warning CITROEN C6 2005 Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C6, Model: CITROEN C6 2005Pages: 223, PDF Size: 4.26 MB

Page 96 of 223

Downloaded from www.Manualslib.com manuals search engine 90

INJECTION

PROHIBITED OPERATIONS: SIEMENS HDI DIRECT INJECTION SYSTEM

Engine: DT17BTED4

Cleaning.

The use of high pressure cleaners is prohibited.

Do not use compressed air.

Fuel supply circuit.

Required fuel: Diesel.

WARNING: Do not use other fuels.

Electrical circuit.

Swapping injection ECUs between two vehicles will render it impossible to start either vehicle.

It is forbiddento supply a diesel injector with 12 volts.

Do not disconnect a diesel injector when the engine is running.

Fuel high pressure pump.

Do not separate the fuel high pressure pump (1)from the following components:

- The sealing ring (a)(no replacement parts).

- The high pressure outlet connector (b)(will cause a malfunction).

- The fuel pressure regulator (c)(no replacement parts).

- The flow electrovalve (d)(no replacement parts).

B1HP23GC

Angl-C6-page83-100-2005 4/02/05 17:22 Page 90

Page 97 of 223

Downloaded from www.Manualslib.com manuals search engine 91

INJECTION

PROHIBITED OPERATIONS: SIEMENS HDI DIRECT INJECTION SYSTEM

Engine: DT17BTED4

B1HP23JCB1HP23HC

Diesel injectors.

WARNING: Diesel and ultrasonic cleaners are prohibited.Do not separate the diesel injector carrier (2)from the following components:

- Diesel injector (g)(no replacement parts).

- The fuel flow actuator (e)(destruction).

Do not move the nut (f)(will cause a malfunction).

Do not separate the union (h)from a diesel injector.

It is forbidden

to clean the carbon deposits from the diesel injector nozzle.

Central fuel high pressure common injection rail.

Do not separate the fuel high pressure sensor (j)from the central fuel high pressure injection rail (3).

Angl-C6-page83-100-2005 4/02/05 17:22 Page 91

Page 98 of 223

Downloaded from www.Manualslib.com manuals search engine 92

INJECTION

SAFETY REQUIREMENTS: HDi DIRECT INJECTION SYSTEM

Safety requirements.

Preamble.

All interventions on the injection system must be carried out to conform

with the following requirements and regulations:

- Competent health authorities.

- Accident prevention.

- Environmental protection.

WARNING: Repairs must be carried out by specialised personnel

informed of the safety requirements and of the precautions to be

taken.

Safety requirements.

IMPERATIVE: Take into account the very high pressures in the high

pressure fuel circuit (1600 bars), and respect the requirements

below:

- No smoking in proximity to the high pressure circuit when work is being

carried out.

- Avoid working close to flame or sparks.

Engine running:

- Do not work on the high pressure fuel circuit.

- Always stay clear of the trajectory of any possible jet of fuel, which could

cause serious injuries.

- Do not place your hand close to any leak in the high pressure fuel circuit.After the engine has stopped, wait 30 secondsbefore any intervention.

NOTE:This waiting time is necessary in order to allow the high pressure

fuel circuit to return to atmospheric pressure.

Cleanliness requirements.

Preliminary operations.

IMPERATIVE: The technician should wear clean overall.

Before working on the injection system, it may be necessary to

clean the apertures of the following sensitive componen (refer to

corresponding procedures):

- Fuel filter.

- Fuel high pressure pump.

- Fuel high pressure common injection rail.

- Fuel high pressure pipes

- Diesel injector carriers.

IMPERATIVE: After dismantling, immediately block the apertures of

sensitive components with plugs, to avoid the entry of impurities.

Work area:

- The work area must be clean and free of clutter.

- Components being worked on must be protected from dust.

