tow Citroen C4 PICASSO 2016 2.G Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2016, Model line: C4 PICASSO, Model: Citroen C4 PICASSO 2016 2.GPages: 527, PDF Size: 13.72 MB

Page 292 of 527

290

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

Checking /adjusting tyre pressures

You can also use the compressor without

injecting any product, to check and if necessary

a

djust your tyre pressures.

F

T

urn the selector A to the "Air"

position.

F

U

ncoil the black pipe H

f

ully.

F

C

onnect the black pipe to the

t

yre valve. F

C onnect the compressor's electrical

c

onnector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(

to inflate: switch B in position "I";

t

o deflate: switch B in position "O" and

press button C ),

according to the vehicle's

t

yre pressure label.

F

R

emove the kit then stow it.Should the pressure of one or more

tyres

be adjusted, it is necessary to

r

einitialise the under-inflation detection

system.

For more information on Under-

inflation detection , refer to the

corresponding

s

ection.

In the event of a breakdown

Page 294 of 527

292

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

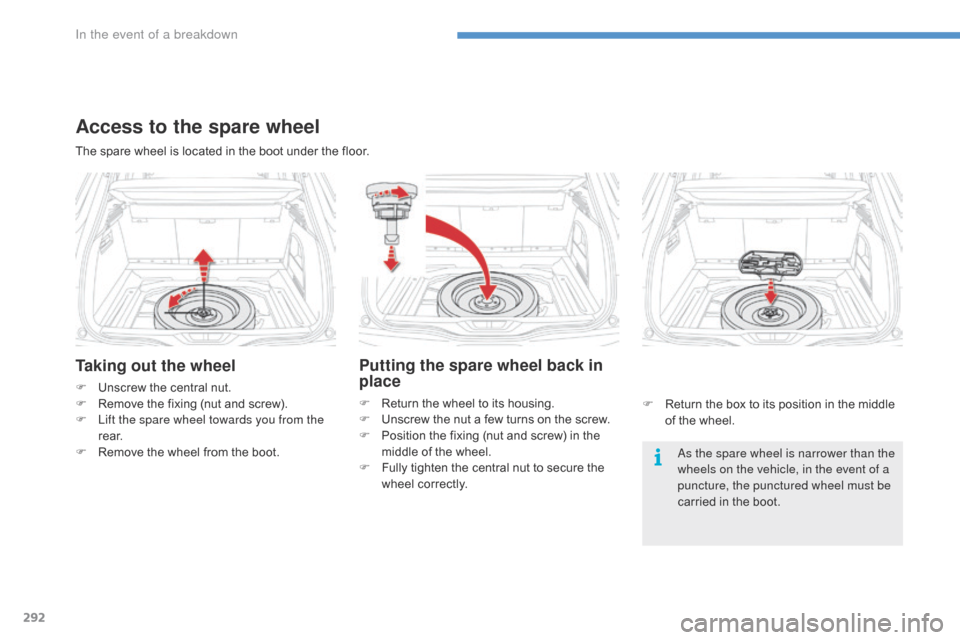

Taking out the wheel

F Unscrew the central nut.

F R emove the fixing (nut and screw).

F

L

ift the spare wheel towards you from the

r e a r.

F

R

emove the wheel from the boot. As the spare wheel is narrower than the

wheels on the vehicle, in the event of a

puncture, the punctured wheel must be

carried

in the boot.

The

spare wheel is located in the boot under the floor.

Access to the spare wheel

Putting the spare wheel back in

place

F Return

the wheel to its housing.

F U nscrew the nut a few turns on the screw.

F

P

osition the fixing (nut and screw) in the

m

iddle of the wheel.

F

F

ully tighten the central nut to secure the

w

heel correctly. F

R eturn the box to its position in the middle

o

f the wheel.

