suspension Citroen CX 1976 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1976, Model line: CX, Model: Citroen CX 1976 1.GPages: 394

Page 239 of 394

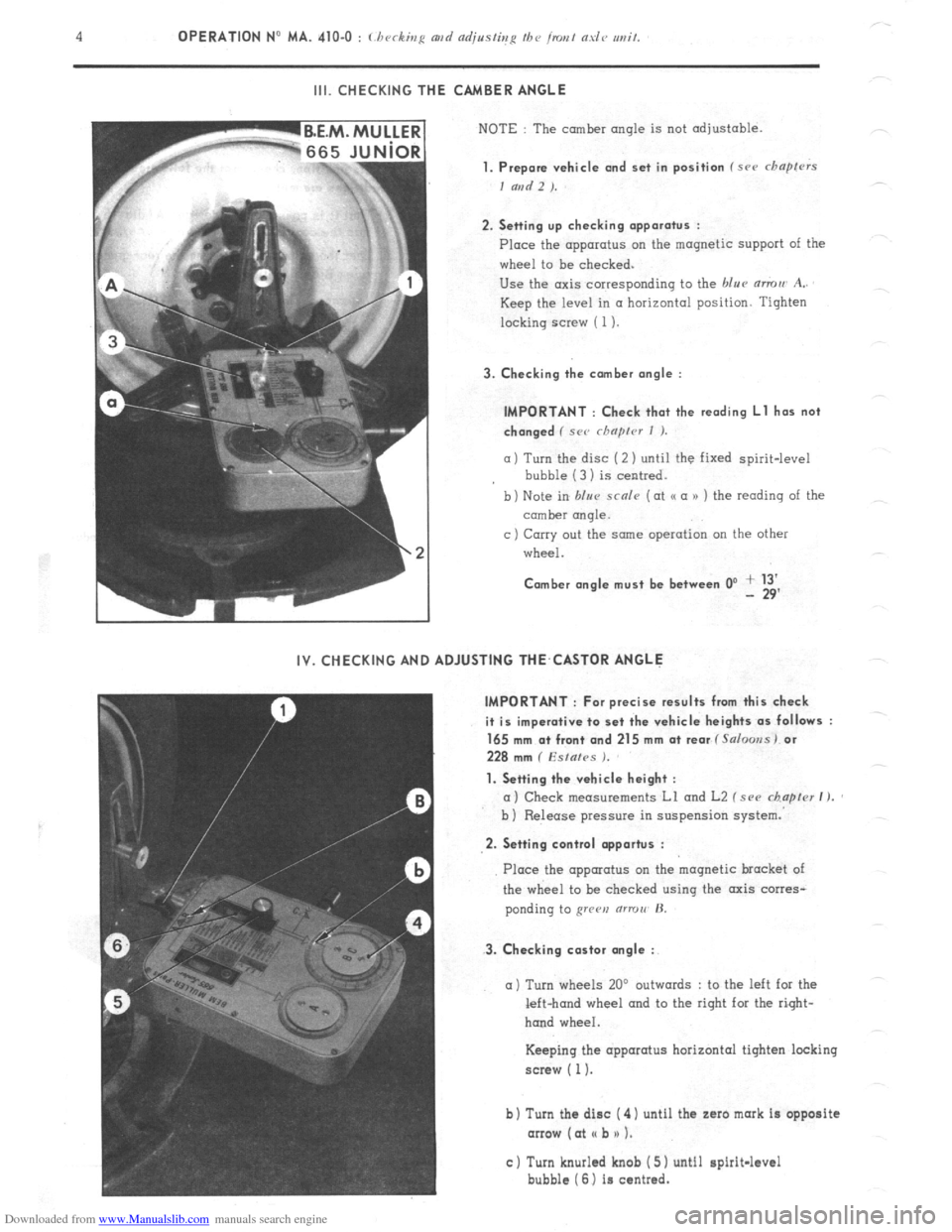

Downloaded from www.Manualslib.com manuals search engine III. CHECKING THE CAMBER ANGLE

NOTE : The camber angle is not adjustable.

1. Prepare vehicle and set in position f src chapfrrs

I and 2 ).

2. Setting up checking apparatus :

Place the apparatus on the magnetic support of the

wheel to be checked.

Use the axis corresponding to the blue mmu A..

Keep the level in a horizontal position. Tighten

locking screw ( 1).

3. Checking the comber angle :

IMPORTANT : Check that the reading Ll has not

changed ( SC<’ rhnprcr I ).

a) Turn the disc (2 ) until the fixed spirit-level

bubble (3 1 is centred.

b) Note in blur scnle (at o a n ) the reading of the

comber rmqle.

c ) Carry out the same operation on the other

wheel.

Comber angle must be between 0’ + 13’ - 29’

IV. CHECKING AND ADJUSTING THE,CASTOR ANGLE

IMPORTANT : For precise results from this check

it is imperative to set the vehicle heights as follows :

165 mm a+ front and 215 mm at rear f Salooss) or

228 mm ( Esfafes ).

