hydraulic Citroen CX 1981 1.G User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1981, Model line: CX, Model: Citroen CX 1981 1.GPages: 394

Page 43 of 394

Downloaded from www.Manualslib.com manuals search engine 2

OPERATION No MA. 02 : I!‘orki//g OI/ hyc/rt/t/lic s\,s/vN/.

5. PRECAUTIONS TO BE TAKEN BEFORE WORKING ON THE HYDRAULIC SYSTEM :

a) (.~rvJuI/)~ CIVOII the area of work, the unions and the unit to be removed

Disconnect the lead from the negative terminal of the battery

Only use petrol or lead-free petrol for cleaning.

b ) I~~J/VNSO

the /)twsure in the circuits

- Place the vehicle in the G /arc B

position. stop the engine.

- Slacken the Pressure Requlator release screw.

Wait until the front of the car has reached the low position 6, PRECAUTIONS TO BE TAKEN DURING REMOVAL :

a) t3lnuk o!! the w~~tnl pi/~es with plugs, and rubber tubes with round pins of the correct diameter

b)

t3lmk of/ //IV op,c,/li,lg.s of components with pluqs of the correct diameter

NOTE : Plugs and pins must be carefully cleaned before insertion. 7.. CHECK OR TEST OF HYDRAULIC UNITS :

- Use 3654-T t~sf hc~~c-h equipped and designed for use with LHM fluid

This bench is /)ciitltc’d ~IY’~‘~/ and its accessories are marked in green.

- Never use the bench with another fluid or for testing components operating with another fluid (units of a (( D ))

car using LHS2 for instance ).

NOTE The (< Le Bozec )) pump used on test benches for checking DIESEL injectors can be resorted to for

testing components operating with LHM mineral fluid provided that the bench is cleaned first. 8. PRECAUTIONS TO BE TAKEN DURING REFITTING :

E steel pipes must be blown through with compressed air,

5 rubber tubes and joints must be washed in petrol or white spirit and then dried with compressed air,

= hydraulic units must also be cleaned with petrol or white spirit and blown through with compressed air.

NOTE Renew all joints and seals during refittinq .

b

) 12rlbrijicntim :

- Follow the indications as stated in the operations in the Manual..

- Joints and internal parts must be liqhtly oiled hefore fitting ( use mineral fluid LHM only )

L If parts in contact with hydraulic units have to be qreased use a mineral grease only ( as employed for

Cardan shafts or bearings ).

Page 44 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 02 : I+ 4’ 0, “‘g 01, Ill<, l1\~c!).ollli(- s\‘sfell~. Op. MA. 02

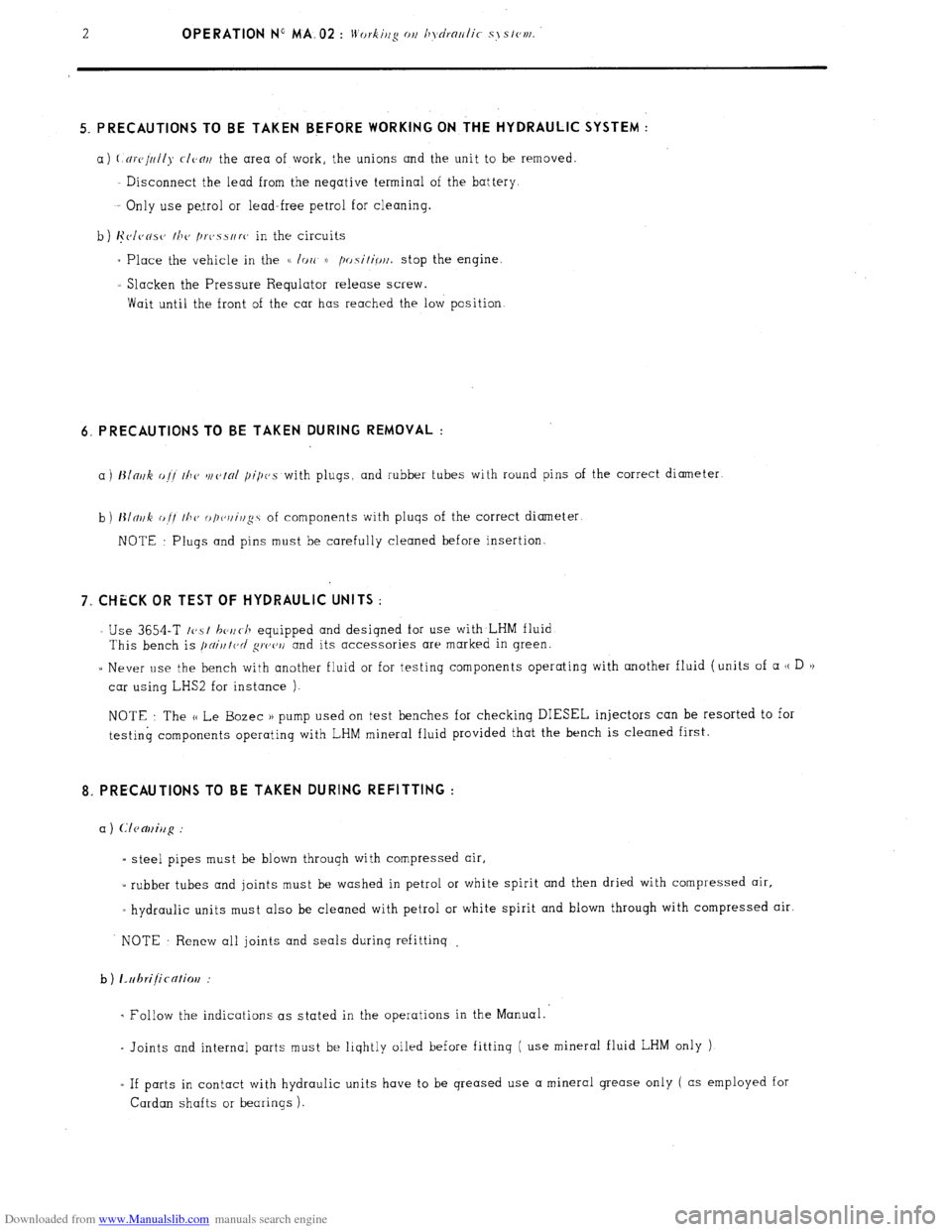

I To connect a union proceed as follows :

- Position sleeve-seal (( a u lightly coated with

L,HM fluid; this sleeve seal must not reach the

extremity of pipe (( b )).