Angl-C6-page83-100-2005 4/02/05 17:22 Page 92

Page 99 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 93

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Engine: DT17BTED4

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2] Ø 8 mmlow pressu CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 93

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Engine: DT17BTED4

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2] Ø 8 mmlow pressu](/img/9/57744/w960_57744-98.png)

Downloaded from www.Manualslib.com manuals search engine 93

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Engine: DT17BTED4

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2] Ø 8 mmlow pressure connector: 4218-T

[3]Pressure gauge for testing boost pressure: 4073-T Kit 4073-T

[4]Extension: 4251-T

Checks.

IMPERATIVE : Respect the safety and cleanliness requirements specific to high pressure

diesel injection (HDi) engines.

Connect the tool [1]between the booster pump and the fuel filter (white mark on the fuel supply

pipe).

Connect the tool [2]downstream of the diesel injectors, between the high pressure fuel pump and

the fuel filter green mark on the fuel return pipe.

Connect the tool [3]on tool [1]or on tool [2].

WARNING: Any check of pressure downstream of the fuel filter is prohibited.

NOTE:To check the pressures while the vehicle is being driven, insert the extension [4] between

tool [3]and tools [1]or [2].

B1BP3CRD

Angl-C6-page83-100-2005 4/02/05 17:22 Page 93

Page 101 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 95

INJECTION

CHECKS: TURBO PRESSURE

Engine: DT17BTED4

Tools.

[1]Pressure gauge for checking the pressure: 7073-T.A

[2]Tool for checking the inl CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 95

INJECTION

CHECKS: TURBO PRESSURE

Engine: DT17BTED4

Tools.

[1]Pressure gauge for checking the pressure: 7073-T.A

[2]Tool for checking the inl](/img/9/57744/w960_57744-100.png)

Downloaded from www.Manualslib.com manuals search engine 95

INJECTION

CHECKS: TURBO PRESSURE

Engine: DT17BTED4

Tools.

[1]Pressure gauge for checking the pressure: 7073-T.A

[2]Tool for checking the inlet air pressure/vacuum: (-).0171.G3

[3] LEXIAdiagnostic tool: 4171-T

[4] PROXIAdiagnostic tool: 4165-T

Checks.

IMPERATIVE: Respect the safety and cleanliness specific to high pressure diesel injection

engines.

Preliminary operations.

WARNING: Prior to any intervention, check the connections of the turbocharger pressure

regulation actuators.

NOTE:If an air flow fault is memorised by the diagnostic tool, refer to the chapter "Air flow from

the turbochargers".

Turbo pressure sensor.

Remove the engine cover.

Disconnect the connector "a".

Remove the turbo pressure sensor (1).

B1BP3CZC

Angl-C6-page83-100-2005 4/02/05 17:22 Page 95

Page 109 of 223

Downloaded from www.Manualslib.com manuals search engine 103

CLUTCH

GEARBOX

TRANSMISSION

PROCEDURE PRIOR TO OPERATIONS: AM6 AUTOMATIC GEARBOX

If a gearbox malfunction occurs, there are two possible configurations

depending on the seriousness of the fault:

- Gearbox in back-up mode with a replacement programme of (the fault

values are taken in substitution).

- Gearbox in back-up mode with an emergency programme (3rd hydraulic).

WARNING: In the emergency programme, an impact is felt when

changing P/R or N/R.

Reception of the customer.

Discuss with the customer, to find out all the malfunction symptoms.

Oil quality.

If the gearbox has suffered a serious fault resulting in a malfunction or

the destruction of a clutch, the oil will overheat and become

contaminated with impurities: the oil is said to be «burnt».

This is characterised by a black colour and the presence of an

unpleasant smell.

ESSENTIAL: The gearbox must be replaced.Oil level.

Preliminary conditions:

- Vehicle horizontal, parking brake off.

- Check that the gearbox is not in back-up mode (using a diagnostic tool).

- The oil temperature should be 60°C (+8, -2)(using a diagnostic tool).

- Press on the brake pedal, change through all the gears.

- Place the gear lever in position P.

With the engine running at idle, without power consumers (aircon,

heating, etc.):

- Remove the oil level plug.

The oil should flow out, then drip-drip.

Refit the oil level plug (the oil level is correct).

The oil does not flow out through the oil level plug (see operation: drain

fill - bleed the gearbox).