1. Setting the vehicle height :

a) Check measurements Ll and L2 f see chapter I ).

b ) Release pressure in suspension system.

2. Setting control opportus :

3. Checking castor angle :

Place the apparatus on the magnetic bracket of

the wheel to be checked using the axis corres-

ponding to grren (ITTOII’ H.

a) Turn wheels 20’ outwards : to the left for the

left-hand wheel and to the right for the right-

hand wheel.

Keeping the apparatus horizontal tighten locking

screw ( 1).

b) Turn the disc ( 4) until the zaro mark is opposite

arrow (at I( b n 1.

c) Turn knurled knob ( 5) until spirit-level

bubble (6) is centred.

Page 252 of 394

Downloaded from www.Manualslib.com manuals search engine SUSPENSION

OPERATION No MA. 430-00 : ( hnmrtcristics mrd spccinl jeatrrres oj /ha susp~~sio~~. Op. MA. 430-00 1

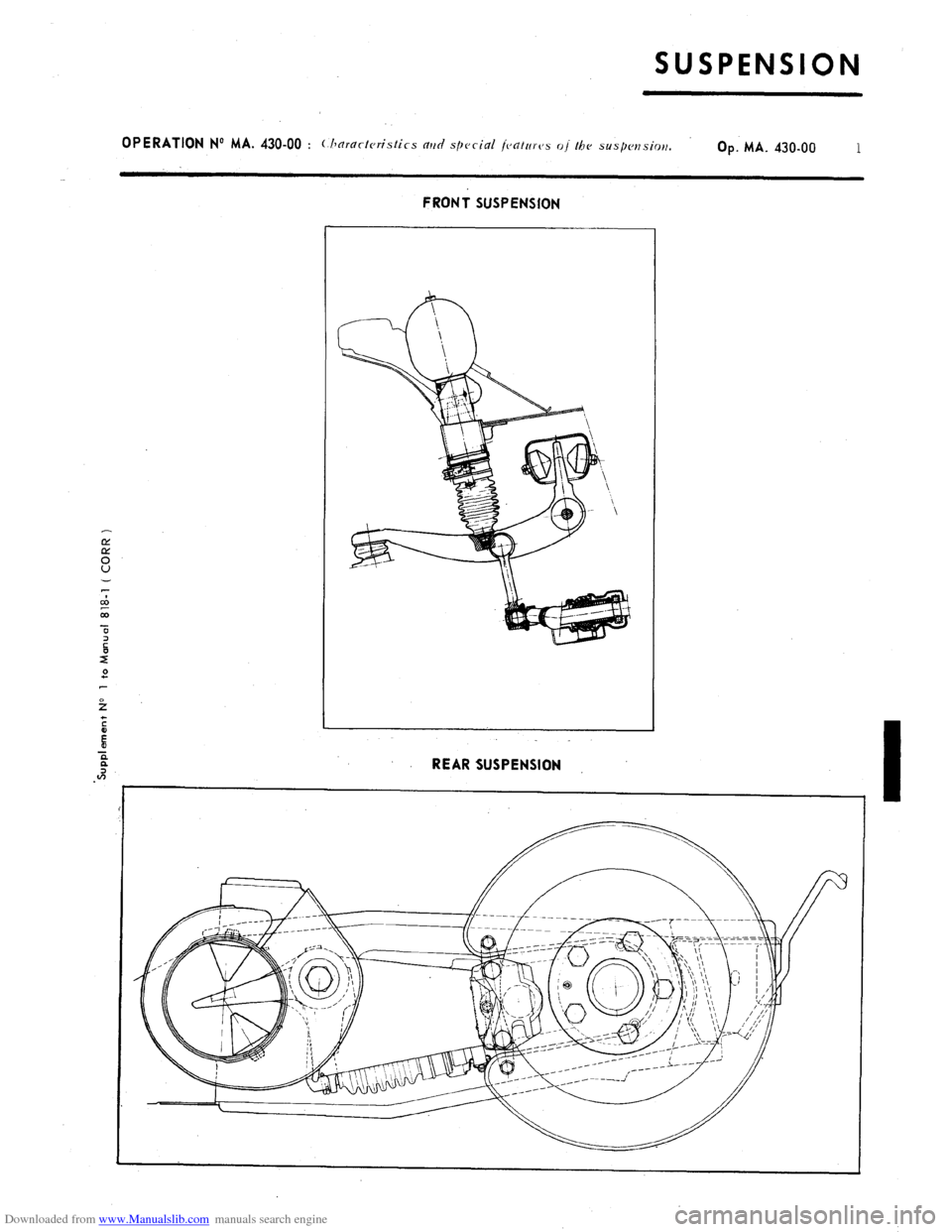

FRONT SUSPENSION

f

c

s

6

-E

J REAR SUSPENSION

I

,

Page 253 of 394

Downloaded from www.Manualslib.com manuals search engine I. CHARACTERISTICS

..-.-..- --~~~

HEIGHT CORRECTOR

SUSPENSION CYLINDER ( All Saloon vehicles )

L.43-6

SUSPENSION CYLINDER ( Estate vehicles )

-- --.

