Belt tens Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 156

ENGINE

B1BP2LSC

B1BP2LTC

AUXILIARY EQUIPMENT DRIVE BELT

Engines: KFU - NFU

Tools.

[1]Pliers for removing plastic pegs: 7504 -T

[2]Belt tens](/img/9/4138/w960_4138-161.png)

Downloaded from www.Manualslib.com manuals search engine 156

ENGINE

B1BP2LSC

B1BP2LTC

AUXILIARY EQUIPMENT DRIVE BELT

Engines: KFU - NFU

Tools.

[1]Pliers for removing plastic pegs: 7504 -T

[2]Belt tension measuring instrument (SEEM) : 4122 -T

[3]Compression lever for dynamic tensioner: (-).0194.D

[4] Peg for dynamic tensioner roller of Ø 4 mm : (-) 0194.F

WARNING: (With or without air conditioning)

The auxiliaries drive belt cannot be re-used

with a manual tensioner roller.

The auxiliaries drive belt can be re-usedwith a dynamic tensioner roller.

Removing.

Raise and support the vehicle, front wheels hanging.

Disconnect the battery.

Remove the front RH wheel and the front RH splash-shield, using tool [1].

V

ehicle without air conditioning.Slacken bolts (2), screw (3)and the tensioning screw (1).

Push back the alternator towards the engine.

Remove the auxiliary equipment drive belt.

Refitting.

Refit the new auxiliary equipment drive belt.

Respect the following sequence: Crankshaft pinion, alternator pulley.

Position tool [2]on the belt.

Tighten the screw (1)to tension the belt to: 120 ± 4 SEEM units.

Tighten screw (3), bolts (2).

Remove tool [2].

Complete the refitting.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 156

Page 169 of 462

Downloaded from www.Manualslib.com manuals search engine 163

ENGINE

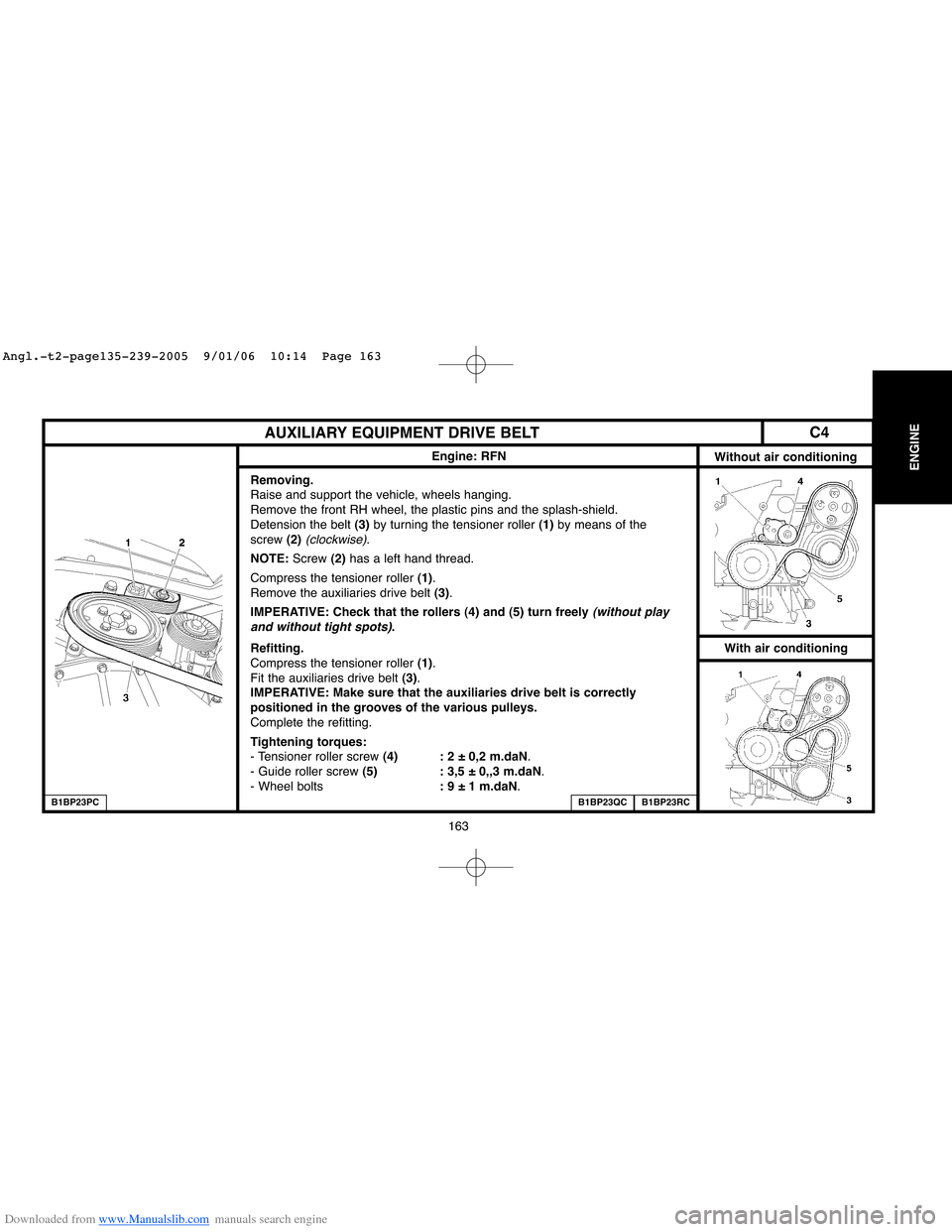

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFN

Without air conditioning

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Detension the belt (3)by turning the tensioner roller (1)by means of the

screw (2)

(clockwise).

