engine Citroen CX 1978 1.G Repair Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1978, Model line: CX, Model: Citroen CX 1978 1.GPages: 394

Page 61 of 394

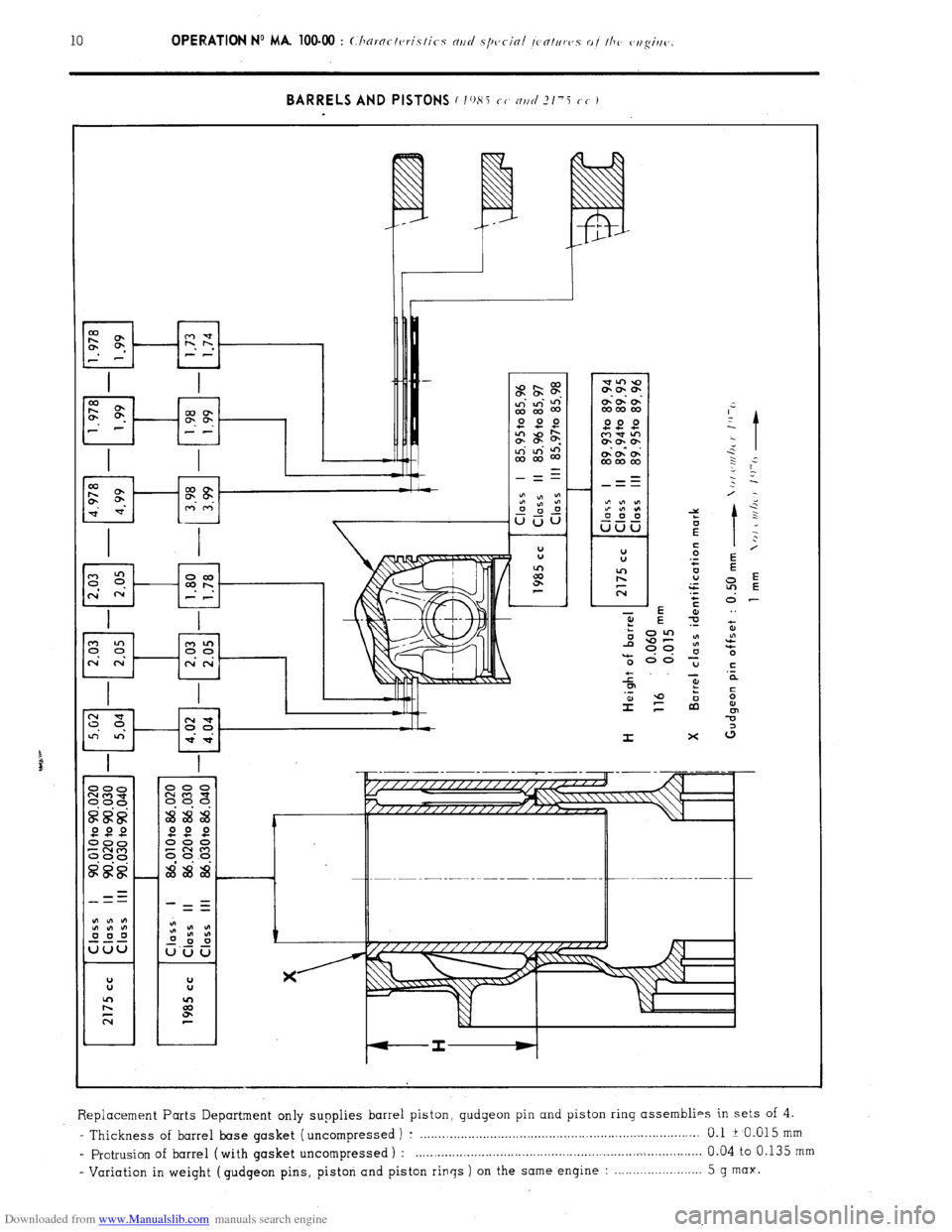

Downloaded from www.Manualslib.com manuals search engine BARRELS AND PISTONS c 1()8j cc nr/cl ?/‘i cc I

t

:

0

ln

d

. .

E

-0”

(3

I x

Replacement Parts Department only supplies barrel piston, gudgeon pin and piston ring assemblies in sets of 4.