In the event of a breakdown

Page 295 of 527

293

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

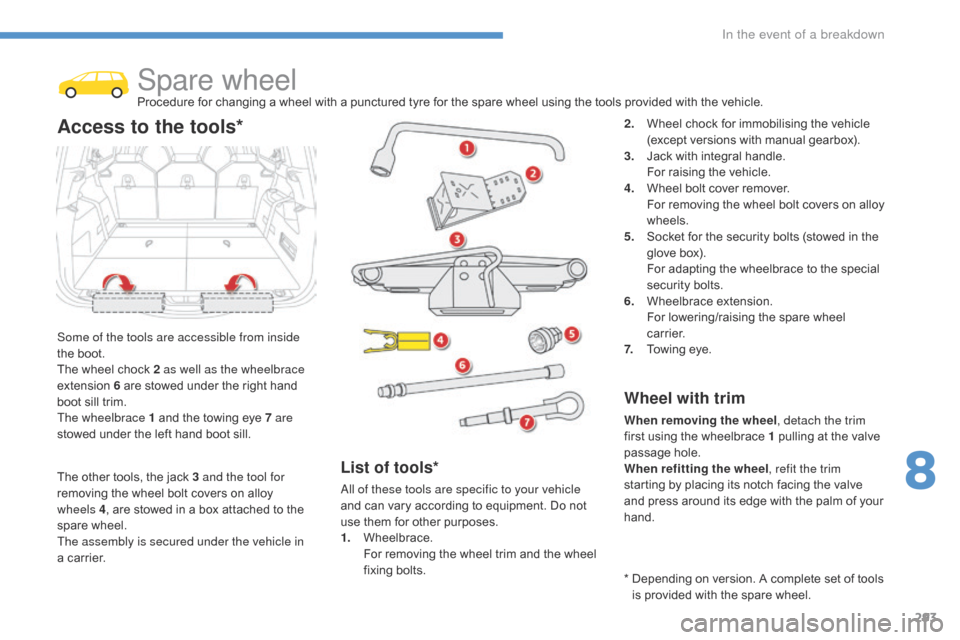

Spare wheelProcedure for changing a wheel with a punctured tyre for the spare wheel using the tools provided with the vehicle.

S

ome of the tools are accessible from inside

the

boot.

The

wheel

chock 2 as well as the wheelbrace

extension

6

are stowed under the right hand

b

oot

sill

trim.

The wheelbrace 1

and the towing eye 7 are

stowed

under

the left hand boot sill.

Access to the tools*2. Wheel chock for immobilising the vehicle (

except versions with manual gearbox).

3.

J

ack with integral handle.

F

or raising the vehicle.

4.

W

heel bolt cover remover.

F

or removing the wheel bolt covers on alloy

w

heels.

5.

S

ocket for the security bolts (stowed in the

g

love box).

F

or adapting the wheelbrace to the special

s

ecurity bolts.

6.

W

heelbrace

e

xtension.

F

or lowering/raising the spare wheel

c

a r r i e r.

7.

T

owing eye.

Wheel with trim

When removing the wheel , detach the trim

first using the wheelbrace 1 pulling at the valve

p

assage hole.

When refitting the wheel , refit the trim

starting

by placing its notch facing the valve

a

nd press around its edge with the palm of your

han

d.

List of tools*

All of these tools are specific to your vehicle

and can vary according to equipment. Do not

u

se them for other purposes.

1.

W

heelbrace.

F

or removing the wheel trim and the wheel

f

ixing

bol

ts. *

D

epending on version. A complete set of tools

i

s provided with the spare wheel.

The

other

tools,

the

jack

3 and the tool for

removing

the

wheel

bolt

covers

on

alloy

w

heels

4 ,

are

stowed

in

a

box

attached

to

the

spar

e

w

heel.

The assembly is secured under the vehicle in

a

carrier.

8

In the event of a breakdown

Page 297 of 527

295

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

A punctured wheel from the vehicle

cannot be fitted under the vehicle. It

m

ust

b

e

c

arried

i

n

t

he

b

oot.

U

se

a

c

over

t

o protect the boot.

