CITROEN C4 PICASSO 2020 Owners Manual

Manufacturer: CITROEN, Model Year: 2020, Model line: C4 PICASSO, Model: CITROEN C4 PICASSO 2020Pages: 316, PDF Size: 10.36 MB

Page 211 of 316

209

F Park the vehicle without obstructing any traffic and apply the parking brake.

F

F

ollow the safety instructions (hazard

warning lamps, warning triangle, wearing

high visibility vest, etc.) according to the

legislation in force in the country where you

are driving.

F

S

witch off the ignition.

F

U

ncoil the pipe stowed under the

compressor. Avoid removing any foreign bodies which

have penetrated into the tyre.F

R

emove the valve cap from the tyre to be

repaired, and place it in a

clean area.

F

C

heck that the compressor switch is at the

" O " position.

F U ncoil fully the electric cable, stowed under

the compressor.

Only the 12

V socket located at the front of

the vehicle can be used.

F

A

ffix the speed limit sticker.

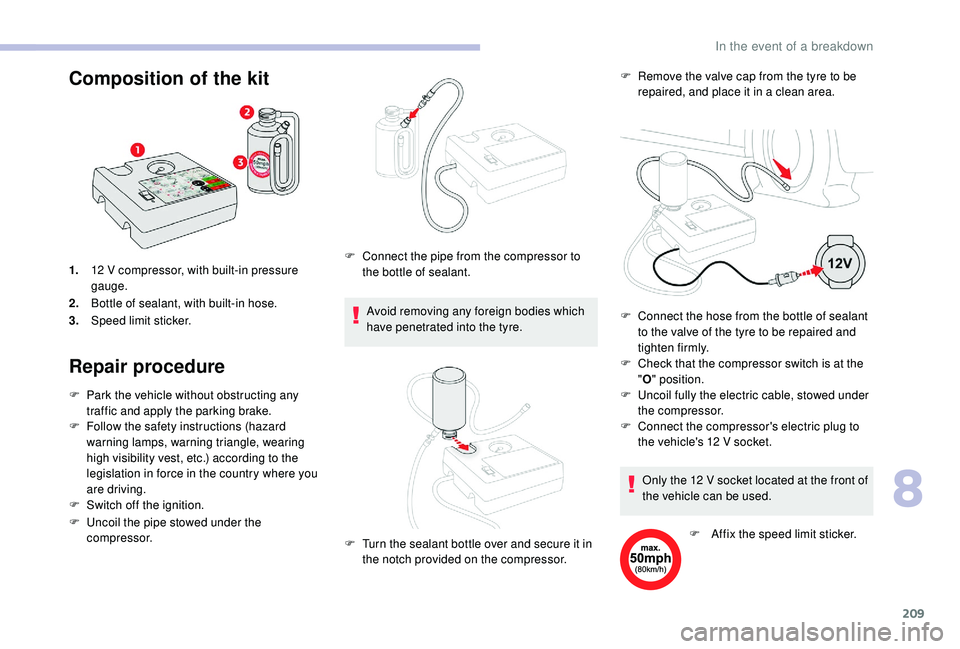

1.

12 V compressor, with built-in pressure

gauge.

2. Bottle of sealant, with built-in hose.

3. Speed limit sticker.

Repair procedure Composition of the kit

F Connect the pipe from the compressor to

the bottle of sealant.

F

T

urn the sealant bottle over and secure it in

the notch provided on the compressor. F

C

onnect the hose from the bottle of sealant

to the valve of the tyre to be repaired and

tighten firmly.

F

C

onnect the compressor's electric plug to

the vehicle's 12

V socket.

8

In the event of a breakdown

Page 212 of 316

210

The speed limit sticker must be secured

to the interior of the vehicle in the driver's

field of vision, to remind you that a wheel

is in temporary use.

The tyre inflation pressures are given on

this label.

F

S

witch on the ignition.

