Camshaft Citroen CX 1984 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1984, Model line: CX, Model: Citroen CX 1984 1.GPages: 394

Page 52 of 394

Downloaded from www.Manualslib.com manuals search engine I. CHARACTERISTICS

:

0

u

5 Cooling system : Water cooled.

z

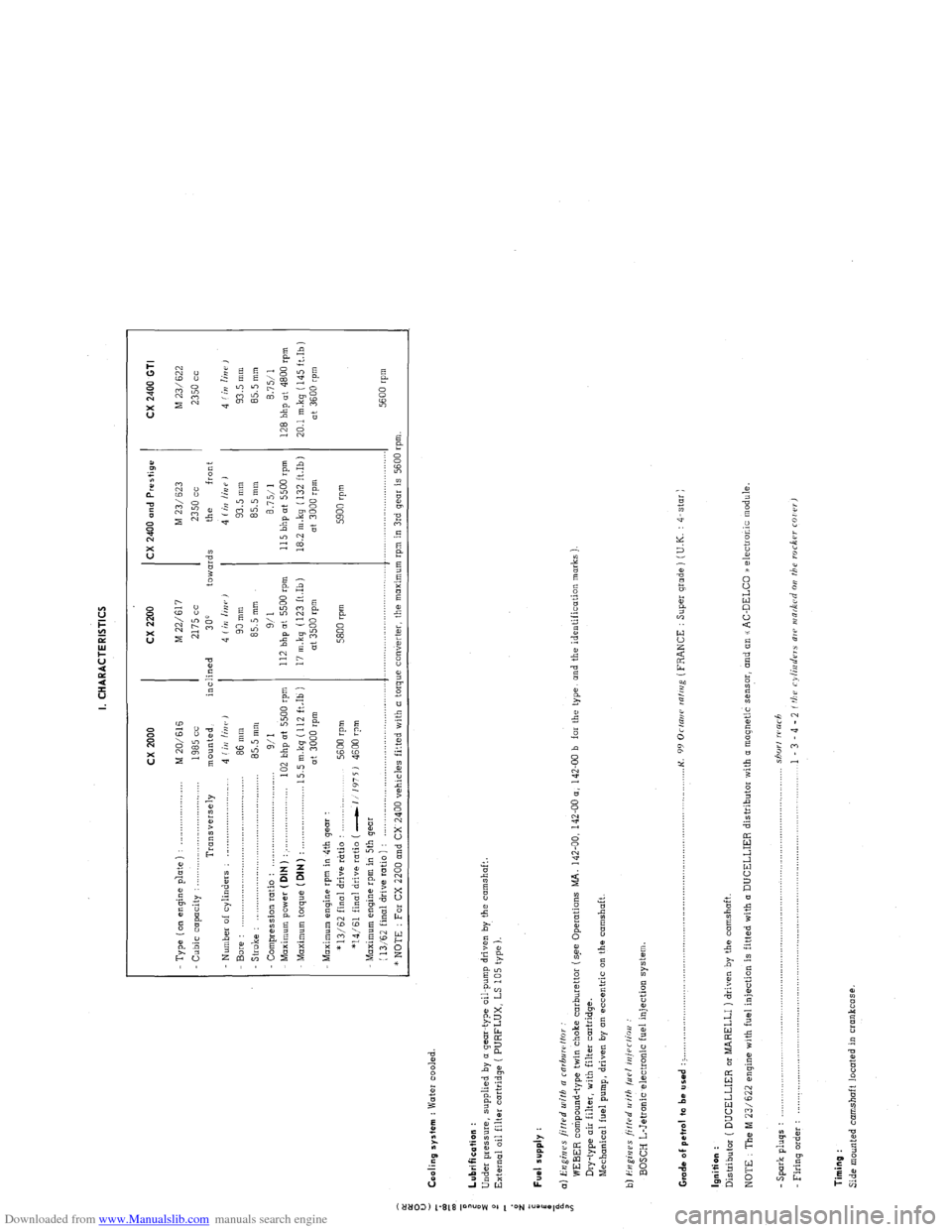

T cx 2000 cx 2200 CX 2400 and Prestige

CX 2400 GTI

- Type ( on engine p’late ) : _..._................... M 20/616 M 22/617 M 23/ 623

M 23/622

Cubic capacity : . . .._......_...............

1985 cc 2175 cc 2350 cc 2350 cc

Transversely mounted, inclined

300 towards the front

Number of cylinders : _........................... 4 (iI/ linr, J 4 Iin linr,)

4 (irr /iUP J 4 f in lin i’ ,

Bore : 86 mm 90 mm 93.5 mm 93.5 mm

- Stroke : .,.,,_,.,.,....____.,.. .._._.....................