Engines: ES9A - DT17BTED4

Angl-C6-page101-120-2005 4/02/05 17:25 Page 103

Page 121 of 223

Downloaded from www.Manualslib.com manuals search engine 115

CLUTCH

GEARBOX

TRANSMISSION

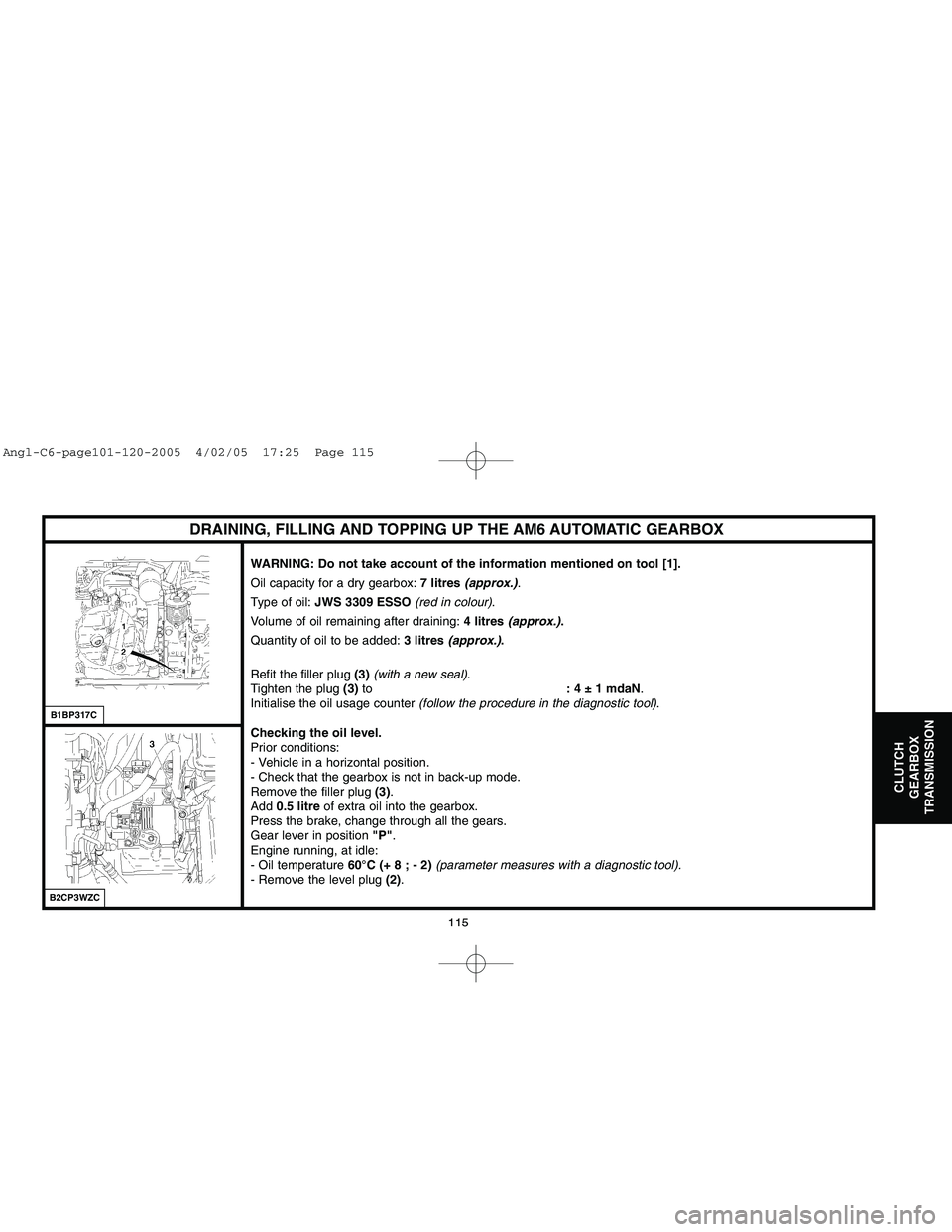

DRAINING, FILLING AND TOPPING UP THE AM6 AUTOMATIC GEARBOX

WARNING: Do not take account of the information mentioned on tool [1].

