wiring Citroen CX 1985 1.G Owner's Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1985, Model line: CX, Model: Citroen CX 1985 1.GPages: 394

Page 334 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 510-00 b 17 WIRING DIAGRAMS’FOR COOLING FAN AND AIR-CONDITIONING SYSTEM CONTROL

SPECIAL FEATURES

From 1977 models the fast-idle electro-valve ( 9) is manufactured by 1, PIERBURG 1).

When it is not enerqized the electro-valve lets low pressure through towards the carburettor capsule (fast

idle ) contrary to the (1 WEBER )) electromvalve fitted previously.

Fitting the N PIERBURG )) electro-valve necessitates fitting a relay (8) which is enerqized when the air-

conditioning system is operating This relay, with its c( o/)t/i 1) contact cuts off supply to electro-valve (9)

which therefore produces fast idle. DESCRIPTION OF COMPONENTS :

1

- Heater relay ( .s/o~/~/Q~c/ )

2 - Air blower ( .S~n~~dnr(i i

3 - Speed control for blower ( S/nr/clnrt/ J

4 - Regulating thermostat

5 - Air-conditioning switch 6

- Pressure switch ( 01, dc,-rt,cr/t,rit,,q lnr~k ) 7

- Compressor clutch

8 - Control relay for fast idle melectro-valve

9 - Fast idle electro-valve lo-

Relay for L.H. supplementary electric fan f nip-cor/rli/ior/illS ) 1

I- Supplementary L.H. electric fan ( foolir2~~ ) 12-

Relay for L.H. supplementary electric fan ( cooli~/g ) ?3-

Control thermostat ( on radiator ) for electric fans ( Stnr~d& )

14- Relay for R.H. electric fan ( Stmzdnrrl )

15 Electric cooling fan ( Stal?dn~/ )

Page 339 of 394

Downloaded from www.Manualslib.com manuals search engine 20 OPERATION No MA. 510-00 b : Ivstallatiov oj the c,lcctriral iv~stallatiov

( [KM 9 / I 07 5 )