85.5 mm 85.5 mm 85.5 mm

85.5 mm

Compression ratio :

9/I 9/l 8.7511 8.7511

Maximum power ( DIN ) : . . . .._................... 102 bhp at 5500 rpm 112 bhp at 5500 rpm 115 bhp ot 5500 rpm

128 bhp at 4800 rpm

Maximum torque (DIN)

: . . 15.5 m.kg (112 ft.Ib ) 17 m.kq (123 ft.Ib) 18.2 m.kg ( 132 ft.Ib)

20.1 mkq (145 ft.Ib)

at 3000 rpm at 3500 rpm at 3000 rpm

at 3600 rpm

Maximum engine rpm in 4th gear :

* 13/62 final drive rtrtio :

5600 rpm 5800 rpm 5900 rpm

*14/61 final drive ratio ( -1 1’175 J 4600 rpm

Maximum engine rpm in 5th gear

(

13,‘62 final drive ratio ) : ,._............,..,........,....,.,........,..,.,..... .._.........,................ .._..._...................

5600 rpm

* NOTE : For CX 2200 and CX 2400 vehicles fitted with a torque converter, the maximum rpm in 3rd gear is 5600 rpm.

: Lubrification :

i

Under pressure, supplied by o gear-type oil-pump driven by the camshaft.

2

External oil filter cartridge ( PURFLUX, LS 105 type ).

d

z

;

i Fuel supply :

a

i a) Engines fitted u~ifh a rnrbuwffor

WEBER compound-type twin choke carburettor (s.ee Operations MA. 142-00, 142-00 a, 142-00 b far the type, and the identification marks )

Dry-type air filter, with filter cartridge.

Mechanical fuel pump, driven by on eccentric on the camshaft.

b) i?ugi,jes ji/f.rd II ith /LIP/ iniPr/ioo :

BOSCH L-Jetronic electronic fuel injection system

Grade of pet,ol to be used : > ._,,,,.,_.._,,,,,.,......... . .._...o....._............................................. K.

99 Orrani ralrrig (FRANCE : Super grade ) (U.K. : 4-star )

Ignition :

Distributor ( DUCELLIER or MARELLI ) driven by the camshaft.

NOTE : The M 23/622 engine with fuel injection is fitted with (I DUCELLIER distributor with a magnetic sensor, and an u AC-DELCO /a electronic module.

- Spark pluqs : .................................................................................................................................... shorf warh

Firing o&r : .................................................................................................................................... 1 - 3 - 4 - 2 f tbu cylinders ale INR&Cd 011 the roc6w COI rr,

Timing :

Side mounted camshaft located in crankcase.