- Centre the pipe in the housinq by lininq it up

with the axis of the hole, avoidinq all stress.

( Ensure that the end u b )I of the pipe enters

into the smali bore C< c )> j.

Start screwing in the union nut by hand.

- Tiqhten nut moderately : excessive force could

cause a leak because of deformation of the pipe

NOTE Tiqhteninq torques :

3.5 -mm pipe t 5.8 to 6 6 ft lbs

4 5 mm pipe 5 8 to 0 mN ( 0.8 to.0 9 ‘1 kg )

6 6 to 8 0 ft.lbs

6. O-mm pipe

1

9 to 11 mN (0 9 to 1 1 m.kg ) c ) Fittilzg :

I Only use joints of a quality compatible with LHM mineral fluid.

The design of the various seals ensures that their sealing action increases with fluid pressure The oiltiqhtness e

is therefore not improved by greater tiqhtness of the unions

2 To connect a rubber tube a rubber rinq of suitabie diameter has to be positioned between thr, tube and the hose

:

E clip.

0

x

a

A 9, CHECKS ON COMPLETION OF WORK

On completion of work on hydraulic units or the system itself check the followinq :

h) ‘1’11~ C./CJ~~~IIC-C, I~c,lrt,c,c,rt I/J<

pipvs : pipes must not touch one another or any other component, nor may any other

unit, whether fixed or movable, exert any stress on them.

Page 48 of 394

Downloaded from www.Manualslib.com manuals search engine 2 OPERATION No MA. 03 : I~grhdicwts prdcomis&.

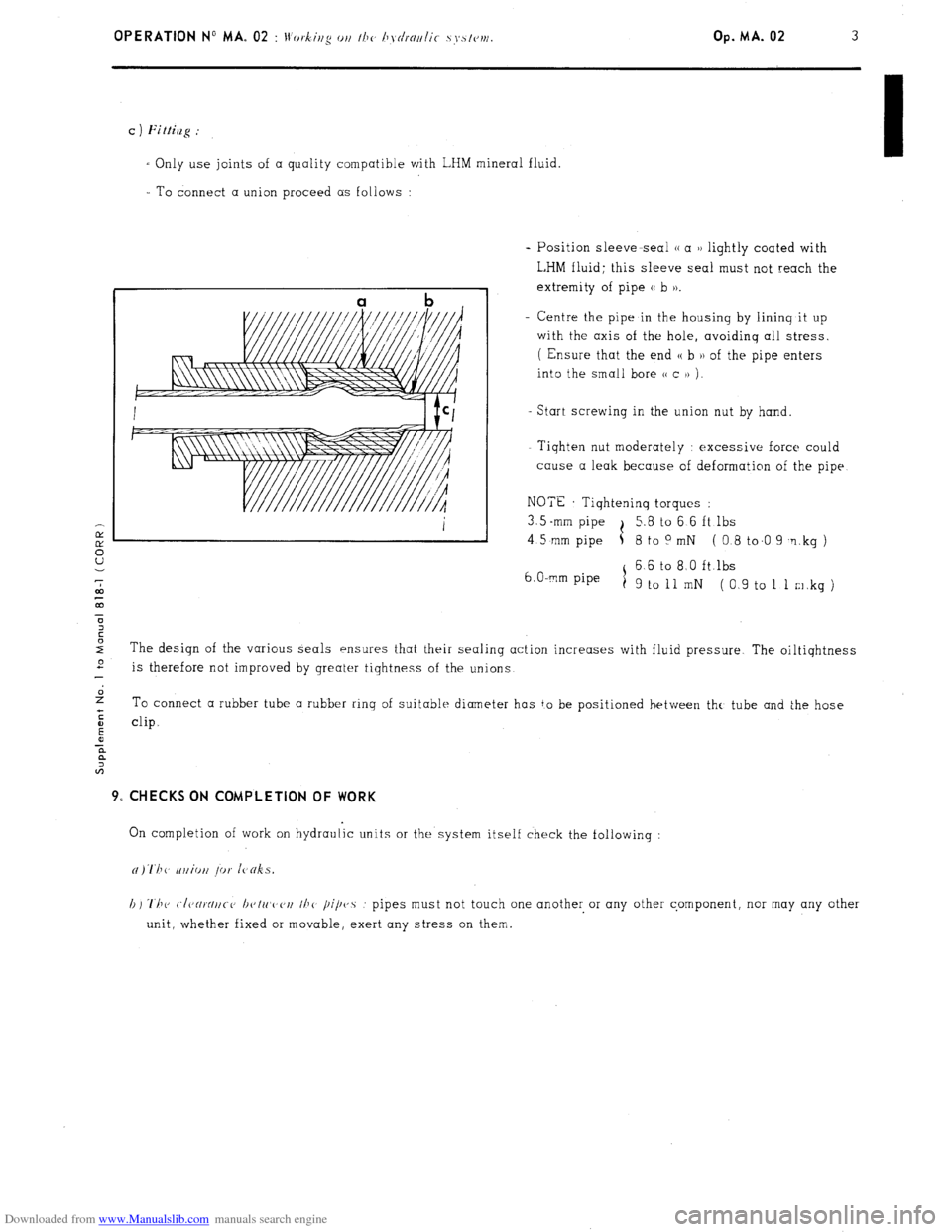

II. CLEANSING PRODUCTS

-

USAGE PRODUCT

R insing LHM hydraulic

Pi

ping

D egreasing of mechanical

a: ssemblies, when cold

oint face cleanser

‘leaning of carburettors CHARACTERISTICS

I MANUFACTURERS.

