ESP CITROEN C5 AIRCROSS DAG 2022 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2022, Model line: C5 AIRCROSS DAG, Model: CITROEN C5 AIRCROSS DAG 2022Pages: 276, PDF Size: 7.92 MB

Page 171 of 276

169

Practical information

7Closing

► Hold the bonnet and pull out the stay from the

support slot.

►

Clip the stay in its housing.

►

Lower the bonnet and release it near the end

of its travel.

►

Pull on the bonnet to check that it is locked

correctly

.

Because of the presence of electrical

equipment under the bonnet, it is strongly

recommended that exposure to water (rain,

washing, etc.) be limited.

Engine compartment

The engine shown here is an example for

illustrative purposes only.

The locations of the following elements may

vary:

–

Air filter

.

–

Engine oil dipstick.

–

Engine oil filler cap.

Petrol engine

Diesel engine

1. Screenwash fluid reservoir

2. Engine coolant reservoir

3. Brake fluid reservoir

4. Battery/Fuses

5. Remote earth point (-)

6. Fusebox

7. Air filter

8. Engine oil filler cap

9. Engine oil dipstick

The Diesel fuel system operates under

very high pressure.

All work on this circuit must be carried out

only by a CITROËN dealer or a qualified

workshop.

Checking levels

Check all of the following levels regularly in

accordance with the manufacturer's service

schedule. Top them up if required, unless

otherwise indicated.

If a level drops significantly, have the

corresponding system checked by a CITROËN

dealer or a qualified workshop.

The fluids must comply with the manufacturer's requirements and with

the vehicle's engine.

Take care when working under the bonnet, as certain areas of the engine

may be extremely hot (risk of burns) and the

cooling fan could start at any time (even with

the ignition off).

Used products

Avoid prolonged contact of used oil or fluids with the skin.

Most of these fluids are harmful to health and

very corrosive.

Do not discard used oil or fluids into

sewers or onto the ground.

Empty used oil into the containers reserved

for this purpose at a CITROËN dealer or a

qualified workshop.

Engine oil

The level is checked, with the engine having been switched off for at least 30

minutes and on level ground, either using the oil

level indicator in the instrument panel when the

Page 172 of 276

170

Practical information

Once the pressure has dropped, remove the cap

and top up to the required level.

Cooling of the engine when stopped

The engine cooling fan may start after

the engine has been switched off.

Take care with objects or clothing that

could be caught in the blades of the fan!

Screenwash fluid

Top up to the required level when necessary.

Fluid specification

The fluid must be topped up with a pre-mixed

product.

In winter (temperatures below zero), a fluid

containing an anti-freeze agent which is

appropriate for the temperature conditions

must be used in order to protect the system's

components (pump, tank, ducts, jets).

Filling with pure water is prohibited in all

circumstances (risk of freezing,

limescale, etc.).

Diesel fuel additive (Diesel

with particle filter)

or On reaching the minimum level

in the particle filter additive tank,

this warning lamp comes on fixed, accompanied

by an audible signal and a warning message.

ignition is switched on (for vehicles equipped

with an electric gauge), or using the dipstick.

It is normal to top up the oil level between two

services (or oil changes). It is recommended

that you check the level, and top up if necessary,

every 3,000 miles (5,000 km).

In order to maintain the reliability of the

engine and emissions control system,

never use additives in the engine oil.

