Indicator Citroen CX 1979 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1979, Model line: CX, Model: Citroen CX 1979 1.GPages: 394

Page 341 of 394

Downloaded from www.Manualslib.com manuals search engine dent,

nark

B9

90

DESCRIPTION OF COMPONENTS

Description and Location

instrument panel

Speed0 and tacho lighting

79 ..............

. Tachometer 25-26

........... ............

I Battery meter and lighting ............ 81-107

Fuel gauge ...................... 83

- Lighting for odometers

...................... 108

- Clock and lighting

.................... 70-109

warning lamps for

- Heated rear window ............................... 97

- Dipped beam ... ..... ............................ 101

- Front brake pad wear ...................... 80

- Low fuel ....

............................ 82

-. Engine oil temperature ..... .................

71

- Coolant temperature ...........................

77

- Engine oil pressure ....... .... ............ ...

73

- Emergency STOP (and test button )74-76-78

- Hydraulic fluid’pressure ................... 75

- Hazard warning lamps ....................... 63

- Sidelamps 106

....................... ..... ..............

- Direction indicators ....... ............... 69

- Main beam

99 .....

.............................. ...

- Handbrake

98 ........ ............ ., .............. ...

- Rear foglamps .......... ................. ..lO 4

L.H. switch unit

- Horns 54-55

..... ....................................

- Direction indicators and hazard warning

lamps ...................................... 63 to 67

- Windscreen wiper and washers ...... 56 to 59

- Front foglamps ........ ....... ................. 111

DESCRIPTIOI dent

nark

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106 Description and Location

Ignition switch lighting .................... : 110

Flasher unit ....................... 68-69

Speaker ( in L..H. front door )

......... 84

Rear R.H. door lighting switch

90 ..........

Fuel pump 7

.............................

Rear R H. interior lamp ....................

90

Fuel qauge rheostat

.................... 82-83

Boot lamp

....................................... 86

Heated rear window

......................... 96

Rear L.H. interior lamp

.................. 89

Rear L.H. door lighting switch

............ 89

Rear R.H. lamp cluster

- Foglamp

..................................... 105

- Reversing lamp .............................

95

- Direction indicator ...................

65

- Stoplamp ........... ......................... 51

- Sidelamp ...........................

105

R .H. number plate lamp .......... ... ........

114

L H. number plate lamp ..... ........... ...

113 Boot lamp switch .................................

86

Rear L.H. lamp cluster

- Foglamp

....................................... 104

- Reversing lamp ................................

94

- Direction indicator ............................. 64

- Stoplamp

........................................ 52

- Sidelamp

... ..... ................................. 112

IING HARNESSES

I Id. Mark Description

I Id. Mark Description

AV

Front wiring harness FV Flying lead

No mark on circuit diaqram

IC Injection. on body- shell

R Rear IM Injection, on engine

C Boot

M Engine

CL Air-conditioning (optional ) PC Boot lid

co Compressed air horn

TB Instrument panel

D (( Diagnostic 1) UF Front brake pad wear ( 2 harnesses )

