alternator belt Citroen CX 1985 1.G Workshop Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1985, Model line: CX, Model: Citroen CX 1985 1.GPages: 394

Page 181 of 394

Downloaded from www.Manualslib.com manuals search engine 2

TENSION OF BELTS

RECOMMENDED TENSIONS f /or i//jormation I

Water pump belt :

New belt : ........................................... ................................................. 400 to 450 N ( 40 to 45 kg ) 88 to 99 lb

Run-in belt ...................................................................................... 250 to 300 N ( 25 to 30 kg ) 55 to 66 Ib

Alternator belt :

New belt ......................................................................................... 400 to 450 N ( 40 .to 45 kg ) 88 to 99 lb

Run-in belt .................................................................................. 250 to 300 N ( 25 to 30 kg ) 55 to 66 Ib

Vchicic)s with power slcvring :

H.P. pump belt :’

New belt ........................................................................................... 350 to 400 N ( 35 to 40 kg ) 77 to 88 lb

Run-in belt ............................................................................... 200 to 225 N ( 20 to 22.5 kg ) 44 to 50 lb

Compressor belt :

New belt ......................................................................... ............... 400 to 450 N ( 40 to 45 kg ) 88 to 99 lb

Run-in belt 2% N

..................................................................................

( 25 kg 1 55 Ib

Toothed belt for water pump : ........................................................ 150to180N( 15to18kg)33to40lb

NOTE : Insufficient tension reduces considerably the reliability of the toothed belt.

Tension in excess of 180 N ( 18 kg ) ( 40 Ib ) will cause whistling noises.

Consequently. adjust toothed belt tension as tight as possible without it whistling tighten until it whistles whilst

running. and slacken until the noise disappears.

Page 353 of 394

Downloaded from www.Manualslib.com manuals search engine OPERATION N9 MA. 530.0 : Cbcc-king thv c)lcctrical com&r~cr~ts Op. MA. 530.0 1