Page 255 of 394

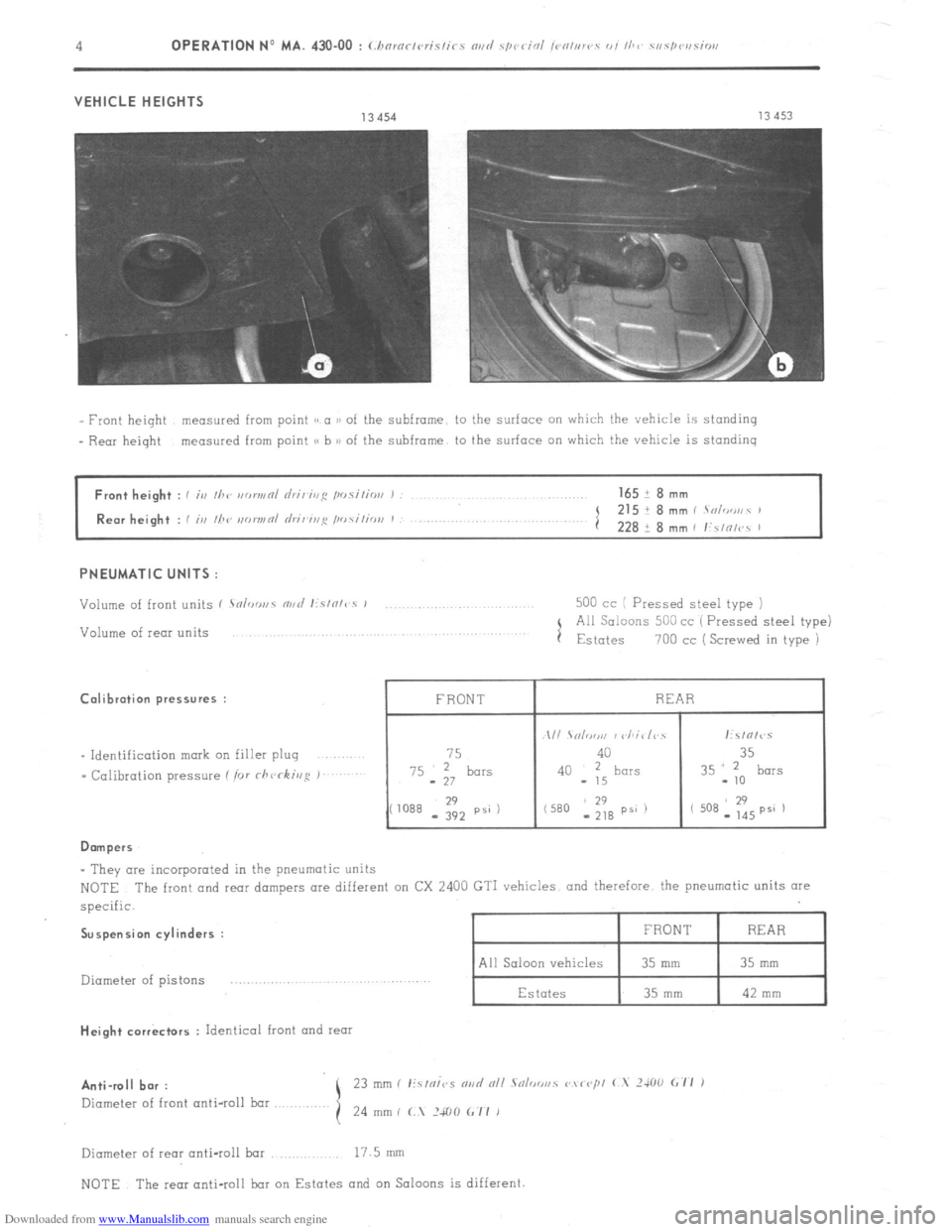

Downloaded from www.Manualslib.com manuals search engine VEHICLE HEIGHTS 13454

- Front height measured from point SG a 8) of the subfrome. to the surface on which the vehicle is stondinq

_ Rear height measured from point (, b )B of the subfrome to the surface on which the vehicle is standinq Calibration pressures :

FRONT REAR

\// \~~lr~r,,i J v/xii

/c,.5 I:\lol,‘s

_ Identification mark on filler plug 75 40 35

- Calibration pressure ( /or rhc’rkiqg 1. 75 2 bars 40 2 bars

- 27 - 15 35 1 ;, bars

(1088 _ ;;, P51 1

(580 : ;;, P51 i ( 508; :',, PSP 1 Dampers

- They are incorporated in the pneumatic units

NOTE The front and rear dampers ore different on CX 2400 GTI vehicles and therefore the pneumatic units are PNEUMATIC UNITS :

Volume of front units i Soloor, mid I:s/fll<,s 1

500 cc f Pressed steel type )

Volume of rear units

i All Saloons 500 cc ‘j Pressed steel type)

Estates 700 cc (Screwed in type i

I

specific. Suspension cylinders :

Diameter of pistons ,,,, Height

corr&tors : Identical front and rear Anti-roll bar :

23 mm i lisfoir~s mid o/l Salormc <~,c,,,,, ( Y ‘Xl(i VII I

Diameter of front anti-roll bar.

i 24 mm , (. 2400 (.‘/I J

Diameter of rear anti-roll bar 17.5 mm

NOTE The rear anti-roll bar on Estates and on Saloons is different.