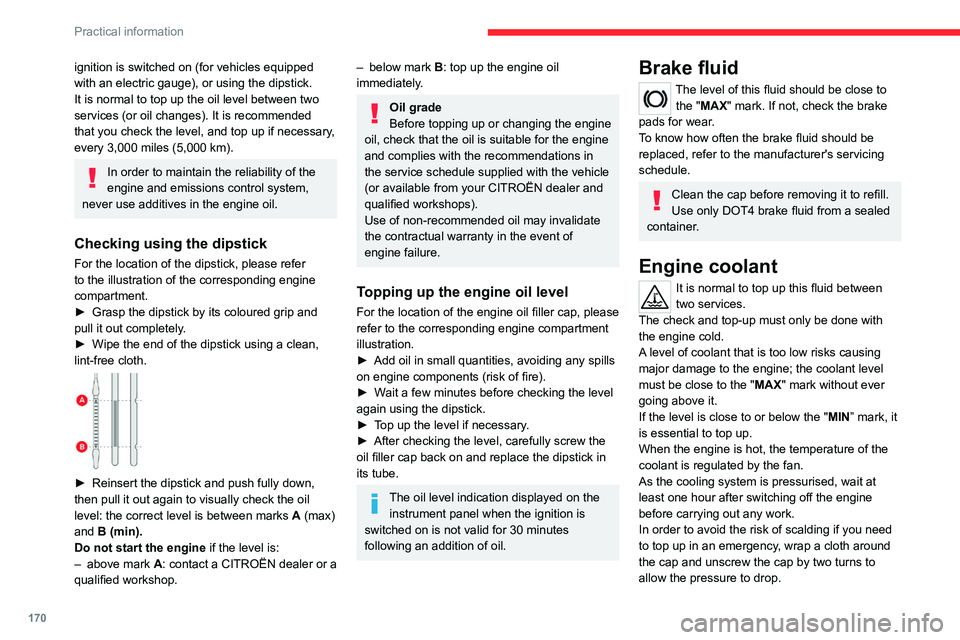

Checking using the dipstick

For the location of the dipstick, please refer

to the illustration of the corresponding engine

compartment.

►

Grasp the dipstick by its coloured grip and

pull it out completely

.

►

Wipe the end of the dipstick using a clean,

lint-free cloth.

► Reinsert the dipstick and push fully down,

then pull it out again to visually check the oil

level: the correct level is between marks A

(max)

and B (min).

Do not start the engine if the level is:

–

above mark

A: contact a CITROËN dealer or a

qualified workshop.

– below mark B : top up the engine oil

immediately.

Oil grade

Before topping up or changing the engine

oil, check that the oil is suitable for the engine

and complies with the recommendations in

the service schedule supplied with the vehicle

(or available from your CITROËN dealer and

qualified workshops).

Use of non-recommended oil may invalidate

the contractual warranty in the event of

engine failure.

Topping up the engine oil level

For the location of the engine oil filler cap, please

refer to the corresponding engine compartment

illustration.

►

Add oil in small quantities, avoiding any spills

on engine components (risk of fire).

►

W

ait a few minutes before checking the level

again using the dipstick.

►

T

op up the level if necessary.

►

After checking the level, carefully screw the

oil filler cap back on

and replace the dipstick in

its tube.

The oil level indication displayed on the instrument panel when the ignition is

switched on is not valid for 30 minutes

following an addition of oil.

Brake fluid

The level of this fluid should be close to the "MAX" mark. If not, check the brake

pads for wear.

To know how often the brake fluid should be

replaced, refer to the manufacturer's servicing

schedule.

Clean the cap before removing it to refill.

Use only DOT4 brake fluid from a sealed

container.

Engine coolant

It is normal to top up this fluid between

two services.

The check and top-up must only be done with

the engine cold.

A level of coolant that is too low risks causing

major damage to the engine; the coolant level

must be close to the "MAX" mark without ever

going above it.

If the level is close to or below the " MIN” mark, it

is essential to top up.

When the engine is hot, the temperature of the

coolant is regulated by the fan.

As the cooling system is pressurised, wait at

least one hour after switching off the engine

before carrying out any work.

In order to avoid the risk of scalding if you need

to top up in an emergency, wrap a cloth around

the cap and unscrew the cap by two turns to

allow the pressure to drop.

Page 173 of 276

171

Practical information

7Once the pressure has dropped, remove the cap

and top up to the required level.

Cooling of the engine when stopped

The engine cooling fan may start after

the engine has been switched off.

Take care with objects or clothing that

could be caught in the blades of the fan!

Screenwash fluid

Top up to the required level when necessary.