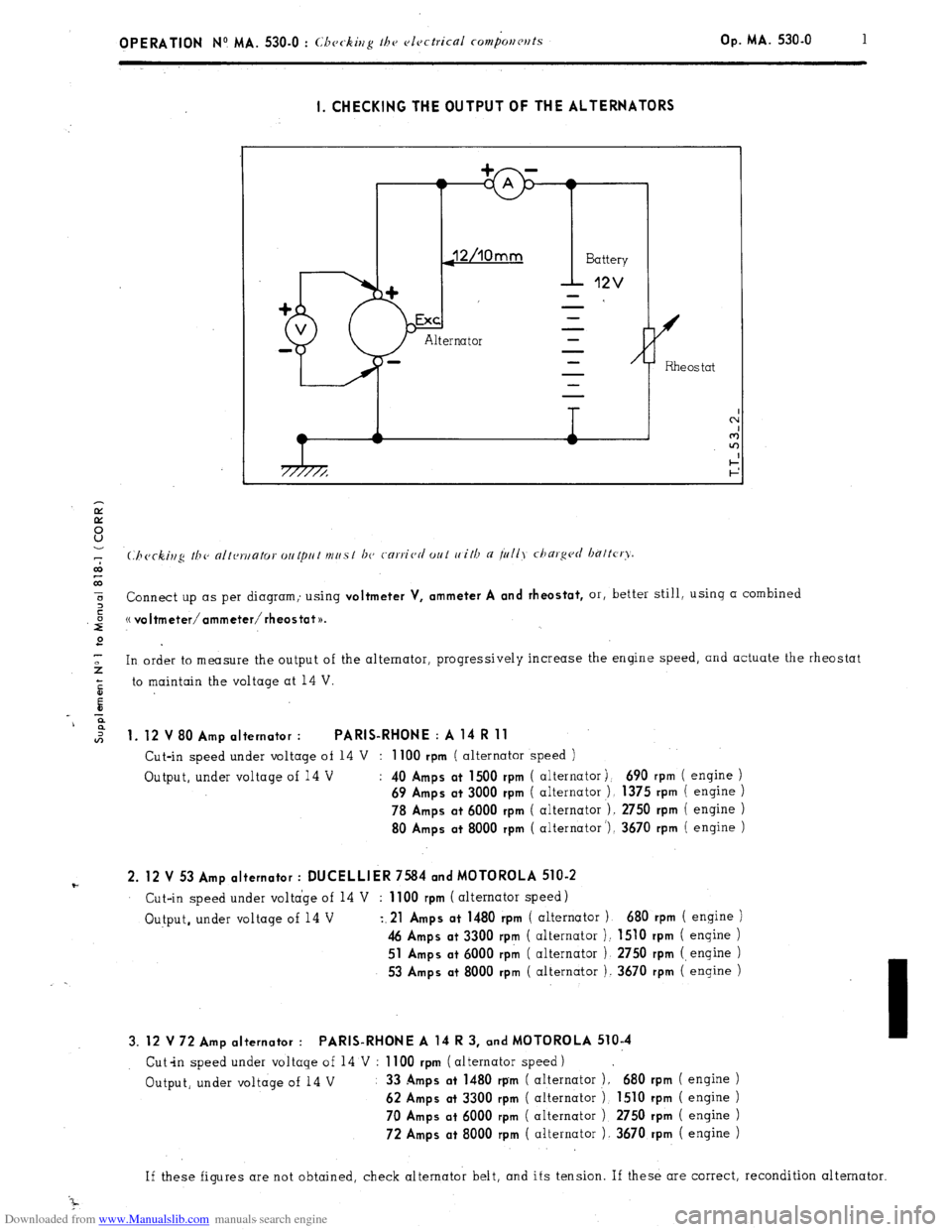

I. CHECKING THE OUTPUT OF THE ALTERNATORS

7

co

co

5 or, better still, using a combined

z Connect up as per diagram; using

voltmeter V, ammeter A and rheostat,

,iiJ (( voItmeter/ammeter/rheostat~~.

2

-

2 In order to measure the output of the alternator, progressively increase the engine speed, and actuate the rheostat

5 to maintain the voltage at 14 V.

E

-c

9

*

1. 12 V 80 Amp alternator : PARIS-RHONE : A 14 R 11

Cut-in speed under voltage of 14 V : 1100 rpm ( alternator speed )

Output, under voltage of 14 V :

40 Amps at 1500 rpm ( alternator j. 690 rpm ( engine )

69 Amps at 3000 rpm ( alternator ), 1375 rpm ( engine )

78 Amps at 6000 rpm ( alternator ). 2750 rpm ( engine )

80 Amps at 8000 rpm ( alternator ‘), 3670 rpm ( engine )

F 2. 12 V 53 Amp alternator : DUCELLIER 7584 and MOTOROLA 510-2 Cut-in speed under voltage of 14 V : 1100 rpm ( alternator speed)

Output, under voltage of 14 V

z.21 Amps at 1480 rpm ( alternator 1 680 rpm ( engine )

46 Amps at 3300 rpm ( alternator ): 1510 rpm ( engine )

51 Amps at 6000 rpk ( alternator ) 2750 rpm (engine )

53 Amps at 8000 rpm ( alternator ). 3670 rpm ( engine )

3. 12 V 72 Amp alternator : PARIS-RHONE A 14 R 3, and MOTOROLA 510-4

Cut-in speed under voltage of 14 V : 1100 rpm ( alternator speed)

Output, under voltage of 14 V : 33

Amps at 1480 rpm ( alternator ). 680 rpm ( engine )

62 Amps at 3300 rpm ( alternator 1 1510 rpm ( engine )

70 Amps at 6000 rpm

( alternator ) 2750 rpm ( engine )

72 Amps at 8000 rpm ( alternator 1. 3670 rpm ( engine )

If these figures are not obtained, check alternator belt, and its tension. If these are correct, recondition alternator

Page 370 of 394

Downloaded from www.Manualslib.com manuals search engine Op. MA. 640-O 1 II CHECKING AND ADJUSTING :

1. Checking the operation of the air-conditioning :

Faulty operation may be due to the following

Insufficient quantity of R.12 fluid, caused by

improper filling 01 a leak.

Water in the system.

Insufficient quantity of fluid may be detected by examining the transparent index mark of the de-watering tank.

This lack of fluid would be shown up by the appearance of air-bubbles during operation.

The presence of water is shown up by the formation of a small quantity of ice near the pressure release valve

which causes irregular functioning of the system.

In both cases. the system must be drained. the circuits niust be put under vwzuum (to eliminate any trace of

water ). and refilled with R.12 fluid. 2. Corburation

: Adjusting the idling speeds (as soon as electric coolinq fans cut out )

a) Vc,hirlcs wi/hou/ loryue con wrtcr :

Engine idling speed 850 to 900 rpm ( compressor switched off )

Fast idling speed 1000 to 1050 rpm ( compressor in operation )

b) Vrhirles with torque co~twrt~~r

Engine idling speed 700 to 750 rpm ( compressor switched off )

Fast idling speed 725 to 775 rpm ( handbrake on, vehicle immobilised. one gear engaged, and compressor

switched off 1

The fast idling speed is adjustable by means of adjusting screw located on top of the vacuum capsule on the

cmburettor. NOTE

: In case the fast idle is impossible to obtain, the vacuum capsule may be moved ( slacken both fixing

screws on carburettor ). in order to reduce the clearance at the fixing point of the rod controlling the first