Page 362 of 394

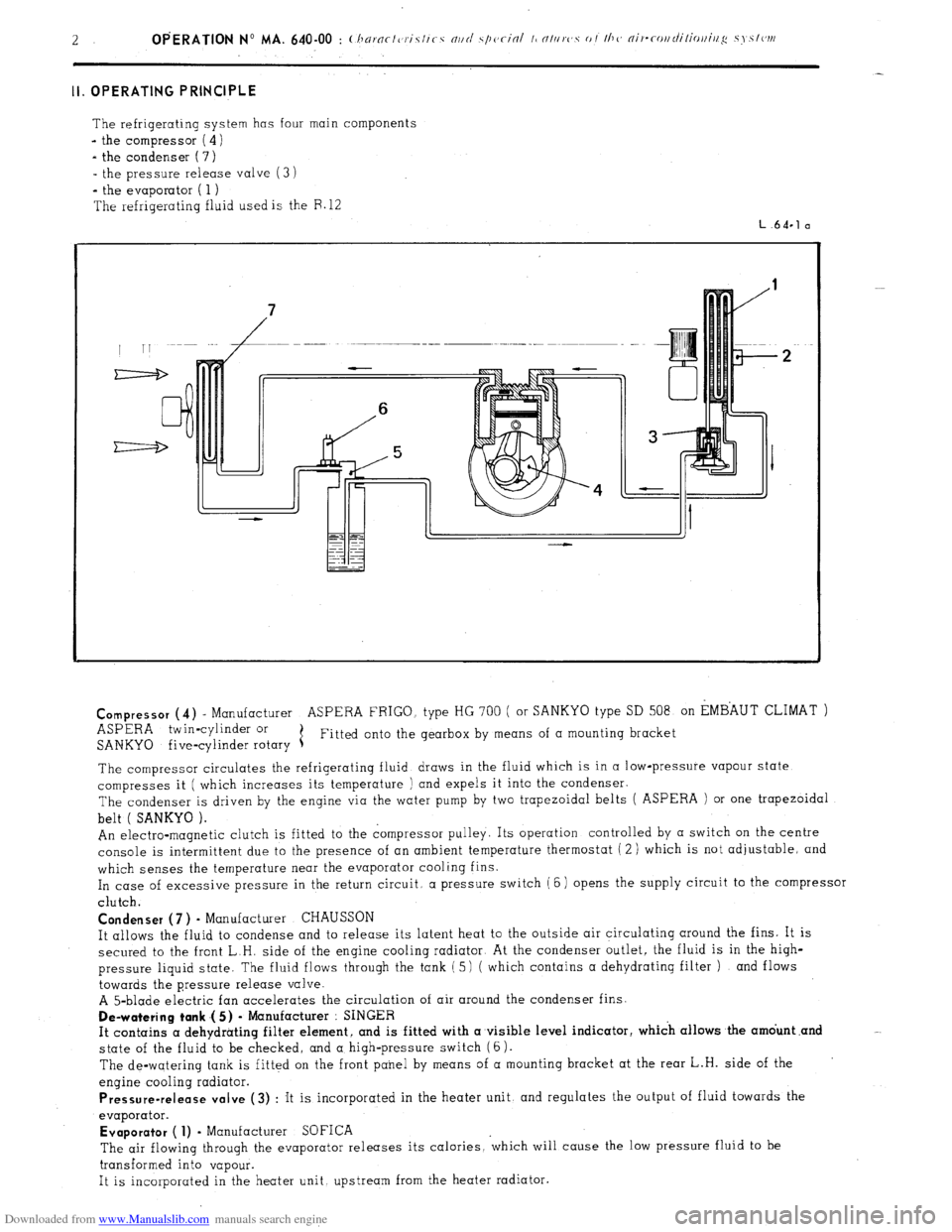

Downloaded from www.Manualslib.com manuals search engine II. OPERATING PRINCIPLE

The refrigerating system has four main components

- the compressor ( 4)

- the condenser ( 7)

- the pressure release valve (3 i

*

the evaporator ( 1 )

The refrigerating fluid used is the F. 12

L.64.1 a

Compressor

(4) - Manufacturer ASPERA FRIGO. type HG 700 ( or SANKYO type SD 508 on EMBAUT CLIMAT )

ASPERA twin-cylinder or

SANKYO five-cylinder rotary 1 Fitted onto the gearbox by means of a mounting bracket

The compressor circulates the refrigerating fluid draws in the fluid which is in a low-pressure vapour state

compresses it ( which increases its temperature ) and expels it into the condenser.

The condenser is driven by the engine via the water pump by two trapezoidal belts ( ASPERA ) or one trapezoidal

belt ( SANKYO ).

An electro-magnetic clutch is fitted to the compressor pulley. Its operation controlled by a switch on the centre

console is intermittent due to the presence of an ambient temperature thermostat ( 2 ) which is not adjustable, and

which senses the temperature near the evaporator cooling fins.

In case of excessive pressure in the return circuit, a pressure switch (6) opens the supply circuit to the compressor

clutch.

Condenser (7 ) - Manufacturer CHAUSSON

It allows the fluid to condense and to release its latent heat to the outside air circulating around the fins. It is

secured to the front L.H. side of the engine cooling radiator At the condenser outlet, the fluid is in the high-

pressure liquid state. The fluid flows through the tank ( 5) ( which contains a dehydrating filter ) and flows

towards the pressure release valve.

A 5-blade electric fan accelerates the circulation of air around the condenser fins.

De-watering tank .( 5) - Manufacturer : SINGER

It contains a dehydrating filter element, and is fitted with a visible level indicator, which allows the amdunt .and

state of the fluid to be checked, and a high-pressure switch (6).

The de-watering tank is fitted on the front panel by means of a mounting bracket at the rear L.H. side of the

engine cooling radiator.

Pressure-release valve (3) : It is incorporated in the heater unit, and regulates the output of fluid towards the

evaporator.

Evaporator ( 1) - Manufacturer SOFICA

The air flowing through the evaporator releases its calories, ‘which will cause the low pressure fluid to be

transformed into vapour.

It is incorporated in the heater unit upstream from the heater radiator.