NOTE:Screw (2)has a left hand thread.

Compress the tensioner roller (1).

Remove the auxiliaries drive belt (3).

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play

and without tight spots).

Refitting.

Compress the tensioner roller (1).

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly

positioned in the grooves of the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4) : 2 ± 0,2 m.daN.

- Guide roller screw (5) : 3,5 ± 0,,3 m.daN.

- Wheel bolts: 9 ± 1 m.daN.

B1BP23PCB1BP23QCB1BP23RC

With air conditioning

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 163

Page 170 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner rolle](/img/9/4138/w960_4138-169.png)

Downloaded from www.Manualslib.com manuals search engine 164

ENGINE

B1BP39AC

B1BP23RC

AUXILIARY EQUIPMENT DRIVE BELT

Engine: RFK

Tools.

[1]Detensioning lever for auxiliaries drive belt tensioner roller:

Dynamic spanner extension: FACOM SJ.214

Adaptor for socket 9x12 : FACOM J.274

Polygon socket 9x12 : 016

Removing.

Raise and support the vehicle, wheels hanging.

Remove the front RH wheel, the plastic pins and the splash-shield.

Turn the tensioner roller(1)by the screw (2)

(anti-clockwise), using tool [1]to detension the belt (3).

NOTE: Screw (2)has a left hand thread.

Remove the auxiliaries drive belt (3).

Refitting.

IMPERATIVE: Check that the rollers (4) and (5) turn freely

(without play and without tight spots).

Refitting.

Compress the tensioner roller (1), using tool [1].

Fit the auxiliaries drive belt (3).

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in the grooves of

the various pulleys.

Complete the refitting.

Tightening torques:

- Tensioner roller screw (4)tighten to: 2 ± 0,2 m.daN.

- Guide roller screw (5)tighten to: 3,5 ± 0,3 m.daN.

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 164

Page 171 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 165

ENGINE

XSARA

AUXILIARY EQUIPMENT DRIVE BELT

Tools.

[1] Dynamic tensioner compression lever: (-).0188.Z

[2] Peg for dynamic tensioner roller Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 165

ENGINE

XSARA

AUXILIARY EQUIPMENT DRIVE BELT

Tools.

[1] Dynamic tensioner compression lever: (-).0188.Z

[2] Peg for dynamic tensioner roller](/img/9/4138/w960_4138-170.png)

Downloaded from www.Manualslib.com manuals search engine 165

ENGINE

XSARA

AUXILIARY EQUIPMENT DRIVE BELT

Tools.

[1] Dynamic tensioner compression lever: (-).0188.Z

[2] Peg for dynamic tensioner roller: (-).0194.F

Removing.

IMPERATIVE: Respect the safety and cleanliness requirements specific to High pressure

Diesel injection (HDi) engine versions.

Remove:

- the front RH wheel.

- the sound insulation under the engine.

- the splash-shield.

WARNING: Mark the direction of fitting of the accessories belt if it is to be re-used.

Compress the dynamic tensioner roller (1)by acting at «a»

(clockwise), using tool [1].

Peg at «b». using tool [2].

Keep the dynamic tensioner roller (1)compressed and remove the auxiliaries drive belt.

IMPERATIVE: Check that the rollers (1) and (2) can turn freely

(without play and without

tight spots).

B1BP2VZD

Engines: 8HX - 8HZ

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 165

Page 175 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 169

ENGINE

B1BP2Z6D

B1BP2ZCD

AUXILIARY EQUIPMENT DRIVE BELT

Engines: 9HZ - 9HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z

[2]Peg Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 169

ENGINE

B1BP2Z6D

B1BP2ZCD

AUXILIARY EQUIPMENT DRIVE BELT

Engines: 9HZ - 9HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z

[2]Peg](/img/9/4138/w960_4138-174.png)

Downloaded from www.Manualslib.com manuals search engine 169

ENGINE

B1BP2Z6D

B1BP2ZCD

AUXILIARY EQUIPMENT DRIVE BELT

Engines: 9HZ - 9HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z

[2]Peg for dynamic tensioner roller: (-).0194.F

Removing.

Remove the front RH wheel, the under-engine sounddeadening and the splash-shield.

V

ehicle with air conditioning.

WARNING: Mark the direction of fitting of the accessories drive belt, if it is to be re-used.

Compress the tensioner roller(1)by acting at «a»

(clockwise), using tool [1].

Peg at «b», using tool [2].

Remove the accessories drive belt.

IMPERATIVE: Check that the rollers (1) and (2) can turn freely

(without play and without tight

spots).

Refitting.