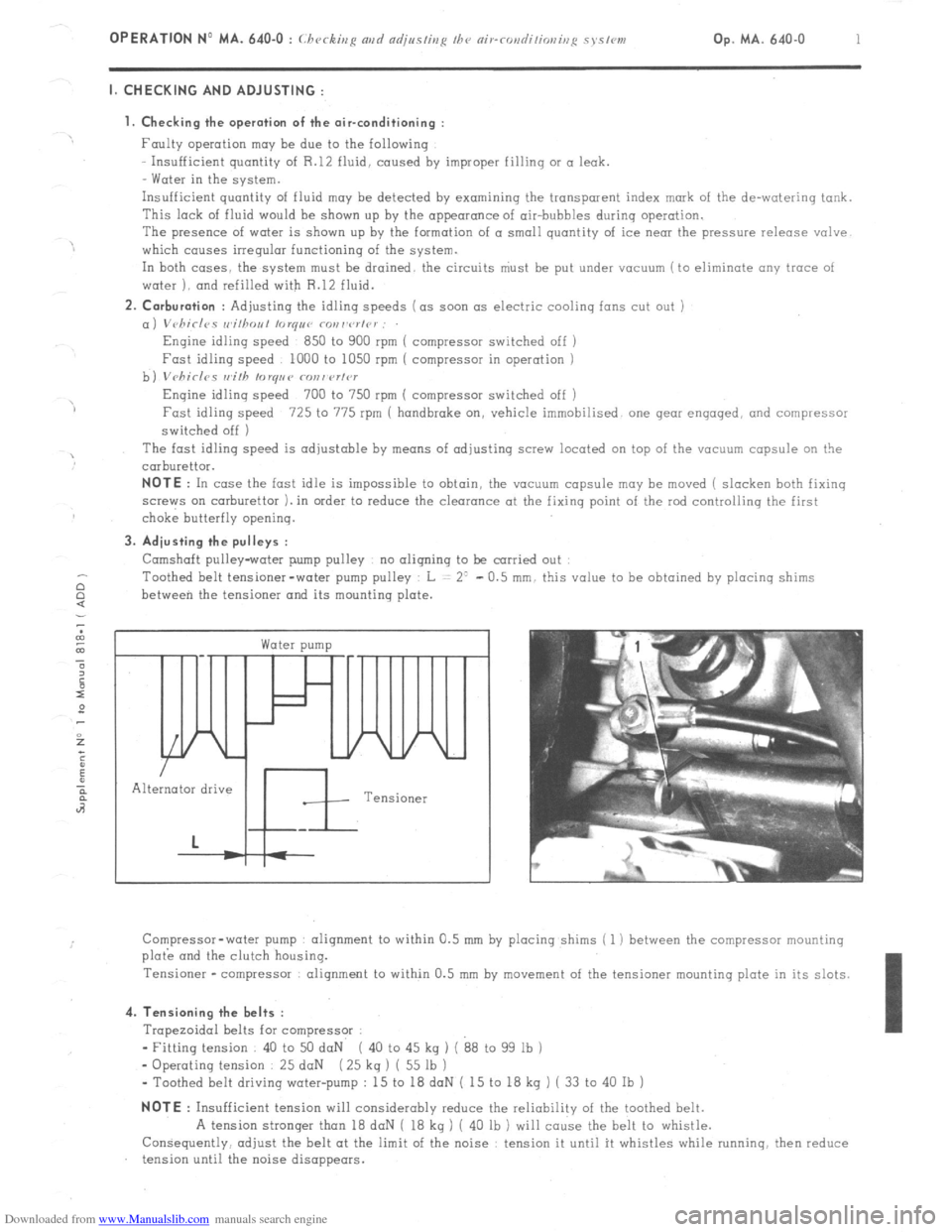

choke butterfly opening. 3. Adjusting the pulleys :

Camshaft pulley-water pump pulley no aligning to be carried out

Toothed belt tensioner-water pump pulley L = 2’ - 0.5 mm. this value to be obtained by placing shims

between the tensioner and its mounting plate. c

Water pump /

In

Alternator drive

Tensioner

Compressor-water pump alignment to within 0.5 mm by placing shims ( 1 ) between the compressor mounting

plo& and the clutch housing.

Tensioner -compressor alignment to within 0.5 mm by

movement of the tensioner mounting plate in its slots. 4. Tensioning the belts :

Trapezoidal belts for compressor :

- Fitting tension 40 to 50 daN ( 40 to 45 kg ) ( 88 to 99 lb )

- Operating tension 25 daN ( 25 kq ) ( 55 lb )

- Toothed belt driving water-pump : 15 to 18 doN ( 15 to 18 kg ) ( 33 to 40 Ib ) NOTE

: Insufficient tension will considerably reduce the reliability of the toothed belt.

A tension stronger than 18 daN ( 18 kg ) ( 40 lb ) will cause the belt to whistle.

Consequently, adjust the belt at the limit of the noise : tension it until it whistles while running. then reduce

tension until the noise disappears.