boot Citroen CX 1978 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1978, Model line: CX, Model: Citroen CX 1978 1.GPages: 394

Page 338 of 394

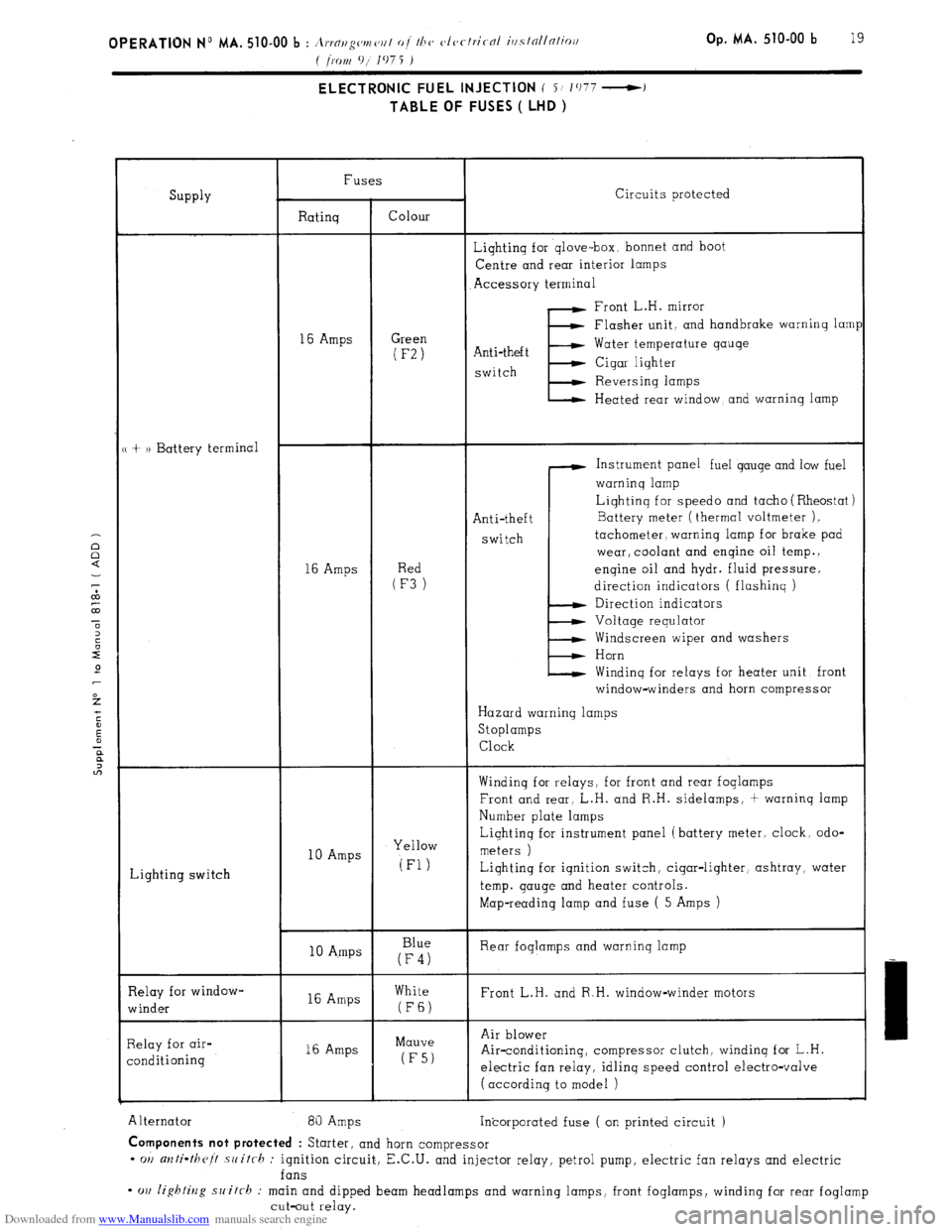

Downloaded from www.Manualslib.com manuals search engine Op. MA. 510-00 b 19 ELECTRONIC FUEL INJECTION ( i/ 1077 -)

TABLE OF FUSES ( LHD )

