change time Citroen CX 1974 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1974, Model line: CX, Model: Citroen CX 1974 1.GPages: 394

Page 10 of 394

Downloaded from www.Manualslib.com manuals search engine 4 OPERATION N” MA. 000 : General characteristics

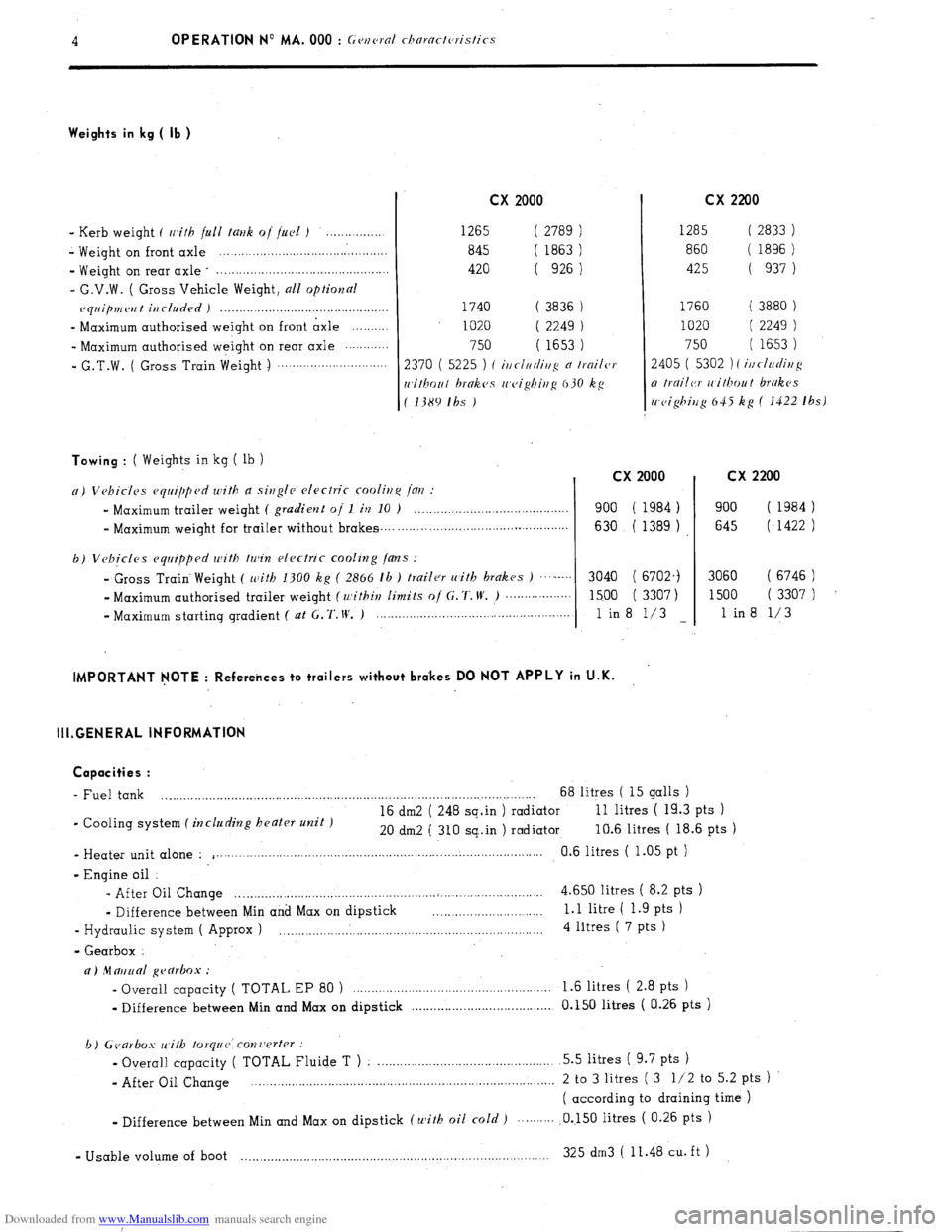

Weights in kg ( lb )

- Kerb weight ( with full tallk oj fuel ) . . . . . . . . . .

- Weight on

front axle ...............................................

- Weight on rear axle ................................................

- G.V.W. ( Gross Vehicle Weight, all optional

ecpiip777ei7t i77cluded )

..............................................

- Maximum authorised weight on front axle ..........

- Maximum authorised weight on rear axle ............

I G.T.W. ( Gross Train

Weight )

..............................