Fluid specification

The fluid must be topped up with a pre-mixed

product.

In winter (temperatures below zero), a fluid

containing an anti-freeze agent which is

appropriate for the temperature conditions

must be used in order to protect the system's

components (pump, tank, ducts, jets).

Filling with pure water is prohibited in all

circumstances (risk of freezing,

limescale, etc.).

Diesel fuel additive (Diesel

with particle filter)

or On reaching the minimum level

in the particle filter additive tank,

this warning lamp comes on fixed, accompanied

by an audible signal and a warning message.

Topping up

This additive must be topped up without delay by

a CITROËN dealer or a qualified workshop.

AdBlue® (BlueHDi)

An alert is triggered when the reserve level is

reached.

For more information on the Indicators and in

particular the AdBlue range indicators, refer to

the corresponding section.

To avoid the vehicle being immobilised in

accordance with regulations, you must top up the

AdBlue tank.

For more information on AdBlue

® (BlueHDi),

and in particular the supply of AdBlue, refer to

the corresponding section.

Checks

Unless otherwise indicated, check these

components in accordance with the

manufacturer's service schedule and according

to your engine.

Otherwise, have them checked by a CITROËN

dealer or a qualified workshop.

Only use products recommended by

CITROËN or products of equivalent

quality and specification.

In order to optimise the operation of

components as important as those in the

braking system, CITROËN selects and offers

very specific products.

12 V battery

The battery does not require any maintenance.

However, check regularly that the terminals

are correctly tightened (versions without quick

release terminals) and that the connections are

clean.

For more information on the precautions

to take before any work on the 12 V

battery, refer to the corresponding section.

Versions equipped with Stop & Start are

fitted with a 12 V lead-acid battery of

specific technology and specification.

Its replacement should be carried out only by

a CITROËN dealer or a qualified workshop.

Passenger compartment

filter

Depending on the environment and the

use of the vehicle (e.g. dusty atmosphere,

city driving), change it twice as often, if

necessary .

A clogged passenger compartment filter

can adversely affect air conditioning

system performance and generate

undesirable odours.

Page 174 of 276

172

Practical information

Driving with worn or damaged tyres reduces the

braking and road holding performance of the

vehicle. It is recommended to regularly check the

condition of the tyres (tread and sidewalls) and

wheel rims as well as the presence of the valves.

When the wear indicators no longer appear set

back from the tread, the depth of the grooves is

less than 1.6 mm; it is essential to replace the

tyres.

Using different size wheels and tyres from those

specified can affect the lifetime of tyres, wheel

rotation, ground clearance, the speedometer

reading and have an adverse effect on road

holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

Shock absorbers

It is not easy for drivers to detect when

shock absorbers are worn. Nevertheless,

the shock absorbers have a major impact on

road-holding and braking performance.

For your safety and driving comfort, it is

important to have them regularly checked by a

CITROËN dealer or a qualified workshop.

Timing and accessory kits

Timing and accessory kits are used from the time the engine is started until it is

switched off. It is normal for them to wear over

time.

A faulty timing or accessory kit can damage

the engine, rendering it unusable. Observe the

Air filter

Depending on the environment and the

use of the vehicle (e.g. dusty atmosphere,

city driving), change it twice as often, if

necessary .

Oil filter

Change the oil filter each time the engine

oil is changed.

Particle filter (Diesel)

When the particle filter is

approaching saturation, this

warning lamp comes on temporarily,

accompanied by a message warning of the risk

of the filter clogging.

As soon as the traffic conditions permit,

regenerate the filter by driving at a speed of at

least 37

mph (60 km/h) until the warning lamp

goes off.

If the warning lamp stays on, this

indicates a low Diesel additive level.

For more information on Checking levels,

refer to the corresponding section.

Following prolonged operation of the

vehicle at very low speed or at idle, you

may, in exceptional circumstances, notice

water vapour coming from the exhaust while

accelerating. These emissions have no

impact on the vehicle’s behaviour and the

environment.