F

S

tart the compressor by turning the switch

to the " l" position until the pressure of the

tyre reaches 2.0

bars. The sealant product

is injected under pressure into the tyre;

do not disconnect the pipe from the valve

during this operation (risk of blowback). If a

pressure of 2 bars is not reached after

about 7 minutes, this indicates that the

tyre is not repairable; contact a

CITROËN

dealer or a

qualified workshop for

assistance.

F

P

lace the switch in the "O" position.

F

D

isconnect the compressor's electric plug

from the vehicle's 12

V socket.

F

R

eplace the cap on the valve.

F

R

emove the kit.

F

R

emove and then store the bottle of sealant.

Take care, the sealant product is harmful

if swallowed and causes irritation to the

eyes.

Keep this product out of the reach of

children.

The use-by date of the fluid is marked on

the bottle.

After use, do not discard the bottle in

standard waste, take it to a

CITROËN

dealer or an authorised waste disposal

site.

Do not forget to obtain a

new bottle of

sealant, available from a

CITROËN dealer

or a

qualified workshop.F

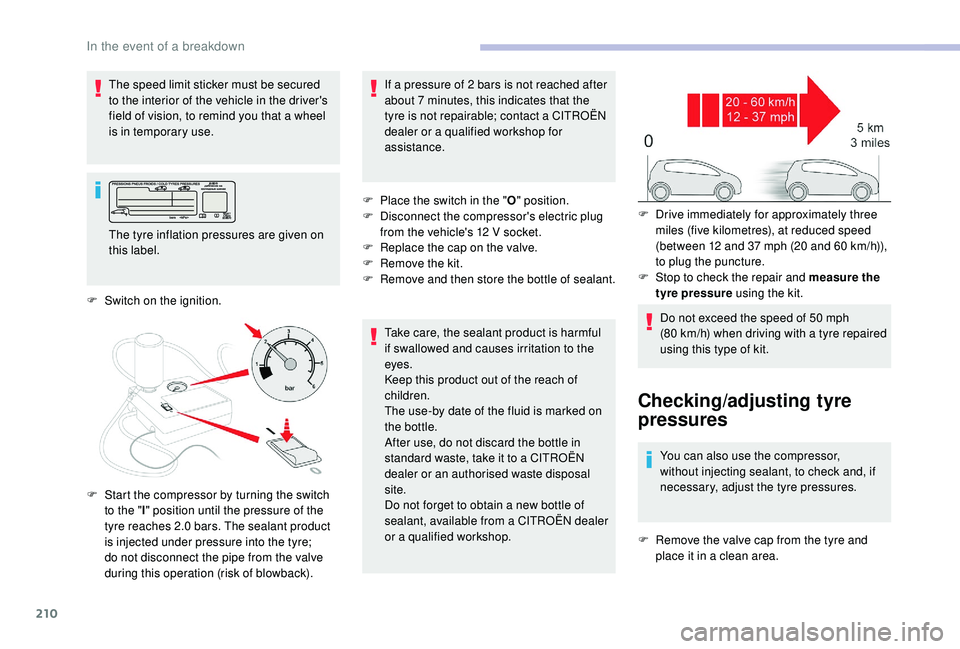

D

rive immediately for approximately three

miles (five kilometres), at reduced speed

(between 12

and 37 mph (20 and 60 km/h)),

to plug the puncture.

F

S

top to check the repair and measure the

tyre pressure using the kit.

Do not exceed the speed of 50

mph

(80

km/h) when driving with a tyre repaired

using this type of kit.

Checking/adjusting tyre

pressures

You can also use the compressor,

without injecting sealant, to check and, if

necessary, adjust the tyre pressures.

F

R

emove the valve cap from the tyre and

place it in a

clean area.

In the event of a breakdown

Page 213 of 316

211

F Check that the compressor switch is at the "O " position.

F

U

ncoil fully the electric cable, stowed under

the compressor.

Only the 12

V socket located at the front

of the vehicle can be used to power the

compressor. F

S

tart the compressor by placing the switch

at position " I" and adjust the pressure to the

value shown on the vehicle's tyre pressure

label. To deflate: press the black button

located on the compressor pipe, near the

valve connection.

If a pressure of 2 bars is not reached after

7 minutes, this indicates that the tyre is

not repairable; contact a CITROËN dealer

or a

qualified workshop for assistance.

