sensor CITROEN C6 2005 Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C6, Model: CITROEN C6 2005Pages: 223, PDF Size: 4.26 MB

Page 178 of 223

Downloaded from www.Manualslib.com manuals search engine 172

BRAKES

B3FP7GFC

BRAKING SYSTEM: GENERAL SPECIFICATIONSComponents Supplier Reference Observations

Hydraulic valve blockLocated on the front LH chassis member:

TRWESP 4regulation channels

ECUVSC 440

25-way connector

Integral to the hydraulic valve block

2-way blackconnector

Front wheel sensor The sensors, of inductive type, are fitted on the pivot

SIEMENSAir gap non-adjustable: 0.25 to 1.65 mm

VDO 2-way blackconnector

Rear wheel sensor The sensors, of inductive type, are fitted on the pivot

Air gap non-adjustable: 0.23 to 1.35 mm

Front pivot bearingThe hub has a bearing with integral magnetic wheel

NSK(48 pairs of poles)

Rear hub bearingThe rear hub-bearing has a radial ABS target

(48 pairsof poles)

ABS/ESP hydraulic valve block

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 172

Page 180 of 223

Downloaded from www.Manualslib.com manuals search engine 174

BRAKES

TIGHTENING TORQUES: BRAKING SYSTEM

Front brakes

1 Front brake disc 1 ± 0,12 Yoke on brake caliper 3 ± 0,23 Unions on brake piping 4 ± 0,54 Front brake caliper 11,5 ± 1

5 Hydraulic valve block on intermediate support

0,8 ± 0,26 Intermediate support on support7 Front wheel sensor 0,8 ± 0,1

B3FP7HNDB3FP7HMD

B3FP7HPD

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 174

Page 182 of 223

Downloaded from www.Manualslib.com manuals search engine 176

BRAKES

TIGHTENING TORQUES: BRAKING SYSTEM

Rear brakes

11 Rear brake caliper 3,5 ± 0,312 Unions on brake piping 1,5 ± 0,113 Rear brake caliper support 10,8 ± 114 Rear wheel sensor 0,8 ± 0,1

B3FP7HTDB3FP7HSD

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 176

Page 183 of 223

Downloaded from www.Manualslib.com manuals search engine 177

BRAKES

TIGHTENING TORQUES: BRAKING SYSTEM

15 Electric parking brake system (FSE) 0,4 ± 0,0616 Nut for parking brake cables 6 ± 0,617 Gyrometer/accelerometer sensor on support 0,9 ± 0,118 Sensor support on body 0,4 ± 0,06

B3FP7HVDB3FP7HUD

Parking brake

Gyrometer/accelerometer sensor

Angl-C6-PAGE170-194-2005 4/02/05 17:35 Page 177

Page 202 of 223

Downloaded from www.Manualslib.com manuals search engine 196

HYDRAULICS

SAFETY REQUIREMENTS: ACTIVE SUSPENSION WITH VARIABLE DAMPING

During the operation.

Wait for the pressure in the hydraulic circuit to fall fully before disconnecting the unions on the following components (risk of sudden sinking of the

vehicle):

- Built-in Hydro-electronic Interface (BHI).

- Front suspension cylinder.

- Rear suspension cylinder.

- Front stiffness regulator.

- Rear stiffness regulator.

- Suspension pressure sensors.

IMPERATIVE: Do not operate on the hydraulic circuit without making the pressure drop (see corresponding operation).

Engine running.

Do not operate on the hydraulic suspension circuit.

Always remain out of range of any possible projections of fluid, as these could cause serious injuries.

NOTE:In the event of contact of LDSfluid with the eyes, rinse them with copious amounts of water and seek specialist advice.

NOTE:In the event of lengthy contact of LDSfluid with the skin, wash it with soap and water.

WARNING: After the engine has stopped, wait 30 seconds before commencing any operation.