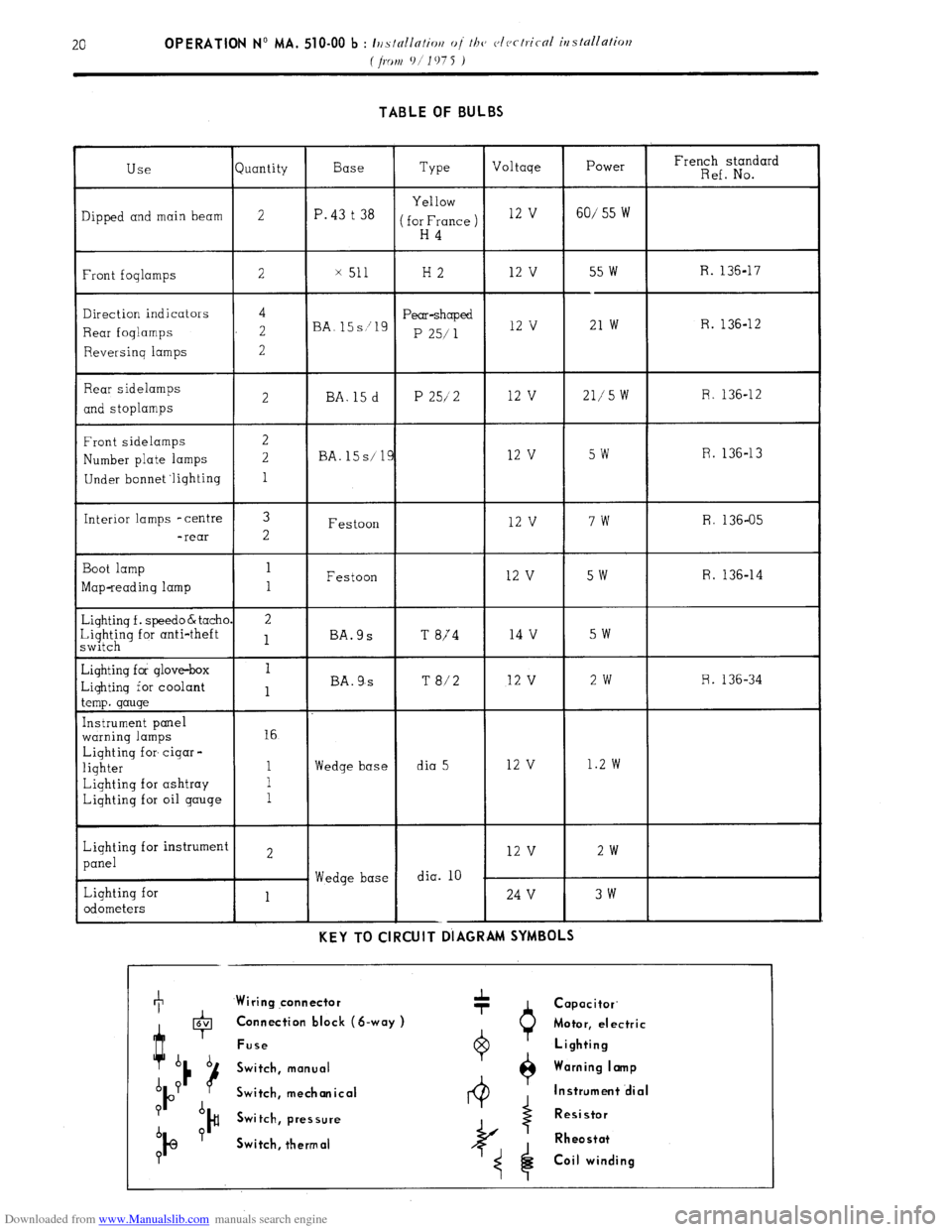

TABLE OF BULBS

juantity Type French standard

Ref. No. Power

60/ 55 W Voltage

12 v Base

P. 43 t 38 Use

lipped and main beam

Front foqlamps

Direction indicators

Rear foqlamps

Reversinq lamps

Rear sidelamps

and stoplamps

Front sidelamps

Number plate lamps

Under bonnet ‘lighting

Interior lamps -centre

-rear

Boot lamp

Map-reading lamp

&iqhtinq f . speed0 & tachl

~~$;~q for anti-theft

diqhtinq for glove-box

-iqhtinq for coolant

.emp. gauge

[nstrument panel

warning lamps

Lighting for cigar -

lighter

Lighting for ashtray

Lighting for oil gauge

Lighting for instrumen

panel

Lighting for

odometers Yellow

for France )

H4 2

x 51 H2 12 V 55 w

--

21 w R. 136-17

4

2

2 Pear-shaped

P 25/ 1 R. 136-12

BA. 12 v

12 v 21,‘5 W R. 136-12

2 BA. 15 d P 25/2

R. 136-13

BA. 15s/ 5w

7w

5w

5w 12 v

12 v

12 v

14 v 3

2 R. 136-05

Festoon

Festoon

BA.9s

T 874 R. 136-14 1

1

2

1

T 8/2 12 v 2w R. 136-34

BA. 9,s

16

Wedge base dia 5 12 v 1.2 w

Wedge base dia. 10 2w 12 v

24 V 3w

1 --

KEY TO CIRCUIT DIAGRAM SYMBOLS +

Wiring qonnector

0 Capacitor.

4 6V Connection block (S-way )

Motor, electric

Fuse Lighting

b b

Switch, manual Warning I amp

A P

P u

Switch, mechanical Instrument .dial

P A

)# Switch, pressure Resistor

b P

IQ Switch, thermal Rheostat

?