F

O

nce the correct pressure is reached, put

the switch to the " O" position.

F

R

emove the kit then stow it.

Do not drive more than 125

miles (200 km)

with the repaired tyre; see a

CITROËN

dealer or a

qualified workshop to change

the tyre.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-

inflation detection , refer to the

corresponding section.

F

U

ncoil the pipe stowed under the

compressor.

F

S

crew the pipe onto the valve and tighten

f i r m l y.

F

C

onnect the compressor's electric plug to

the vehicle's 12

V socket.

F

S

witch on the ignition.

The tyre inflation pressures are given on

this label.

Spare wheel

Scan the QR code on page 3 to view

e xplanatory videos.

Access to tooling

Procedure for changing a wheel with

a damaged or punctured tyre for the spare

wheel using the tools provided with the vehicle.

The tools are installed in the boot under the

f l o o r.

Remove the boot carpet to access them.

8

In the event of a breakdown

Page 214 of 316

212

List of tools

(Depending on equipment.)4.

Wheel bolt cover removal tool.

Removes the wheel bolt covers on alloy

wheels.

5. Socket for the security bolts (located in

the glove box).

For adapting the wheelbrace to the special

"security" bolts.

6. Towing eye and tool to open the front

protective cover.

1. Wheelbrace.

For removing the wheel trim and the wheel

fastening bolts.

2. Chock to immobilise the vehicle (except

versions with manual gearbox).

3. Jack with integrated handle.

Used to raise the vehicle. For more information on To w i n g

, refer to the

corresponding section.

All of these tools are specific to your

vehicle and may vary according to the

level of equipment.

Do not use them for any other purposes.

The jack must only be used to change

a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact a

CITROËN dealer or a qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

maintenance.

Access to the spare wheel

The spare wheel is located in the boot, under

t h e f l o o r.

Taking out the wheel

F Loosen the central nut.

F R emove the fastening device (nut and bolt).

F

R

aise the spare wheel towards you from the

r e a r.

F

T

ake the wheel out of the boot.

In the event of a breakdown

Page 215 of 316

213

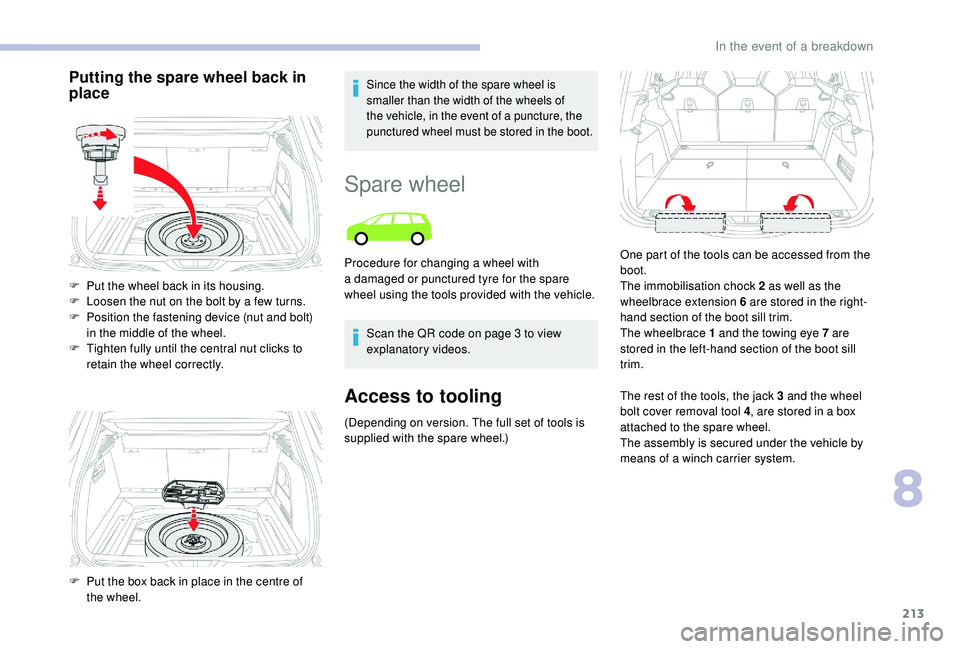

Putting the spare wheel back in

placeSince the width of the spare wheel is

smaller than the width of the wheels of

the vehicle, in the event of a puncture, the

punctured wheel must be stored in the boot.