New vehicle

During the first few particle filter

regeneration operations, you may notice a

"burning" smell. This is perfectly normal.

Manual gearbox

The gearbox does not require any maintenance (no oil change).

Automatic gearbox

The gearbox does not require any maintenance (no oil change).

Brake pads

Brake wear depends on the style of

driving, particularly in the case of vehicles

used in town, over short distances. It may be

necessary to have the condition of the brakes

checked, even between vehicle services.

Unless there is a leak in the circuit, a drop in the

brake fluid level indicates that the brake pads

are worn.

After washing the vehicle, moisture, or in wintry conditions, ice can form on the

brake discs and pads: braking efficiency may

be reduced. Gently dab the brakes to dry and

defrost them.

Brake disc wear

For information on checking brake disc

wear, contact a CITROËN dealer or a

qualified workshop.

Electric parking brake

This system does not require any routine servicing. However, in the event of a

problem, do not hesitate to have the system

checked by a CITROËN dealer or a qualified

workshop.

For more information on the Electric

parking brake, refer to the

corresponding section.

Wheels and tyres

The inflation pressure of all tyres, including the spare wheel, must be

checked on "cold” tyres.

The pressures indicated on the tyre pressure

label are valid for "cold" tyres. If you have driven

for more than 10 minutes or more than 6 miles

(10 kilometres) at over 31 mph (50

km/h), add

0.3 bar (30 kPa) to the values indicated on the

label.

Under-inflation increases energy

consumption. Non-compliant tyre

pressure causes premature wear on tyres and

has an adverse effect on the vehicle's road

holding - risk of an accident!

Page 175 of 276

173

Practical information

7Driving with worn or damaged tyres reduces the

braking and road holding performance of the

vehicle. It is recommended to regularly check the

condition of the tyres (tread and sidewalls) and

wheel rims as well as the presence of the valves.

When the wear indicators no longer appear set

back from the tread, the depth of the grooves is

less than 1.6 mm; it is essential to replace the

tyres.

Using different size wheels and tyres from those

specified can affect the lifetime of tyres, wheel

rotation, ground clearance, the speedometer

reading and have an adverse effect on road

holding.

Fitting different tyres on the front and rear axles

can cause the ESC to mistime.

Shock absorbers

It is not easy for drivers to detect when

shock absorbers are worn. Nevertheless,

the shock absorbers have a major impact on

road-holding and braking performance.

For your safety and driving comfort, it is

important to have them regularly checked by a

CITROËN dealer or a qualified workshop.

Timing and accessory kits

Timing and accessory kits are used from

the time the engine is started until it is

switched off. It is normal for them to wear over

time.

A

faulty timing or accessory kit can damage

the engine, rendering it unusable. Observe the recommended replacement frequency, stated in

distance travelled or time elapsed, whichever is

reached first.

AdBlue® (BlueHDi)

To respect the environment and ensure

compliance with the Euro 6 standard, without

adversely affecting the performance or fuel

consumption of its Diesel engines, CITROËN

has taken the decision to equip its vehicles with

a system that combines SCR (Selective Catalytic

Reduction) with a Diesel Particle Filter (DPF) for

the treatment of exhaust gases.

SCR system

Using a liquid called AdBlue® that contains

urea, a catalytic converter turns up to 85% of

the nitrogen oxides (NOx) into nitrogen and

water, which are harmless to health and the

environment.

The AdBlue® is contained in a special

tank holding about 17 litres.

Its capacity allows a driving range of

approximately 4,000

miles (6,500 km),

which

may vary considerably depending on your

driving style.

An alert system is triggered once the reserve

level is reached: it is then possible to drive for a

further 1,500 miles (2,400

km) before the tank is

empty and the vehicle is immobilised.

For more information on the Warning

and indicator lamps and the associated

alerts, or the Indicators, please refer to the

corresponding sections.

Once the AdBlue® tank is empty, a device

required by law prevents the engine from

being restarted.

If the SCR system is faulty, the level of

emissions from the vehicle will no longer meet

the Euro 6 standard and the vehicle starts

polluting the environment.

