fuel pressure CITROEN C6 2005 Owners Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2005, Model line: C6, Model: CITROEN C6 2005Pages: 223, PDF Size: 4.26 MB

Page 5 of 223

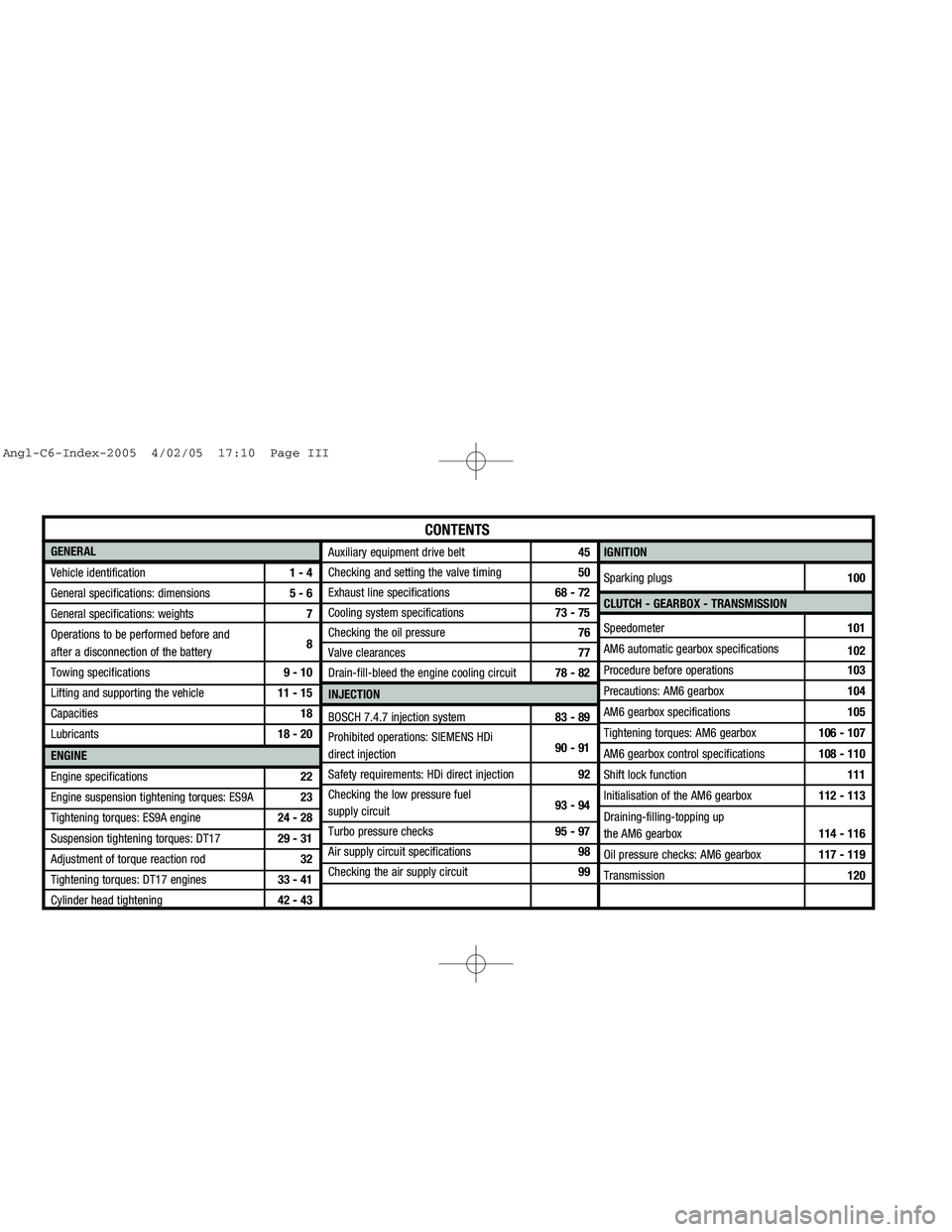

Downloaded from www.Manualslib.com manuals search engine GENERAL

Vehicle identification1 - 4

General specifications: dimensions 5 - 6

General specifications: weights7

Operations to be performed before and

after a disconnection of the battery8

Towing specifications9 - 10

Lifting and supporting the vehicle11 - 15

Capacities18

Lubricants18 - 20

ENGINE

Engine specifications22

Engine suspension tightening torques: ES9A23

Tightening torques: ES9A engine24 - 28

Suspension tightening torques: DT1729 - 31

Adjustment of torque reaction rod32

Tightening torques: DT17 engines33 - 41

Cylinder head tightening42 - 43IGNITION

Sparking plugs100

CLUTCH - GEARBOX - TRANSMISSION

Speedometer101

AM6 automatic gearbox specifications

102

Procedure before operations103

Precautions: AM6 gearbox104

AM6 gearbox specifications105

Tightening torques: AM6 gearbox106 - 107

AM6 gearbox control specifications 108 - 110