Page 256 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 430.00 : c ,,<,,a< ,<,r;s,;rs mi/ .s/wrin/ ,vn/srrs oi /he srmf~rw.~ion Op. MA. 430-00 5

II. SPECIAL FEATURES

Adjusting the anti-roll bars :

A, t/xv ,ms,

- Lateral positioning equal protrusion on either side to within 2 mm

- Anti-roll bar bearing preload 300 N ( 30kg) ( 66 lb )

- Lateral clearance of anti-roll bar. under pressure of 500 N i 50kq I( 110 fb i 0.2 to 1 mm

,I, l/X“ rcnr :

- Lateral positioning same thickness of shim on both sides. within 1 mm

- Shimming, if necessary. level with the split collars to within 0.6 mm

Greasing of the suspension piston con-rod ioint :

( Carried out with LHM liquid contained in the dust cover )

- Front suspension cylinder

- Rear suspension cylinder

Upper front wheelarm stops :

WARNING ‘,hc ,,,;,,,i<~, ~,op ,,,I (i, he ii,,, r/ 01 //I< ,,I?<,<‘/ wd. 7cm3

25 cm3

Tightening torques :

- Anti-roll bar link-rod on upper wheelarm. i Bush nut 3 doNm ( 21 11 2 ft.lb )

NYLSTOP nut 4.5 to 5daNd32 1/‘2to 36ft.lb)

- Link-rod on anti-roll bar 4.5 to SdaNm(32 1/2to36ft.lb)

. Screw securing front anti-roll bar bearing 2.7 daNm ( 19 l/2 ft.lb )

^ - Clamps for adjusting pie-load on front anti-roll bar 13 doNm ( 9 l/2 ft.lb)

b2 - 1.5 daNm [ 11 ft.lb i

0 Clomp for height corrector control

rod ( front and rem )

”