Angl-C6-page195-202-2005 4/02/05 17:36 Page 196

Page 203 of 223

Downloaded from www.Manualslib.com manuals search engine HYDRAULICS

197

SAFETY REQUIREMENTS: ACTIVE SUSPENSION WITH VARIABLE DAMPING

IMPERATIVE: Do not remain underneath the vehicle during an operation to adjust vehicle heights or during actuator (electrovalve) tests.

IMPERATIVE: Any deforming of the wheel travel sensor supports is forbidden. If there is any deformation found, replace the component.

Cleanliness requirements.

WARNING: Non-respect of the cleanliness requirements may cause a contamination of the circuit and a malfunctioning of the suspension.

Preliminary operations.

The work area must be kept clean and uncluttered.

The technician must wear clean overalls.

Components being stored during the repair must be protected from dust.

The tooling required for an operation on the suspension system should always be cleaned prior to the operation.

During the operation:

- Before operating on the suspension circuit, proceed to clean the hydraulic components and unions.

IMPERATIVE: Approved cleaner: SODIMAC degreaser.

IMPERATIVE: After a dismantling, immediately blank the hydraulic components and unions with plugs. The plugs should be used for one

operation only.

Any component that has been removed must be plugged and placed in a clean plastic bag.

IMPERATIVE: After a dismantling, any cleaning using compressed air or products is strictly prohibited

. Any LDS fluid that is collected must

not be re-used. Any topping-up must be done with new fluid.