Shift lock function111

Initialisation of the AM6 gearbox112 - 113

Draining-filling-topping up

the AM6 gearbox114 - 116

Oil pressure checks: AM6 gearbox117 - 119

Transmission120

CONTENTS

Auxiliary equipment drive belt45

Checking and setting the valve timing50

Exhaust line specifications68 - 72

Cooling system specifications73 - 75

Checking the oil pressure76

Valve clearances77

Drain-fill-bleed the engine cooling circuit78 - 82

INJECTION

BOSCH 7.4.7 injection system83 - 89

Prohibited operations: SIEMENS HDi

direct injection90 - 91

Safety requirements: HDi direct injection92

Checking the low pressure fuel

supply circuit 93 - 94

Turbo pressure checks95 - 97

Air supply circuit specifications98

Checking the air supply circuit99

Angl-C6-Index-2005 4/02/05 17:10 Page III

Page 44 of 223

Downloaded from www.Manualslib.com manuals search engine 38

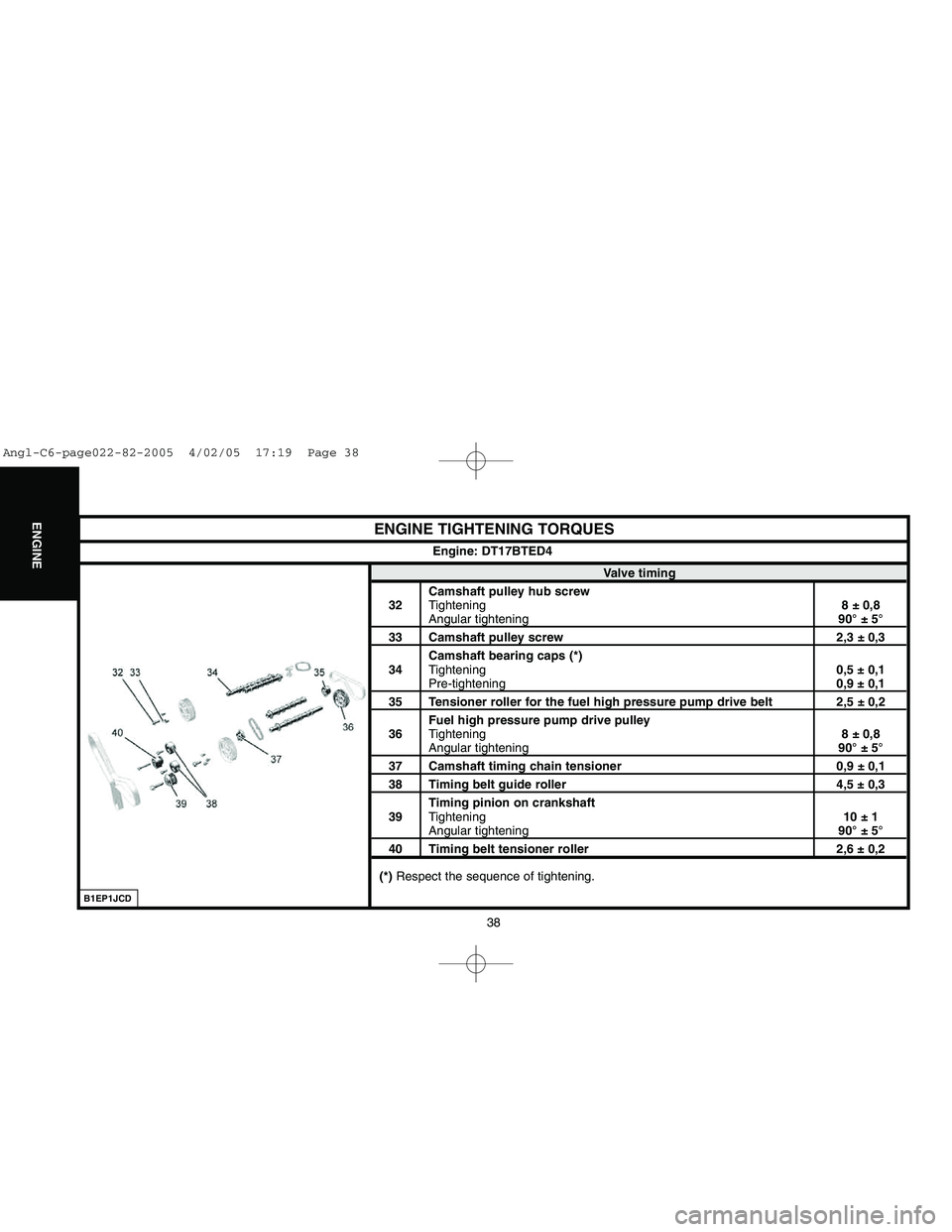

ENGINE

ENGINE TIGHTENING TORQUES

Valve timing

Camshaft pulley hub screw

32Tightening8 ± 0,8

Angular tightening90° ± 5°

33 Camshaft pulley screw 2,3 ± 0,3

Camshaft bearing caps (*)