SUPPlY Fuses

Circuits protected

Ratinq Colour

Lightinq for qlove-box, bonnet and boot

Centre and rear interior lamps

Accessory terminal

Front L.H. mirror

16 Amps Green (F-2)

Flasher unit. and handbrake warninq lam1

Anti-theft

E Water temperature gauge

switch Cigar lighter

Reversinq lamps

Heated rear window, and warning lamp

+ )) Battery terminal

Instrument panel fuel gauge and low fuel

warninq lamp

Anti-theft

switch Liqhtinq for speed0 and tacho ( Rheostat )

16 Amps

(RFe3d)

_ Battery meter (thermal voltmeter ).

tachometer, warning lamp for brake pad

wear, coolant and engine oil temp. 1

enqine oil and hydr. fluid pressure.

direction indicators ( flashing )

Direction indicators

Voltage requlator

Windscreen wiper and washers

Horn

Windinq for relays for heater unit front

window-winders and horn compressor

Hazard warning lamps

Stoplamps

Clock

Winding for r-elays, for front and rear foglamps

Front and rear, L.H. and R.H. sidelamps, + warninq lamp

Number plate lamps

Lighting switch 10 Amps Yellow Liqhtinq for instrument panel (battery meter. clock. odo-

meters )

(Fl) Lighting for iqnition switch, cigar-lighter, ashtray, water

temp. gauge and heater controls.

Map-reading lamp and fuse ( 5 Amps )

10 A.mps Blue

(F4) Rear foglamps and warninq lamp

Relay for window-

winder 16 Amps White

Front L.H. and R.H. window-winder motors (FE)

Relay for air-

conditioning 16 Amps Mauve

(F5) Air blower

Air-conditioning, compressor clutch, windinq for L.H.

electric fan relay, idlinq speed control electro-valve

( according to model )

Alternator 81) Amps

Incorporated fuse ( on printed circuit ) Components not protected

: Starter, and horn compressor

- OII anti-theit .switrh : ignition circuit, E.C.U. and injector relay, petrol pump, electric fan relays and electric

fans

- cm lighting switch : main and dipped beam headlamps and warning lamps, front foglamps, winding for rear foglamp

cut-out relay.

Page 339 of 394

Downloaded from www.Manualslib.com manuals search engine 20 OPERATION No MA. 510-00 b : Ivstallatiov oj the c,lcctriral iv~stallatiov

( [KM 9 / I 07 5 )