Oil capacity for a dry gearbox: 7 litres (approx.).

Type of oil: JWS 3309 ESSO(red in colour).

Volume of oil remaining after draining: 4 litres (approx.).

Quantity of oil to be added: 3 litres (approx.).

Refit the filler plug (3)(with a new seal).

Tighten the plug (3)to: 4 ± 1 mdaN.

Initialise the oil usage counter (follow the procedure in the diagnostic tool).

Checking the oil level.

Prior conditions:

- Vehicle in a horizontal position.

- Check that the gearbox is not in back-up mode.

Remove the filler plug (3).

Add 0.5 litreof extra oil into the gearbox.

Press the brake, change through all the gears.

Gear lever in position "P".

Engine running, at idle:

- Oil temperature 60°C (+ 8 ; - 2)(parameter measures with a diagnostic tool).

- Remove the level plug (2).

B2CP3WZCB1BP317C

Angl-C6-page101-120-2005 4/02/05 17:25 Page 115

Page 124 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 118

CLUTCH

GEARBOX

TRANSMISSION

CHECKING THE OIL PRESSURE IN THE AM6 AUTOMATIC GEARBOX

WARNING: Clean the flexible pipe of the tool [1] each t CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 118

CLUTCH

GEARBOX

TRANSMISSION

CHECKING THE OIL PRESSURE IN THE AM6 AUTOMATIC GEARBOX

WARNING: Clean the flexible pipe of the tool [1] each t](/img/9/57744/w960_57744-123.png)

Downloaded from www.Manualslib.com manuals search engine 118

CLUTCH

GEARBOX

TRANSMISSION

CHECKING THE OIL PRESSURE IN THE AM6 AUTOMATIC GEARBOX

WARNING: Clean the flexible pipe of the tool [1] each time before use; the different

automatic gearbox oils cannot be intermixed.

Fit the tool [1]on the tool [2].

Perform the following operations:

- Raise the vehicle, wheels hanging.

- Apply the parking brake.

- Start the engine.

- Check the oil pressure.

WARNING: Wait for the gearbox oil to reach a temperature between 58°C and 68°C.

Check the level of oil in the gearbox (see corresponding operation).

NOTE:Check the temperature of the oil using the diagnostic tool in parameter measures.

Gear lever position: D.

Engine speed: Idling.

Principal oil pressure: 3.7 to 4.2 bars.