34Tightening0,5 ± 0,1

Pre-tightening0,9 ± 0,1

35 Tensioner roller for the fuel high pressure pump drive belt 2,5 ± 0,2

Fuel high pressure pump drive pulley

36Tightening8 ± 0,8

Angular tightening90° ± 5°

37 Camshaft timing chain tensioner 0,9 ± 0,138 Timing belt guide roller 4,5 ± 0,3

Timing pinion on crankshaft

39Tightening10 ± 1

Angular tightening90° ± 5°

40 Timing belt tensioner roller 2,6 ± 0,2

(*) Respect the sequence of tightening.Engine: DT17BTED4

B1EP1JCD

Angl-C6-page022-82-2005 4/02/05 17:19 Page 38

Page 46 of 223

Downloaded from www.Manualslib.com manuals search engine 40

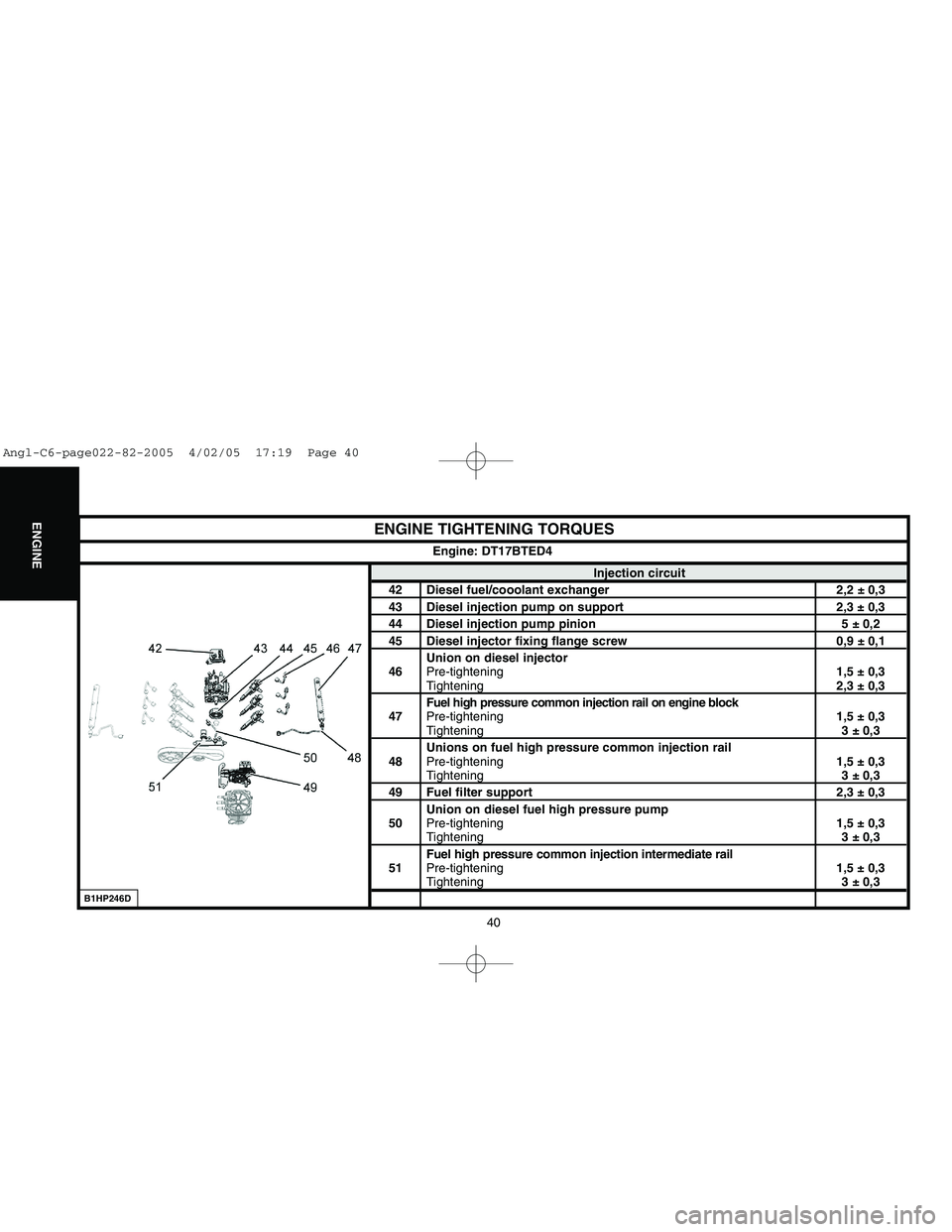

ENGINE

ENGINE TIGHTENING TORQUES

Injection circuit

42 Diesel fuel/cooolant exchanger 2,2 ± 0,343 Diesel injection pump on support 2,3 ± 0,344 Diesel injection pump pinion 5 ± 0,245 Diesel injector fixing flange screw 0,9 ± 0,1

Union on diesel injector

46Pre-tightening1,5 ± 0,3

Tightening2,3 ± 0,3

Fuel high pressure common injection rail on engine block

47Pre-tightening1,5 ± 0,3Tightening3 ± 0,3

Unions on fuel high pressure common injection rail

48Pre-tightening1,5 ± 0,3Tightening3 ± 0,3

49 Fuel filter support 2,3 ± 0,3

Union on diesel fuel high pressure pump

50Pre-tightening1,5 ± 0,3

Tightening3 ± 0,3

Fuel high pressure common injection intermediate rail

51Pre-tightening1,5 ± 0,3Tightening3 ± 0,3 Engine: DT17BTED4

B1HP246D

Angl-C6-page022-82-2005 4/02/05 17:19 Page 40

Page 57 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 51

ENGINE

51

CHECKING THE VALVE TIMING

Engine: ES9A

Tools.

[1]Camshaft setting pegs: (-).0187.B

[2]Crankshaft setting peg: (-).0187.A

[3]Fuel p CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 51

ENGINE

51

CHECKING THE VALVE TIMING

Engine: ES9A

Tools.