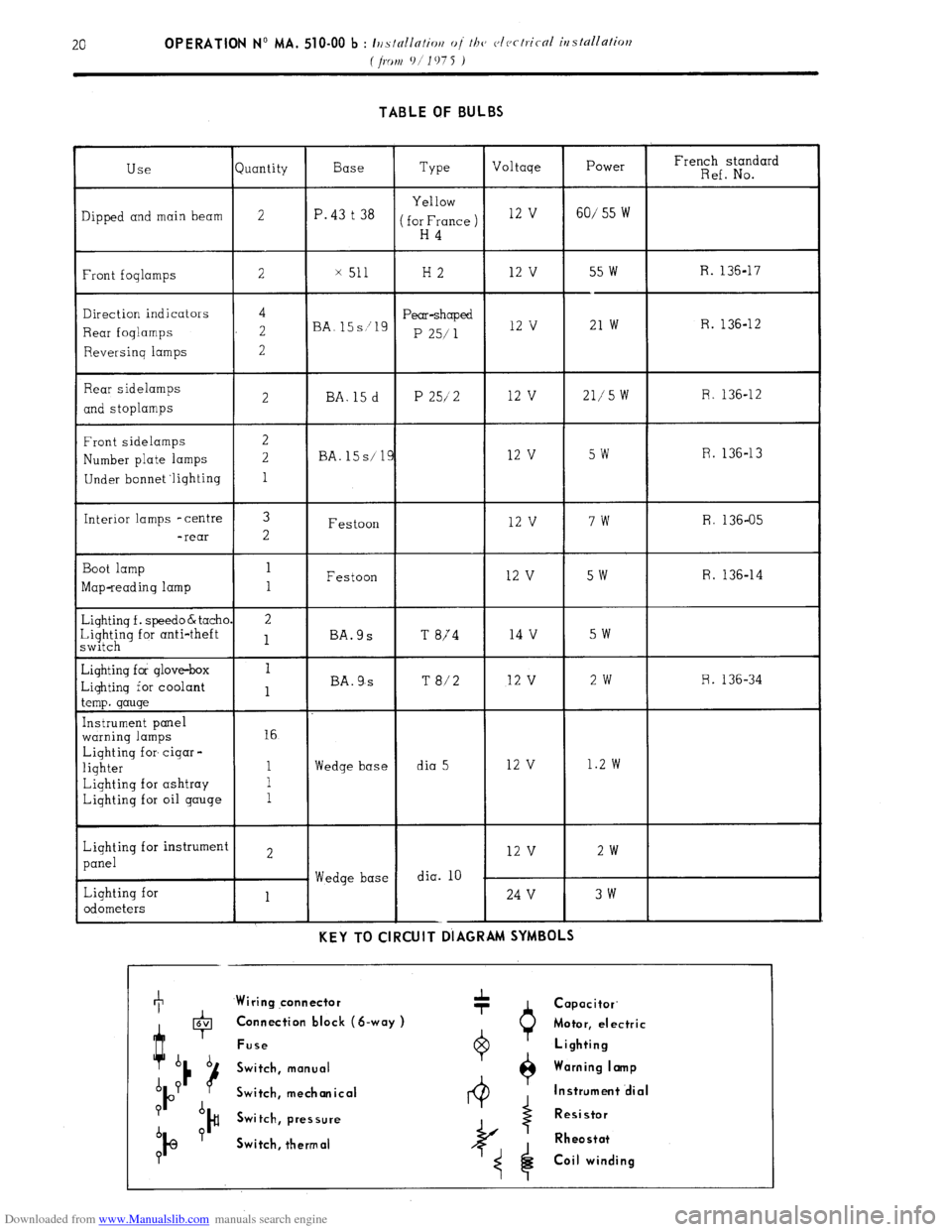

TABLE OF BULBS

juantity Type French standard

Ref. No. Power

60/ 55 W Voltage

12 v Base

P. 43 t 38 Use

lipped and main beam

Front foqlamps

Direction indicators

Rear foqlamps

Reversinq lamps

Rear sidelamps

and stoplamps

Front sidelamps

Number plate lamps

Under bonnet ‘lighting

Interior lamps -centre

-rear

Boot lamp

Map-reading lamp

&iqhtinq f . speed0 & tachl

~~$;~q for anti-theft

diqhtinq for glove-box

-iqhtinq for coolant

.emp. gauge

[nstrument panel

warning lamps

Lighting for cigar -

lighter

Lighting for ashtray

Lighting for oil gauge

Lighting for instrumen

panel

Lighting for

odometers Yellow

for France )

H4 2

x 51 H2 12 V 55 w

--

21 w R. 136-17

4

2

2 Pear-shaped

P 25/ 1 R. 136-12

BA. 12 v

12 v 21,‘5 W R. 136-12

2 BA. 15 d P 25/2

R. 136-13

BA. 15s/ 5w

7w

5w

5w 12 v

12 v

12 v

14 v 3

2 R. 136-05

Festoon

Festoon

BA.9s

T 874 R. 136-14 1

1

2

1

T 8/2 12 v 2w R. 136-34

BA. 9,s

16

Wedge base dia 5 12 v 1.2 w

Wedge base dia. 10 2w 12 v

24 V 3w

1 --

KEY TO CIRCUIT DIAGRAM SYMBOLS +

Wiring qonnector

0 Capacitor.

4 6V Connection block (S-way )

Motor, electric

Fuse Lighting

b b

Switch, manual Warning I amp

A P

P u

Switch, mechanical Instrument .dial

P A

)# Switch, pressure Resistor

b P

IQ Switch, thermal Rheostat

?