In the event of a confirmed SCR system

malfunction, it is essential to visit a CITROËN

dealer or a qualified workshop. After 685

miles (1,100 km), a device is automatically

activated to prevent the engine from starting.

In both cases, a range indicator indicates

the distance that can be travelled before the

vehicle is stopped.

Freezing of the AdBlue®

AdBlue® freezes at temperatures below

around -11°C.

The SCR system includes a heater for the

AdBlue

® tank, allowing you to continue driving

in very cold conditions.

Supply of AdBlue®

It is recommended that the AdBlue® be topped

up as soon as the first alert is issued indicating

that the reserve level has been reached.

Page 180 of 276

178

In the event of a breakdown

Warning triangle

As a safety precaution, before leaving your

vehicle to set up and install the triangle, switch

on the hazard warning lamps and put on your

high visibility vest.

Storage compartment

There is a compartment in the interior trim of the

tailgate to store a triangle.

►

Open the tailgate.

►

Release the cover by turning the screw a

quarter turn anti-clockwise.

Assembling and placing the triangle

For versions supplied with a triangle as original

equipment, refer to the illustration above.

For other versions, refer to the assembly

instructions provided with the triangle.

►

Put the triangle in place behind the vehicle,

as required by local legislation.

Running out of fuel

(Diesel)

With Diesel engines, the fuel system must be

primed if you run out of fuel.

Before starting to prime the system, it is

essential to put at least 5 litres of Diesel into the

fuel tank.

For more information on Refuelling and

on Misfuel prevention (Diesel), refer to

the corresponding section.

BlueHDi 130 engines

► Switch on the ignition (without starting the

engine).

►

W

ait around 1 minute and switch off the

ignition.

►

Operate the starter motor to start the engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

BlueHDi 180 engines

► Switch on the ignition (without starting the

engine).

►

W

ait around 6 seconds and switch off the

ignition.

►

Repeat the operation 10

times.

►

Operate the starter motor to start the engine.

If the engine does not start at the first attempt,

do not keep trying, but restart the procedure.

Tool kit

Set of tools supplied with the vehicle.

Its content depends on your vehicle's equipment:

–

T

emporary puncture repair kit.

–

Spare wheel.

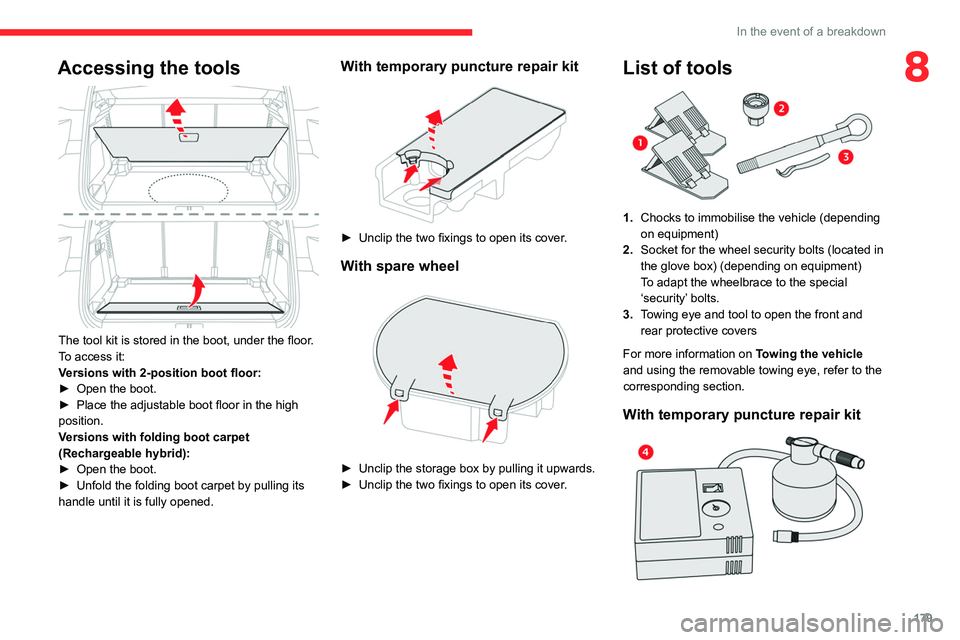

Accessing the tools

The tool kit is stored in the boot, under the floor.