[1]Camshaft setting pegs: (-).0187.B

[2]Crankshaft setting peg: (-).0187.A

[3]Fuel p](/img/9/57744/w960_57744-56.png)

Downloaded from www.Manualslib.com manuals search engine 51

ENGINE

51

CHECKING THE VALVE TIMING

Engine: ES9A

Tools.

[1]Camshaft setting pegs: (-).0187.B

[2]Crankshaft setting peg: (-).0187.A

[3]Fuel pressure take-off union: 4192-T

[4]Belt retaining pin: (-).0187.J

[5]Exhaust camshaft hubs immobilising tool: (-).0187.F

[6]Inlet camshaft hubs immobilising tool: FACOM D12

[7]SEEM belt tension measuring equipment: 4122-T

Remove components as necessary for this operation.

Remove the auxiliaries drive belt (see corresponding operation).

Checking the valve timing.

Remove:

- The power steering pulley.

- The roller/dynamic tensioner assembly (11).

- The crankshaft pulley (12).

- The upper timing covers (9)and (10).

- The lower timing cover (13).

B1BP2BKC

Angl-C6-page022-82-2005 4/02/05 17:19 Page 51

Page 89 of 223

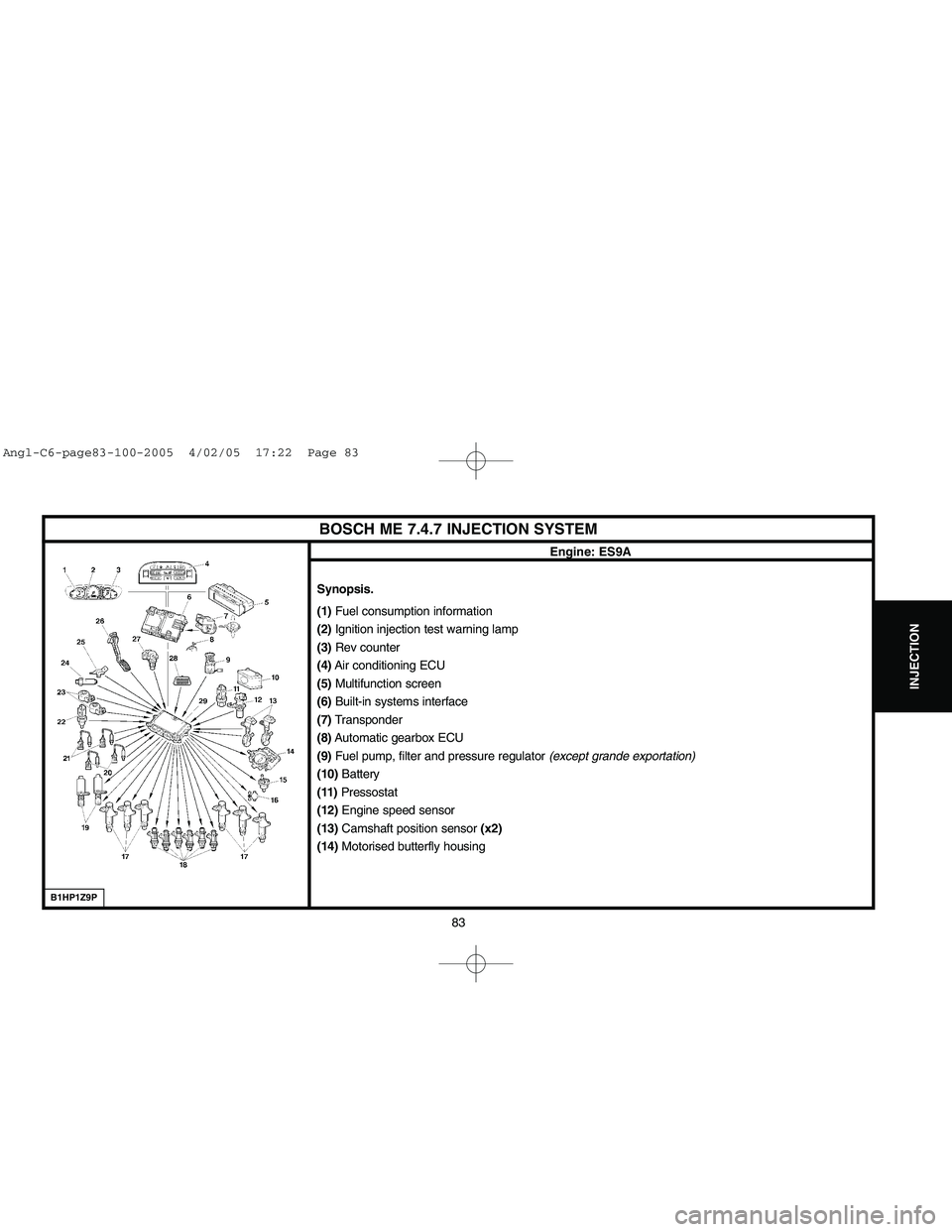

Downloaded from www.Manualslib.com manuals search engine 83

INJECTION

BOSCH ME 7.4.7 INJECTION SYSTEM

Engine: ES9A

Synopsis.

(1) Fuel consumption information

(2)Ignition injection test warning lamp

(3)Rev counter

(4)Air conditioning ECU

(5)Multifunction screen

(6)Built-in systems interface

(7)Transponder

(8)Automatic gearbox ECU

(9)Fuel pump, filter and pressure regulator (except grande exportation)

(10)Battery

(11)Pressostat

(12)Engine speed sensor

(13)Camshaft position sensor (x2)