Coil winding

Page 341 of 394

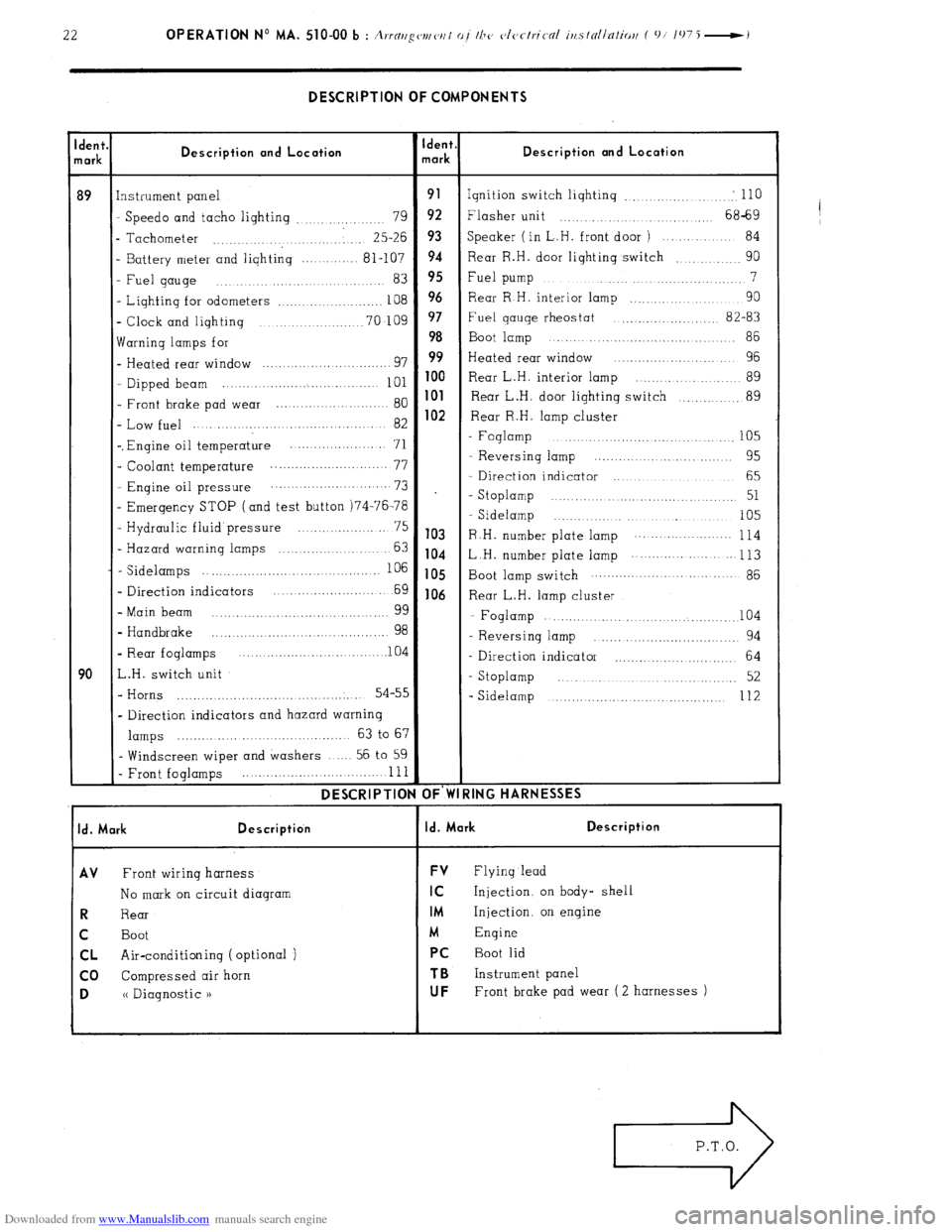

Downloaded from www.Manualslib.com manuals search engine dent,

nark

B9

90

DESCRIPTION OF COMPONENTS

Description and Location

instrument panel

Speed0 and tacho lighting

79 ..............

. Tachometer 25-26

........... ............

I Battery meter and lighting ............ 81-107

Fuel gauge ...................... 83

- Lighting for odometers

...................... 108

- Clock and lighting

.................... 70-109

warning lamps for

- Heated rear window ............................... 97

- Dipped beam ... ..... ............................ 101

- Front brake pad wear ...................... 80

- Low fuel ....