Page 56 of 394

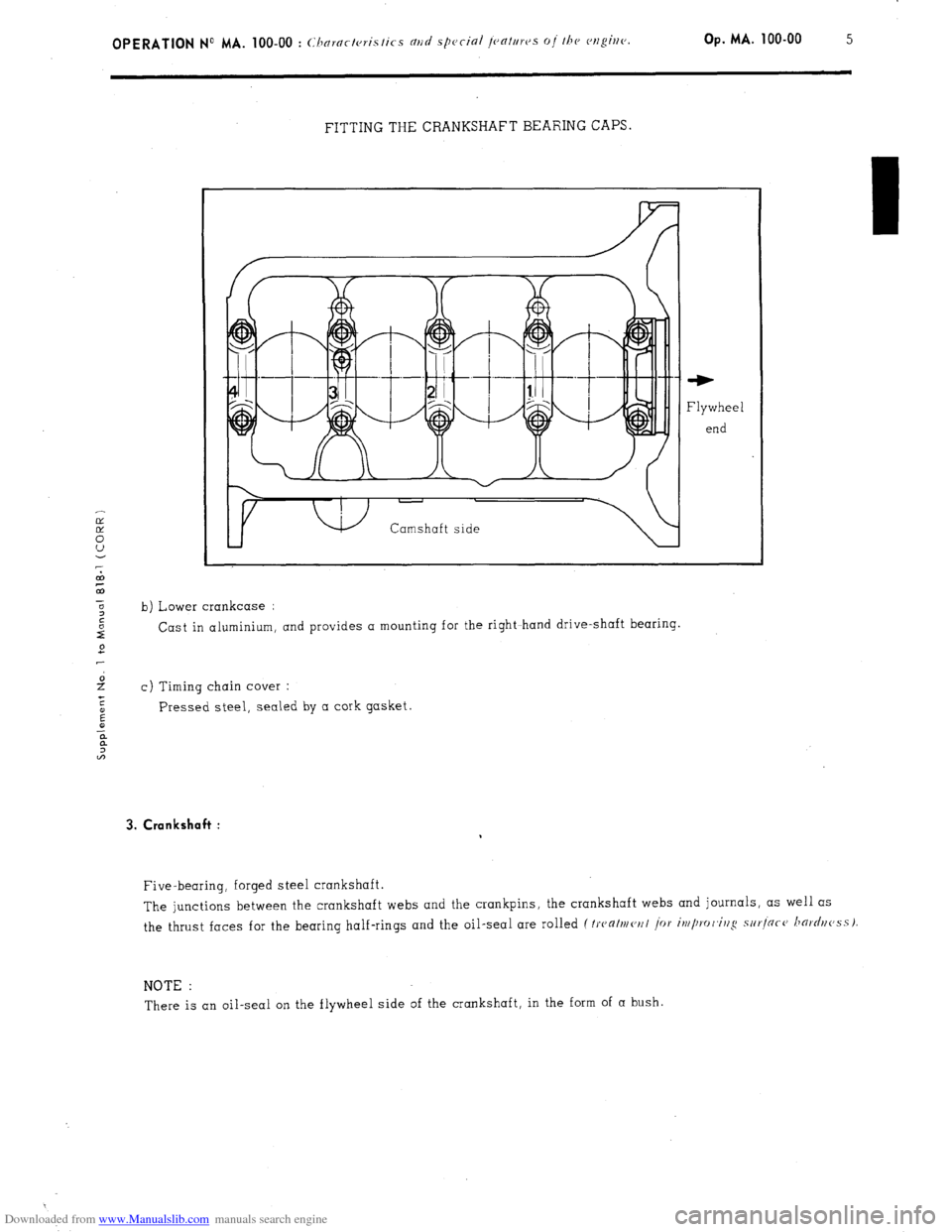

Downloaded from www.Manualslib.com manuals search engine FITTING THE CRANKSHAFT BEARING CAPS

Camshaft side Camshaft side ‘W

Flywheel

end

b) Lower crankcase :

Cast in aluminium, and provides a mounting for the right~hand drive-shaft bearing.

c) Timing chain cover :

Pressed steel, sealed by a cork gasket. 3. Crankshaft :

Five-bearing, forged steel crankshaft.

The junctions between the crankshaft webs and the crankpins, the crankshaft webs and journals, as well as

the thrust faces for the bearing half-rings and the oil-seal are rolled

(Iwalmc,r/l i~r iw/lro/~ir/g sur]ncc~ horr/r/c,ssI

NOTE :

There is an oil-seal on the flywheel side of the crankshaft, in the form of a bush.

Page 65 of 394

Downloaded from www.Manualslib.com manuals search engine d) Valve springs :

The inlet and exhaust valve springs are identical.

Characteristics :

- Diameter of wire : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6 + 0.02 mm

Interior diameter : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 2 0.2 mm

- Length of spring under load : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 39mm(load=m40t2,8kg)

30.6 mm ( load = 84 ~‘1.8 kg )

Coating : ._._................................................................................................ Red or blue varnish

e) Upper spring cups : Identical inlet and exhaust.