To access it:

Versions with 2-position boot floor:

► Open the boot.

► Place the adjustable boot floor in the high

position.

Versions with folding boot carpet

(Rechargeable hybrid):

► Open the boot.

► Unfold the folding boot carpet by pulling its

handle until it is fully opened.

Page 181 of 276

179

In the event of a breakdown

8Accessing the tools

The tool kit is stored in the boot, under the floor.

To access it:

Versions with 2-position boot floor:

►

Open the boot.

►

Place the adjustable boot floor in the high

position.

V

ersions with folding boot carpet

(Rechargeable hybrid):

►

Open the boot.

►

Unfold the folding boot carpet by pulling its

handle until it is fully opened.

With temporary puncture repair kit

► Unclip the two fixings to open its cover .

With spare wheel

► Unclip the storage box by pulling it upwards.

► Unclip the two fixings to open its cover .

List of tools

1.Chocks to immobilise the vehicle (depending

on equipment)

2. Socket for the wheel security bolts (located in

the glove box) (depending on equipment)

To adapt the wheelbrace to the special

‘security’ bolts.

3. Towing eye and tool to open the front and

rear protective covers

For more information on Towing the vehicle

and using the removable towing eye, refer to the

corresponding section.

With temporary puncture repair kit

Page 182 of 276

180

In the event of a breakdown

4.12 V compressor with cartridge of sealant

and speed limit sticker

For temporary repair of a tyre and to adjust

the tyre pressure.

For more information about the Temporary

puncture repair kit, refer to the corresponding

section.

With spare wheel

5. Wheelbrace

For removing the wheel trim and the wheel

bolts.

6. Jack with integrated handle

To raise the vehicle.

7. Wheel bolt cap removal tool (depending on

equipment)

For removing the wheel bolt head finishers on

alloy wheels.

For more information on the Spare wheel, refer

to the corresponding section.

These tools are specific to the vehicle and may vary according to the level of

equipment.

Do not use them for any other purpose.

The jack must only be used to change a wheel with a damaged or punctured tyre.

Do not use any jack other than the one

supplied with the vehicle.

If the vehicle does not have its original jack,

contact a CITROËN dealer or a qualified

workshop to obtain the one that was intended

by the manufacturer.

The jack meets European standards, as

defined in the Machinery Directive 2006/42/

CE.

The jack does not require any maintenance.

Temporary puncture repair kit

Scan the QR Code on page 3 to view

explanatory videos.

Made up of a compressor and a sealant

cartridge,

it allows you to carry out a temporary

repair of the tyre so that you can drive to the

nearest garage.

It is designed to repair most punctures located

on the tyre tread.

The vehicle's electric system allows the connection of the compressor to the 2 V

power supply for long enough to repair a tyre

after a puncture.

For more information on the Tool kit,

refer to the corresponding section.

Tyre inflation pressures are indicated on this label.

For more information on Identification

markings, particularly this label, refer to the

corresponding section.

Should the pressure of one or more tyres

be adjusted, it is necessary to reinitialise

the under-inflation detection system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

Repair procedure

Do not remove any foreign bodies (e.g.

nail, screw) which have penetrated into

the tyre.

►

Park the vehicle without obstructing traffic

and apply the parking brake.

Page 184 of 276

182

In the event of a breakdown

With a tyre repaired using this type of kit,

do not exceed a speed of 50 mph

(80

km/h) and do not drive more than

125

miles (200 km).

Contact a CITROËN dealer or a qualified

workshop to have the tyre changed.

Checking/adjusting tyre

pressures

The compressor can be used, without injecting

sealant, to check and, if necessary, adjust the

tyre pressures.