(14)Motorised butterfly housing

B1HP1Z9P

Angl-C6-page83-100-2005 4/02/05 17:22 Page 83

Page 92 of 223

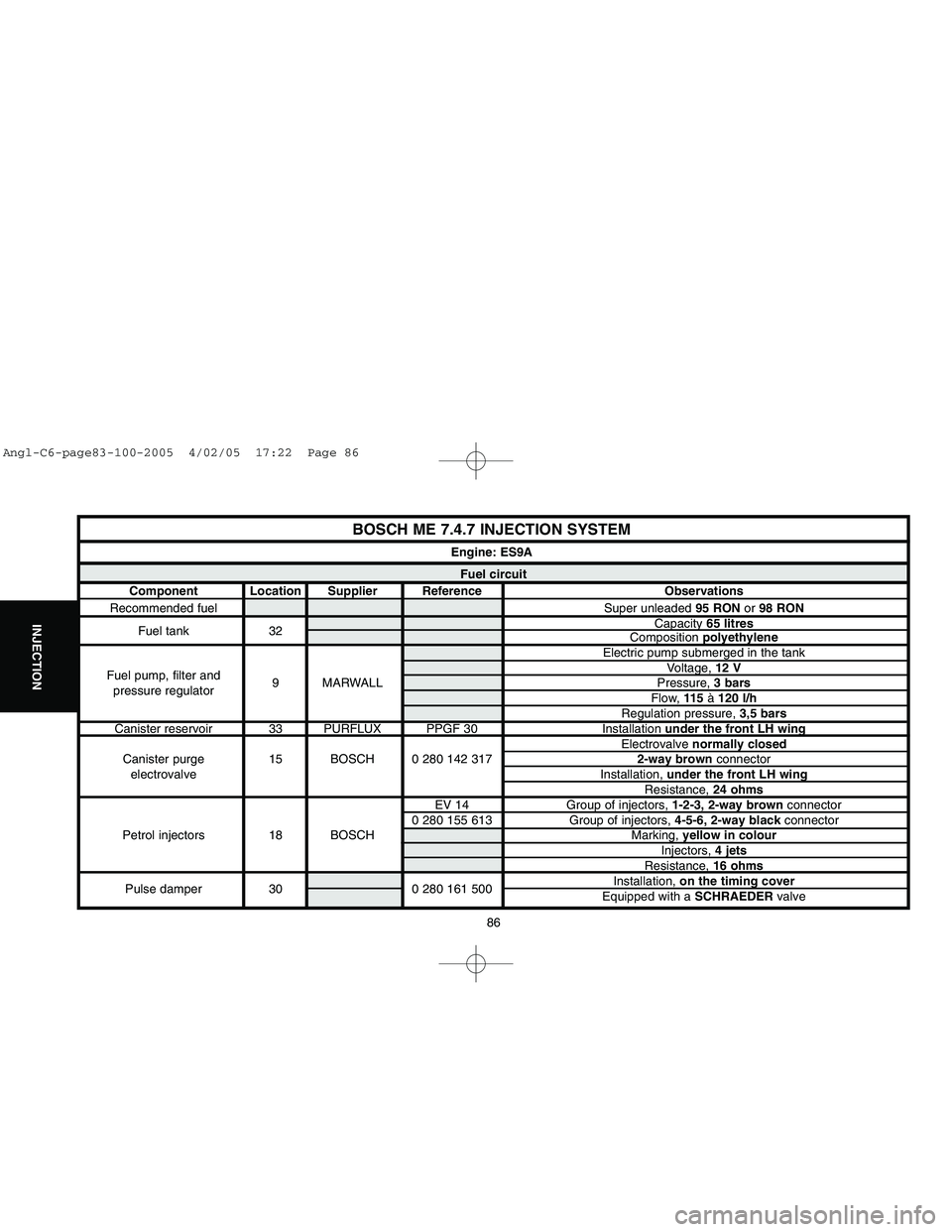

Downloaded from www.Manualslib.com manuals search engine 86

INJECTION

BOSCH ME 7.4.7 INJECTION SYSTEM

Engine: ES9AFuel circuit

Component Location Supplier Reference Observations

Recommended fuel Super unleaded 95 RONor 98 RON

Fuel tank 32Capacity 65 litres

Composition polyethylene

Electric pump submerged in the tank

Fuel pump, filter andVoltage, 12 V

pressure regulator9 MARWALL Pressure, 3 bars

Flow, 115 à 120 l/h

Regulation pressure, 3,5 bars

Canister reservoir 33 PURFLUX PPGF 30 Installation under the front LH wing

Electrovalve normally closed

Canister purge 15 BOSCH 0 280 142 3172-way brownconnector

electrovalveInstallation, under the front LH wing

Resistance, 24 ohms

EV 14 Group of injectors, 1-2-3, 2-way brownconnector

0 280 155 613 Group of injectors, 4-5-6, 2-way blackconnector

Petrol injectors 18 BOSCH Marking, yellow in colour

Injectors, 4 jets

Resistance, 16 ohms

Pulse damper 30 0 280 161 500Installation, on the timing cover

Equipped with a SCHRAEDERvalve

Angl-C6-page83-100-2005 4/02/05 17:22 Page 86