f ) Retaining clips : Identical inlet and exhaust

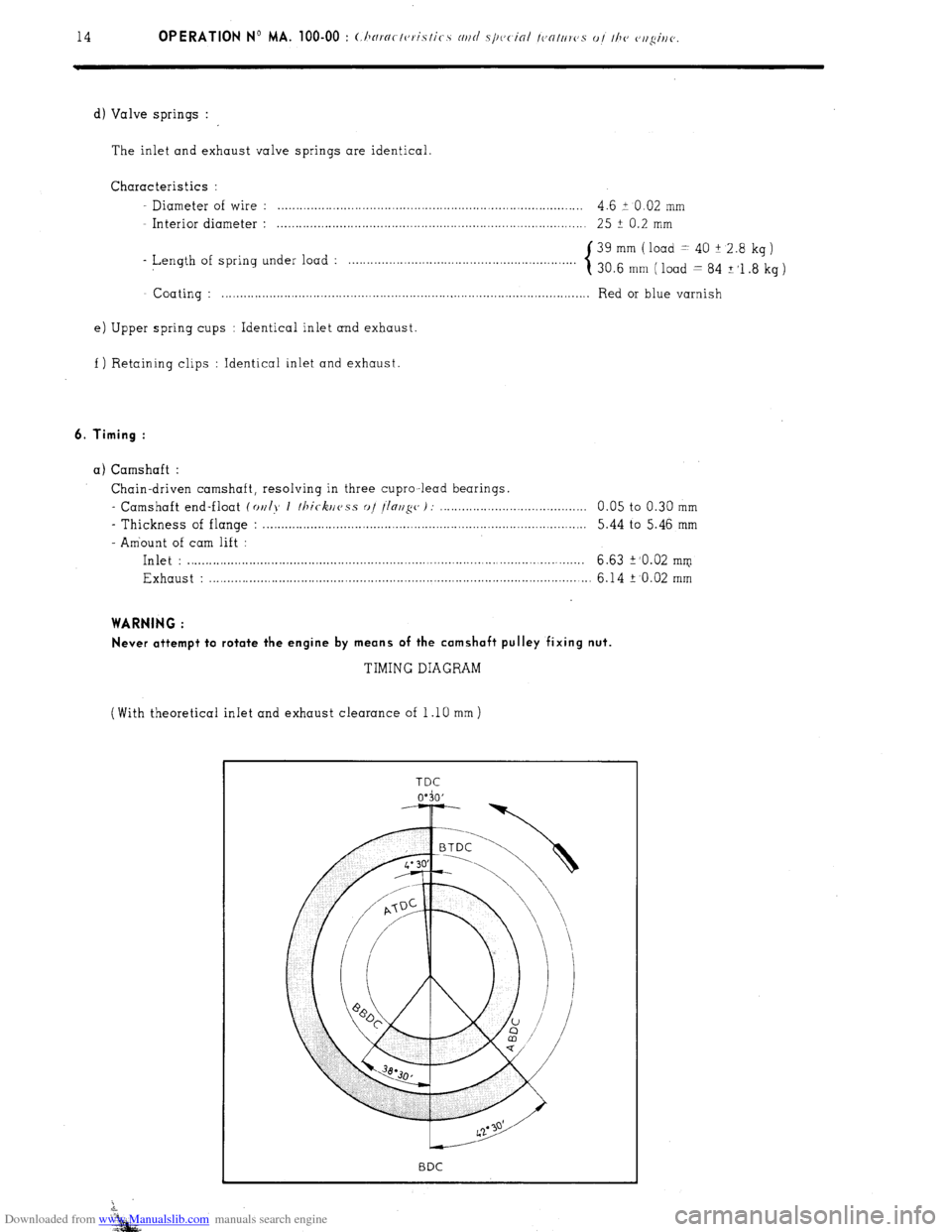

6. Timing :

a) Camshaft :

Chain-driven camshaft, resolving in three cupro -lead bearings.

- Camshaft end-float (a,//>~ I /hi<-krlc~ss a,/ !/o,/s(, I: 0.05 to 0.30 mm

- Thickness of flange : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.44 to 5.46 mm

- Amount of cam lift :

Inlet : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..__.._..._ _.;._.; .._...._ ..__.___.., 6.63

2’0.02 mm

Exhaust : ___._._..._.........................................................................................,... 6.14 + ‘0.02 mm

WARNING :

Never attempt to rotate the engine by means of the camshaft pulley fixing nut.

TIMING DIAGRAM

(With theoretical inlet and exhaust clearance of 1 .lO mm )

Page 68 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 100-00 : Characteristics and special jeafruvs oj the cvlghv.

Op. MA. 100-00 17

9..Tightening torque :

a) Engine suspension :

4-.spc~~d manrlal gearbox :

7 Torque bar (( Nylstop )) fixing nuts : .............................................................. 8.2 da Nm ( 59 ft.Ib )

- Securing screws for the flexible bearer on the subframe ; ........................ 3 da Nm ( 22 ft.lb)

- Flexible bearer assembly screws :

..................................................... .

........ 10 da Nm (72 ft.lb)

S-sp~~tl n1m11ra1 gca~box. and forq~~c cour,c~rtrr gc~arkos

- Torque bar (( Nylstop )) fixing nuts : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 da Nm (72 ft.lb)

- R:H. flexible mountinq assembly screws : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 da Nm ( 72 ‘ft.lb )

- L.H. flexible bearer assembly screws : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 to 17 da Nm ( 116 to 123 ft.lb )

b) Crankcase :

Screws and nuts securing the timing cover : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4 to 1.9 da Nm (10 to 14 ft.lb)

c) Timing :

- Screw on the camshaft thrust bearing : . . . . . . . . . . . .._............................................ 1 .4 to 1 .9 da Nm ( 10 to 14 ft.lb )

- Timing chain guide securing screw : . . . . . . . . . . . ..__................................ . . . . . . . . . . . . . . .

1.4 to 1.9 da Nm ( 10 to 14 ft.lb)

- Timing chain tensioner securing screw : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9 to 1 .I da Nm (6.5 to 8 ft.lb )

d) Lubrication system :

- Oil filter mounting ( LOCTITE FRENETANCH ) : ......................................

1 to 1 .5 da Nm ( 7 to 11 ft.lb )

- Oil temperature switch : .................................................................................. 3 to 3.5 da Nm ( 22 to 25 ft.lb )

- Union screw for cylinder head lubrication passage : ..................................

1 to 1 .2 da Nm ( 7 to 9 ft.lb )

- Oil filter cartridge ( SPV

wnrt/r]nctc/rer‘s rmte ) : ............................................ 1 .l to 1 .5 da Nm ( 8 to 11 ft.lb )

- Engine oil drain plug ( lo~!,c,r s/t~/p

co/‘cr) : .................................................. 3.5 to 4.5 da Nm (25 to 32.5 ft.lb)

Page 69 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 112-O : ChcJcking and adjusting the valrv mechanism. Op. MA. 112-O