............................ 82

-. Engine oil temperature ..... .................

71

- Coolant temperature ...........................

77

- Engine oil pressure ....... .... ............ ...

73

- Emergency STOP (and test button )74-76-78

- Hydraulic fluid’pressure ................... 75

- Hazard warning lamps ....................... 63

- Sidelamps 106

....................... ..... ..............

- Direction indicators ....... ............... 69

- Main beam

99 .....

.............................. ...

- Handbrake

98 ........ ............ ., .............. ...

- Rear foglamps .......... ................. ..lO 4

L.H. switch unit

- Horns 54-55

..... ....................................

- Direction indicators and hazard warning

lamps ...................................... 63 to 67

- Windscreen wiper and washers ...... 56 to 59

- Front foglamps ........ ....... ................. 111

DESCRIPTIOI dent

nark

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106 Description and Location

Ignition switch lighting .................... : 110

Flasher unit ....................... 68-69

Speaker ( in L..H. front door )

......... 84

Rear R.H. door lighting switch

90 ..........

Fuel pump 7

.............................

Rear R H. interior lamp ....................

90

Fuel qauge rheostat

.................... 82-83

Boot lamp

....................................... 86

Heated rear window

......................... 96

Rear L.H. interior lamp

.................. 89

Rear L.H. door lighting switch

............ 89

Rear R.H. lamp cluster

- Foglamp

..................................... 105

- Reversing lamp .............................

95

- Direction indicator ...................

65

- Stoplamp ........... ......................... 51

- Sidelamp ...........................

105

R .H. number plate lamp .......... ... ........

114

L H. number plate lamp ..... ........... ...

113 Boot lamp switch .................................

86

Rear L.H. lamp cluster

- Foglamp

....................................... 104

- Reversing lamp ................................

94

- Direction indicator ............................. 64

- Stoplamp

........................................ 52

- Sidelamp

... ..... ................................. 112

IING HARNESSES

I Id. Mark Description

I Id. Mark Description

AV

Front wiring harness FV Flying lead

No mark on circuit diaqram

IC Injection. on body- shell

R Rear IM Injection, on engine

C Boot

M Engine

CL Air-conditioning (optional ) PC Boot lid

co Compressed air horn

TB Instrument panel

D (( Diagnostic 1) UF Front brake pad wear ( 2 harnesses )

Page 365 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 640-00 : (:hnrnc-/eris/ics nrtd s.pcc-in/ ~bntttrcs of I/T<< nir- Op. ihA. 640-00 5