Page 96 of 223

Downloaded from www.Manualslib.com manuals search engine 90

INJECTION

PROHIBITED OPERATIONS: SIEMENS HDI DIRECT INJECTION SYSTEM

Engine: DT17BTED4

Cleaning.

The use of high pressure cleaners is prohibited.

Do not use compressed air.

Fuel supply circuit.

Required fuel: Diesel.

WARNING: Do not use other fuels.

Electrical circuit.

Swapping injection ECUs between two vehicles will render it impossible to start either vehicle.

It is forbiddento supply a diesel injector with 12 volts.

Do not disconnect a diesel injector when the engine is running.

Fuel high pressure pump.

Do not separate the fuel high pressure pump (1)from the following components:

- The sealing ring (a)(no replacement parts).

- The high pressure outlet connector (b)(will cause a malfunction).

- The fuel pressure regulator (c)(no replacement parts).

- The flow electrovalve (d)(no replacement parts).

B1HP23GC

Angl-C6-page83-100-2005 4/02/05 17:22 Page 90

Page 97 of 223

Downloaded from www.Manualslib.com manuals search engine 91

INJECTION

PROHIBITED OPERATIONS: SIEMENS HDI DIRECT INJECTION SYSTEM

Engine: DT17BTED4

B1HP23JCB1HP23HC

Diesel injectors.