1

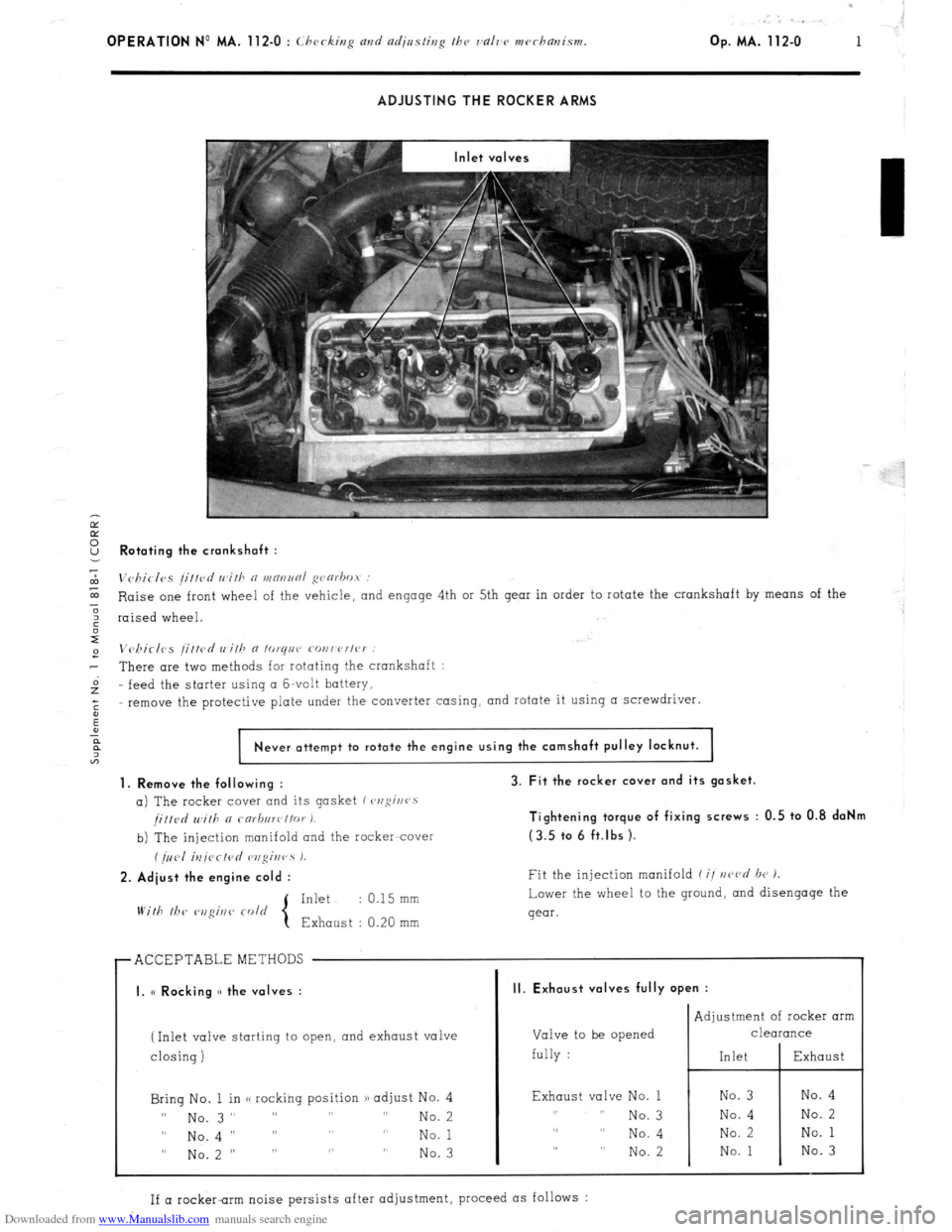

ADJUSTING THE ROCKER ARMS

Ir

E

2 Rotating the crankshaft :

7

m

Vc,birlvs /i//cd wifh n WRIINRI ~varbot :

E Raise one front wheel of the vehicle,

and engage 4th or 5th gear in order to rotate the crankshaft by means of the

3

6 raised wheel.

I

e Vchirlcs /ittcd wilh a lo~qnr covwrlc~ :

- There are two methods for rotating the crankshaft :

Gz feed the

starter using CI G-volt battery,

;

remove the protective plate under the converter casing, and rotate it using a screwdriver.

:

Never attempt to rotate the engine using the camshaft pulley locknut.

1. Remove the following :

a) The rocker cover and its gasket (~,ofii~rr~s

/i//d Will, a rarb,,wt/or I.

b) The injection manifold and the racker-cover

(/,,<,I iU/<~CfPd r,zgir,rs 1.

2. Adiust the engine cold :

Inkt : 0.15 mm

With lb<‘

3. Fit the rocker cover and its gasket.

Tightening torque of fixing screws : 0.5 to 0.8 daNm

(3.5 tc. 6 ft.lbs ).

Fit the injection manifold f i/ nczvd br 1.

Lower the wheel to the ground,

and disengage the

gear.

r ACCEPTABLEMETHODS

I I

I. (< Rocking )> the valves :

(Inlet valve starting to open, and exhaust valve

I

closing) closing)

Bring No. 1 in <, rocking position /) adjust No. 4 Bring No. 1 in <, rocking position /) adjust No. 4

II II

No. 3” ” ” ” No. 3” ” ” ” No. 2 No. 2

0 0

No.4 I’ ” ” ” No.4 I’ ” ” ” No. 1 No. 1

” No.2 ” ” ” ” ” No.2 ” ” ” ” No. 3 No. 3

II. Exhaust valves fully open :

Valve to be opened

fully : Adjustment of rocker arm

CleUKUlCe

Exhaust valve No. 1

,, I, No. 3

,, ,, No. 4

,, ,, No. 2

If a rocker-rim noise persists after adjustment, proceed as follows :