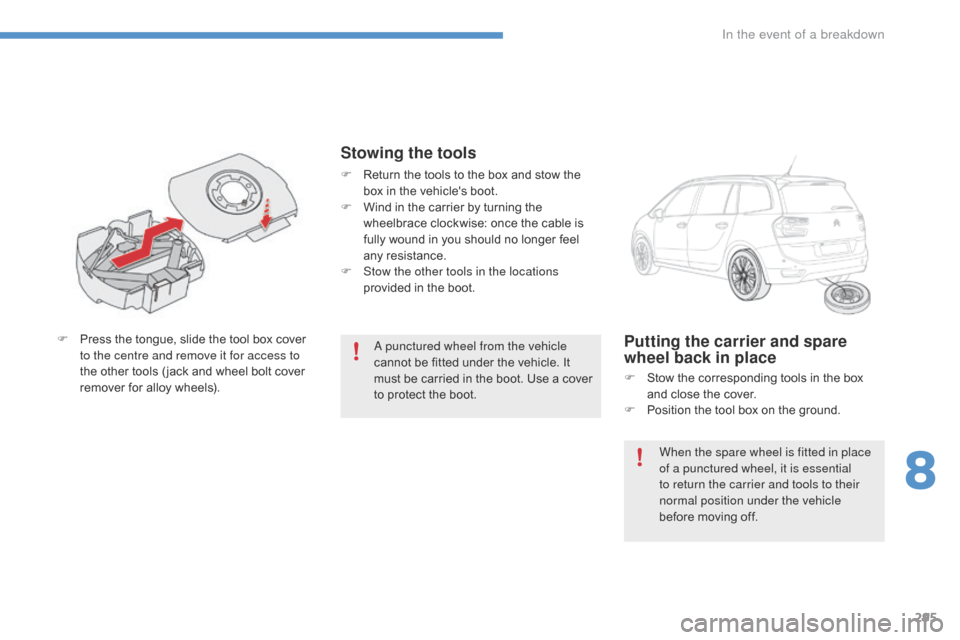

F

P

ress

the

tongue,

slide

the

tool

box

cover

t

o the centre and remove it for access to

the

other

tools

( jack

and

wheel

bolt

cover

r

emover

for

alloy

wheels).Putting the carrier and spare

wheel back in place

F Stow the corresponding tools in the box a

nd close the cover.

F

P

osition the tool box on the ground.

Stowing the tools

F Return the tools to the box and stow the b

ox in the vehicle's boot.

F

W

ind in the carrier by turning the

w

heelbrace clockwise: once the cable is

f

ully wound in you should no longer feel

an

y

r

esistance.

F

S

tow the other tools in the locations

provided

in the boot.

When the spare wheel is fitted in place

of a punctured wheel, it is essential

to return the carrier and tools to their

normal position under the vehicle

before

moving off.

8

In the event of a breakdown

Page 302 of 527

300

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

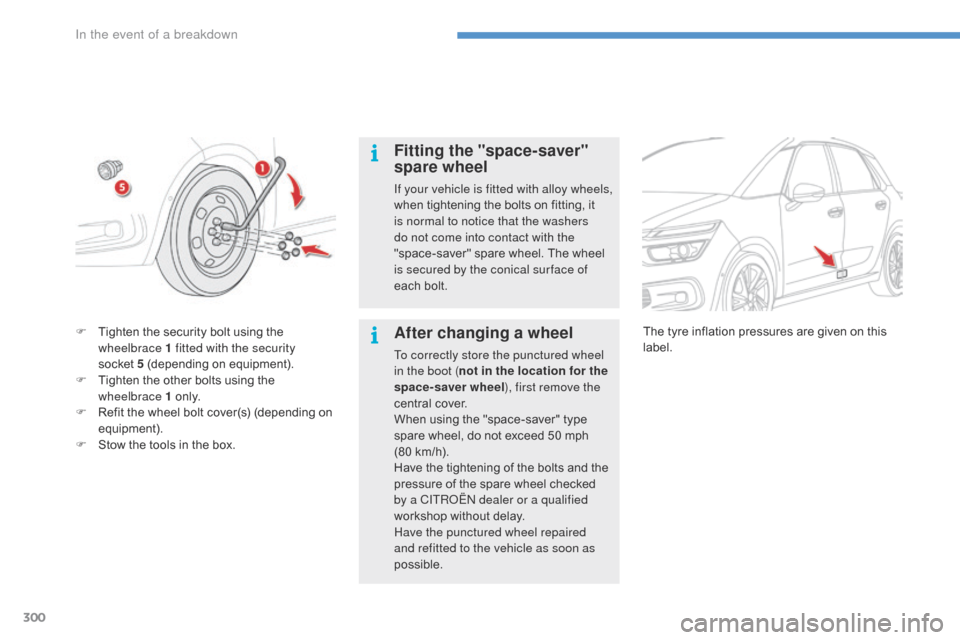

Fitting the "space-saver"