c-ottdiliottittg systc~ttt

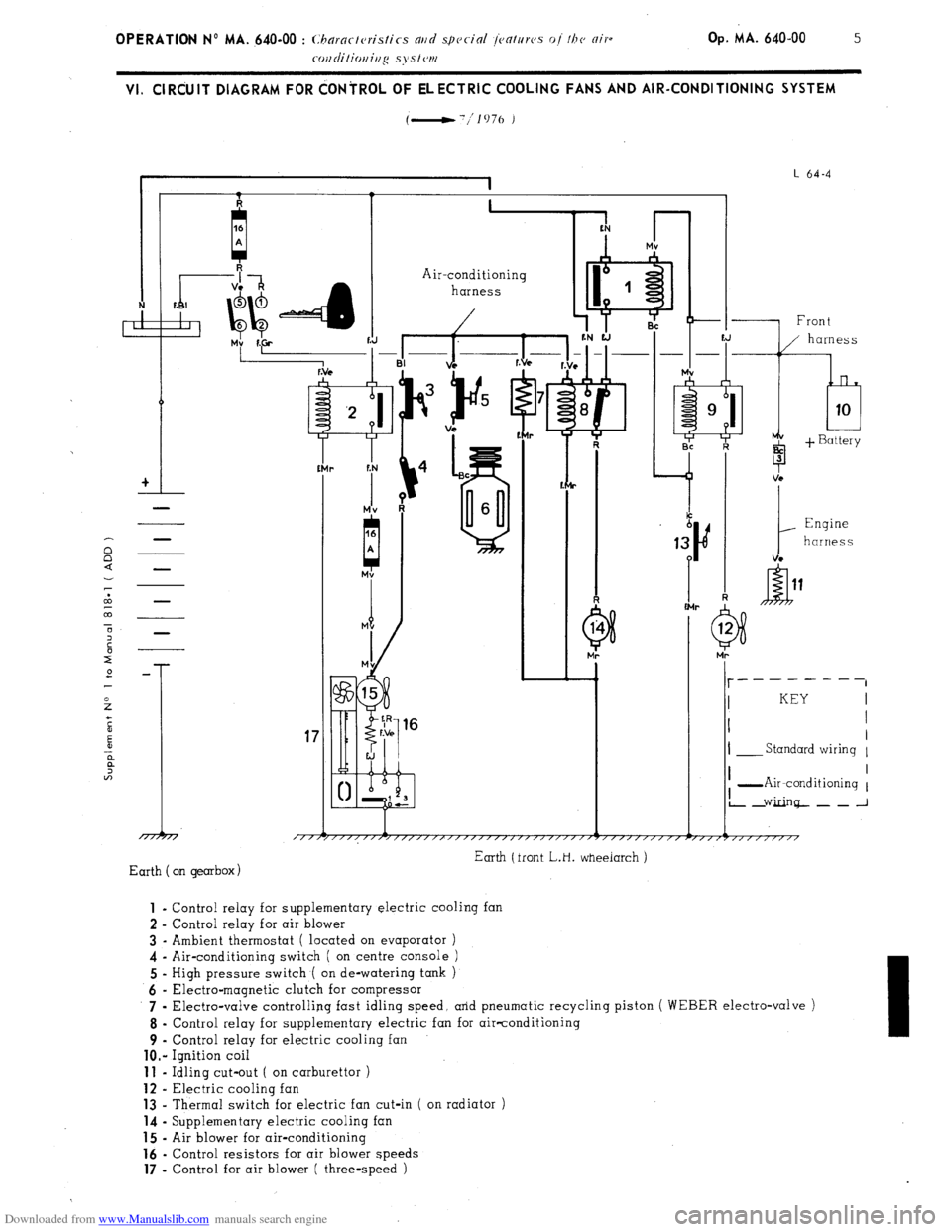

VI. ClRdUlT DIAGRAM FOR dONiROL OF ELECTRIC COOLING FANS AND AIR-CONDITIONING SYSTEM

(-'/lo76 )

I

I L 64-4

I 1. I

+I

-

Air-conditioning

harness

r

-I% ii.+

f:N

r

Mv

A

-1 Front

b 3

1

Engine

harness

VC -

I- __------

I KEY

I I

I

I- Standard wiring 1

17

/TTj I I

I -Air-conditioning 1

L2Ginq--~_J

Earth (front L.H. wheeiarch )

Earth on gearbox) 1

- Control relay for supplementary electric cooling fan

2 - Control relay for air blower

3 - Ambient thermostat ( located on evaporator )

4 - Air-conditioning switch ( on centre console )

5 - High pressure switch ( on de-watering tank )

6 - Electra-magnetic clutch for compressor

7 .

Electra-valve controlling fast idling speed, arid pneumatic recycling piston ( WEBER electro-valve )

8 - Control relay for supplementary electric fan for air-conditioning

9 - Control relay for electric cooling fan

lo.- Ignition coil 11

- Idling cut-out ( on carburettor ) 12

- Electric cooling fan 13

- Thermal switch for electric fan cut-in ( on radiator ) 14

- Supplementary electric cooling fan 15

- Air blower for air-conditioning 16

- Control resistors for air blower speeds 17

- Control for air blower ( three-speed )

Page 367 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION No MA. 640-00 : (hnrnct~~tis~ics md special jenttrrvs of the nir-

coi~ditiouing systcw. 1 Op. MA. 640-00

7

VII. WIRING DIAGRAMS FOR COOLING FAN AND AIR-CONDITIONING SYSTEM CONTROLS

7.; 1976 - Special features :

From 1977 models, the fast-idle electro-valve ( 9) is manufactured by (( PIERBLJRG )).