I

TOTAL

Hydro-rincage

MAGNET 6

OIL AND GREASE

REMOVER

PROTOLAN 3 D

RAVITOL X

MAGSTRIP

SUPER-CLEAN

Carburettor cleaner

P.D.R.

Carbuclin For a thorough rinse, leave the

product in the circuit for 1000 km

(600m) TOTAL

C.F.R.

Insoluble, in water, dries rapidly

has high insulating qualities MAGNUS

Let the product act

(undiluted in solvent ) then

rinse with water MULLERANDCO

Is used undiluted and must be

rinsed with water

Gelatineous liquid for removing

liquid gaskets and non-metal

gaskets Ets N BREGER

Ets RAVICOLOR

MAGNUS

Dry cleanser to be used before

application of Loctite products COMET

Department D.A.V.A. /

III. SEALING PASTES.

PRODUCT

PROTO-JOINT

CURTYLON

LOWAC

FRENETANCH

FRENEBLOC

FORMAJOINT

SILICOMET

noir

(blark ) CHARACTERISTICS

Resist mechanical stress, and

oil-derived products MANUFACTURERS USAGE

JEAN - BRASSART

CEFILAC

Department Joint Curty Clean with alcohol -

Resists hydrocarbons

SEBIS

Locks and seals any assembly

which is screwed on, but must

remain removable Sealing of joint faces,

screws, studs and nuts

Locks and seals studs, screws

and nuts with maximum

effectiveness COMET

Department D.A.V.A.

NOTE : These five

products are available as

a kit, with in addition

SCELBLOC (to be used

when securing bearings,

bushes etc.. ) and SUPER-

CLEAN (cleansing pro-

duct ) Seals joint faces and unions

Seals joint faces, as replacement

of ordinary gaskets

Sealing of door and wind-

screen sealing rubbers

Page 185 of 394

Downloaded from www.Manualslib.com manuals search engine TORQUE CONVERTER

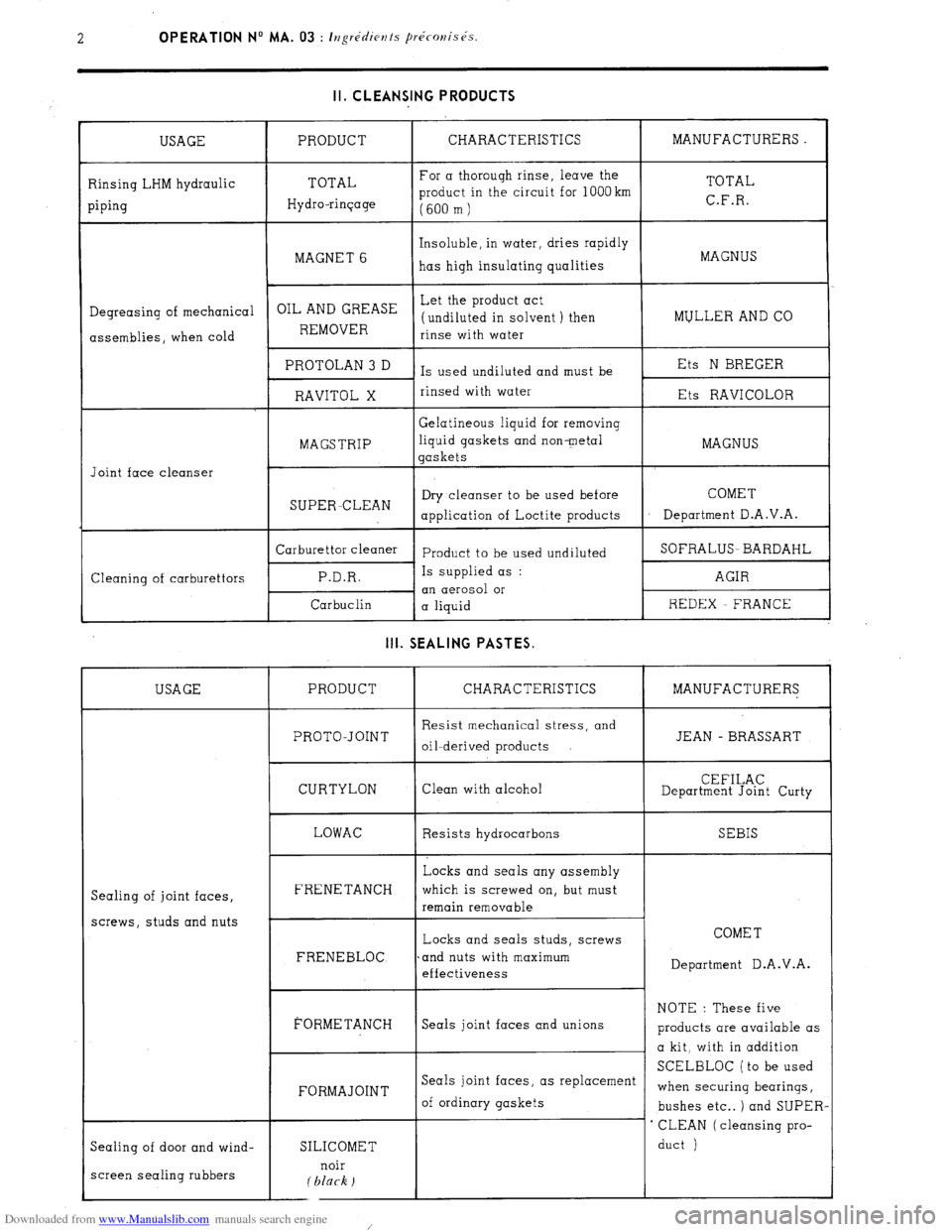

I. CHARACTERISTICS

- Torque converter with incorporated disc clutch. Make FERODO ( VERTO system ). Type 697 ( CX 2200 )

or 693 ( CX 2400 ).