spare wheel

If your vehicle is fitted with alloy wheels,

when tightening the bolts on fitting, it

i

s normal to notice that the washers

do not come into contact with the

"space-saver"

spare wheel. The wheel

i

s secured by the conical sur face of

each

bolt.

After changing a wheel

To correctly store the punctured wheel

in the boot ( not in the location for the

space-saver wheel ), first remove the

central

cover.

When

using the "space-saver" type

s

pare wheel, do not exceed 50 mph

(

80 km/h).

Have

the tightening of the bolts and the

p

ressure of the spare wheel checked

b

y a CITROËN dealer or a qualified

workshop

without delay.

Have the punctured wheel repaired

and refitted to the vehicle as soon as

possible.

F

T

ighten

the

security

bolt

using

the

w

heelbrace 1 fitted with the security

socket 5

(depending

on

equipment).

F

T

ighten

the

other

bolts

using

the

w

heelbrace 1

o

n l y.

F

R

efit

the

wheel

bolt

cover(s)

(depending

on

e

quipment).

F

S

tow

the

tools

in

the

box. The

tyre inflation pressures are given on this lab

el.

In the event of a breakdown

Page 304 of 527

302

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

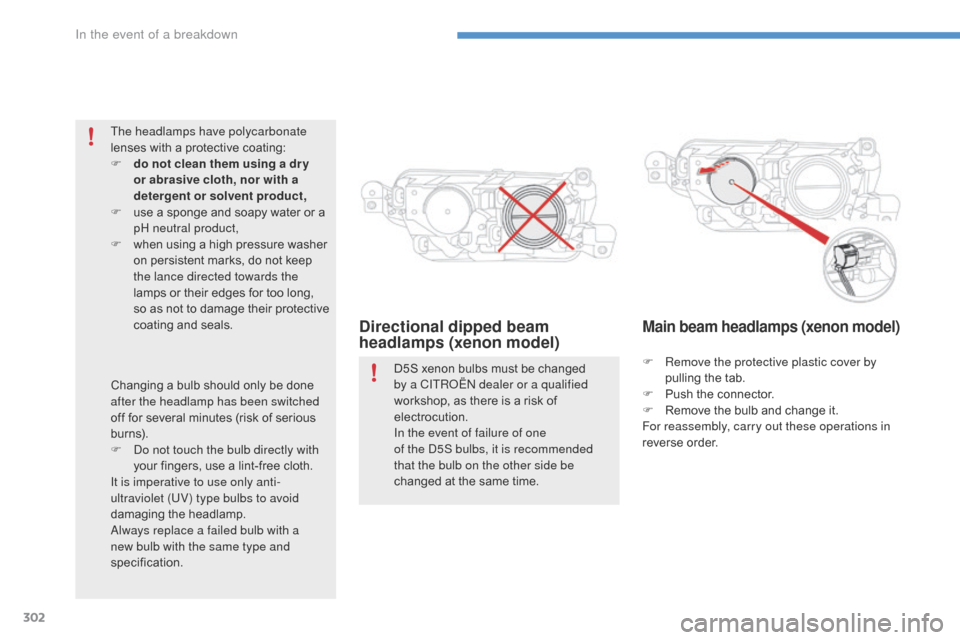

Directional dipped beam

headlamps (xenon model)Main beam headlamps (xenon model)

F Remove the protective plastic cover by pulling the tab.

F

P

ush the connector.

F

R

emove the bulb and change it.

For reassembly, carry out these operations in

reverse

o

rder.

D5S

xenon

bulbs

must

be

changed

b

y a CITROËN dealer or a qualified

workshop,

as

there

is

a

risk

of

el

ectrocution.