- Thickness of barrel base gasket ( uncompressed ) : ............................................................................ 0.1 i 0.015 mm - profusion of barrel (with gasket uncompressed ) : .............................................................................. 0.04 to 0.135

mm

- Variation in weight ( gudgeon pins, piston and piston rings ) on the same engine : ........................

5 g max.

Page 62 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 100-00

BARRELS AND PISTONS (2350 cc 1

-I

-I

The. Replacement Parts Department only supplies barrel, piston, gudgeon pin and piston ring assemblies in

sets of 4.

. Thickness of barrel base gasket ( uncompressed ) : . . . . . . . . . . . . . .._.._....................................................... 0.1 2 JO.O1O mm

protrusion of barrel ( with gasket uncompressed ) : _..._,_,...,._,............................................................ 0.045 to 0.115 mm

- Variation in weight (pistons, gudgeon pins, and gudgeon pin circlips ) on the same engine : . . . 5 g max.

Page 63 of 394

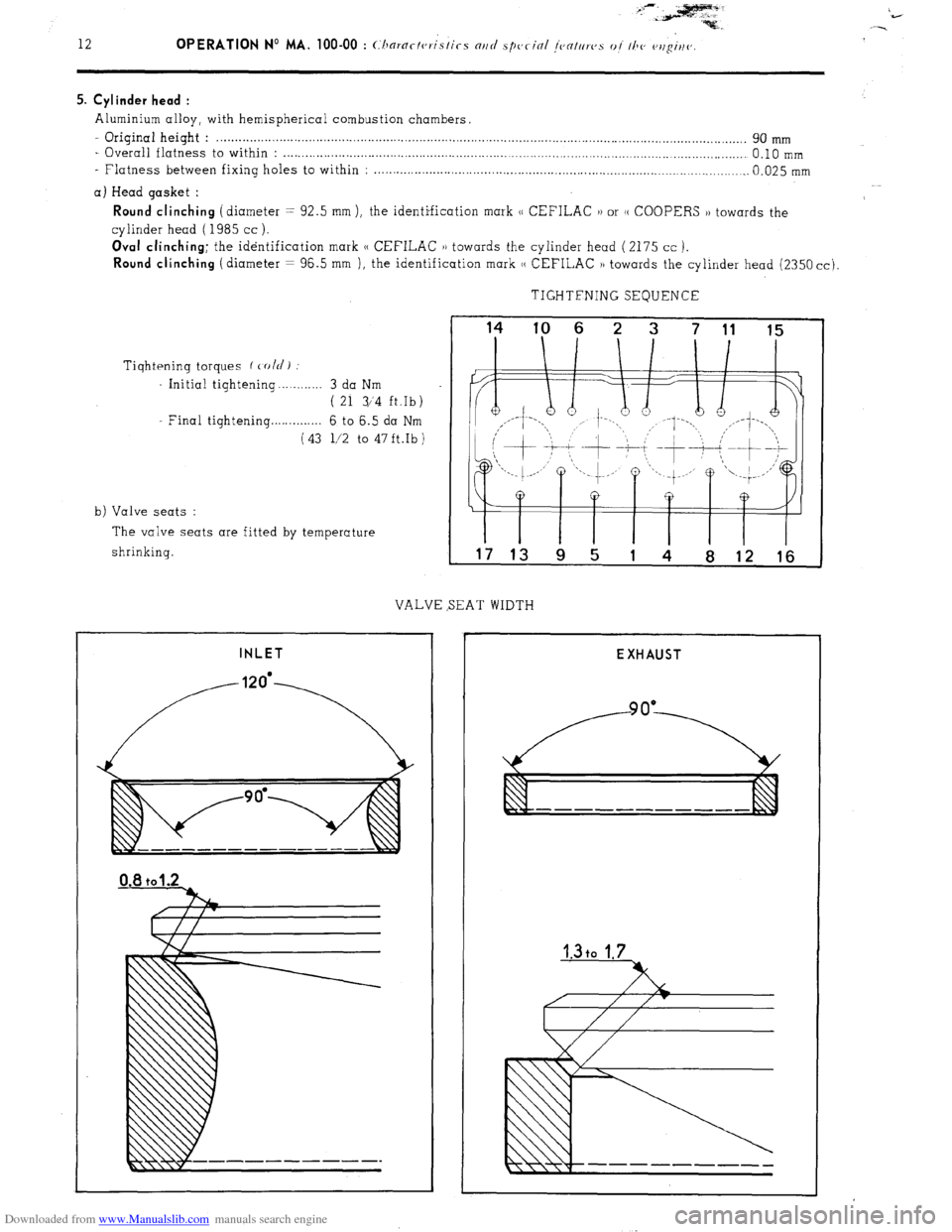

Downloaded from www.Manualslib.com manuals search engine 5. Cylinder head :

Aluminium alloy, with hemispherical combustion chambers.