_ Clutch engagement and disengagement are controlled by a hydraulic system with an electro valve unit

I This electro-va,lve is itself controlled by an electric switch operated by the gearbox selector shafts.

- Conversion ratio of converter 2 30 1 ( 697 type )

2.20 1 ( 693 type ) II. SPECIAL FEATURES

Adiustments :

- Contact gap in electric switch unit ,controlling the electro-valve

NOTE The gap for the 2nd/ 3rd gear contacts must only be adjusted once the selector shaft stop-screws have

been adjusted ( See Op. MA. 330-00 ),

- Gap at 2nd/ 3rd gear contacts 0 8 to 1.1 mm

- Gap at lst/ Rev. gear contacts ’ 13+02mm

. . . . . . . . . . . . .._.......

- Operating pressure for the converter oil system c /)IIv//~ ~c,I//v/I J :

- at 700 rpm 3.5 bars ( 51 psi ) min

_ at 2000 i A00 rpm 5.5 bars ( 80 psi 1 min 1

Oil l,c~~~i/~~~i’NItrrc~ 80: (.

- at maximum revs .,......... 10 bars ( 145 psi ) ( II./IN/<‘I (‘7 /h(, I<,ml,(a,‘flt~ro )

Page 214 of 394

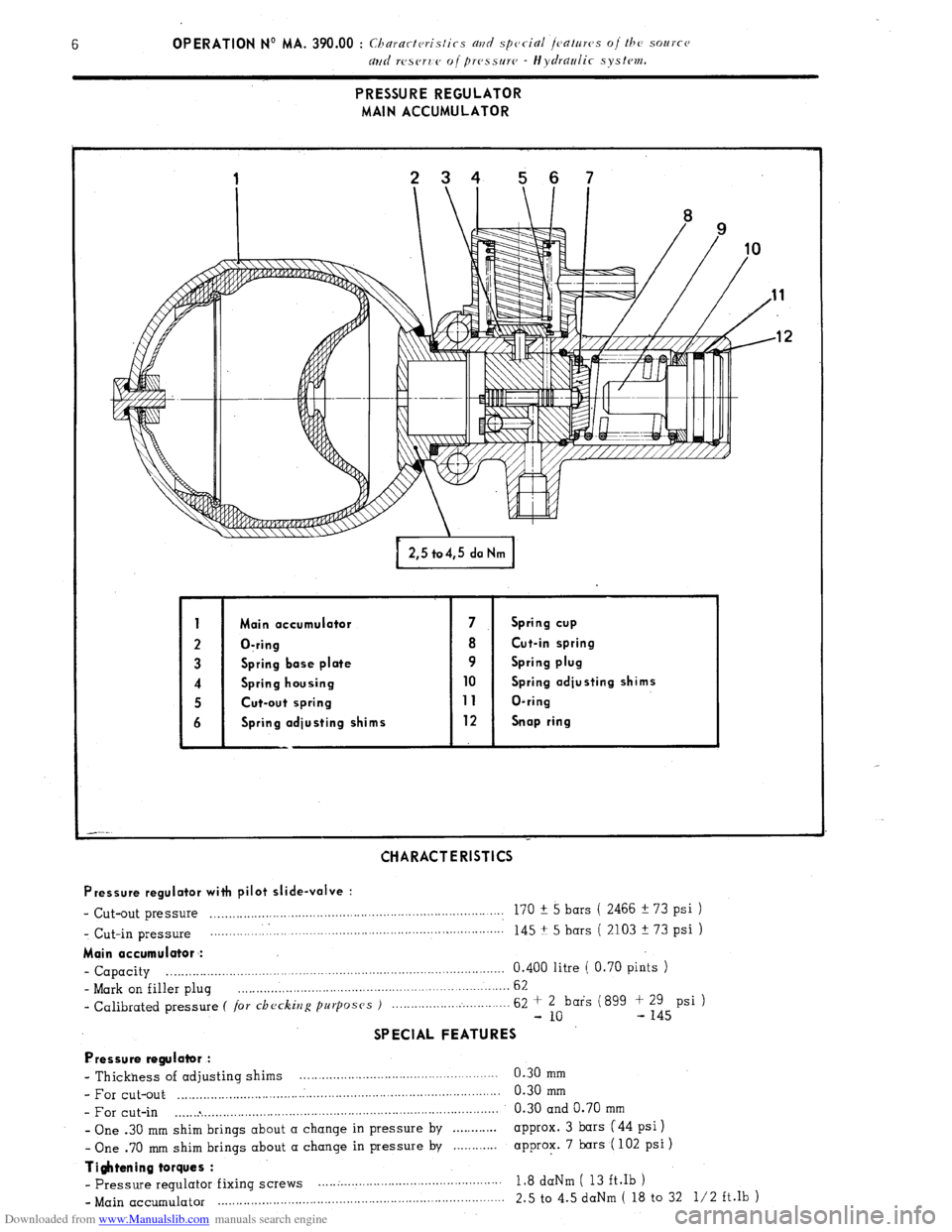

Downloaded from www.Manualslib.com manuals search engine 6 OPERATION No MA, 390.00 : C1 ,ararteristics

ad special fratuws oj the source

apfd rescr7,e o/ pressur(~ - Hydraulic system.