Towing : ( Weights in kg ( lb ) cx 2000

1265 ( 2789

) 1285

( 2833 )

845

( 1863 ) 860

( 1896)

420 ( 926

1 425

( 937 1

1740 ( 3836

) 1760 ( 3880 )

1020 ( 2249 ) 1020 ( 2249 )

750 ( 1653 ) 750 ( 1653)

2370 ( 5225

) I i77cI77rfi77!: n Ir.oiler 2405 ( 5302 )

( i/7t/ur/i77g

rc,i/hou/ brnkes cc,eighiug 630 kg o trc7ilcr rt~ithou t brakes

( 1389 Ihs ) rc~ei$iu~ 645 kg ( 1422 Ibs)

n) Vehicles equipped with a single electric cooli,f,c /c[i7 :

”

Maximum trailer weight ( gradient of 1 h 10 ) .__._..,...__,_____............

- Maximum

weight for bailer without brakes _.., .__._. ,. _._..,.,_..,__.._...... . . . . . . . . . . . .

b)

Vehicles equipped with tu& electric cooling /ans :

-

Gross Train. Weight ( zc:ith 1300 kg ( 2866 lb ) trailer with brakes ) .....-.’

- Maximum authorised trailer weight (within limits o/ C. 7‘. W’. ) ~..~~...~.....~~~

- Maximum starting gradient ( at G. ‘f. IV, )

_______.._....._...,.................................

cx 2200

cx 2000

900 ( 1984 )

630 ( 1389 )

3040 ( 6702.)

1500 ( 3307)

1 in8 l/3

- cx 2200

900 ( 1984)

645 (,I422 )

3060 ( 6746 )

1500 ( 3307 )

1 in8 l/3

IMPORTANT NOTE : Referehces to trailers without brakes DO NOT APPLY in U.K.

III.GENERAL INFORMATION

Capacities :

- Fuel tank

. . .._....__........................................................................................... 68 litres ( 15 galls )

- Cooling system

(including beater unit ) 16 dm2 ( 248 sq.in ) radiator 11 litres ( 19.3 pts )

20 dm2 ( 310 sq..in ) radiator 10.6 litres ( 18.6 pts )

- Heater unit alone :

i . . ..___.___.._.._.._..........................,..,.,..................................... Cl.6 litres ( 1.05 pt )

- Engine oil :

- After Oil Change _......_._.,_....,..,....,.......,....,................~.,.........................,

4.650 litres ( 8.2 pts )

w

Difference between Min and Max on dipstick 1.1 litre ( 1.9 pts )

- Hydraulic system ( Approx ) 4 litres ( 7 pts )

- Gearbox

a) ‘11 mud ~earlmx :

- Overall capacity ( TOTAL EP 80 ) _.__.__._..._..._._................................... 1 .6 litres ( 2.8 pts )

w

Difference between Min and Max on dipstick . . . . . . . . . . . . . . . . . .._................... 0.150 litres ( a.26 pts )

b) Ccarbos with

/orque: con7jerter :

- Overall capacity ( TOTAL Fluide T ) . ..__.,_.____________....,.,....,....,,.......... 5.5 litres ( 9.7 pts )

- After Oil Change . . 2 to 3 litres ( 3 l/2 to 5.2 pts )

( according to draining time )

v

Difference between Min and Max on dipstick (with oil

cold ) .0..150 litres ( 0.26 pts )

- Usable volume of boot

325 dm3 ( 11.48 cu. ft ) . . . . . . . . . . . . . . . . . .._................................................................

Page 86 of 394

Downloaded from www.Manualslib.com manuals search engine ALL CX VEHICLES

ANTI-POLLUTION SYSTEM ( SWEDISH MARKET )

I - cx 2200 :

The object of the system is to reduce the amount of unburnt hydrocarbons and the amount of CO in the exhaust

( 2 to 3 Z. of CO ) by injecting air under pressure into the exhaust manifold OPERATION :

As the engine rotates air pump ( 1 )supplies the air injectors (4) situated close to the exhaust valves: flap (3)

prevents the exhaust fumes from entering the air pump ( 1 ) and valve ( 2) assembly

There are two cases when it is necessary to stop the injection of air into the exhaust manifold. 1. During deceleration :

During fast decelerations. the mixture becomes richer combustion is incomplete, and the injection of air is

stopped in order 1.0 avoid a second combustion taking place in the exhaust system ( which would result in back

firinq ). During deceleration there is extreme low pressure downstream of the but!erfly ( 8 ). This in turn draws

in for a short period of time the diaphragm in valve (2 )

The air supplied by pump ( 1 ) is released into the atmosphere the calibrated hole u a )) on the diaphraqm

balances the pressure on either side of it, and the diaphragm returns to its initial position, allowinq air to

be once more injected into the exhaust manifold. 2. With the choke out :

With the choke in this position, the quantities of unburned hydrocarbons and CO are very considerable. It is

therefore necessary to stop the injection of air into the exhaust manifold so as to avoid an excessive

increase of temperature in the manifold. With the choke out, lever ( 5 ) connects relay ( 7 ) to earth.