In the event of failure of one

of the D5S bulbs, it is recommended

that the bulb on the other side be

changed

at

the

same

time.

The headlamps have polycarbonate

lenses

with

a

protective

coating:

F

d

o not clean them using a dr y

or abrasive cloth, nor with a

detergent or solvent product,

F

u

se

a

sponge

and

soapy

water

or

a

p

H neutral product,

F

w

hen

using

a

high

pressure

washer

o

n

persistent

marks,

do

not

keep

t

he lance directed towards the

lamps

or

their

edges

for

too

long,

s

o

as

not

to

damage

their

protective

c

oating

a

nd

sea

ls.

Changing

a

bulb

should

only

be

done

a

fter the headlamp has been switched

off

for

several

minutes

(risk

of

serious

b

urns).

F

D

o not touch the bulb directly with

your

fingers,

use

a

lint-free

cloth.

It is imperative to use only anti-

ultraviolet (UV) type bulbs to avoid

damaging

t

he

h

eadlamp.

Always replace a failed bulb with a

new bulb with the same type and

specification.

In the event of a breakdown

Page 316 of 527

314

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

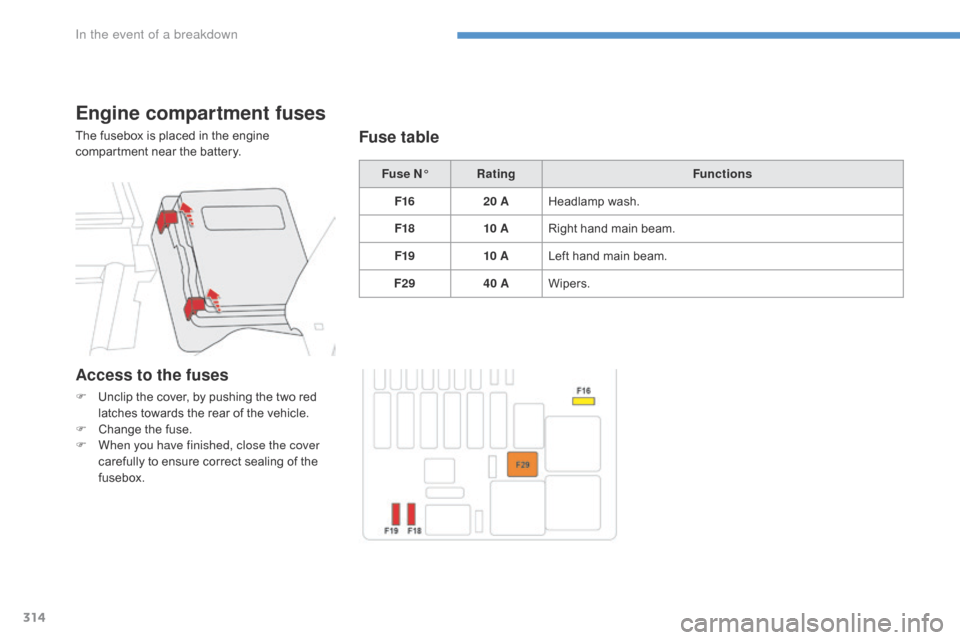

Engine compartment fuses

The fusebox is placed in the engine compartment near the battery.

Fuse N°Rating Functions

F16 20 AHeadlamp

w

ash.

F18 10 ARight

hand main beam.

F19 10 ALeft

hand main beam.

F29 40 AWipers.Fuse table

Access to the fuses

F Unclip the cover, by pushing the two red l

atches towards the rear of the vehicle.

F

C

hange the fuse.

F

W

hen you have finished, close the cover

carefully

to ensure correct sealing of the

f

usebox.