PRESSURE REGULATOR

MAIN ACCUMULATOR

Main occumulotor 7 Spring cup

O-ring 8 Cut-in spring

Spring base plate 9 Spring plug

Spring housing 10 Spring adjusting shims

Cut-out spring 11 O-ring

Spring odjusting shims 12 Snap ring

CHARACTERISTICS

Pressure regulator with pilot slide-valve :

- Cut-out pressure . .._......,_....____.............,.,......................................... 170 f 5 bars ( 2466 !I 73 psi ) _ Cut-in pressure __.....___.__.,..,.....,..,................,,...................................

145 + 5 bars ( 2103 + 73 psi )

Main accumulator :

- Capacity . . . . 0.400 litre ( 0.70 pints )

- Mark on filler plug . . , 62

- Calibrated pressure C /or checking purposes ) 62 + 2 bars (899 f 29 psi )

- 10 - 145

SPECIAL FEATURES

Pressure regulator :

- Thickness of adjusting shims . 0.30 mm

- For cut-out ..I.._......._..... .._. ,. .._. .:.. ,. ,. ..__.. ,. ..__ ,. ,. ._ ._.. .___ 0.30

mm

- For cut-in .._.... * .__....._._.,.,.,._.,....................................... 0.30 and 0.70 mm

- One .30 mm shim brings about a change in pressure by . . . . . . . . . . , approx. 3 bars (44 psi 1

- One .70 mm shim brings about a change in pressure by . . . . . . . . . approx. 7 bars ( 102 psi )

Ti$ttening torques :

- pressure regulator fixing Screws . . . . .._.__.....__._............................... 1.8 daNm ( 13 ft.Ib )

- Main accumulator ..,.. ,. . . ,. __ . . . . .._. ., ,__. ._ __ 2.5 to 4.5 daNm ( 18 to 32 l/2 ft.lb )

Page 218 of 394

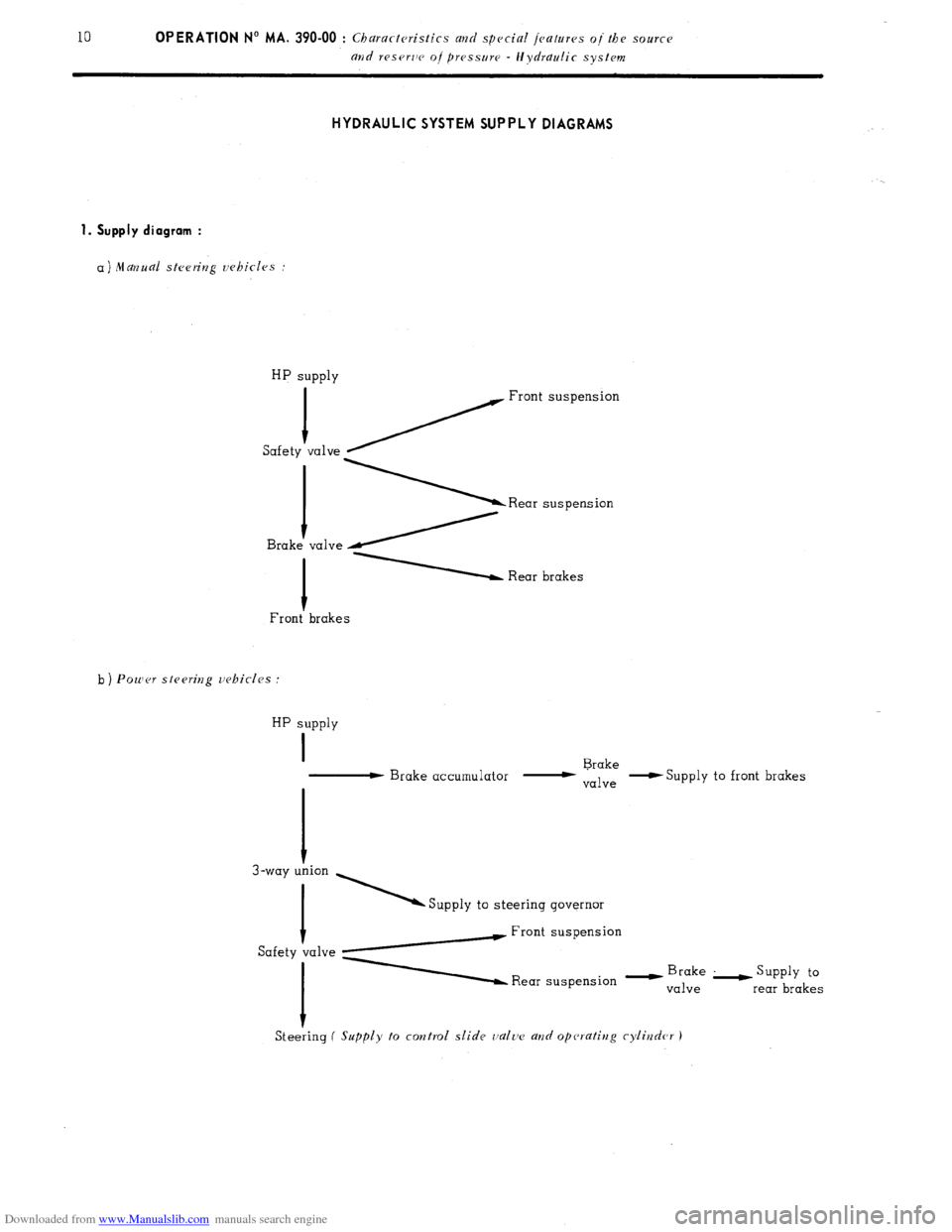

Downloaded from www.Manualslib.com manuals search engine 10 OPERATION No MA. 390-00 : Churarteristics and special features oi the source

and reserlv oj pressure - Hydraulic system HYDRAULIC SYSTEM SUPPLY DIAGRAMS

1. Supply diagram :

a) Manual steering vehicles :