Page 70 of 394

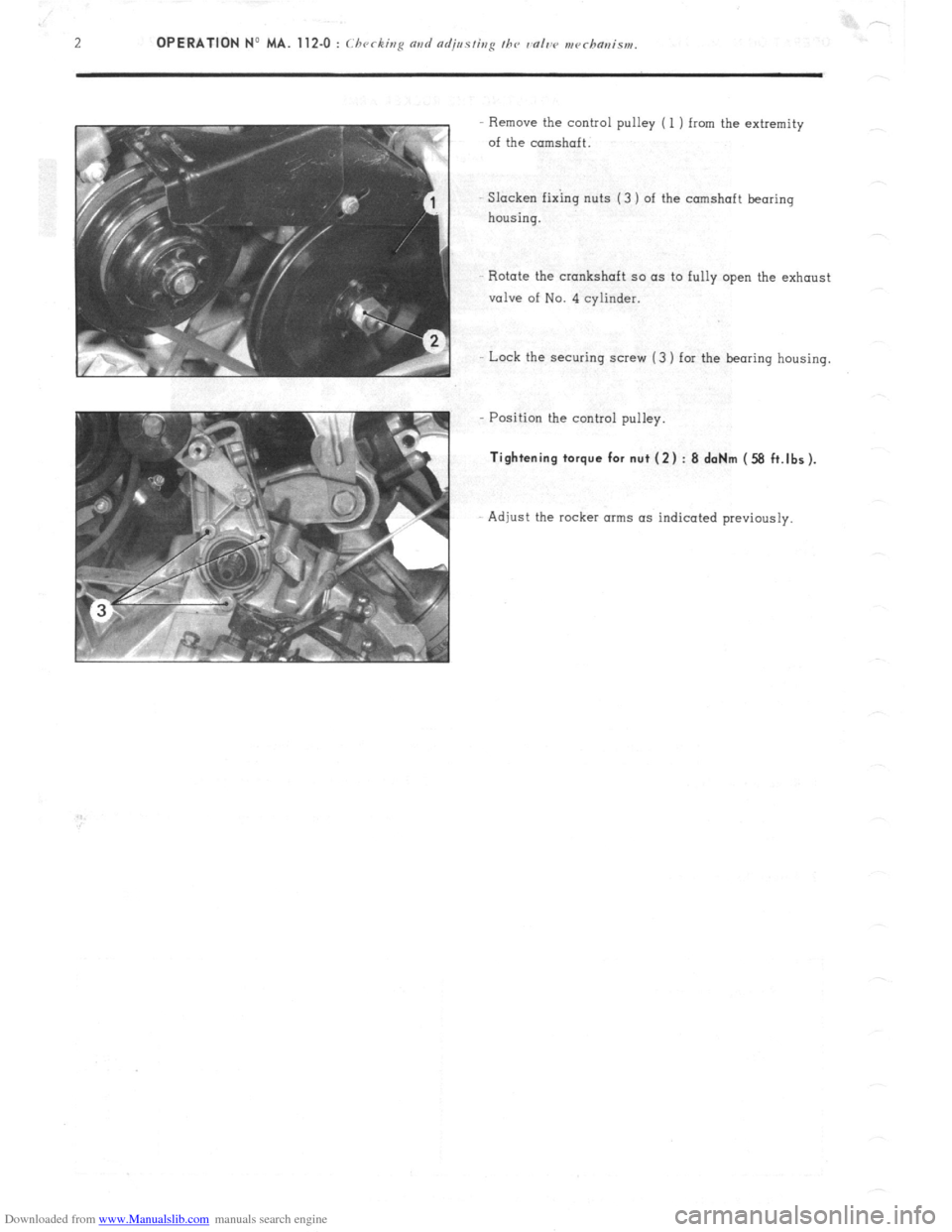

Downloaded from www.Manualslib.com manuals search engine Remove the control pulley ( 1 ) from the extremity

of the camshaft.

SIacken fixing nuts (3 ) of the camshaft bearing

housing.

Rotate the crankshaft so as to fully open the exhaust

valve of No. 4 cylinder.

Lock the securing screw (3 ) for the bearing housing.

Position the control pulley.

Tightening torque for nut (2) : 8 daNm (58 ft.lbs).

Adjust the rocker arms as indicated previously.

Page 78 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 142-000 : Gcnrrd 1.cnturcs 01. the cnrfxrr~tion. Op. MA. 142-000 7

In order to conform to current regulations, checking and adjustment the exhaust emission on u Petrol )) vehicles must

without fail be carried out after the following operations :

I. REPLACEMENT OF ENGINE.

II. REPLACEMENT OF CARBURETTOR.

Ill. WORKING ON THE CARBURATION

- Replacing the components of the carburettor

- Adjusting the carburettor

- Worki? - rri the carburettor controls

IV. WORKING ON THE INLET SYSTEM

Replacing or removing the following :

the inlet manifold,

- the air-filter,

- the crankcase gases recycling system.

V. WORKING ON THE ENGINE

Adjusting the rocker arms

Replacing or removing the following :

the cylinder head,

- the camshaft,

- the rockers,

- the valves,

_ the barrels and pistons.

VI. WORKING ON THE IGNITION

- Replacing or reconditioning the distributor ( partly or cpmpletely )

~ Adjusting or replacing the spark plugs

- Adjusting the ignition timing

VII. WORKING ON THE EXHAUST SYSTEM

Replacing or removing the following :

- the exhaust manifold,

- the exhaust pipe, or any other section of the exhaust system.