Coil winding

Page 341 of 394

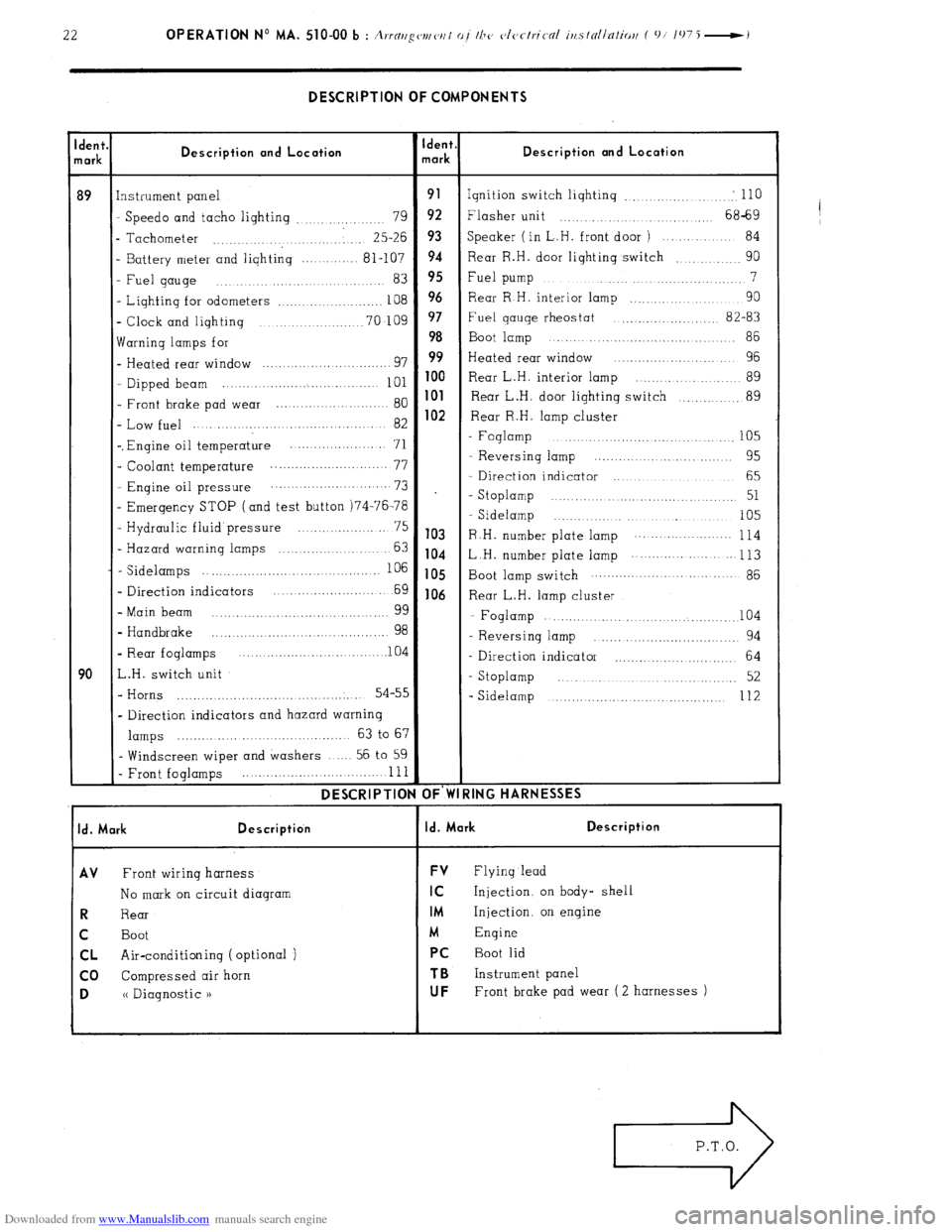

Downloaded from www.Manualslib.com manuals search engine dent,

nark

B9

90

DESCRIPTION OF COMPONENTS

Description and Location

instrument panel

Speed0 and tacho lighting

79 ..............

. Tachometer 25-26

........... ............

I Battery meter and lighting ............ 81-107

Fuel gauge ...................... 83

- Lighting for odometers

...................... 108

- Clock and lighting

.................... 70-109

warning lamps for

- Heated rear window ............................... 97

- Dipped beam ... ..... ............................ 101

- Front brake pad wear ...................... 80

- Low fuel ....

............................ 82

-. Engine oil temperature ..... .................

71

- Coolant temperature ...........................