- Original height : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........................ 90 mm

- Overall flatness to within : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...... 0.10 mm

- Flatness between fixing holes to within : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 mm

a) Head gasket :

Round clinching (diameter = 92.5 mm ), the identification mark (( CEFILAC 1) or (( COOPERS )) towards the

cylinder head ( 1985 cc ).

Oval clinching; the identification mark (( CEFILAC 1) towards the cylinder head (2175 cc ).

Round clinching (diameter = 96.5 mm ), the identification mark (( CEFILAC )) towards the cylinder head (2350 cc).

TIGHTFNING SEQUENCE

Tiqhtening torques f cold)

Initial tightening . . . . . . . . . . 3 da Nm

( 21 3/‘4 ft.Ib)

Final tightening . . . . . . . . . . . . . 6 to 6.5 da Nm

(43 l/2 to 47ft.Ib)

b) Valve seats :

The valve seats are fitted by temperature

shrinking.

VALVE SEAT WIDTH

INLET

I I I I I I T

17 13 9 5 1 4 8 12 16

EXHAUST

Page 64 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 100-00 13

c) Valve guides and valves :

5

7 q+- j

-- - -

Y

NOTE : Inlet. and exhaust valves are fitted with oil-seals.

Page 65 of 394

Downloaded from www.Manualslib.com manuals search engine d) Valve springs :

The inlet and exhaust valve springs are identical.

Characteristics :

- Diameter of wire : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6 + 0.02 mm

Interior diameter : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 2 0.2 mm

- Length of spring under load : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 39mm(load=m40t2,8kg)

30.6 mm ( load = 84 ~‘1.8 kg )

Coating : ._._................................................................................................ Red or blue varnish

e) Upper spring cups : Identical inlet and exhaust.