F Put the wheel back in its housing.

F L oosen the nut on the bolt by a few turns.

F

P

osition the fastening device (nut and bolt)

in the middle of the wheel.

F

T

ighten fully until the central nut clicks to

retain the wheel correctly.

F

P

ut the box back in place in the centre of

the wheel.

Spare wheel

Scan the QR code on page 3 to view

e xplanatory videos.

Access to tooling

(Depending on version. The full set of tools is

supplied with the spare wheel.) The rest of the tools, the jack 3

and the wheel

bolt cover removal tool 4 , are stored in a box

attached to the spare wheel.

The assembly is secured under the vehicle by

means of a

winch carrier system.

Procedure for changing a

wheel with

a damaged or punctured tyre for the spare

wheel using the tools provided with the vehicle. One part of the tools can be accessed from the

boot.

The immobilisation chock 2 as well as the

wheelbrace extension 6 are stored in the right-

hand section of the boot sill trim.

The wheelbrace 1 and the towing eye 7 are

stored in the left-hand section of the boot sill

trim.

8

In the event of a breakdown

Page 216 of 316

214

List of tools

(Depending on version. The full set of tools is

supplied with the spare wheel.)

1.Wheelbrace.

For removing the wheel trim and removing

the wheel bolts.

2. Chock to immobilise the vehicle (except

for versions with manual gearbox).

3. Jack with integrated handle.

Used to raise the vehicle. 4.

Wheel bolt cover removal tool.

Removes the wheel bolt covers on alloy

wheels.

5. Socket for wheel security bolts (stored in

the glove box).

For adapting the wheelbrace to the special

"security" bolts.

6. Wheelbrace extension.

For slackening/tightening the spare wheel

winch cable carrier nut.

7. Towing eye and tool to open the front

protective cover.

For more information on To w i n g , refer to the

corresponding section.

All of these tools are specific to your

vehicle and may vary according to the

level of equipment.

Do not use them for any other purposes.

The jack must only be used to change

a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with this vehicle.

If the vehicle does not have its original jack,

contact a

CITROËN dealer or a qualified

workshop to obtain the correct jack for it.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

The jack does not require any

maintenance.

Wheel with wheel trim

When removing the wheel , first remove the

trim using the wheelbrace 1 by pulling at the

valve aperture.

When refitting the wheel , refit the trim

starting by placing its notch facing the valve

and press around its edge with the palm of your

hand.

Access to the spare wheel

(Depending on version.)

Only a "space-saver" type spare wheel

may be fixed underneath the vehicle.

The spare wheel is supported by a

winch

carrier system underneath the vehicle.

In the event of a breakdown

Page 217 of 316

215

Taking out the spare wheel

F Fold back the concertina board and install the third row seat, on the left-hand side (if

your vehicle is equipped with it).

F

L

ift the pre-cut section of carpet to remove

the fixing winch nut from the spare wheel. F

D

etach the assembly of wheel and box from

the rear of the vehicle.

Tool storage

F Put the tools back in the box and store the box in the boot of the vehicle.

F

R

eel in the winch by turning the key in

the clockwise direction: once the cable is

completely reeled in, you should no longer

feel any resistance.

F

S

tore the rest of the tools in the storage

areas in the boot.

The wheel with the punctured tyre cannot

be fitted under the vehicle. It must be

stored in the boot. Use a

cover to protect

the interior of the boot.

F

W

ith the extension 6 placed on the end of

wheelbrace 1 , "tighten" the nut to unwind

the winch cable until the spare wheel is

flat on the ground. Unwind as much as

necessary in order to access the wheel

easily. F

S

traighten the spare wheel to access tool

box ( A).

F

D

etach the connecting piece from the cover

of the tool box ( B – C).