Angl-C6-page195-202-2005 4/02/05 17:36 Page 197

Page 218 of 223

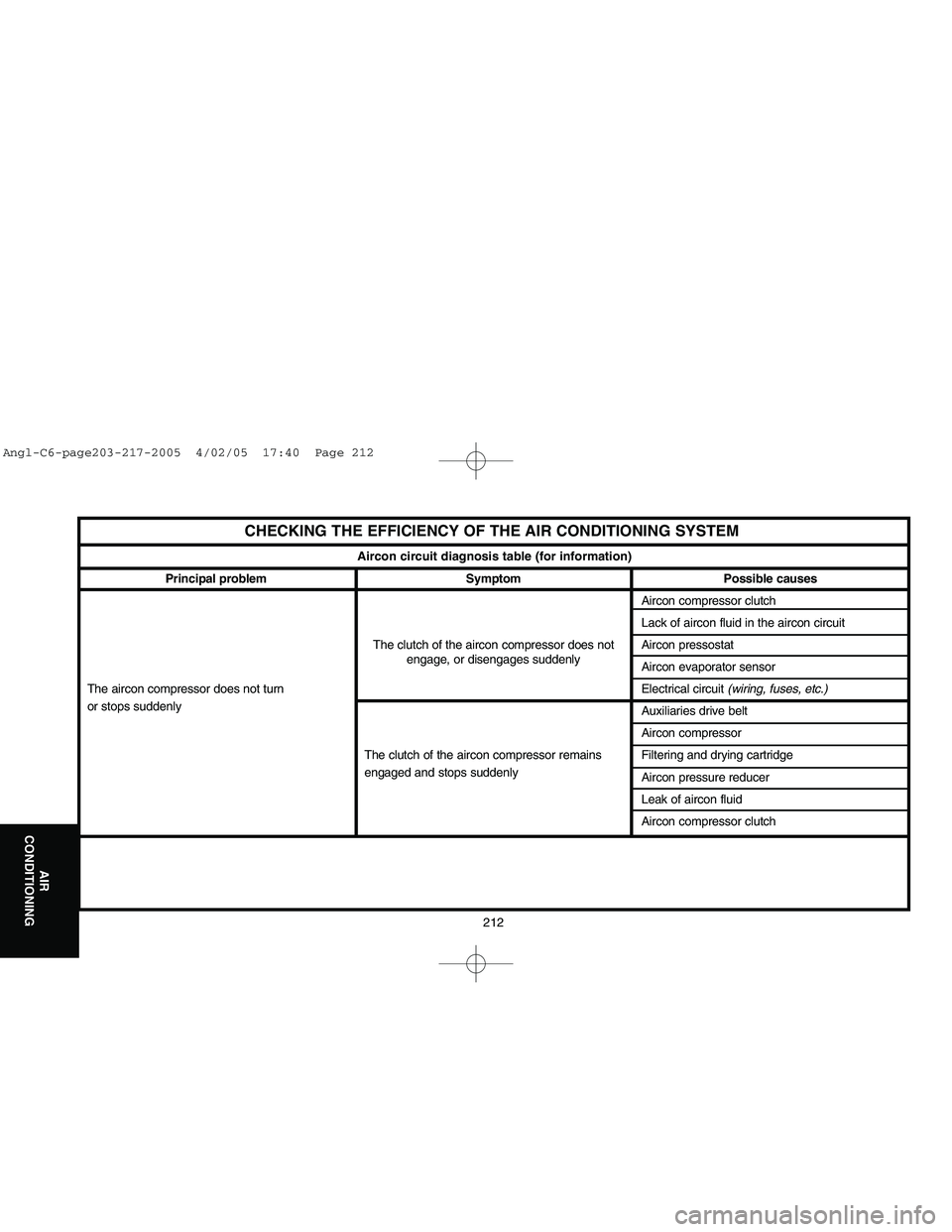

Downloaded from www.Manualslib.com manuals search engine 212

AIR

CONDITIONING

CHECKING THE EFFICIENCY OF THE AIR CONDITIONING SYSTEM

Aircon circuit diagnosis table (for information)

Principal problem Symptom Possible causes

Aircon compressor clutch

Lack of aircon fluid in the aircon circuit

The clutch of the aircon compressor does not Aircon pressostat

engage, or disengages suddenly

Aircon evaporator sensor

The aircon compressor does not turn Electrical circuit (wiring, fuses, etc.)

or stops suddenly

Auxiliaries drive belt

Aircon compressor

The clutch of the aircon compressor remains Filtering and drying cartridge

engaged and stops suddenly

Aircon pressure reducer

Leak of aircon fluid

Aircon compressor clutch

Angl-C6-page203-217-2005 4/02/05 17:40 Page 212

Page 220 of 223

Downloaded from www.Manualslib.com manuals search engine 214

AIR

CONDITIONING

CHECKING THE EFFICIENCY OF THE AIR CONDITIONING SYSTEM

Aircon circuit diagnosis table (for information)

