fuel CITROEN CX 1988 User Guide

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1988, Model line: CX, Model: CITROEN CX 1988Pages: 648, PDF Size: 95.8 MB

Page 216 of 648

Raise the R.H side of the vehicle and support it on

stands.

Disconnect the negative lead from the battery

Engage the highest gear. Using the road wheel, turn

the engine.

Set No. I cylinder to the initial timing point, Fig. I.

(look into the oil filler hole)

- Bring cylinder No. 1 valves into the rocking position

by rotating the engine one turn clockwise.

- Marks- and- should be aligned.

Remove:

- the road wheel,

- the wheelarch lining,

- the belt upper protection cover.

Loosen:

- the injection pump drrvrng pinion nut,

- the belt tensioner nut,

- compress the spring of the tensioner.

Remove:

- the pinion nut,

- the injection pump driving belt. MANDATORY: TO AVOID THE PUMP BEING

DAMAGED INTERNALLY WHEN REMOVING

THE DRIVING PINION, PULLER REF. H AND ITS

NUT J FROM TOOL BOX 6028.T MUST BE

USED.

Fit the nut and clamp of tool 6028.T, Fig. II.

Slacken the nut of tool 6028.T until the injection

pump drive shaft starts moving.

Disconnect the electrical STOP solenoid

Uncouple:

- the accelerator cable,

- the fast idling cable,

- the fuel supply pipe,

- the fuel return pipe.

DPC injection pump, Fig. ill:

Disconnect from the overfuelling circuit:

- the diesel fuel return pipe (21,

- the air pipe (I 1.

Push the diesel fuel filter to one side

Remove:

- the spring,

- the injectors sets of feed pipes,

- the pump fixing nuts (3) Fig. IV.

by means of a 73 mm A/F open spanner

and a 6 mm hexagon Allen key.

Page 218 of 648

REMOVING/REFITTING D.P.A. AND D.P.C.

ROT0 DIESEL INJECTION PUMPS MA

146.1/l 5

REFITTING

Prepare

- the pump (see Op. @ MA 146.0/l/

Fit

- the pump with the mounting studs in the middle of

the slots,

- the pump fixing nuts but do not tighten home.

Assemble, Fig. I:

- the injection pump driving pinion t I); hand tighten

nut (2),

- the pump drive belt with the side opposed to the

tension roller being without slack (take care not to

rotate the pump).

Unscrew, Fig. I:

- tensioner nut (3); let the tensioner load the belt

without assistance.

Retighten, Fig. I:

- tensioner nut (3) to 2 mdaN,

- pinion nut (2) to 5 mdaN.

Carry out the pump timing:

Turn the pump towards the engine to find the point

of injection, (needle facing the “0” mark on the dial).

Screw up, Fig. II, to 2.4 mdaN,

- the pump fixing screws (4); when tightening, the dial

gauge needle should not move.

Check the pump timing (refer to @ MA 146.011)

Remove the tools

Refit:

- either the plug (tighten to 2 mdaN),

- or the inspection plate.

Seal the injection pump plug.

Refit:

- the belt upper protection cover,

- the wheelarch lining,

- the accelerator return spring,

- the injector set of feed pipes.

Tighten to 2.5 mdaN.

Recouple:

- the fast idle cable,

- the accelerator cable,

- the fuel pipe,

- the return pipe, D.P.C. pump, Fig. III.

Connect to the overfuelling circuit,

- the diesel fuel return pipe (61,

- the air pipe (5).

Put the fuel filter back into place.

Reconnect:

- the electric STOP solenoid,

- the negative cable to the battery.

Prime the fuel system using the manually operated

pump located on the filter.

Adjust the injection pump controls and idling speed

as explained in Op. @ MA 146.0/l.

8531

Page 224 of 648

CHECKING THE PETROL SUPPLY

829.A5-J6T.A500

Pump AC DELCO TYPE: PB3

CHECKING THE PETROL PRESSURE WITH APPARATUS 4005-T:

- Position apparatus 4005-T.

- Disconnect the carburettor fuel return pipe; fit plug (2)

- Unscrew tap @ by one turn approx.

- Start the engine.

a) Check the petrol pressure at zero delivery:

- Fully screw up the tap; the pressure should not show a reading of more than 325 m.bar for the stabilised

pressure.

b) Check the tightness of the pump delivery valve:

- Stop the engine: there should not be a sudden drop in pressure.

c) Check the tightness of the carburettor needle valve:

- Unscrew tap @ ; start the engine, leave it running for a few minutes.

- Stop the engine: there should not be a sudden drop in pressure.