HP supply

1

Safety ~ Front suspension

va1ve \Rear suspension valve /

1 Rear brakes

Front’ brakes

b ) Power stesritzg vehicles :

HP supply

I

- Brake accumulator - Brake

valve -S

upply to front brakes

I

3-way T ’ Supply to steering governor

Safety talve yw Front suspension

A Rear suspension - y”,;“,“,’ L supp1y to

rear brakes

Steeiing

( Supply to control slide valtv a?zd operating cylirzder J

Page 219 of 394

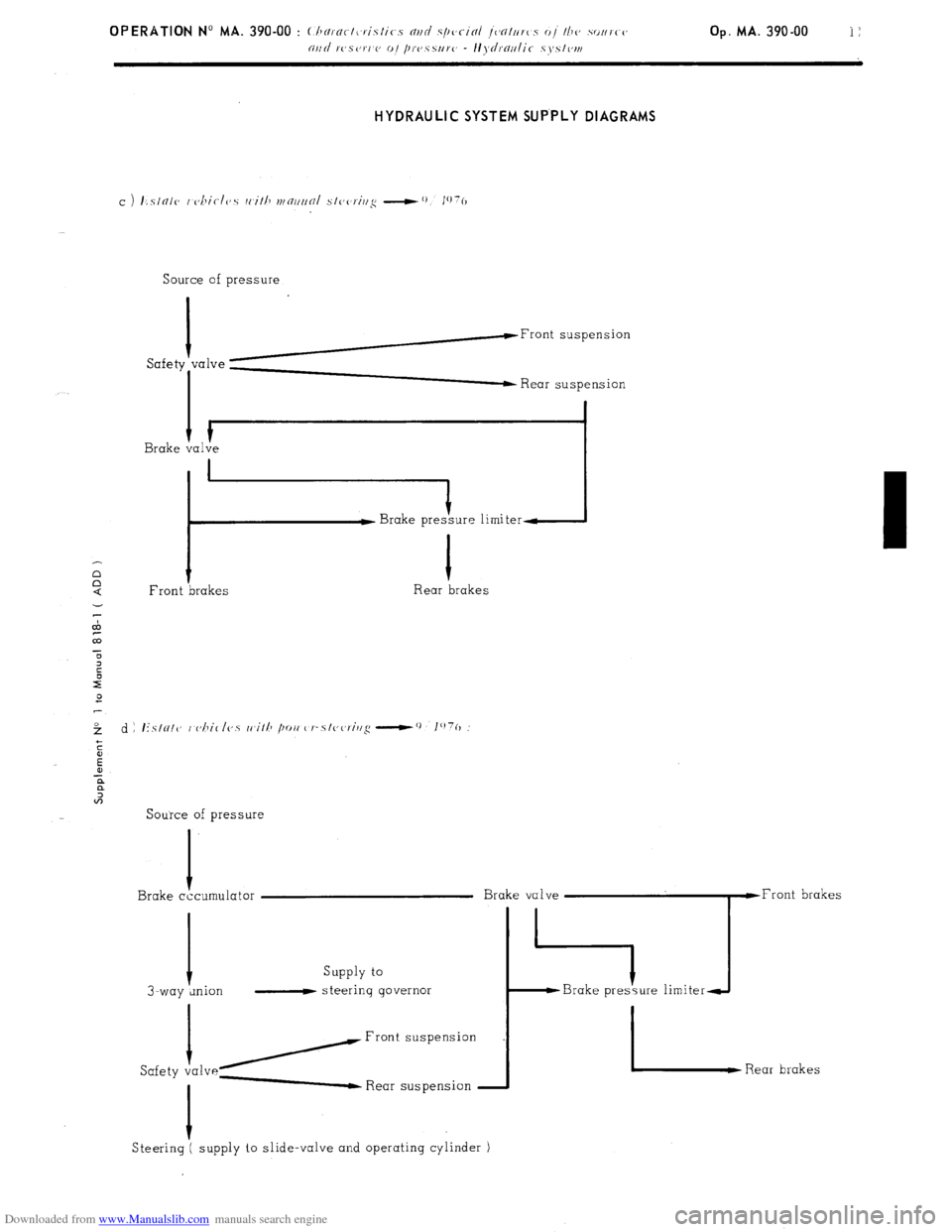

Downloaded from www.Manualslib.com manuals search engine HYDRAULIC SYSTEM SUP.PLY DIAGRAMS

Source of pressure

I

h-Front suspension

Safety “‘lve ; Rear suspension

I

I Brake valve

i :ure limiter-

1

Front brakes Rear brakes

Source of pressure

I

Brake cccumulator

Supply to

I-way wion - steering governor

/Front

Safety va1ve- Rear suspension

I

Steering ( supply to slide-valve and operating cylinder )