F

P

ass the connecting piece through the

wheel hub to release it ( D). F

P

ress the tab, slide the lid on the box up

to the middle and remove it to access the

other tools ( jack and alloy wheel bolt cover

removal tool).

8

In the event of a breakdown

Page 218 of 316

216

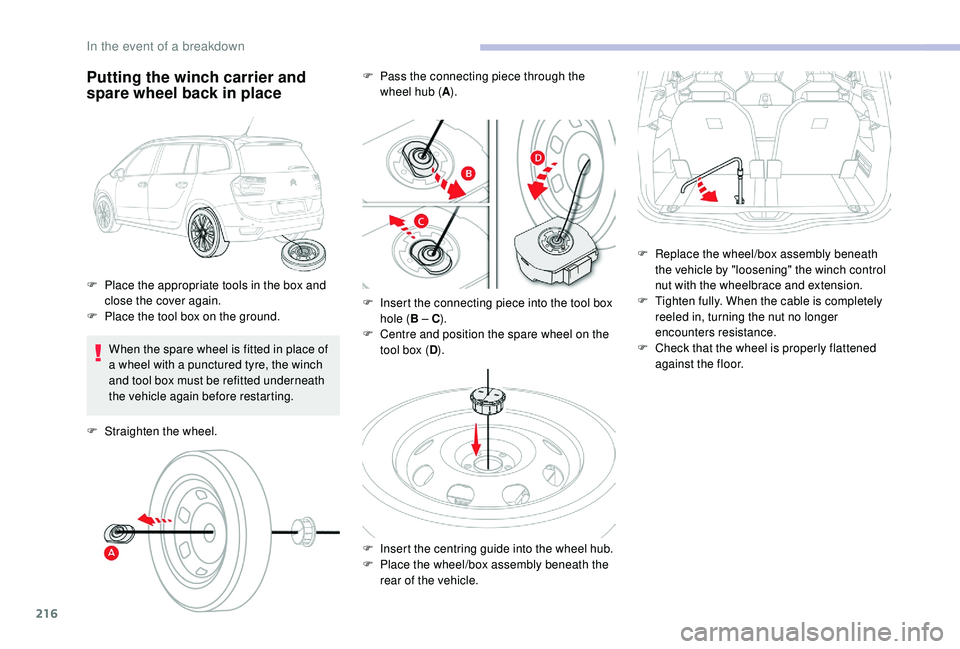

Putting the winch carrier and

spare wheel back in place

When the spare wheel is fitted in place of

a wheel with a punctured tyre, the winch

and tool box must be refitted underneath

the vehicle again before restarting.

F

S

traighten the wheel.

F

P

lace the appropriate tools in the box and

close the cover again.

F

P

lace the tool box on the ground. F

P

ass the connecting piece through the

wheel hub ( A).

F

I

nsert the connecting piece into the tool box

hole ( B – C).

F C entre and position the spare wheel on the

tool box ( D).

F

I

nsert the centring guide into the wheel hub.

F

P

lace the wheel/box assembly beneath the

rear of the vehicle. F

R

eplace the wheel/box assembly beneath

the vehicle by "loosening" the winch control

nut with the wheelbrace and extension.

F

T

ighten fully. When the cable is completely

reeled in, turning the nut no longer

encounters resistance.

F C heck that the wheel is properly flattened

against the floor.

In the event of a breakdown

Page 219 of 316

217

Removing a wheel

* position P for the automatic gearbox

Parking the vehicle

Stop the vehicle where it does not block

traffic: the ground must be level, stable

and non-slippery.

Apply the parking brake, unless it is

programmed in automatic mode; switch

off the ignition and put the vehicle into first

gear* so as to block the wheels.

Check that the braking warning lamp and

the P warning lamp in the parking brake

control lever come on.

For more safety, position the

chock

2 against the wheel opposite the one you

are replacing.

Make absolutely certain that all the

occupants have left the vehicle and are

waiting in a safe area.

Never go underneath a vehicle raised

using a jack; use an axle stand.