- Remove apparatus 4005-T and fit the fuel supply pipe and the fuel return pipe to the carburettor

(after plug (2) has been removed).

CHECKING THE PUMP FOR LEAKS:

Close the pump delivery tube. Blow compressed air under 800 m.bar pressure into the suction pipe. Immerse the

pump in a container filled with clean White Spirit: no leak should be detected.

Page 260 of 648

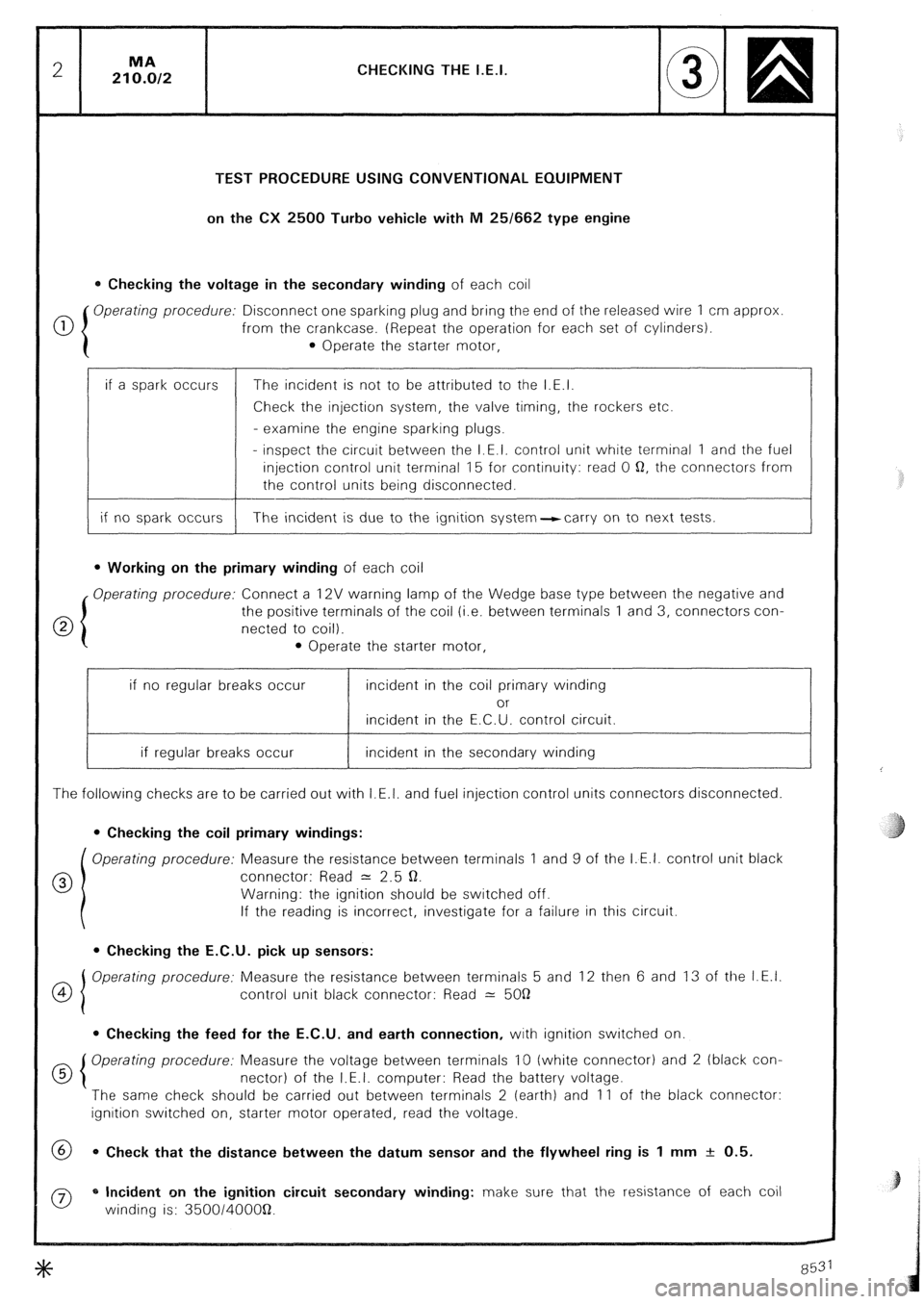

CHECKING THE INTEGRATED ELECTRONlC

IGNITION (I.E.I.)

TEST PROCEDURE USING CONVENTIONAL EQUIPMENT

on the CX 2500 vehicle with M 25/659 type engine

l Checking the voltage in the secondary winding of each coil

0 Operating procedure: Disconnect one sparking plug and bring the end of the released wire 1 cm approx

from the crankcase. (Repeat the operation for each set of cylinders).

l Operate the starter motor:

if a spark occurs The incident is not to be attributed to the I.E.I.