In the event of a breakdown

Page 321 of 527

319

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

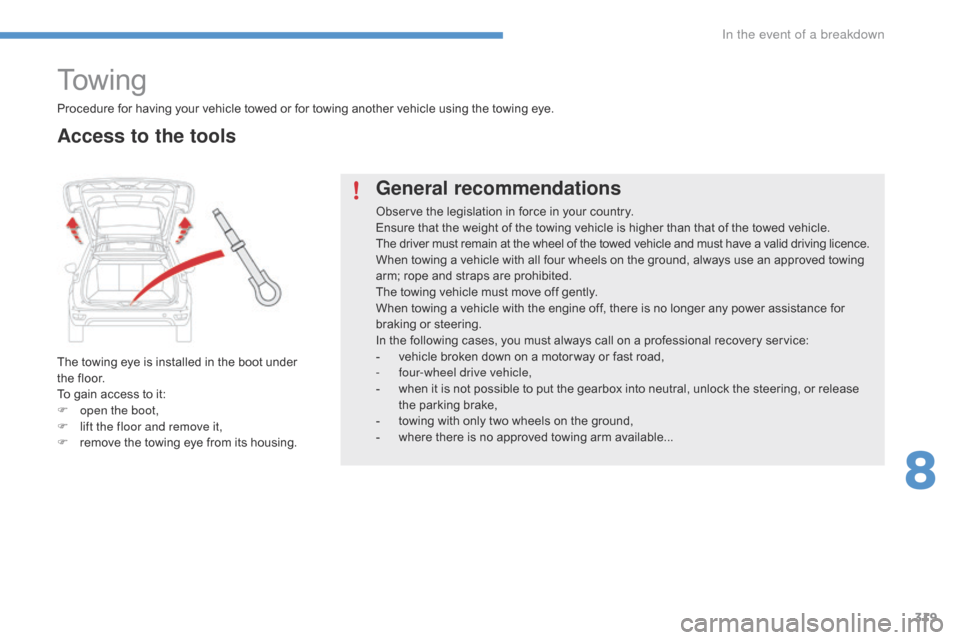

To w i n g

The towing eye is installed in the boot under the floor.

To

gain access to it:

F

o

pen the boot,

F

l

ift the floor and remove it,

F

r

emove the towing eye from its housing.

General recommendations

Observe the legislation in force in your country.

E nsure that the weight of the towing vehicle is higher than that of the towed vehicle.

The

driver must remain at the wheel of the towed vehicle and must have a valid driving licence.

When

towing a vehicle with all four wheels on the ground, always use an approved towing

a

rm; rope and straps are prohibited.

The

towing vehicle must move off gently.

When

towing a vehicle with the engine off, there is no longer any power assistance for

b

raking or steering.

In

the following cases, you must always call on a professional recovery service:

-

v

ehicle broken down on a motor way or fast road,

-

f

our-wheel drive vehicle,

-

w

hen it is not possible to put the gearbox into neutral, unlock the steering, or release

t

he parking brake,

-

t

owing with only two wheels on the ground,

-

w

here there is no approved towing arm available...

Procedure

for

having

your

vehicle

towed

or

for

towing

another vehicle using the towing eye.

Access to the tools

8

In the event of a breakdown

Page 322 of 527

320

C4-Picasso-II_en_Chap08_en-cas-panne_ed01-2016

Towing another vehicle

F On the rear bumper, unclip the cover by pressing at the bottom.

F

S

crew the towing eye in fully.

F

I

nstall the towing bar.

F

S

witch on the hazard warning lamps on

b

oth vehicles.

F

M

ove off gently, drive slowly and for a short

di

stance.

F

O

n the front bumper, unclip the cover by

pressing

on

the

left.

F

S

crew

the

towing

eye

in

fully.

F

I

nstall

the

towing

bar.

F

P

lace

the

gear

lever

in

neutral

(position

N

with

an

automatic

gearbox).

Towing your vehicle

Failure to observe this instruction could

result in damage to certain components

(

braking, transmission...) and the

a

bsence of braking assistance the next

t

ime the engine is started.

F

U

nlock the steering by turning the key

i

n

the ignition one notch and release the

par

king

b

rake.

F

S

witch on the hazard warning lamps on

b

oth vehicles.

F

M

ove off gently, drive slowly and for a short

di

stance.