f ) Retaining clips : Identical inlet and exhaust

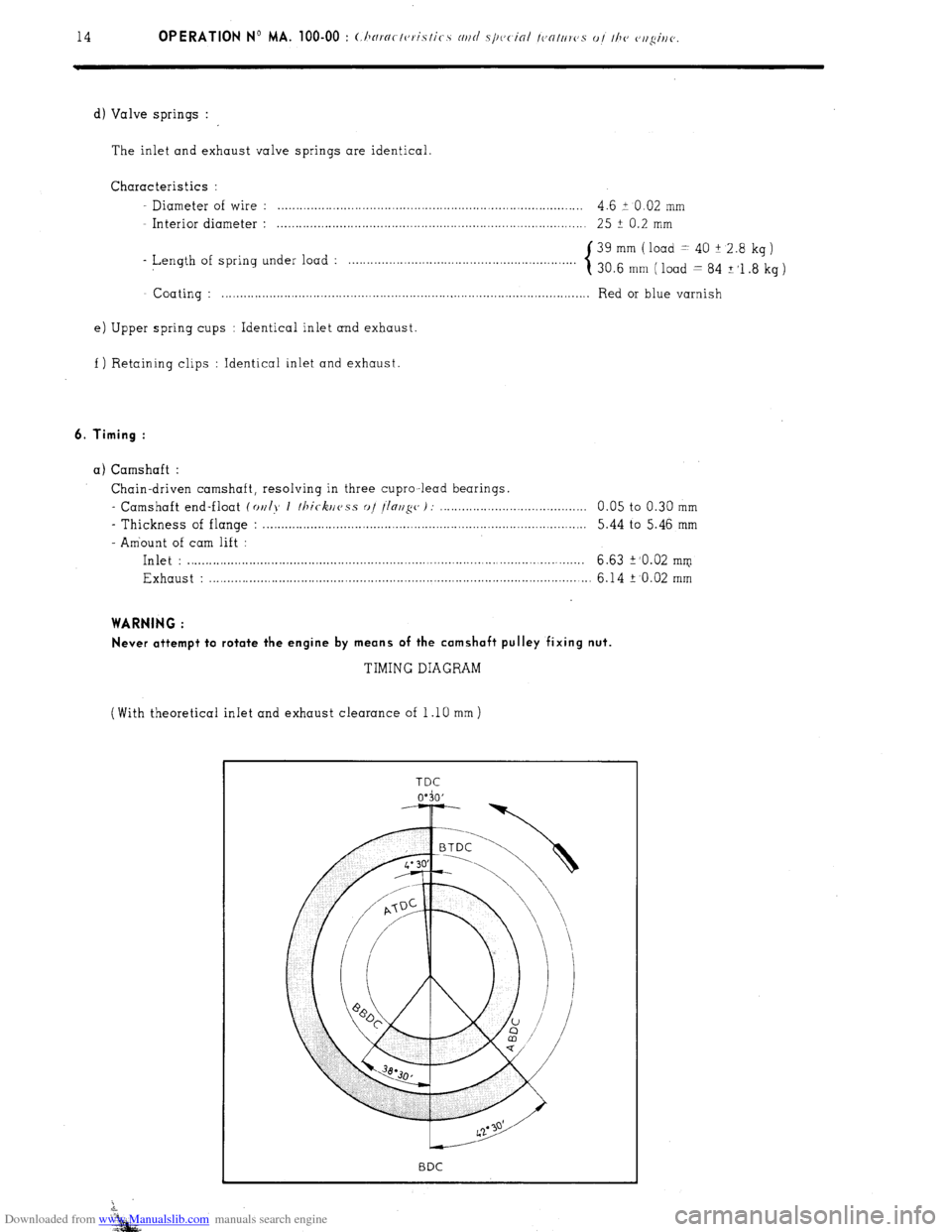

6. Timing :

a) Camshaft :

Chain-driven camshaft, resolving in three cupro -lead bearings.

- Camshaft end-float (a,//>~ I /hi<-krlc~ss a,/ !/o,/s(, I: 0.05 to 0.30 mm

- Thickness of flange : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.44 to 5.46 mm

- Amount of cam lift :

Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..__.._..._ _.;._.; .._...._ ..__.___.., 6.63

2’0.02 mm

Exhaust : ___._._..._.........................................................................................,... 6.14 + ‘0.02 mm

WARNING :

Never attempt to rotate the engine by means of the camshaft pulley fixing nut.

TIMING DIAGRAM

(With theoretical inlet and exhaust clearance of 1 .lO mm )

Page 66 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 100-00 : Characteristics and special features of the engine. Op. MA. 100.00 15