When it is not energized. the electro-valve lets low pressure through to.wards the carburettor capsule (fast-

idle ) I contrary to the (( WEBER )) electro-valve fitted previously.

Fitting the (( PIERBURG )) electro-valve necessitates fitting a relay (8) which is energized when the air-

conditioning system is operating. This relay with its N open )) contact cuts off supply to electro-valve ( 9)

which therefore produces fast-idle.

The rest of the operation is identical to the preceding diagram. DESCRIPTION OF COMPONENTS :

1

- Heater relay ( standard )

2 - Air blower ( Stmdnrd )

3 - Speed control for blower f Stnudnrd )

4 - Regulating thermostat

5 - Air-conditioning switch

6 - Pressure switch ( on dc-wnkrivg t~rrk ,)

7 - Compressor cl.utch

8 - Control relay for fast-idle electro-valve

9 - Fast-idle electro-valve

10 - Relay f0r’L.H. supplementary electric fan ( air-rorzditio)litlg J 11

i Supplementary L.H. electric fan ( cooliug )

12 - Relay for L.H. supplementary electric fan ( cooling ) 13

- Control thermostat ( on radiator ) for electric fans ( Standard ) 14

- Relay for R.H. electric fan ( Stmzdurd 1

15 - Electric cooling fan ( Stnrrdurd )

e

P.T.O.

Page 375 of 394

Downloaded from www.Manualslib.com manuals search engine 6

OPERATION No MA. 640-O : ( hvrsi~/p nsd ndj/w/isyc /I><, nirr~,s~l;/io,,i,,,~ syc,<,,,,