6 daNm ( 43 l/ 2 ft.lb ) - . An+iwroff bar 0” rear &&arm ( rear fixing

points ) I /nc<’ nvrl /hrcn,l~r

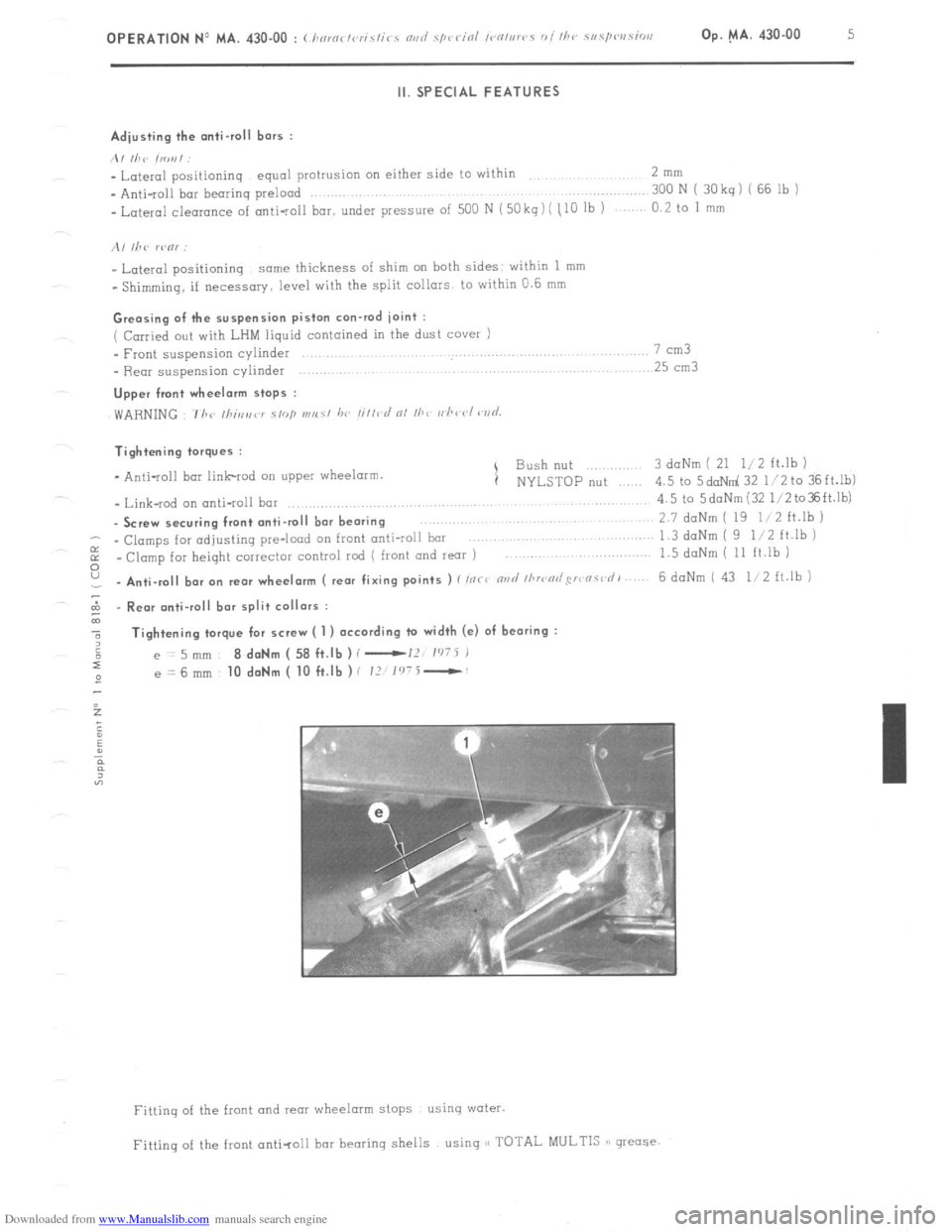

- Rear anti-roll bar split collars :

cc

-5 Tightening torque for screw ( 1 )

according to width (e) of bearing :

:

2

e = 5 mm 8 d.aNm ( 58 ft.lb ) f -I’, I’JiS,

P

e-6mm lOdoNm( lOft.lb)i 121Vi-’

Fitting of the front and rear wheelarm stops using water

Fitting of the front anti-011 bar bearing shells using ,< TOTAL MULTIS I) grease.