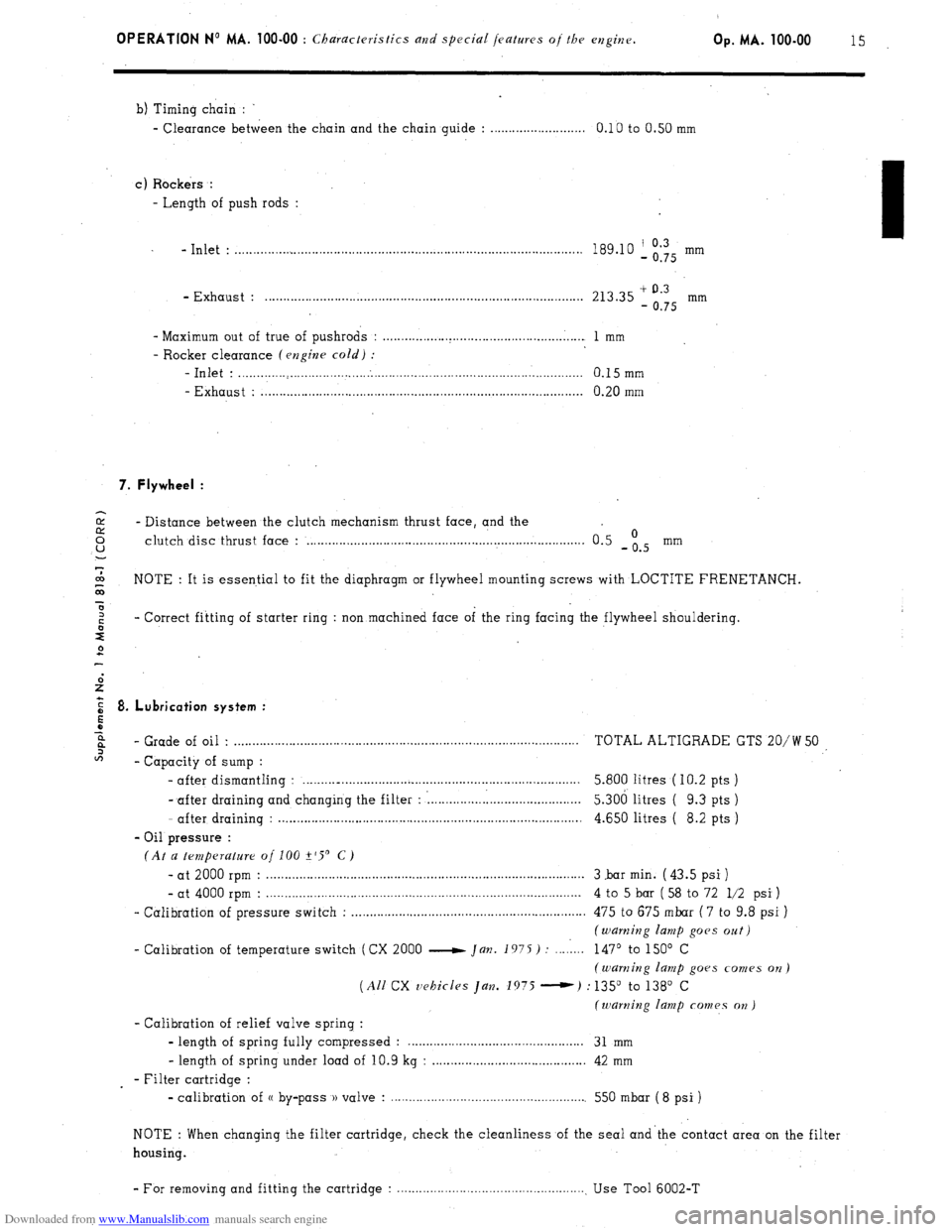

b) Timing chain :

- Clearance between the chain and the chain guide : . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10 to 0.50 mm

c) Rockers :

- Length of push rods :

- Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189.10 ‘, Og’Q5 mm

- Exhaust : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213.35 + 0.3

- 0.75 mm

- Maximum out of true of pushrods : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 mm

- Rocker clearance (engine cold) :

-Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.15mm

- Exhaust : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

7. Flywheel :

2 - Distance between the clutch mechanism thrust face, and the 0 u clutch disc thrust face : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 -is mm

7

co

G NOTE : It is essential to fit the diaphragm or flywheel mounting screws with LOCTITE FRENETANCH.

x

z - Correct fitting of starter ring : non machined face of the ring facing the flywheel shouldering.

s

2

E 8. Lubrication system :

5

z

6%

- Grade of oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TOTAL ALTIGRADE GTS 20/W 50

2

- Capacity of sump :

- after dismantling : . . . . . . . .._................................................................. 5.800 litres ( IO.2 pts )

- after draining and changing the filter : : . . . . . . . . . . . . . . . l......................... 5.306 litres ( 9.3 pts )

- after draining : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.650 litres ( 8.2 pts )

- Oil pressure :

(At a temperature of 100 +‘S’ C)

- at 2000 rpm : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 .bar min. ( 43.5 psi )

- at 4000 rpm : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 to 5 bar ( 58 to 72 l/2 psi )

- Calibration of pressure switch : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475 to 675 mbar ( 7 to 9.8 psi )

(warning lamp goes oat)

- Calibration of temperature switch (CX 2000 e Jan. 1975) : . . . . 1... 147’ to 150’ C

(warning lamp goes comes on)

(All CX vehicles Jan. 1975 -) : 135” to 138’ C

(warning lamp comes on )

- Calibration of relief valve spring :

- length of spring fully compressed : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 mm

- length of spring under load of 10.9 kg : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 mm

- Filter cartridge :

- calibration of (( by-pass )) valve : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550 mbar ( 8 psi )

NOTE : When changing the filter cartridge, check the cleanliness of the seal and’the contact area on the filter

housing.