B1BP3END

Angl-C6-page101-120-2005 4/02/05 17:25 Page 118

Page 125 of 223

Downloaded from www.Manualslib.com manuals search engine 119

CLUTCH

GEARBOX

TRANSMISSION

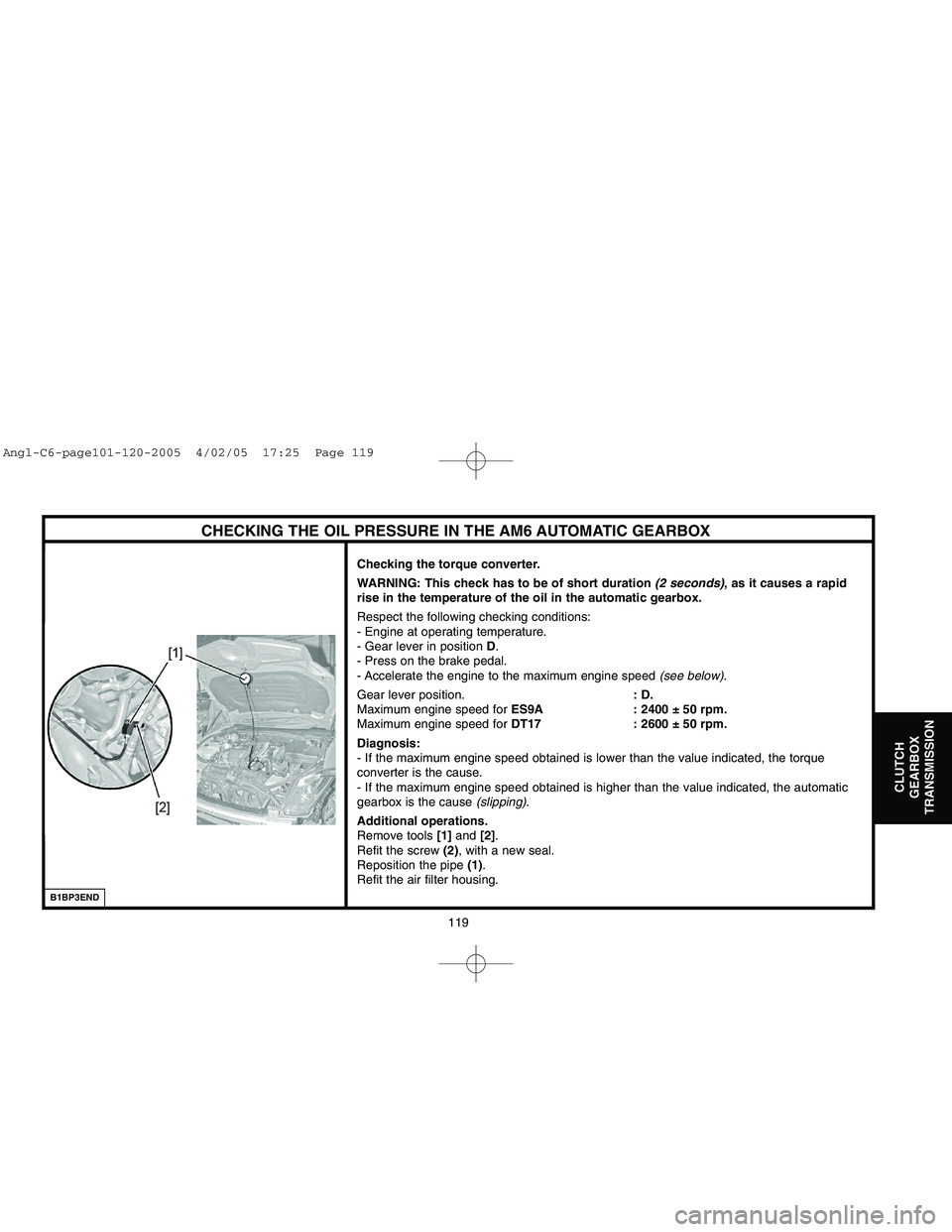

CHECKING THE OIL PRESSURE IN THE AM6 AUTOMATIC GEARBOX

Checking the torque converter.

WARNING: This check has to be of short duration (2 seconds), as it causes a rapid

rise in the temperature of the oil in the automatic gearbox.

Respect the following checking conditions:

- Engine at operating temperature.

- Gear lever in position D.

- Press on the brake pedal.

- Accelerate the engine to the maximum engine speed (see below).

Gear lever position.: D.

Maximum engine speed for ES9A : 2400 ± 50 rpm.

Maximum engine speed for DT17 : 2600 ± 50 rpm.

Diagnosis:

- If the maximum engine speed obtained is lower than the value indicated, the torque

converter is the cause.

- If the maximum engine speed obtained is higher than the value indicated, the automatic

gearbox is the cause (slipping).

Additional operations.

Remove tools [1]and [2].

Refit the screw (2), with a new seal.

Reposition the pipe (1).

Refit the air filter housing.