The u WEBER )) electric contact is enerqized The air pressure at the outlet of air pump ( 1 ) increases the

effect of the low pressure on the diaphragm in valve (2 ) ( the air-pressure is felt above the diaphragm and

the low pressure produced by the carburettor (8) is felt below the diaphraqm ) the sliding valve in valve

unit ( 2 ) changes position, and the air is expelled into the atmosphere

If choke ( 5) is pushed back in, air is once again injected into the exhaust manifold.

Page 287 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 454-O : Ch ec tzg and a&sting the handbrakc k’

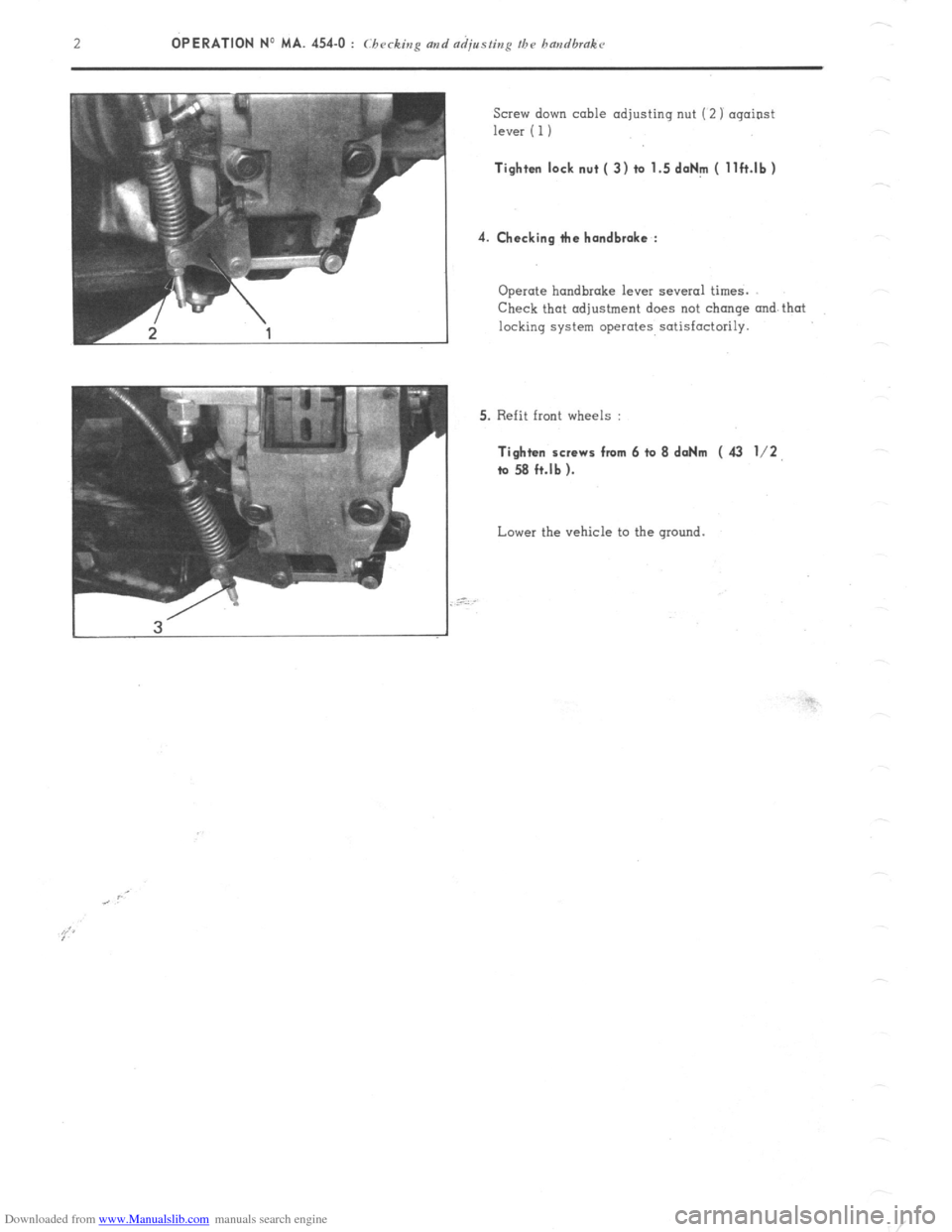

Screw down cable adjusting nut (2) against

lever ( 1) Tighten lock nut ( 3) to 1.5 doNm ( llft.lb)

4. Checking tie handbrake :

Operate handbrake lever several times.

Check that adjustment does not change and that

locking system operates satisfactorily.

5. Refit front wheels : Tighten screws from 6 to 8 daNm ( 43 l/2,

ta 58 ft.lb ).

Lower the vehicle to the ground.