WARNING: Diesel and ultrasonic cleaners are prohibited.Do not separate the diesel injector carrier (2)from the following components:

- Diesel injector (g)(no replacement parts).

- The fuel flow actuator (e)(destruction).

Do not move the nut (f)(will cause a malfunction).

Do not separate the union (h)from a diesel injector.

It is forbidden

to clean the carbon deposits from the diesel injector nozzle.

Central fuel high pressure common injection rail.

Do not separate the fuel high pressure sensor (j)from the central fuel high pressure injection rail (3).

Angl-C6-page83-100-2005 4/02/05 17:22 Page 91

Page 98 of 223

Downloaded from www.Manualslib.com manuals search engine 92

INJECTION

SAFETY REQUIREMENTS: HDi DIRECT INJECTION SYSTEM

Safety requirements.

Preamble.

All interventions on the injection system must be carried out to conform

with the following requirements and regulations:

- Competent health authorities.

- Accident prevention.

- Environmental protection.

WARNING: Repairs must be carried out by specialised personnel

informed of the safety requirements and of the precautions to be

taken.

Safety requirements.

IMPERATIVE: Take into account the very high pressures in the high

pressure fuel circuit (1600 bars), and respect the requirements

below:

- No smoking in proximity to the high pressure circuit when work is being

carried out.

- Avoid working close to flame or sparks.

Engine running:

- Do not work on the high pressure fuel circuit.

- Always stay clear of the trajectory of any possible jet of fuel, which could

cause serious injuries.

- Do not place your hand close to any leak in the high pressure fuel circuit.After the engine has stopped, wait 30 secondsbefore any intervention.

NOTE:This waiting time is necessary in order to allow the high pressure

fuel circuit to return to atmospheric pressure.

Cleanliness requirements.

Preliminary operations.

IMPERATIVE: The technician should wear clean overall.

Before working on the injection system, it may be necessary to

clean the apertures of the following sensitive componen (refer to

corresponding procedures):

- Fuel filter.

- Fuel high pressure pump.

- Fuel high pressure common injection rail.

- Fuel high pressure pipes

- Diesel injector carriers.

IMPERATIVE: After dismantling, immediately block the apertures of

sensitive components with plugs, to avoid the entry of impurities.

Work area:

- The work area must be clean and free of clutter.

- Components being worked on must be protected from dust.

Angl-C6-page83-100-2005 4/02/05 17:22 Page 92

Page 99 of 223

![CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 93

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Engine: DT17BTED4

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2] Ø 8 mmlow pressu CITROEN C6 2005 Owners Manual Downloaded from www.Manualslib.com manuals search engine 93

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Engine: DT17BTED4

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2] Ø 8 mmlow pressu](/img/9/57744/w960_57744-98.png)

Downloaded from www.Manualslib.com manuals search engine 93

INJECTION

CHECKS: LOW PRESSURE FUEL SUPPLY CIRCUIT

Engine: DT17BTED4

Tools.

[1] Ø 10 mmlow pressure connector: 4215-T

[2] Ø 8 mmlow pressure connector: 4218-T

[3]Pressure gauge for testing boost pressure: 4073-T Kit 4073-T

[4]Extension: 4251-T

Checks.

IMPERATIVE : Respect the safety and cleanliness requirements specific to high pressure

diesel injection (HDi) engines.

Connect the tool [1]between the booster pump and the fuel filter (white mark on the fuel supply

pipe).

Connect the tool [2]downstream of the diesel injectors, between the high pressure fuel pump and

the fuel filter green mark on the fuel return pipe.

Connect the tool [3]on tool [1]or on tool [2].

WARNING: Any check of pressure downstream of the fuel filter is prohibited.

NOTE:To check the pressures while the vehicle is being driven, insert the extension [4] between

tool [3]and tools [1]or [2].

B1BP3CRD

Angl-C6-page83-100-2005 4/02/05 17:22 Page 93