- For removing and fitting the cartridge : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Use Tool 6002-T

Page 67 of 394

Downloaded from www.Manualslib.com manuals search engine 16 OPERATION No MA. 100-00 : Ch aractcristics and special features of the engine.. LUBRICATION SYSTEM

Page 68 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 100-00 : Characteristics and special jeafruvs oj the cvlghv.

Op. MA. 100-00 17

9..Tightening torque :

a) Engine suspension :

4-.spc~~d manrlal gearbox :

7 Torque bar (( Nylstop )) fixing nuts : .............................................................. 8.2 da Nm ( 59 ft.Ib )

- Securing screws for the flexible bearer on the subframe ; ........................ 3 da Nm ( 22 ft.lb)

- Flexible bearer assembly screws :

..................................................... .

........ 10 da Nm (72 ft.lb)

S-sp~~tl n1m11ra1 gca~box. and forq~~c cour,c~rtrr gc~arkos

- Torque bar (( Nylstop )) fixing nuts : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 da Nm (72 ft.lb)

- R:H. flexible mountinq assembly screws : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 da Nm ( 72 ‘ft.lb )

- L.H. flexible bearer assembly screws : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 to 17 da Nm ( 116 to 123 ft.lb )

b) Crankcase :

Screws and nuts securing the timing cover : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 to 1.9 da Nm (10 to 14 ft.lb)

c) Timing :

- Screw on the camshaft thrust bearing : . . . . . . . . . . . .._............................................ 1 .4 to 1 .9 da Nm ( 10 to 14 ft.lb )

- Timing chain guide securing screw : . . . . . . . . . . . ..__................................ . . . . . . . . . . . . . . .

1.4 to 1.9 da Nm ( 10 to 14 ft.lb)

- Timing chain tensioner securing screw : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9 to 1 .I da Nm (6.5 to 8 ft.lb )

d) Lubrication system :

- Oil filter mounting ( LOCTITE FRENETANCH ) : ......................................

1 to 1 .5 da Nm ( 7 to 11 ft.lb )

- Oil temperature switch : .................................................................................. 3 to 3.5 da Nm ( 22 to 25 ft.lb )

- Union screw for cylinder head lubrication passage : ..................................

1 to 1 .2 da Nm ( 7 to 9 ft.lb )

- Oil filter cartridge ( SPV

wnrt/r]nctc/rer‘s rmte ) : ............................................ 1 .l to 1 .5 da Nm ( 8 to 11 ft.lb )

- Engine oil drain plug ( lo~!,c,r s/t~/p

co/‘cr) : .................................................. 3.5 to 4.5 da Nm (25 to 32.5 ft.lb)

Page 69 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 112-O : ChcJcking and adjusting the valrv mechanism. Op. MA. 112-O