77

- Engine oil pressure ....... .... ............ ...

73

- Emergency STOP (and test button )74-76-78

- Hydraulic fluid’pressure ................... 75

- Hazard warning lamps ....................... 63

- Sidelamps 106

....................... ..... ..............

- Direction indicators ....... ............... 69

- Main beam

99 .....

.............................. ...

- Handbrake

98 ........ ............ ., .............. ...

- Rear foglamps .......... ................. ..lO 4

L.H. switch unit

- Horns 54-55

..... ....................................

- Direction indicators and hazard warning

lamps ...................................... 63 to 67

- Windscreen wiper and washers ...... 56 to 59

- Front foglamps ........ ....... ................. 111

DESCRIPTIOI dent

nark

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106 Description and Location

Ignition switch lighting .................... : 110

Flasher unit ....................... 68-69

Speaker ( in L..H. front door )

......... 84

Rear R.H. door lighting switch

90 ..........

Fuel pump 7

.............................

Rear R H. interior lamp ....................

90

Fuel qauge rheostat

.................... 82-83

Boot lamp

....................................... 86

Heated rear window

......................... 96

Rear L.H. interior lamp

.................. 89

Rear L.H. door lighting switch

............ 89

Rear R.H. lamp cluster

- Foglamp

..................................... 105

- Reversing lamp .............................

95

- Direction indicator ...................

65

- Stoplamp ........... ......................... 51

- Sidelamp ...........................

105

R .H. number plate lamp .......... ... ........

114

L H. number plate lamp ..... ........... ...

113 Boot lamp switch .................................

86

Rear L.H. lamp cluster

- Foglamp

....................................... 104

- Reversing lamp ................................

94

- Direction indicator ............................. 64

- Stoplamp

........................................ 52

- Sidelamp

... ..... ................................. 112

IING HARNESSES

I Id. Mark Description

I Id. Mark Description

AV

Front wiring harness FV Flying lead

No mark on circuit diaqram

IC Injection. on body- shell

R Rear IM Injection, on engine

C Boot

M Engine

CL Air-conditioning (optional ) PC Boot lid

co Compressed air horn

TB Instrument panel

D (( Diagnostic 1) UF Front brake pad wear ( 2 harnesses )