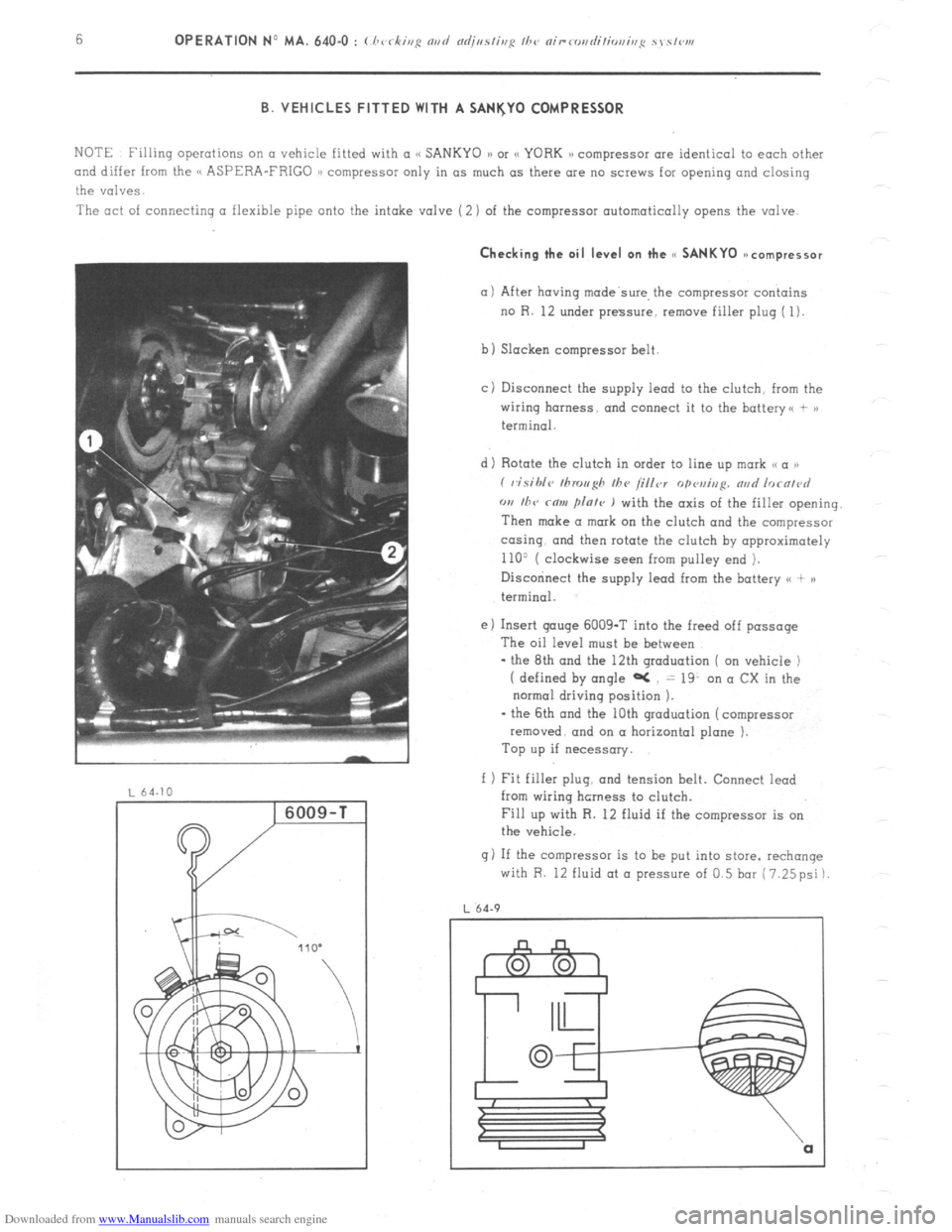

B. VEHICLES FITTED WITH A SANI(Y0 COMPRESSOR

NOTE Filling operations on CI vehicle fitted with a

and differ from the (< ASPERA-FRIGO 1) compressor only in as much as there are no screws for opening and closing

the valves.

The act of connecting a flexible pipe onto the intake valve (2) of the compressor automatically opens the valve. Checking the oil level on the cc SANKYO ~ncompressor

(11 After having made’swe, the compressor contains

no R. 12 under pressure, remove filler plug ( 1).

b) Slacken compressor belt

cj Disconnect the supply lead to the clutch, from the

wiring harness. and connect it to the battery<, + >)

terminal.

d) Rotate the clutch in order to line up mark ,< a ))

( visihlc~ tllrou~h Ihv /i/ler

opvui,,p. nad lorn/~~d

w I/TV rnw flnle ) with the axis of the filler opening.

Then make a mark on the clutch and the compressor

co-sing. and then rotate the clutch by opproximotely

110’ ( clockwise seen from pulley end ).

Disccninect the supply lead from the battery <( + )a

terminal.

e) Insert gouge 6009-T into the freed off passage

The oil level must be between

- the 8th and the 12th graduation ( on vehicle )

( defined by angle aC = 19. on a CX in the

normal driving position ).

- the 6th and the 10th graduation (compressor

removed. and on a horizontal plane ).

Top up if necessary.

f 1 Fit filler plug, and tension belt. Connect iead

from wiring hcrness to clutch.

Fill up with R. 12 fluid if the compressor is on

the vehicle.

g) If the compressor is to be put into store. rechange

with R. 12 fluid at o pressure of 0.5 bar (7.25psi)

L 64.9

Page 380 of 394

Downloaded from www.Manualslib.com manuals search engine Op MA. 642-00 5 II. DEVICE FOR INCREASING THE HEATING OF THE PASSENGER COMPARTMENT

This device entails modifying the following components

- Heater distribution box ( outlets towards side vents unplugged, different radiator )

Side vents with twin outlets ( ambient or heated air )