WARNING: Belt to be re-used, mark the direction of fitting of the belt.

Refit the accessories drive belt.

Compress the tensioner roller (1)by acting at «a»

(clockwise), using tool [1].

Remove tool [2].

IMPERATIVE: Make sure the belt is correctly positioned in the grooves of the various pulleys.

Complete the refitting in the opposite order to removal.

XSARA PICASSO

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 169

Page 186 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic ten Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic ten](/img/9/4138/w960_4138-185.png)

Downloaded from www.Manualslib.com manuals search engine 180

ENGINE

B1BP2J5D

AUXILIARY EQUIPMENT DRIVE BELT

Engines: RHV - 4HY

Tools.

[1]Dynamic tensioner compression lever: (-).0188.Z.

[2]Dynamic tensioner roller retaining peg Ø 4 mm : (-).0188.Q1

Removing.

Remove the splash-shield, under-engine sound-deadening, front RH wheel.

WARNING: Mark the direction of fitting of the auxiliaries drive belt in the case of

re-use of the belt.

Compress the dynamic tensioner roller (1)by acting at «b»

(anti-clockwise), using tool [1].

Peg using tool [2]at «a».

IMPERATIVE : Check that the roller (1) turns freely

(without play and without tight

spots).

Refitting.

Refit the auxiliaries drive belt.

IMPERATIVE: Make sure that the auxiliaries drive belt is correctly positioned in

the grooves of the various pulleys.

Compress the dynamic tensioner roller (1)by acting at «b», using tool [1].

Remove tool [2] at «a».

Complete the refitting.

JUMPER

Without air conditioning

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 180

Page 209 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 203

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFJ

Tools.

[1]Camshaft pinion peg: (-).0194.A

[2]Crankshaft setting peg: (-).0189.R

IM Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 203

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFJ

Tools.

[1]Camshaft pinion peg: (-).0194.A

[2]Crankshaft setting peg: (-).0189.R

IM](/img/9/4138/w960_4138-208.png)

Downloaded from www.Manualslib.com manuals search engine 203

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Engine: RFJ

Tools.

[1]Camshaft pinion peg: (-).0194.A

[2]Crankshaft setting peg: (-).0189.R

IMPERATIVE: Respect the safety and cleanliness requirements.

Disconnect the battery.

Raise and support the vehicle, front wheels hanging.

Remove the front RH wheel, the plastic pins holding the splash-shield, the splash-shield itself.

A:Pegging on the manualgearbox.

B:Pegging on the automaticgearbox.

Turn the engine by means of the crankshaft pinion screw, to bring it to the pegging position.

B1BP2V3D

B1BP38VC

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 203

Page 216 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 210

ENGINECHECKING THE VALVE TIMING

Engine: RFN

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

IMPERATIVE: Re Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 210

ENGINECHECKING THE VALVE TIMING

Engine: RFN

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

IMPERATIVE: Re](/img/9/4138/w960_4138-215.png)

Downloaded from www.Manualslib.com manuals search engine 210

ENGINECHECKING THE VALVE TIMING

Engine: RFN

Tools.

[1]Camshaft setting peg: (-).0189.A

[2]Crankshaft setting peg: (-).0189.R

IMPERATIVE: Respect the safety and cleanliness requirements.

Checking the timing.

Removing.

Disconnect the battery negative terminal.

Raise and support the vehicle, front wheels hanging.

Remove the front RH wheel, the splash-shield and the upper timing cover.

A:Pegging on the manualgearbox.

Turn the engine by means of the crankshaft pinion screw, to bring it to the pegging

position.

Peg the crankshaft, using tool [2].

Unclip the fuel supply hose from the timing cover.

B1BP36QD

C4

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 210

Page 223 of 462

![Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 217

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Tools.

[1]Camshaft setting peg: (-) 0189.A

[2] Crankshaft setting peg: (-).0189.R

[3]Timing be Citroen C4 2005 2.G Workshop Manual Downloaded from www.Manualslib.com manuals search engine 217

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Tools.

[1]Camshaft setting peg: (-) 0189.A

[2] Crankshaft setting peg: (-).0189.R

[3]Timing be](/img/9/4138/w960_4138-222.png)

Downloaded from www.Manualslib.com manuals search engine 217

ENGINE

CHECKING AND SETTING THE VALVE TIMING

Tools.

[1]Camshaft setting peg: (-) 0189.A

[2] Crankshaft setting peg: (-).0189.R

[3]Timing belt retaining pin: (-).0189.K

[4]Adaptor for angular tightening: 4069-T

[5]Tool for moving and locking the tensioner roller: (-).0189.S

[5a] : (-).0189.S1

[5b] : (-).0189 S2

Pliers for removing plastic pins: 7504-T

Checking the setting of the timing.

Removing.

Disconnect the battery negative terminal

(see corresponding operation).

Raise and support the vehicle, front wheels hanging.

Remove:

- The front RH wheel.

- The plastic pins (1).

- The splash-shield (2).

- The upper timing cover.

C4AP12TC

XSARA - XSARA PICASSO

Engines: 6FZ - RFN

Angl.-t2-page135-239-2005 9/01/06 10:14 Page 217