1

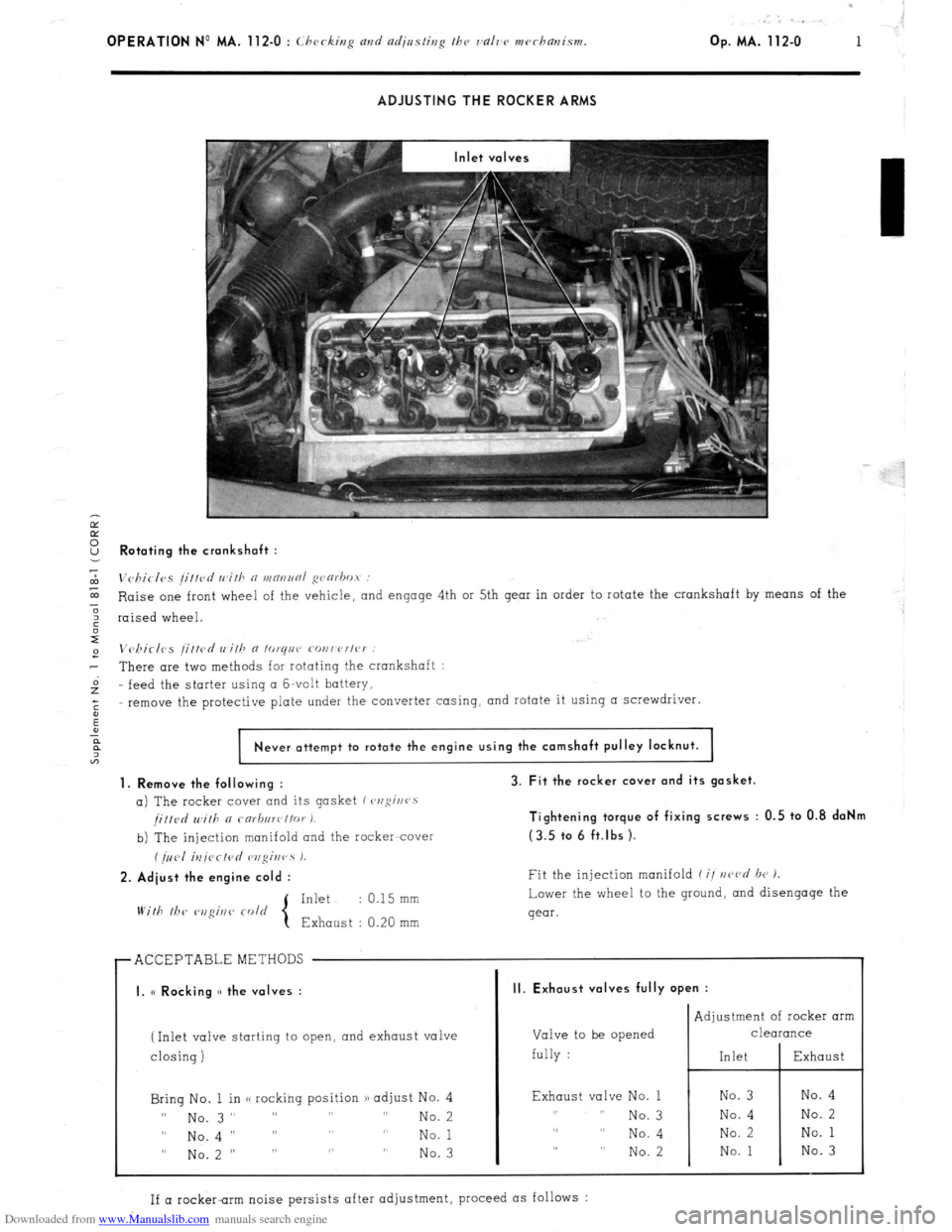

ADJUSTING THE ROCKER ARMS

Ir

E

2 Rotating the crankshaft :

7

m

Vc,birlvs /i//cd wifh n WRIINRI ~varbot :

E Raise one front wheel of the vehicle,

and engage 4th or 5th gear in order to rotate the crankshaft by means of the

3

6 raised wheel.

I

e Vchirlcs /ittcd wilh a lo~qnr covwrlc~ :

- There are two methods for rotating the crankshaft :

Gz feed the

starter using CI G-volt battery,

;

remove the protective plate under the converter casing, and rotate it using a screwdriver.

:

Never attempt to rotate the engine using the camshaft pulley locknut.

1. Remove the following :

a) The rocker cover and its gasket (~,ofii~rr~s

/i//d Will, a rarb,,wt/or I.

b) The injection manifold and the racker-cover

(/,,<,I iU/<~CfPd r,zgir,rs 1.

2. Adiust the engine cold :

Inkt : 0.15 mm

With lb<‘

3. Fit the rocker cover and its gasket.

Tightening torque of fixing screws : 0.5 to 0.8 daNm

(3.5 tc. 6 ft.lbs ).

Fit the injection manifold f i/ nczvd br 1.

Lower the wheel to the ground,

and disengage the

gear.

r ACCEPTABLEMETHODS

I I

I. (< Rocking )> the valves :

(Inlet valve starting to open, and exhaust valve

I

closing) closing)

Bring No. 1 in <, rocking position /) adjust No. 4 Bring No. 1 in <, rocking position /) adjust No. 4

II II

No. 3” ” ” ” No. 3” ” ” ” No. 2 No. 2

0 0

No.4 I’ ” ” ” No.4 I’ ” ” ” No. 1 No. 1

” No.2 ” ” ” ” ” No.2 ” ” ” ” No. 3 No. 3

II. Exhaust valves fully open :

Valve to be opened

fully : Adjustment of rocker arm

CleUKUlCe

Exhaust valve No. 1

,, I, No. 3

,, ,, No. 4

,, ,, No. 2

If a rocker-rim noise persists after adjustment, proceed as follows :