B1BP3END

Angl-C6-page101-120-2005 4/02/05 17:25 Page 119

Page 130 of 223

Downloaded from www.Manualslib.com manuals search engine AXLES

SUSPENSION

STEERING

124

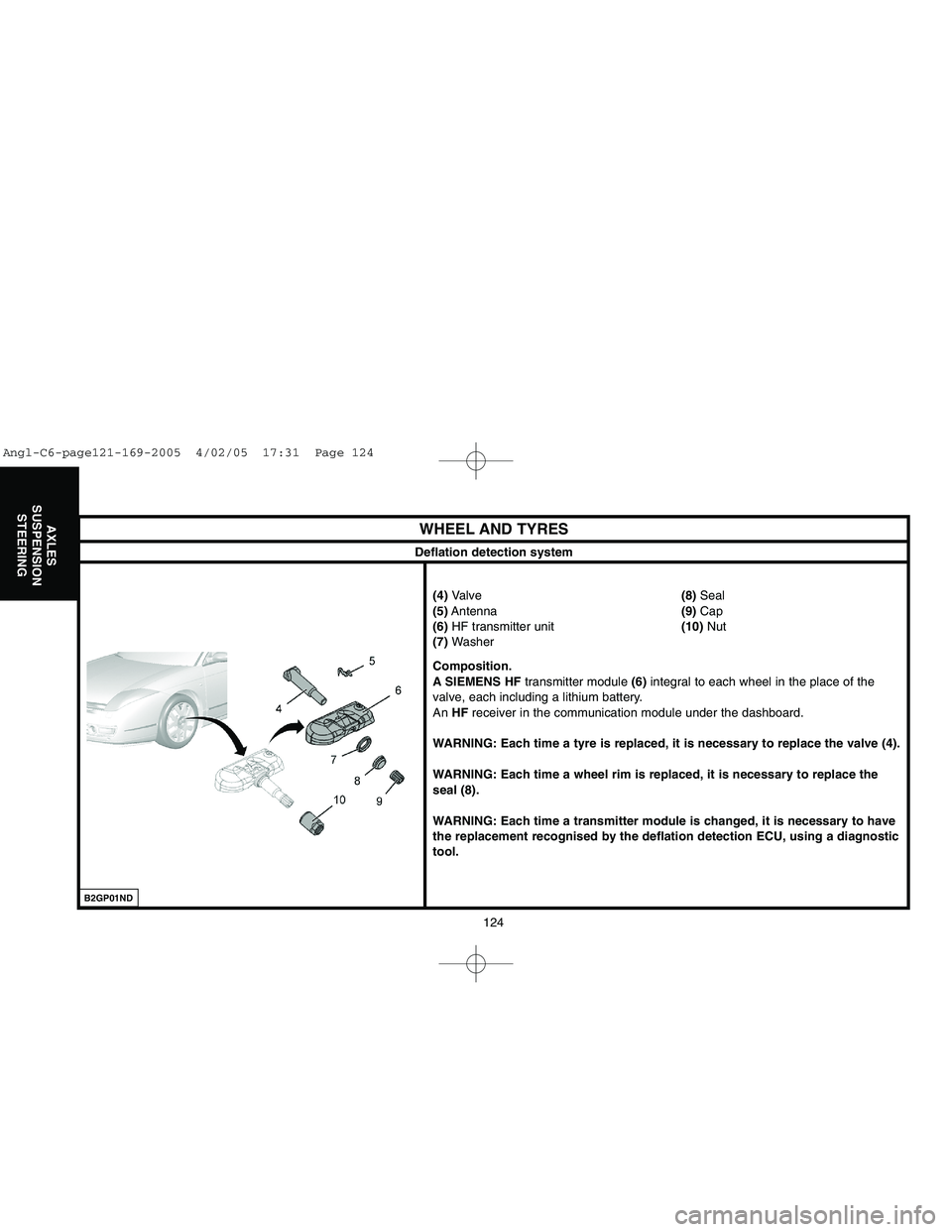

WHEEL AND TYRES(4)Valve(8)Seal

(5)Antenna(9)Cap

(6)HF transmitter unit(10)Nut

(7)Washer

Composition.

A SIEMENS HFtransmitter module (6) integral to each wheel in the place of the

valve, each including a lithium battery.

An HFreceiver in the communication module under the dashboard.

WARNING: Each time a tyre is replaced, it is necessary to replace the valve (4).

WARNING: Each time a wheel rim is replaced, it is necessary to replace the

seal (8).

WARNING: Each time a transmitter module is changed, it is necessary to have

the replacement recognised by the deflation detection ECU, using a diagnostic

tool.

B2GP01ND

Deflation detection system

Angl-C6-page121-169-2005 4/02/05 17:31 Page 124