►

Remove the valve cap from the tyre and keep

it in a clean place.

►

Uncoil

the pipe stowed under the compressor.

►

Screw the pipe onto the valve and tighten

firmly

.

►

Check that the compressor switch is in

position " O

".

►

Fully uncoil the electric cable stowed under

the compressor

.

►

Connect

the compressor's electric plug to one

of the vehicle's 12

V sockets.

►

Switch the ignition on.

►

Start the compressor by placing the switch at

position " I

" and adjust the pressure to the value

shown on the vehicle's tyre pressure label. To

deflate: press the black button located on the

compressor pipe, near the valve connection.

If after 7 minutes the pressure of 2 bar is

not reached, the tyre is damaged;

contact a CITROËN dealer or a qualified

workshop for assistance.

►

Once the correct pressure is reached, put the

switch in position " O

".

►

Remove the kit and stow it.

►

Refit the cap on the valve.

Spare wheel

Scan the QR Code on page 3 to view

explanatory videos.

For more information on the Tool kit,

refer to the corresponding section.

Accessing the spare wheel

The spare wheel is stored in the boot, under the

floor.

To access the spare wheel, first refer to the

Tool

kit

section.

Depending on version, the spare wheel

may be a standard size steel or alloy

wheel.

In some countries, it is a ‘space saver’ wheel.

Removing the spare wheel

► Slacken the central nut.

► Remove the fastening device (nut and bolt).

►

Lift the spare wheel towards you from the

rear

.

►

T

ake the wheel out of the boot.

Putting the spare wheel back in place

The punctured wheel cannot be put under the boot floor.

► Put the spare wheel back in place in its

housing.

► Slacken the nut on the bolt by a few turns.

► Position the fastening device (nut and bolt) in

the middle of the wheel.

► Tighten the central nut sufficiently to retain

the wheel correctly.

► Put the tool box back in place in the middle of

the wheel and clip it in place.

If there is no wheel in the well, the

fastening device (nut and bolt) cannot be

refitted.

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not obstruct traffic: the ground must be level,

stable and non-slippery.

With a manual gearbox, engage first gear

to lock the wheels, apply the parking brake,

unless it is set to automatic mode, and switch

off the ignition.

Page 188 of 276

186

In the event of a breakdown

Front lamps

Model A

1.Daytime running lamps/Sidelamps/Direction

indicators (LED)

2. Dipped beam/main beam headlamps (LED)

Model B

1.Daytime running lamps/Sidelamps/Direction

indicators (LED)

2. Dipped beam headlamps (LED)

3. Main beam headlamps (LED)

Model C

1.Daytime running lamps/Sidelamps (LED)

2. Direction indicators (WY21W)

3. Dipped beam headlamps (LED)

4. Main beam headlamps (LED)

Model D

1.Daytime running lamps/Sidelamps /Direction

indicators (LED)

2. Dipped beam headlamps (H7-55W).

3. Main beam headlamps (HB3-65W)

Model E

1.Daytime running lamps/Sidelamps (LED)

2. Direction indicators (WY21W)

3. Dipped beam headlamps (H7-55W).

4. Main beam headlamps (HB3-65W)

Direction indicators

Rapid flashing of the indicator lamp for a

direction indicator

(left or right) indicates

that one of the bulbs on the corresponding

side has failed.

► Turn the bulb holder a quarter turn

anti-clockwise.

►

Pull the bulb and bulb holder assembly

backwards.

►

Replace the bulb.

Amber-coloured bulbs, such as the direction indicators, must be replaced by

bulbs with identical colour and specifications.

Main beam headlamps

► Remove the protective cover.

► Disconnect the bulb connector.

► Turn the bulb holder anti-clockwise.

► Remove the bulb and replace it.

Dipped beam headlamps

► Remove the protective cover.

► Disconnect the bulb connector.

► Turn the bulb a quarter turn anti-clockwise

and replace it.

Foglamps (P21W)

► Insert a flat screwdriver into the hole in the

trim.