Page 273 of 394

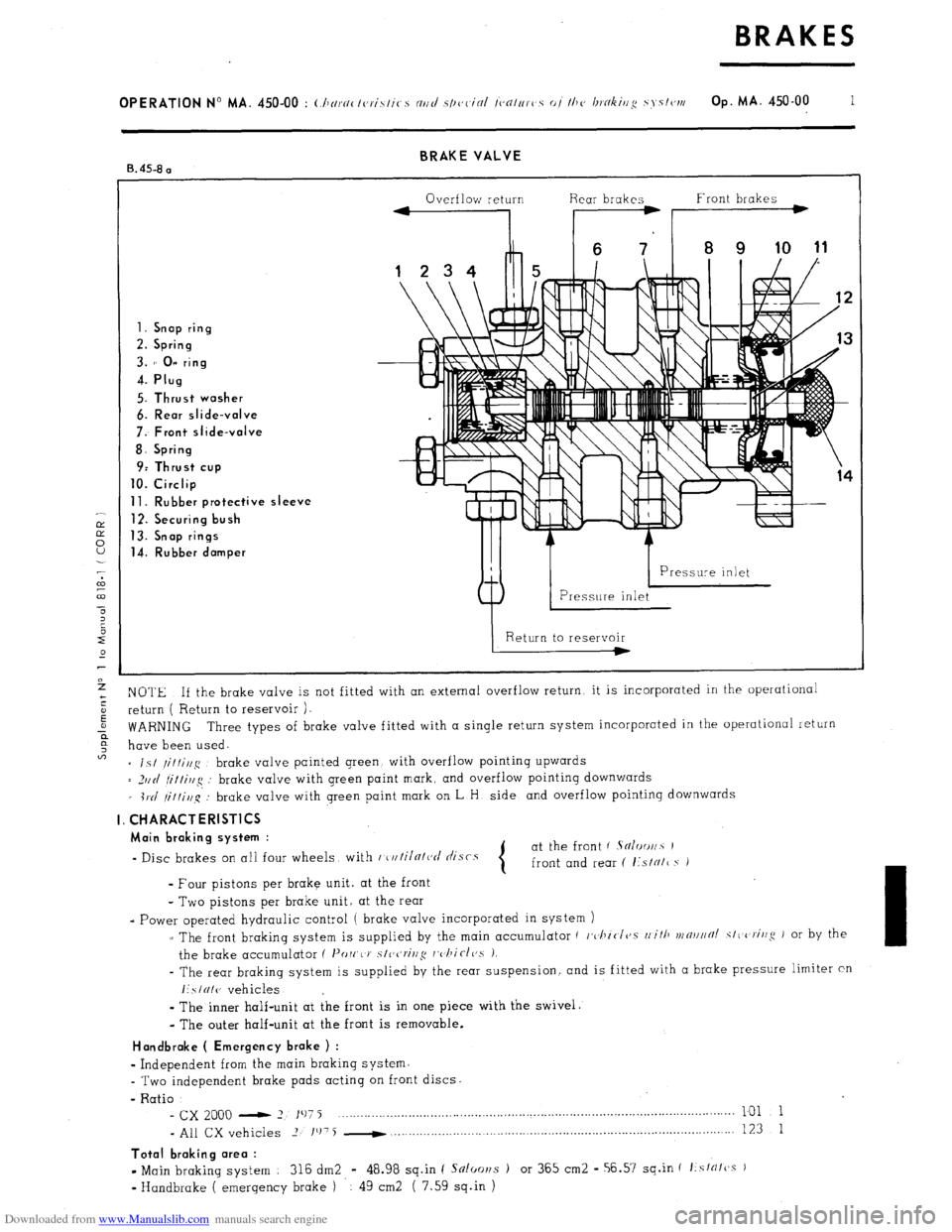

Downloaded from www.Manualslib.com manuals search engine BRAKE VALVE

B. 45-8 a

Overflow return Rear brakes Front brakes

1. Snap ring

2. Spring

3. 1’ 0” ring

4. Plug

5. Thrust washer

6. Rear slide-valve

7: Front slide-valve

8. Spring

9: Thrust cup

10. Circlip

11. Rubber protective sleeve

12. Securing bush

13. Snap rings

14. Rubber damper

NOTE If the brake valve is not fitted with an external overflow return, it is incorporated in the operational

return ( Return to reservoir ).

WARNING Three types of brake valve fitted with a single return system incorporated in the operational return

have been used.

= is/

/it/i//g brake valve painted green with overflow pointing upwards

= _)IIII

fi/tirlg : brake valve with green paint mark, and overflow pointing downwards

_ i1.d

/it/i,l~q’: brake valve with green paint mark on L H side and overflow pointing downwards

I. CHARACTERlSTlCS

Main braking system :

- Disc brakes on all four wheels with r~u/iln/ct/ tlisrs at the front ( Sn/oo//~ I

front and rear ( I:sIN/~ s i

- Four pistons per brake unit. at the front

- Two pistons per brake unit, at the rear

- Power operated hydraulic control ( brake valve incorporated in system )

z The front braking system is supplied by the main accumulator ( c,~l~icI~~.s

rli/ll vrn~l//~/ SIC criug J or by the

the brake accumulator ( I’orr,< J’

s/ccrivg rc,/~iclc,s 1.

- The rear braking system is supplied by the rear suspension. and is fitted with a brake pressure limiter cn

I:SIUI(J vehicles

-

The inner half-unit at the front is in one piece with the swivel.

- The outer half-unit at the front is removable.

Handbroke ( Emergency brake ) :

w

Independent from the main braking system.

- Two independent brake pads acting on front discs.

- Ratio

- cx 2000 - 2 197 j ___._....._..._..._.........,............................................................................... 101 1

- All CX vehicles 2 1’j75 -

. . . . . . 123 1

Total braking area :

- Main braking system : 316 dm2 - 48.98 sq.in ( Snloor~s ) or 365 cm2 - 56.57 sq.in f f:sfrffcss )

v

Handbrake ( emergency brake ) 49 cm2 ( 7.59 sq.in )

Page 277 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 450-00 : Ch nrnclcrislics ortd sp~~c-i~l (c~c~trlrc>s 01 the hokiug S SI~IN Op. MA. 450.00 5