Page 382 of 394

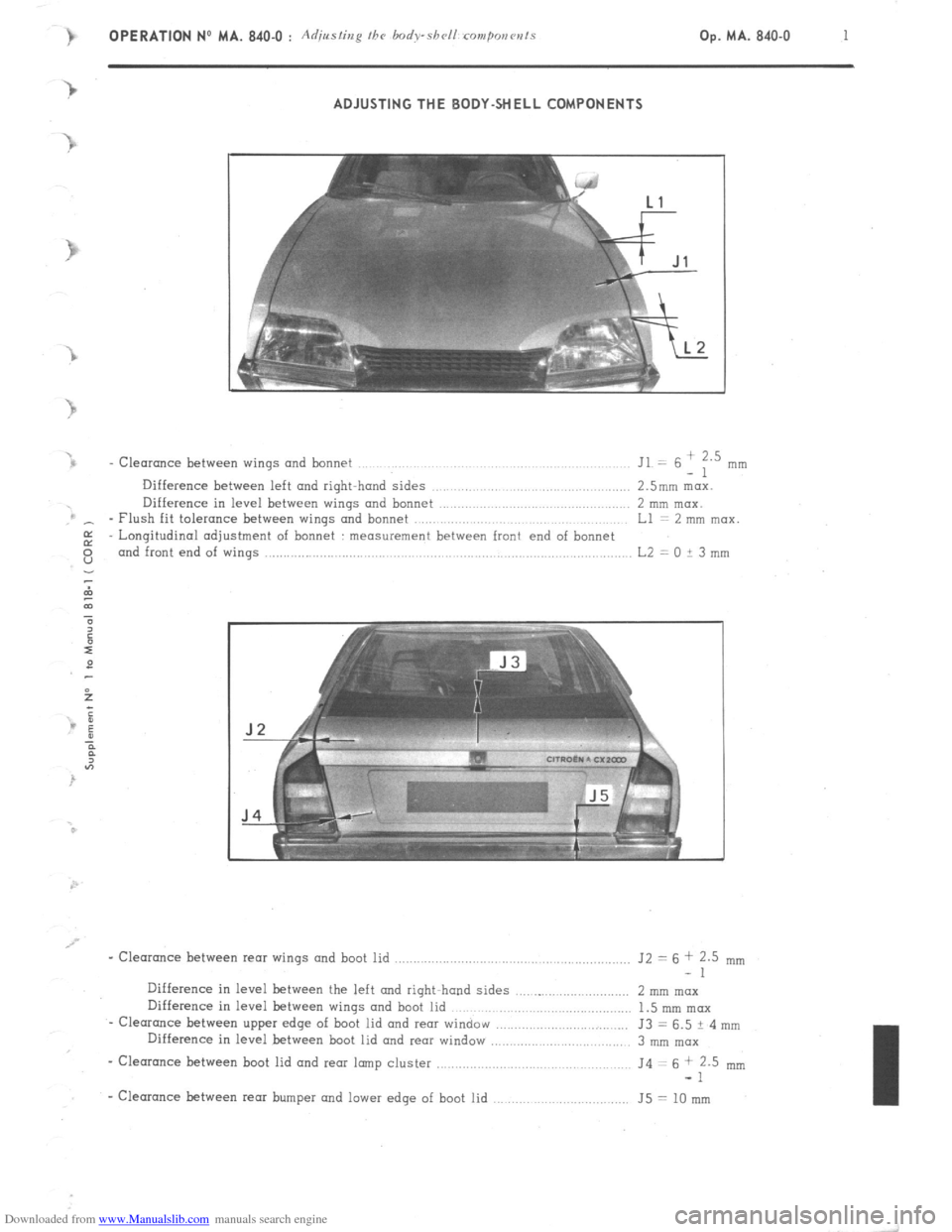

Downloaded from www.Manualslib.com manuals search engine OPERATION NO MA. 840-O : Adjjrrsting the body-shell rompovcnts Op. MA. 840.0 1

ADJUSTING THE BODY-SHELL COMPONENTS

t

Jl

-

- Clearance between wings and bonnet Jl.- 6; F.5 rnrn

Difference between left and right-hand sides 2.smm “lox.

Difference in level between wings and bonnet 2 mm max.

- - Flush fit tolerance between wings and bonnet ., Ll = 2 mm mox

E - Longitudinal adjustment of bonnet : measurement between front end of bonnet

E and front end of wings .,,,,,, ,., L2 = 0 t 3 mm

- Clearance between rear wings and boot lid ...................................... ....................

J2 = 6 + 2.5 mm

-1

Difference in level between the left and right-hand sides ............................... 2 mm max

Difference in level between wings and boot

lid ............................................. 1.5 mm max

- Clearance between upper edge of boot lid and rear window .............................. J3 = 6.5 ? 4 mm

Difference in level between boot lid and rear window ....................... ......... 3 mm max

- Clearance between boot lid rind rem irXI,p cluster ...................... ,, ., ............ J4 = 6 + 2.5 mm

-1

- Clearance between rem bumper and lower edge of boot lid ....................... ............ 55 = 10 mm

Page 386 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 844-O : Ad;,/<~lics /be hoot /ic/ Op. MA. 844-O 1