In the event of a breakdown

Page 326 of 527

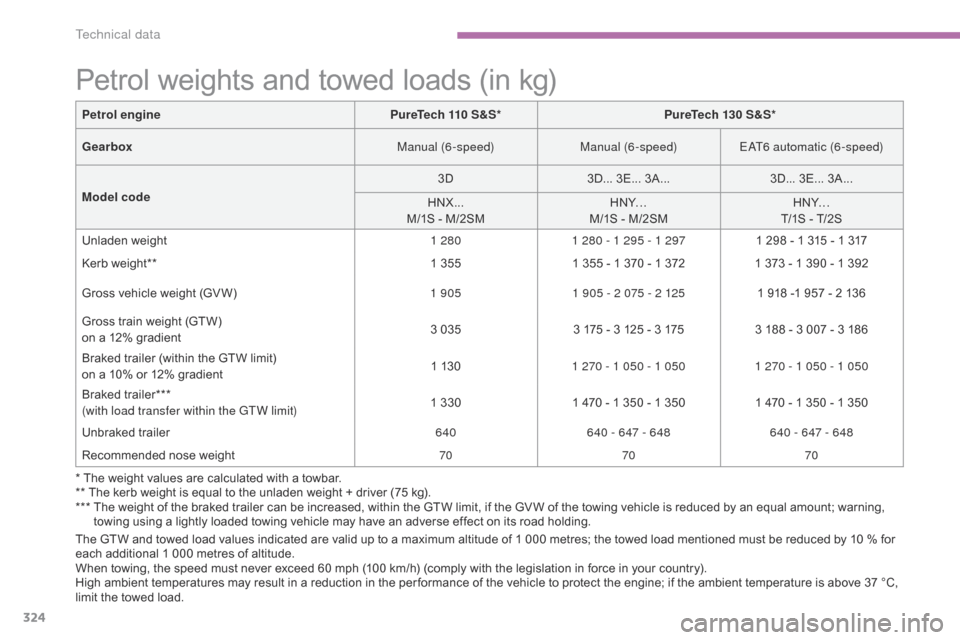

324

C4-Picasso-II_en_Chap09_caracteristiques-techniques_ed01-2016

* The weight values are calculated with a towbar.

* * The kerb weight is equal to the unladen weight + driver (75 kg).

***

T

he weight of the braked trailer can be increased, within the GTW limit, if the GV W of the towing vehicle is reduced by an equal amount; warning,

t

owing using a lightly loaded towing vehicle may have an adverse effect on its road holding.

Petrol engine

PureTech 110 S&S*PureTech 130 S&S*

Gearbox Manual (6-speed)Manual (6-speed)EAT6 automatic (6-speed)

Model code 3D

3D...

3

E...

3

A...

3D...

3

E...

3

A...

HNX...

M/1S - M/2SM

HNY…

M/1S - M/2SM

HNY…

T/1S - T/2S

Unladen weight

1 2801 280 - 1 295 - 1 297 1 298 - 1 315 - 1 317

Kerb weight**

1 355

1 355 - 1 370 - 1 372

1 373 - 1 390 - 1 392

Gross vehicle weight (GV W)

1 9051 905 - 2 075 - 2 125 1 918 -1 957 - 2 136

Gross train weight (GTW)

o

n a 12% gradient

3 035

3 175 - 3 125 - 3 175

3 188 - 3 007 - 3 186

Braked trailer (within the GTW limit)

o

n a 10% or 12% gradient

1 130

1 270 - 1 050 - 1 050 1 270 - 1 050 - 1 050

Braked trailer***

(with load transfer within the GTW limit) 1 330

1 470 - 1 350 - 1 350

1 470 - 1 350 - 1 350

Unbraked

t

railer

640640 - 647 - 648 640 - 647 - 648

Recommended nose weight

707070

Petrol weights and towed loads (in kg)

The GTW and towed load values indicated are valid up to a maximum altitude of 1 000 metres; the towed load mentioned must be reduced by 10 % for e

ach additional 1 000 metres of altitude.

When

towing, the speed must never exceed 60 mph (100 km/h) (comply with the legislation in force in your country).

High

ambient temperatures may result in a reduction in the per formance of the vehicle to protect the engine; if the ambient temperature is above 37 °C,

l

imit the towed load.

Technical data