Page 221 of 394

![Citroen CX 1981 1.G User Guide Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 390-00 : (.hnrncteristics a?zd special fc~atuws oj the SOIUCC

arld ~~~scrm~ o]~prc’ss~~rc - Hydraulic systrm

2. Aisembly d Citroen CX 1981 1.G User Guide Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 390-00 : (.hnrncteristics a?zd special fc~atuws oj the SOIUCC

arld ~~~scrm~ o]~prc’ss~~rc - Hydraulic systrm

2. Aisembly d](/img/9/4131/w960_4131-220.png)

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 390-00 : (.hnrncteristics a?zd special fc~atuws oj the SOIUCC

arld ~~~scrm~ o]~prc’ss~~rc - Hydraulic systrm

2. Aisembly diagram : Op. MA. 390-00 13

Page 227 of 394

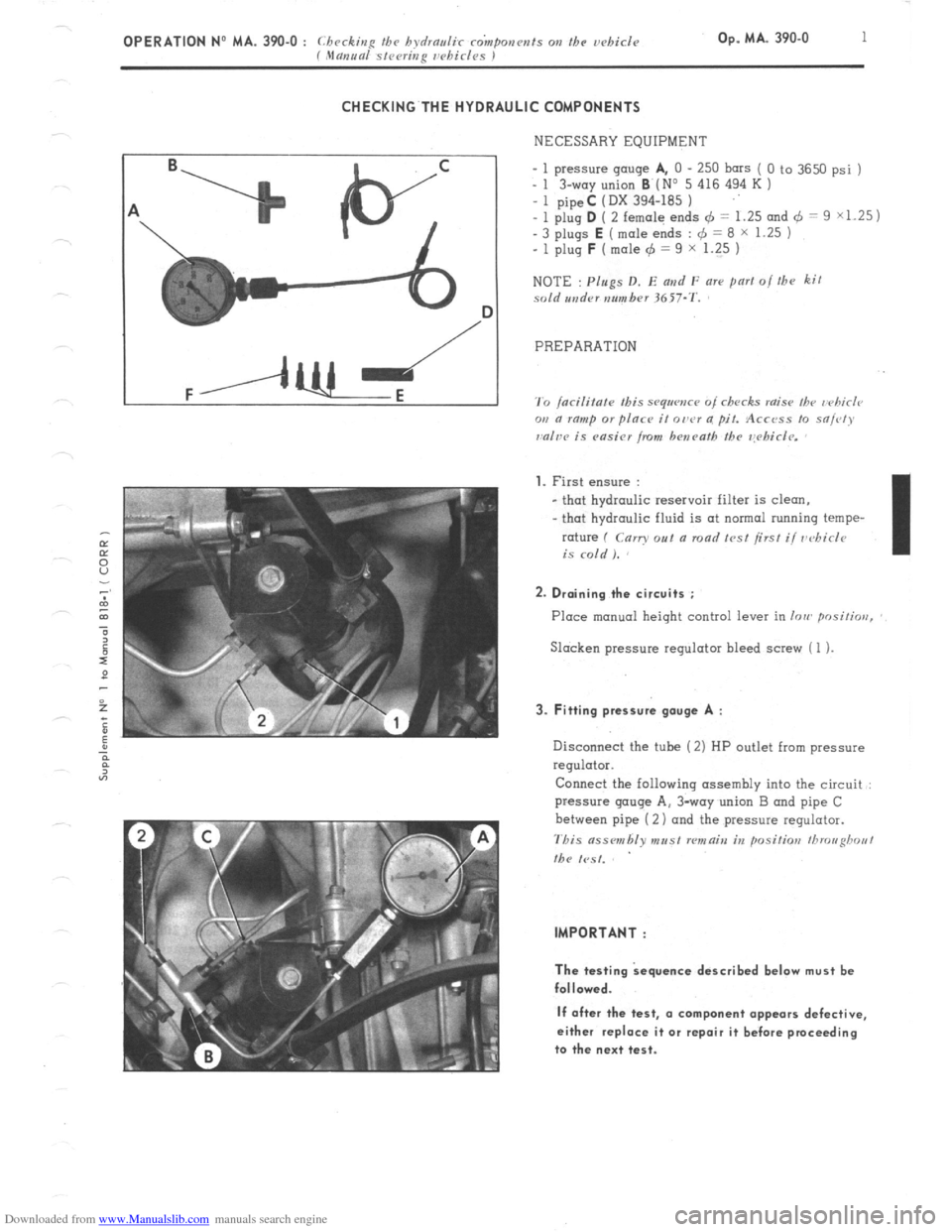

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 390-O : ChrckinR thr bydraalir co’mponcnts on the u&i& f Manual stcprine r~ebidos t Op. MA. 390.0 1

CHECKING’THE HYDRAULIC COMPONENTS

NECESSARY EQUIPMENT

- 1 pressure gauge A,

0 - 250 bars ( 0 to 3650 psi )

_ 1 3-way union B (No 5 416 494 K 1

- 1 pipeC (DX 394-185 ) ..

- 1 plug D ( 2 female ends 4 1.25 and 6 9 X1.25) = =

- 3 plugs E (mole ends : r$ 8 X 1.25 ) =

- 1 plug F (

mole 4 = 9 x 1.25 1

NOTE

: Plugs D, E md F are part 01 fhe kit

sold snder number 3657-T.

PREPARATION 1.

First ensure :

- that hydraulic reservoir filter is clean.

- that hydraulic fluid is ot normal running tempe-

rature ( Carry 0~1 a road lent first i/ vt4icie

is

mid ). 8 2. Draining the circuits :

Place manual height control lever in ion, posirios,

Slacken pressure regulator bleed screw ( 1 ). 3. Fitting pressure gouge A :

Disconnect the tube (2) HP outlet from pressure

regulator.

Connect the following assembly into the circuit :

pressure gaoge A, 3way union B and pipe C

between pipe ( 2) and the pressure regulator.

This ass~nzhly mrtst remain in positioa /brougbo~~l

the test. IMPORTANT :

The testing kquance described below must be

followed.