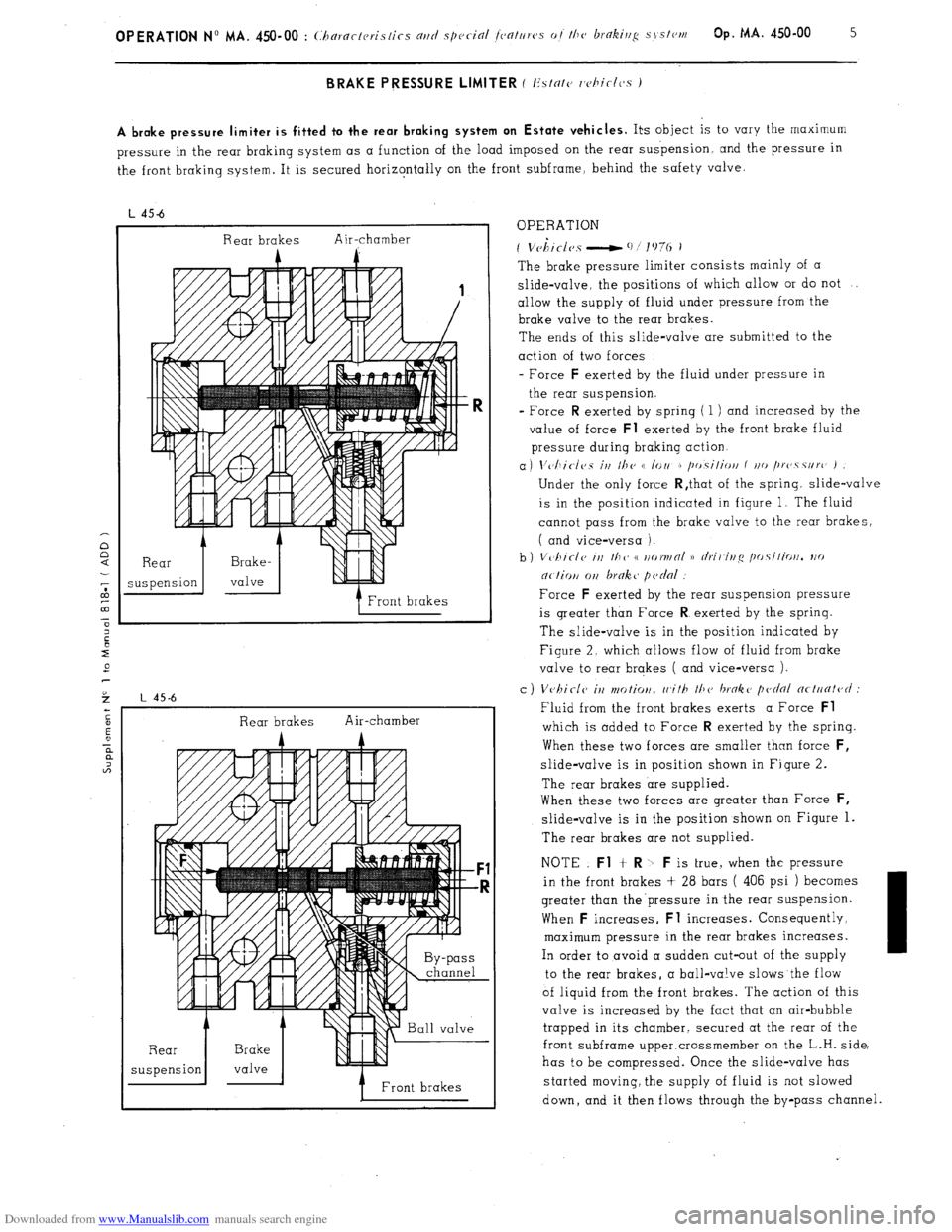

A brake pressure limiter is fitted to the rear braking system on Estate vehicles.

Its object is to vary the maximum

pressure in the rear braking system as a function of the load imposed on the rear suspension and the pressure in

the front braking system. It is secured horizontally on the front subframe, behind the safety valve.

L 45-6

Rear brakes Air-chamber

A

Front brakes

Rear brakes Air-chamber

A A --

7 Front brakes OPERATION

* I

f Vchtclcs - ‘I/]‘,?(, i

The brake pressure limiter consists mainly of a

slide-valve, the positions of which allow or do not

allow the supply of fluid under pressure from the

brake valve to the rear brakes.

The ends of this slide-valve are submitted to the

action of two forces

- Force F

exerted by the fluid under pressure in

the rear suspension.

= Force R

exerted by spring ( 1 ) and increased by the

value of force Fl

exerted by the front brake fluid

pressure during braking action.

a) \‘~~I~i~-/~~s irt Ilte t( lorl r /tr,.silioti f t/o /trc~.s.surc’ )

Under the only force R,that of the spring. slide-valve

is in the position indicated in figure 1. The fluid

cannot pass from the brake valve to the rear brakes,

( and vice-versa ).

Force

F exerted by the rear suspension pressure

is greater than Force R

exerted by the sprinq.

The slide-valve is in the position indicated by

Figure 2. which allows flow of fluid from brake

valve to rear brakes ( and vice-versa ).

c ) Vvhiclc il2 ntotior/. rr,ith 111~’ broke pednl ncl~~fit~~c/ :

Fluid from the front brakes exerts a Force Fl

which is added to Force R exerted by the spring.

When these two forces are smaller than force F,

slide-valve is in position shown in Figure 2.

The rear brakes are supplied.

When these two forces are greater than Force

F,

slide-valve is in the position shown on Figure 1.

The rear brakes are not supplied.

NOTE Fl

+ R -b F is true, when the pressure

in the front brakes + 28 bars ( 406 psi ) becomes

greater than the’pressure in the rear suspension.

When F

increases, Fl increases. Consequently,

maximum pressure in the rear brakes increases.

In order to avoid a sudden cut-out of the supply

to the rear brakes, a ball-valve slows the flow

of liquid from the front brakes. The action of this

valve is increased by the fact that an air-bubble

trapped in its chamber, secured at the rear of the

front subframe upper.crossmember on the L.H. side,

has to be compressed. Once the slide-valve has

started moving, the supply of fluid is not slowed

down, and it then flows through the by-pass channel.