Page 70 of 394

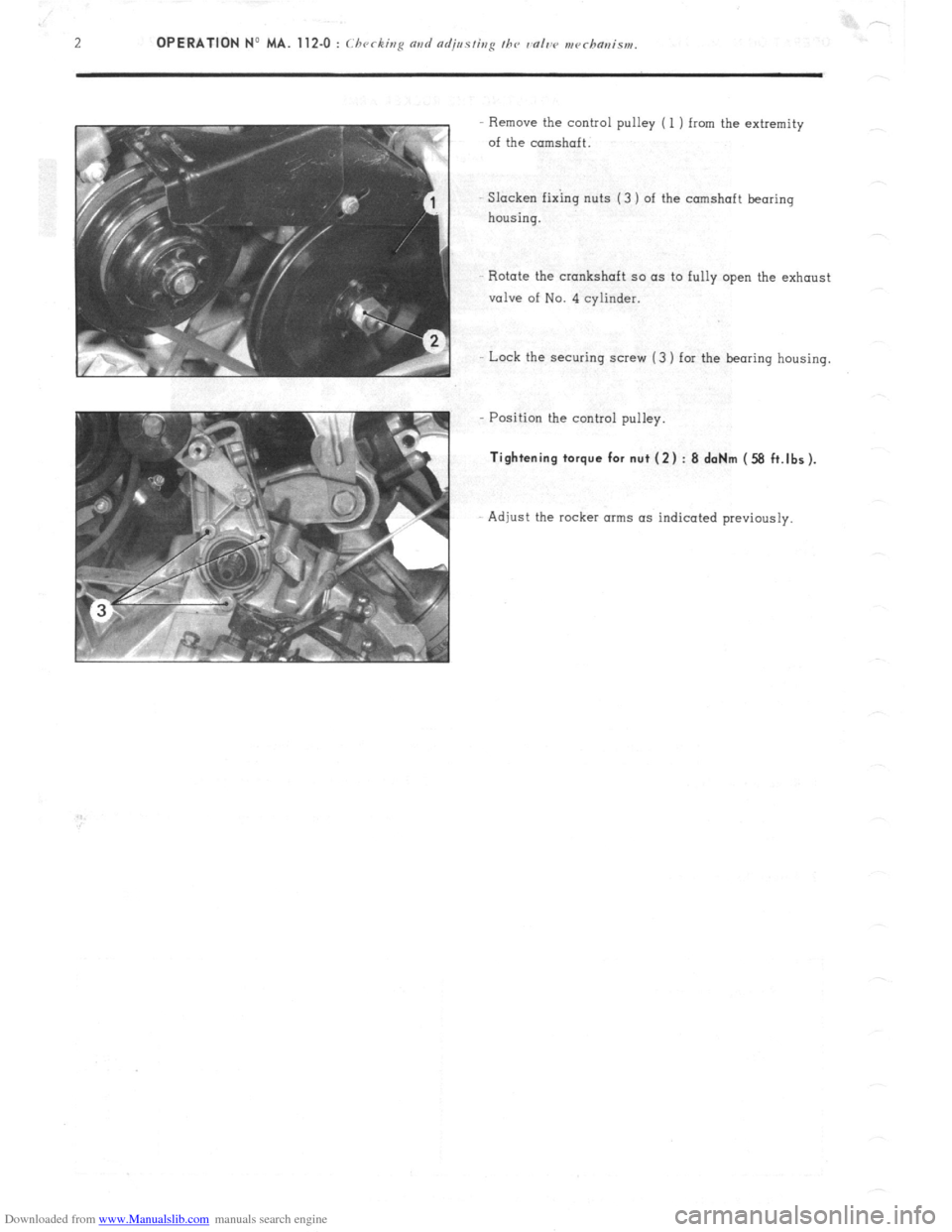

Downloaded from www.Manualslib.com manuals search engine Remove the control pulley ( 1 ) from the extremity

of the camshaft.

SIacken fixing nuts (3 ) of the camshaft bearing

housing.

Rotate the crankshaft so as to fully open the exhaust

valve of No. 4 cylinder.

Lock the securing screw (3 ) for the bearing housing.

Position the control pulley.

Tightening torque for nut (2) : 8 daNm (58 ft.lbs).

Adjust the rocker arms as indicated previously.