Principal problem Symptom Possible causes

Low pressure and high pressure too highAircon pressure reducer defective

Duct clogged

Low pressure too high and high pressure too low Aircon compressor seal defective

Aircon evaporator sensor defective

Low pressure too low and high pressure too high Aircon pressure reducer jammed

Abnormal levels of pressuretoo high

Filtering and drying cartridge obstructed

Duct clogged

Duct clogged

Aircon pressure reducer jammed

Low pressure and high pressure too low

Lack of aircon fluid in the aircon circuit

Aircon compressor defective

Angl-C6-page203-217-2005 4/02/05 17:40 Page 214

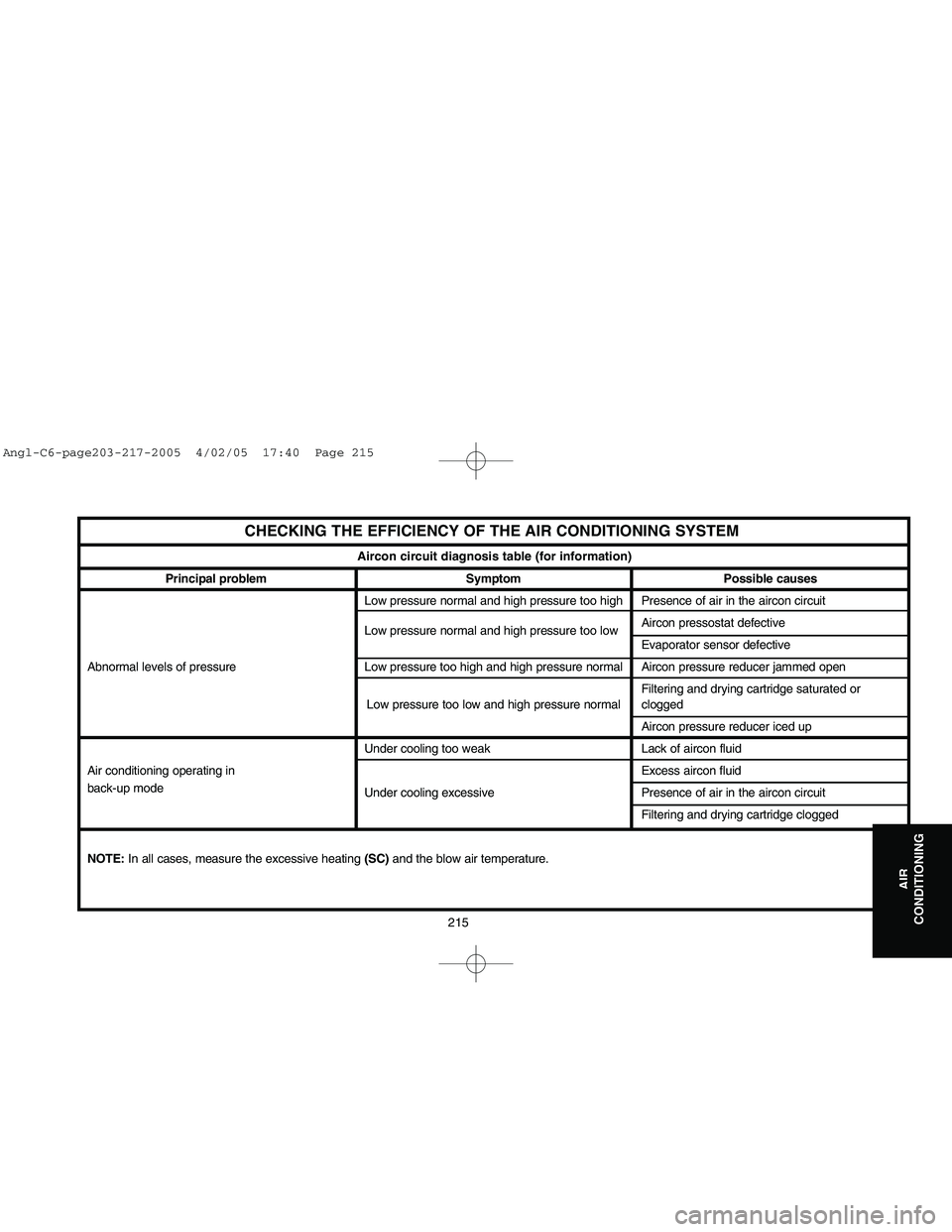

Page 221 of 223

Downloaded from www.Manualslib.com manuals search engine 215

AIR

CONDITIONING

CHECKING THE EFFICIENCY OF THE AIR CONDITIONING SYSTEM

Aircon circuit diagnosis table (for information)

Principal problem Symptom Possible causes

Low pressure normal and high pressure too high Presence of air in the aircon circuit

Low pressure normal and high pressure too lowAircon pressostat defective

Evaporator sensor defective

Abnormal levels of pressure Low pressure too high and high pressure normal Aircon pressure reducer jammed open

Filtering and drying cartridge saturated or

Low pressure too low and high pressure normal clogged

Aircon pressure reducer iced up

Under cooling too weak Lack of aircon fluid

Air conditioning operating inExcess aircon fluid

back-up mode

Under cooling excessive Presence of air in the aircon circuit

Filtering and drying cartridge clogged

NOTE: In all cases, measure the excessive heating (SC)and the blow air temperature.

Angl-C6-page203-217-2005 4/02/05 17:40 Page 215