VIII. WORKING ON THE ANTI-POLLUTION SYSTEM

When the vehicle is fitted with special equipment C I c,hic-1~s /or SWIIllI:‘S. Al'S7'KAl.l~ll m;d JAI'A.\. /ot

Page 104 of 394

Downloaded from www.Manualslib.com manuals search engine OPEdATlON N- MA.IE. 144-00 : C1 3aractcJristics o/ the e L-Jetro~ic n elcctrorlir Op. MA.IE. 144-00 9

fuel injectian systwn. E.C.U; ( ELECTRONIC CONTROL UNIT )

Apart from three integrated circuits ( I.C. ) forming the main part of the E.C.U., there are in addition only a few

semi-conducting components condensers, calibrating resistors and filters so as to avoid.any interference.

I

The function of the E.C.U. is ,to supply an impulse to the injectors, and to control their opening for a precisely

defined amount of time. The E.C.U. to this effect uses the information provided by all the engine sensors which

translate the operating conditions of the engine into electric impulses.

All the injectors are connected in parallel, and inject fuel simultaneously twice for each rotation of the camshaft

( therefore,twice for each engine cycle ), injecting half the quantity of fuel required each time With this system

it is not necessary for the camshaft angle to coincide with the beginning of injection point, which eliminates the

need for a generating switch incorporated in the distributor.

The injection impulse control is ensured by the distributor impulses. The distributor produces four impulses for

every operational cycle. Since injection only occurs twice in every cycle, the E.C.U. must divide the frequency

by 2.

The impulses coming from the distriLti, are transformated into square waves by the waveform shaper. Since

injection only occurs twice for each camshaft rotation, whereas the distributor provides 4 impulses in the same

amount of time, the frequency of the impulses must be divided by 2 in the frequency divider.

These signals are used to charge a condenser. The condenser discharge determines the beginning of injection

point; the position of the air-flow sensor flap ( which determines the quantity of air drawn in ) being the main

parameter for calculating the duration of injection.

At the multiplying stage of the E.C.U., various correction values ( full load and idling speed via throttle butterfly

spindle switch, engine temperature via the water temperature sensor, air temperature via the air-temperature sensor

located in the air-flow sensor ) are combined with the signals from the air-flow sensor and the injt,ztion frequency

in order to determine the injection duration which is transmitted to the injectors by way of impulses.

The time it takes for the injector needle to open and close depends on the battery voltage.

As the supply voltage increases, the injection duration increases.

The fact that the quantity of fuel injected depends

on the voltage is cancelled out by the fact that the injection duration is inversely proportional to the voltaqq,in the

E.C.U.

The final impulse determines the time during which the injectors are connected to earth ( injection duration ‘supplied

by the output stage ).

Page 108 of 394

Downloaded from www.Manualslib.com manuals search engine INJECTORS ( i ) :

Each cylinder is supplied by an electro-magnetically controlled injector which is fitted in the inlet duct;

the injector vaporises the fuel upstream of the inlet valve. In the case of the (( L-Jetronic )) system. all the

injectors operate simultaneously. However, in order to ensure regular fuel supply to the cylinders, there are

two injections for each rotation of the camshaft, each one supplying half the metered quantity of fuel required I

for the complete engine cycle.

The injector consists of a valve housing and an injector needle fitted with a magnetic core. The mobile magnetic

/

core is in one piece with the needle which in turn is compressed against the air-tight injector housing seat by

a helicoidal spring. At the rear end of the injector, there is a solenoid. and at the front a guide for the injector

needle.

Impulses coming from the E.C.U. create a magnetic.field in the solenoid; the magnetic core is attracted, and the

needle lifts off its seat the fuel under pressure is free to pass through, The movement of the magnetic core is

approximately 0.15 mm.

The duration of opening is determined by the E.C.U. as a function of the operating conditions of the engine at the

moment in question{. TEMPERATURE SENSORS t(

When the engine is started, for a temperature of approximately - 20” C, it needs two to three times more fuel than

when it has reached normal operating temperature. The enrichment of the mixture must be reduced as the engine

warms up, and must cease as soon as the engine has reached normal operating temperature. In’order to start off

this regulating procedure, the engine temperature must be communicated to the E.C.U. ( Electronic Control Unit ).

This is the object .of the temperature sensors.

The temperature sensor consists of a hollow threaded rod in which is located an NTC Thermistor made in semi-

conducting material. The letters .NTC, which signify (( negative temperature coefficient )) characterise its specific

property : its electrical resistance decreases as the temperature increases.

The (( L-Jetronic 1) system is fitted with.a water temperature sensor ( 2) and an air temperature sensor, the latter

situated in the air-flow sensor.