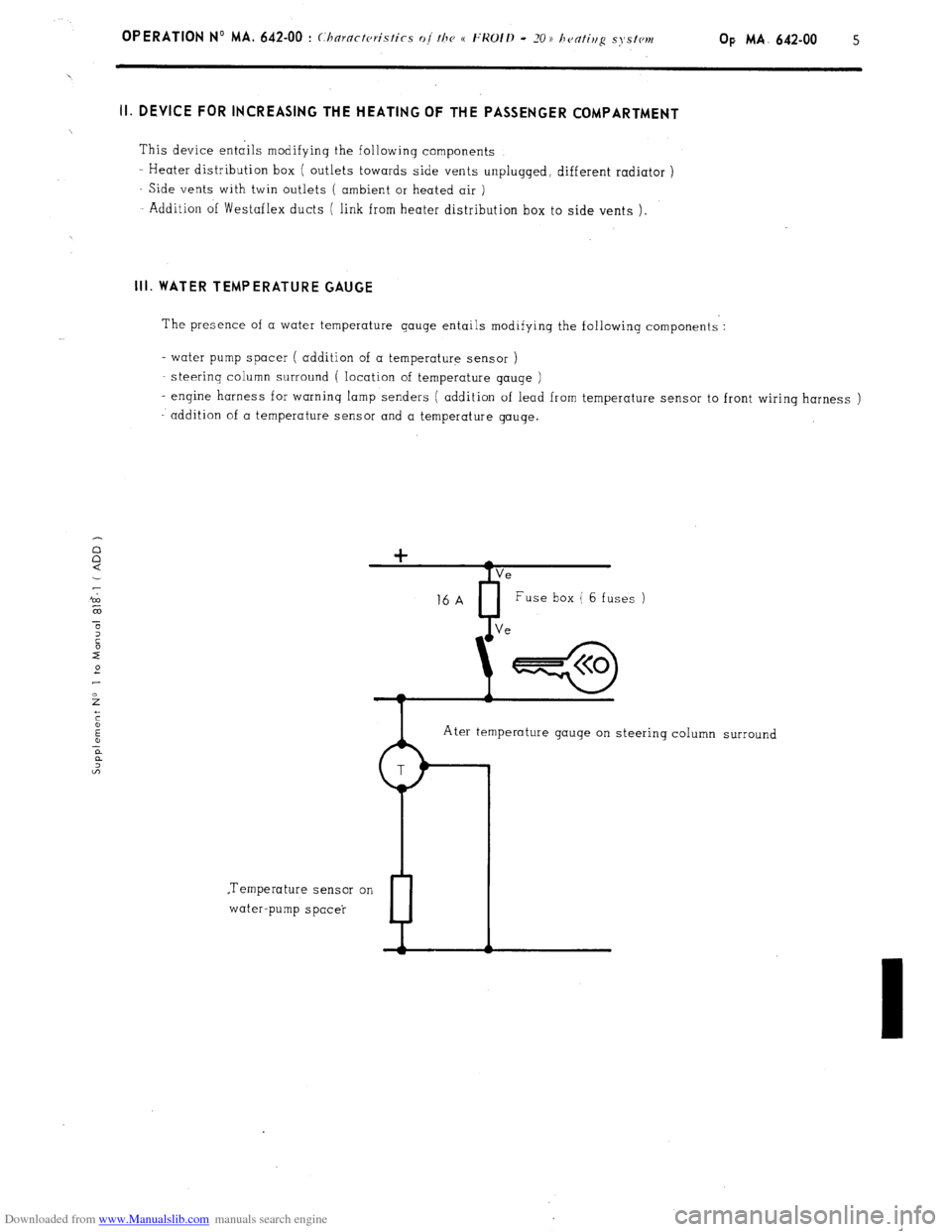

Addition of Westaflex ducts ( link from heater distribution box to side vents ). III. WATER TEMPERATURE GAUGE

The presence of a water temperature gauge entails modifying the following components :

- water pump spacer ( addition of a temperature sensor )

steerinq column surround ( location of temperature gauqe )

- engine harness for warning lamp senders ( addition of lead from temperature sensor to front wiring harness )

addition of a temperature sensor and a temperature gauge.

Ater temperature gauge on steering column surround

.Temperature sensor on

water-pump spacer

P