Page 278 of 394

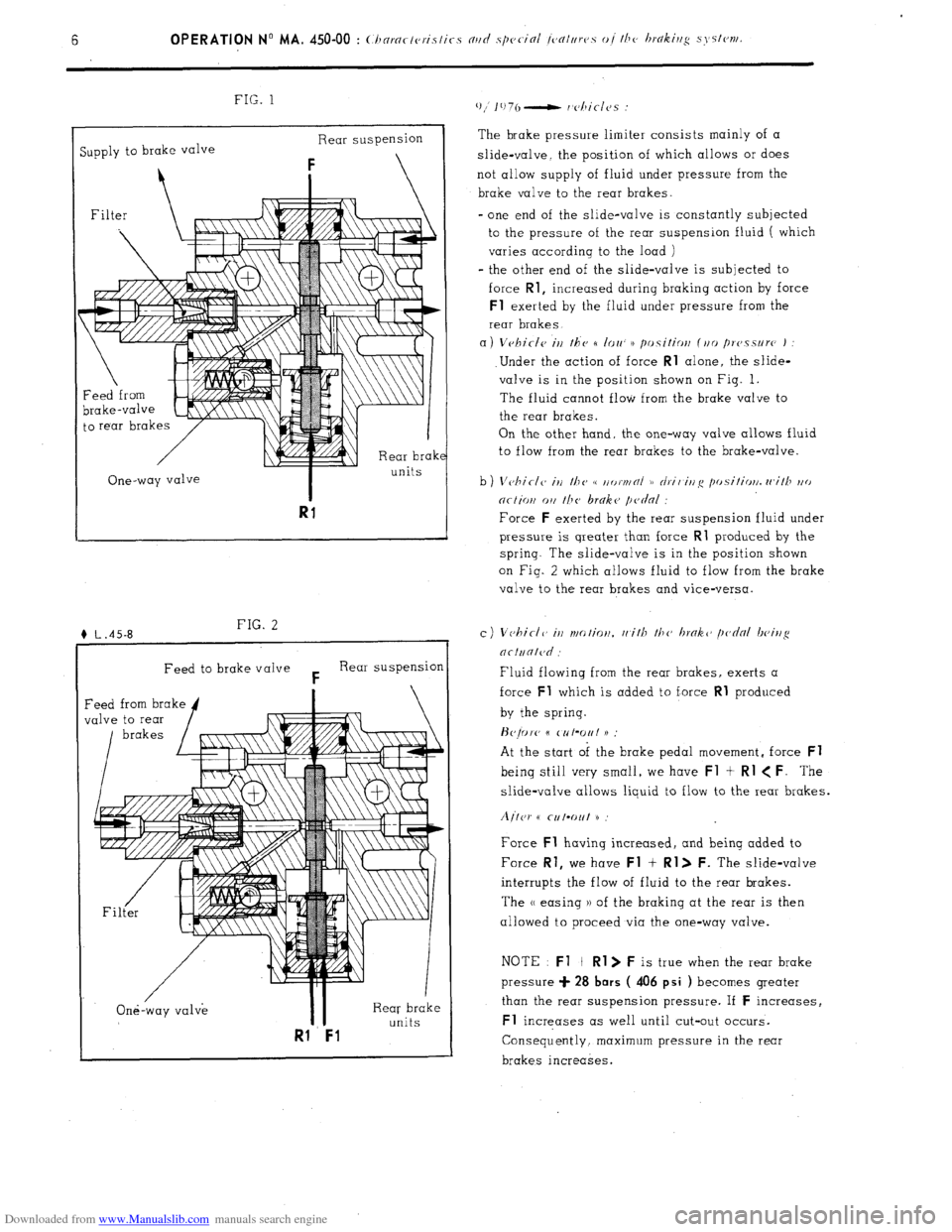

Downloaded from www.Manualslib.com manuals search engine FIG. 1

Supply to brake valve Rear suspension

i

Filter

\--Iii

I

Rear brak

. .

One-way valve

I units

Rl

Feed to brake valve F Rear suspension /

One-way valve II Rear brake

Rl Fl

units The brake pressure limiter consists mainly of a

slide-valve, the position of which allows or does

not allow supply of fluid under pressure from the

brake valve to the rear brakes.

-

one end of the slide-valve is constantly subjected

to the pressure of the rear suspension fluid ( which

varies according to the load )

- the other end of the slide-valve is subjected to

force Rl,

increased during braking action by force Fl

exerted by the fluid under pressure from the

rear brakes

a)

Vvhirlc, irl the n IOU N positiolt (,,o /)rc,.ssurc, )

.Under the action of force Rl alone, the slide-

valve is in the position shown on Fig. 1.

The fluid cannot flow from the brake valve to

the rear brakes.

On the other hand, the one-way valve allows fluid

to flow from the rear brakes to the brake-valve.

Force F

exerted by the rear suspension fluid under

pressure is qreater than force Rl

produced by the

spring. The slide-valve is in the position shown

on Fig. 2 which allows fluid to flow from the brake

valve to the rear brakes and vice-versa.

Fluid flowing from the rear brakes, exerts a

force Fl

which is added to force Rl produced

by the spring.

H~prc 6

CNt’Out 11

At the start of the brake pedal movement, force Fl

being still very small, we have Fl t Rl < F. The

slide-valve allows liquid to flow to the rear brakes.

Aitcr t( CIIIW~~ H

Force Fl

having increased, and being added to

Force Rl,

we have Fl + Rl> F. The slide-valve

interrupts the flow of fluid to the rear brakes.

The (( easing )) of the braking at the rear is then

allowed to proceed via the one-way valve.

NOTE : Fl

+ Rl> F is true when the rear brake

pressure + 28 bars

( 406 psi ) becomes greater

than the rear suspension pressure. If F

increases, Fl

Increases as well until cut-out occurs.

Consequently, maximum pressure in the rear

brakes increases.