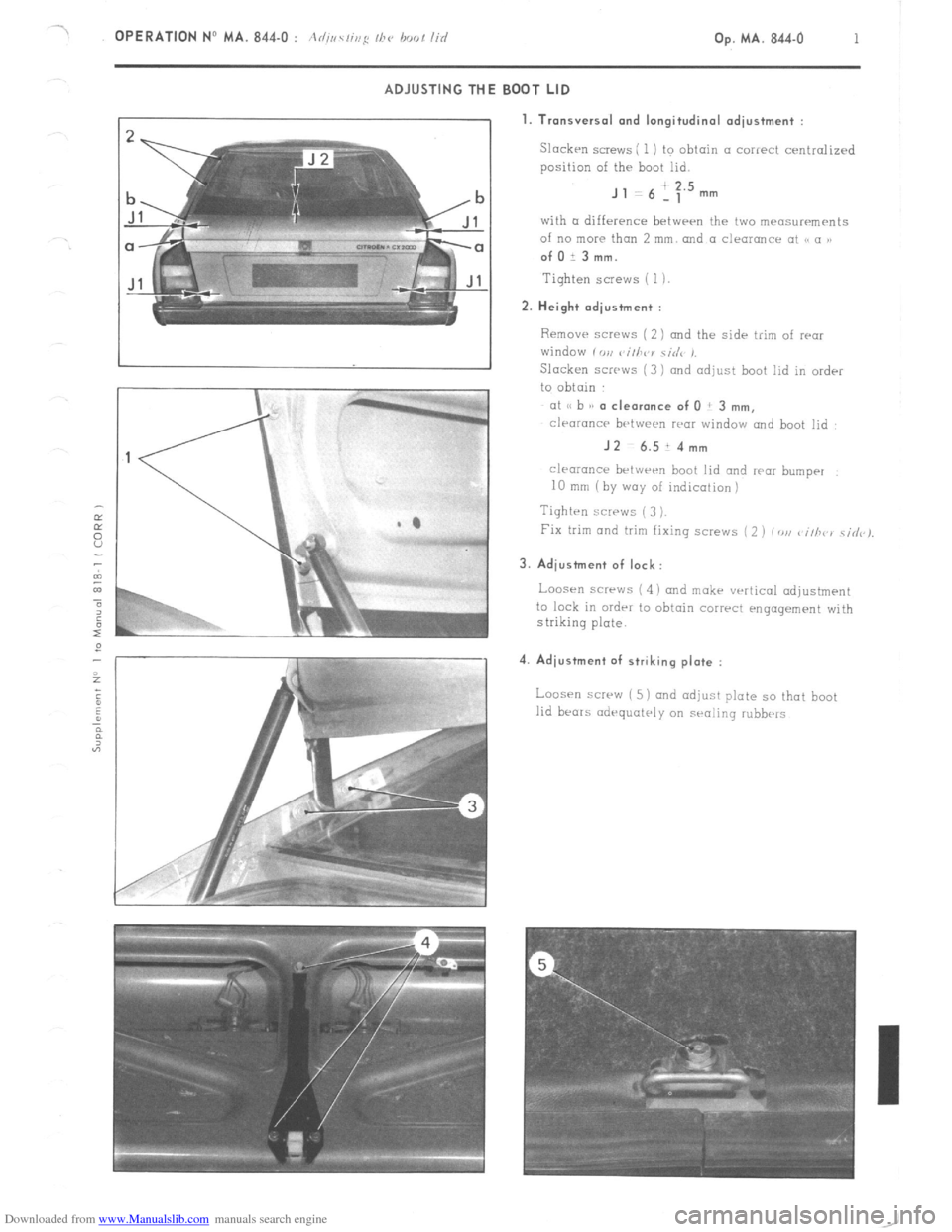

ADJUSTING THE BOOT LID

1. Tronsversol and longitudinal odiustment :

Slacken SCEWS ; 1 ) to obtain (I correct cenirolized

position of the boot lid.

J , 6 ! :‘” mm

with CL difference betwrrn the two meosurrments

of no more than 2 mm. and a clearance ot 18 a 1, ofOi3mm.

Tighten SCIWS ( 1). 2. Height odiustment :

Remove screws ( 2 ) and the sidr trim of rwr

window i vu vi/h~‘r ciriv ,.

Slacken screws ( 3 1 and adjust boot lid in order

to obtain

at I, b a/ a cle.r.nce of 0 ! 3 mm,

clraranc~ brtween war

window rmd boot lid : JZ-6.514mm

clearancr brtwrrn boot lid and rwr bumper

10 rmn (by way of indication)

Tighten screws ( 3 ).

Fix trim and trim fixing screws ( 2 ) /DU c iih~ ) \i&).

3. Adjustment of lock:

Loosen screws ( 4 i and mokr vertical odjustmrnt

to lock in ordrr to obtain correct engagement with

striking plate. 4. Adiustment of striking plate :

Loos-n screw ( 5) and adjust plate so that boot

lid bears odrquatrly on sealing rubbe‘s