If after the test, a component appears defective,

either replace it or repair it before proceeding

to the next test.

Page 229 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 390-O : Checkin

P the hydraulic componm~s on the ucbicle Op. MA. 390-O 3

f Mama sleeting wbi&s I

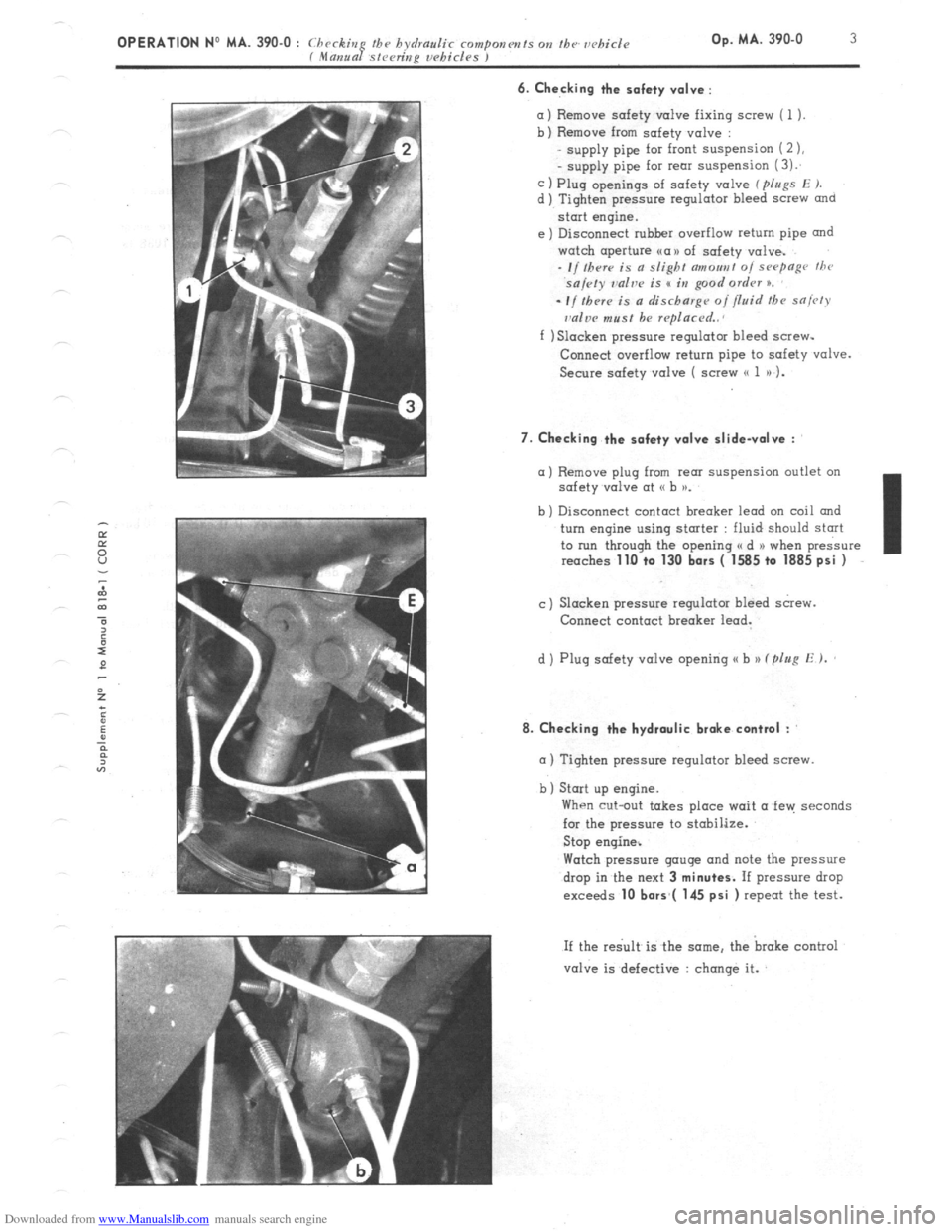

6. Checking the safety valve :

=I

bl

Cl

dl

Remove safety v&e fixing screw ( 1 ).

Remove from safety valve :

supply pipe for front suspension (2 ),

- supply pipe for rem suspension (3):

Plug openings of safety valve ( pIugs E J.

Tighten pressure regulator bleed screw

and

start engine.

Disconnect rubher overflow return pipe and

watch aperture ~a>> of safety valve.

- I/ Iherr is a slight c7moa,,t 0, sHymge thr

sa/cty ~dve is s in good ordrv n.

el

-If thrr~ is a discharge of fluid the sniw

dw must be rqlacrd..

f ) Slacken pressure regulator bleed screw-

Conned overflow return pipe to safety valve.

Secure safety valve ( screw (( 1 a) 1.

7. Checking the safety valve slidevolve :

a) Remove plug from rem suspension outlet on

safety v&e at G b >a.

b ) Disconnect contact breaker lead on coil and

turn engine using stmter : fluid should start

to run through the opening a d N when pressure

reaches

1lLl +o 130 bars ( 1585 to 1885 psi )

c) Slacken pressure regulator bleed screw.

Connect contact breaker lead.

d ) Plug safety valve opening u b )) (plug E ).

8. Checking the hydraulic brake contml :

m ) Tighten pressure regulator bleed screw.

b) Start up engine.

When cut-out takes place wait a fen: seconds

for the pressure to stobilize.

Stop engine%

Watch pressure gauge and note the pressure

drop in the next 3

minutes. If pressure drop

exceeds 10 bors*( 145 psi ) repeat the test.

If the re< is the same. the broke control

valve is defective : change it.