Do not use:

-

t

he jack for any other purpose than

lifting the vehicle,

-

a j

ack other than the one supplied by

the manufacturer.

List of operationsF Place the foot of the jack 3 on the ground

and ensure that it is directly below the front

A or rear B jacking point provided on the

underbody, whichever is closest to the

wheel to be changed.

Ensure that the jack is stable. If the

ground is slippery or loose, the jack may

slip or collapse – Risk of injury!

Ensure that the jack is positioned only at

one of the jacking points A or B under the

vehicle, making sure that the vehicle's

contact sur face is centred on the head of

the jack. Otherwise, the vehicle could be

damaged and/or the jack could collapse –

Risk of injury!

F

R

emove the bolt cover(s) using the tool 4

(according to equipment).

F

F

it security socket 5

on wheelbrace 1

to

slacken the security bolt (according to

equipment).

F

S

lacken the other bolts (no more than

a

1/4

turn) using the wheelbrace 1

o n l y. F

E

xtend the jack 3 until its head comes into

contact with jacking point A or B used,

with contact sur face A or B on the vehicle

correctly engaged with the central part of

the head of the jack.

8

In the event of a breakdown

Page 220 of 316

218

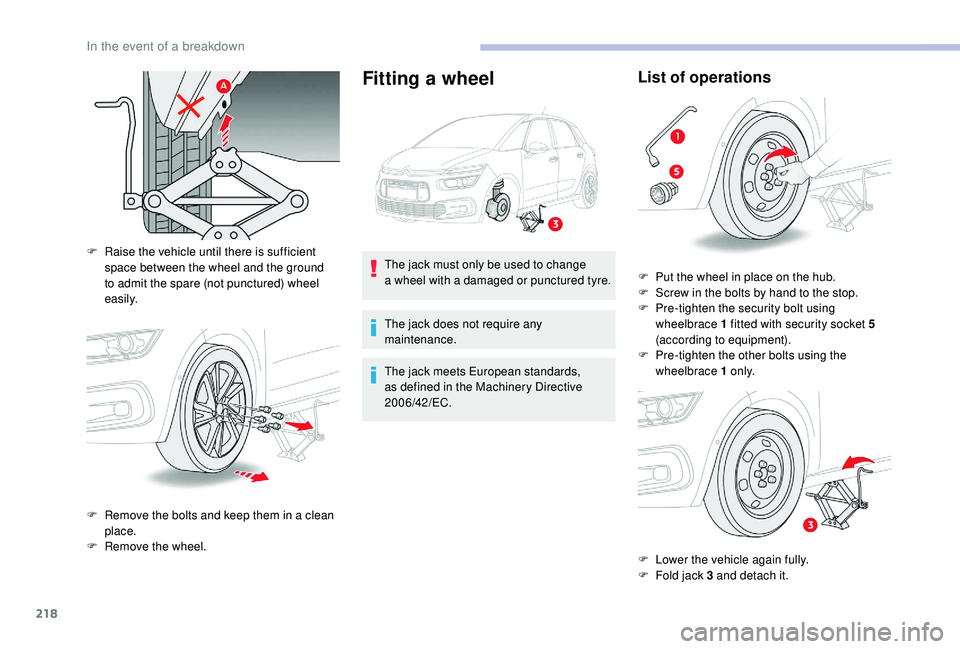

Fitting a wheel

F Raise the vehicle until there is sufficient

space between the wheel and the ground

to admit the spare (not punctured) wheel

easily.

F

R

emove the bolts and keep them in a clean

place.

F

R

emove the wheel. The jack must only be used to change

a

wheel with a damaged or punctured tyre.

The jack does not require any

maintenance.

The jack meets European standards,

as defined in the Machinery Directive

2006/42/EC.

List of operations

F Put the wheel in place on the hub.

F S crew in the bolts by hand to the stop.

F

P

re-tighten the security bolt using

wheelbrace 1

fitted with security socket 5

(according to equipment).

F

P

re-tighten the other bolts using the

wheelbrace 1

o n l y.

F

L

ower the vehicle again fully.

F

F

old jack 3 and detach it.

In the event of a breakdown