Page 150 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 173-O : Chrrkivp fhr prmd s,,pp/> Op. MA. 173.0 1

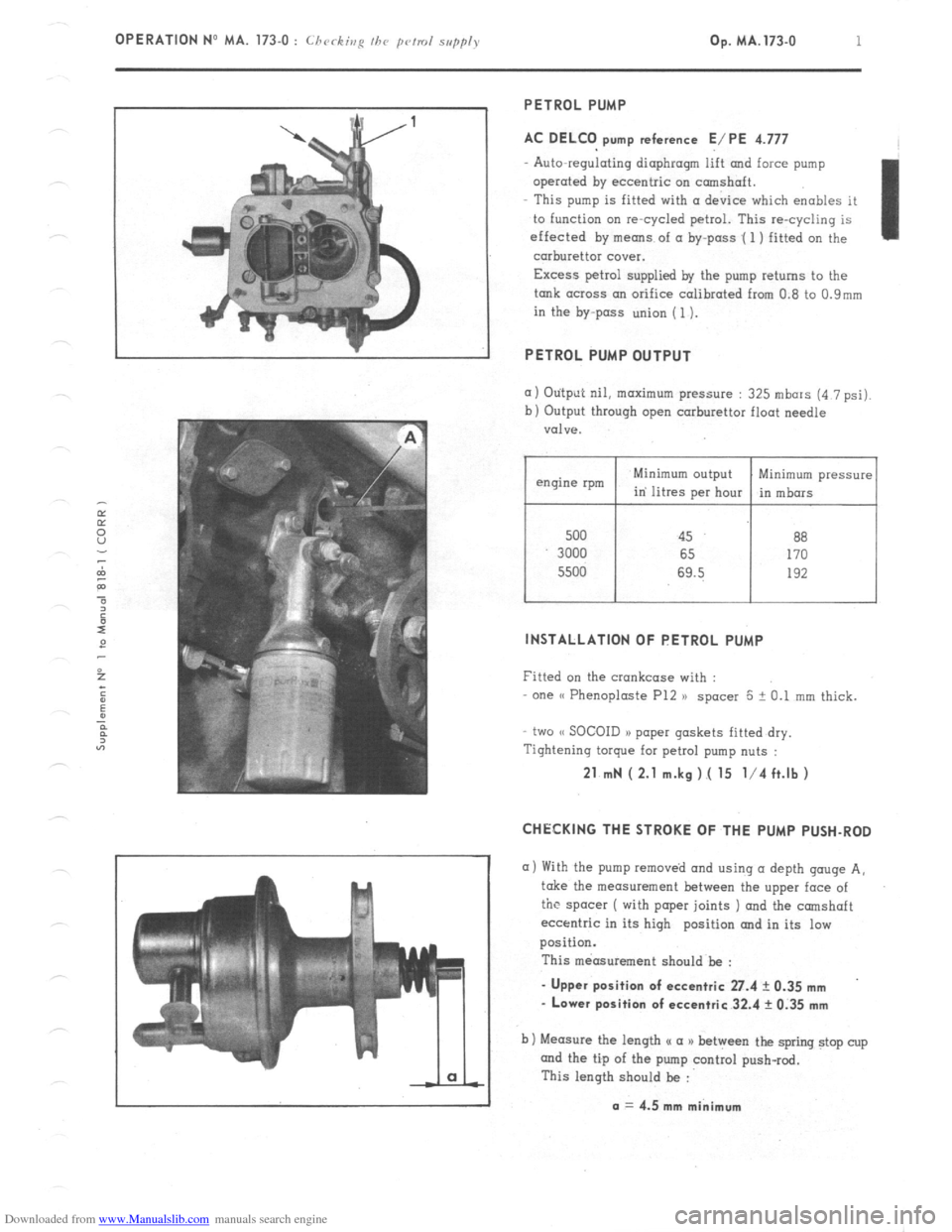

PETROL PUMP

AC DELCO pump reference E/PE 4.777

Auto-regulating diaphragm lift and force pump

operated by eccentric on camshaft.

This pump is fitted with (I device which enables it

to function on re-cycled petrol. This re-cycling is

effected by means of a by-pass .( 1 ) fitted on the

carburettor cover.

Excess petrol supplied by the pump returns to the

tank across an orifice calibrated from 0.8 to 0.9mm

in the by-pass union (1).

PETROL PUMP OUTPUT

(I) Otitput nil, maximum pressure : 325 mbars (4 7 psi).

b) Output through open carburettor float needle

valve.

500 45 88

3000 65 170

5500 69.5 192

I I

Minimum pressure

in mbors

INSTALLATION OF PETROL PUMP

Fitted on the crankcase with :

one (( Phenoploste P12 )) spacer 5 + 0.1 mm thick.

two (< SOCOID a> paper gaskets fitted dry.

Tightening torque for petrol pump nuts :

21 mN ( 2.1 m.kg ).( 15 l/4 ft.lb )

CHECKING THE STROKE OF THE PUMP PUSH-ROD

a) With the pump removed and using (I depth gouge A,

take the measurement between the upper face of

the spacer ( with paper joints ) and the camshaft

eccentric in its high position and in its low

position.

This measurement should be :

- Upper position of eccentric 27.4 ? 0.35 mm

- Lower position of eccentric 32.4 rk 0.35 mm

b) Measure the length u a a) between the spring stop cup

and the tip of the pump control push-rod.

This length should be :

a = 4.5 mm minimum