Check the injection system, the valve timing, the rockers etc.

- examine the engine sparking plugs.

- inspect the circuit between the I.E.I. control unit white terminal 1 and the fuel

injection control unit terminal 15 for continuity: read 0 0, the connectors from

the control units being disconnected.

if no spark occurs The incident is due to the ignition system--ccarry on to next tests.

l Working on the primary winding of each coil

Operating procedure: Connect a 12V warning lamp of the Wedge base type between the negative and

0 the positive terminals of the coil (i.e. between terminals 1 and 3, connectors con-

netted to coil).

l Operate the starter motor:

if no regular breaks occur incident in the coil primary winding

or

incident in the E.C.U. control circuit.

if regular breaks occur incident in the secondary winding

The following checks are to be carried out with I.E.I. and fuel injection control units connectors disconnected.

l Checking the coil primary windings:

Operating procedure: Measure the resistance between terminals 1 and 9 of the I.E.I. control unit black

0 connector: Read = 2.5 0.

Warning: the ignition should be switched off.

If the reading is incorrect, investigate for a failure in this circuit.

l Checking the E.C.U. pick up sensors:

co Operating procedure: Measure the resistance between terminals 5 and 12 then 6 and 13 of the I.E.I.

control unit black connector: Read = 50 a.

l Checking the feed for the E.C.U. and earth connection, with ignition switched on

Operating procedure: Measure the voltage between terminals IO (white connector) and 2 (black con-

nector) of the I.E.I. computer: Read the battery voltage.

The same check should be carried out between terminals 2 (earth) and 11 of the black connector:

ignition switched on, starter motor operated, read the voltage.

69 l Check that the distance between the datum sensor and the flywheel ring is 1 mm + 0.5.

0 l Incident on the ignition circuit secondary winding: make sure that the resistance of each coil

winding is: 350014000 a.

8531

Page 261 of 648

CHECKING THE I.E.I.

TEST PROCEDURE USING CONVENTIONAL EQUIPMENT

on the CX 2500 Turbo vehicle with M 25/662 type engine

0 Checking the voltage in the secondary winding of each coil

0 Operating procedure: Disconnect one sparking plug and bring the end of the released wire 1 cm approx

from the crankcase. (Repeat the operation for each set of cylinders).

0 Operate the starter motor,

if a spark occurs

if no spark occurs The incident is not to be attributed to the I.E.I.

Check the injection system, the valve timing, the rockers etc.

- examine the engine sparking plugs.

- inspect the circuit between the I.E.I. control unit white terminal 1 and the fuel

injection control unit terminal 15 for continuity: read 0 Q, the connectors from

the control units being disconnected.

The incident is due to the ignition system-carry on to next tests.

l Working on the primary winding of each coil

Operating procedure: Connect a 12V warning lamp of the Wedge base type between the negative and

the positive terminals of the coil (i.e. between terminals 1 and 3, connectors con-

netted to coil).

l Operate the starter motor,

if no regular breaks occur incident in the coil primary winding

or

incident in the E.C.U. control circuit.

if regular breaks occur incident in the secondary winding

The following checks are to be carried out with I.E.I. and fuel injection control units connectors disconnected.

0 Checking the coil primary windings:

Operating procedure: Measure the resistance between terminals 1 and 9 of the I.E.I. control unit black

0 connector: Read = 2.5 Q.

Warning: the ignition should be switched off.

If the reading is incorrect, investigate for a failure in this circuit.

l Checking the E.C.U. pick up sensors:

OI Operating procedure: Measure the resistance between terminals 5 and 12 then 6 and 13 of the I.E.I.

4

control unit black connector: Read 2: 5OQ

0 Checking the feed for the E.C.U. and earth connection, with ignition switched on.

d 5 Operating procedure: Measure the voltage between terminals 10 (white connector) and 2 (black con-

nectar) of the I.E.I. computer: Read the battery voltage.

The same check should be carried out between terminals 2 (earth) and 11 of the black connector:

ignition switched on, starter motor operated, read the voltage.

@ 0 Check that the distance between the datum sensor and the flywheel ring is 1 mm + 0.5.

0 * Incident on the ignition circuit secondary winding: make sure that the resistance of each coil

winding is: 350014OOOQ.

Page 264 of 648

CHECKING THE IGNITION SYSTEM

USING CHECKING EQUIPMENT OUT 106 029T

The instrument can be utilised on CX 2400 I.E. with naturally aspirated engine and CX 2500 I.E. TURBO. Howe-

ver, on CX 2400 I.E. having an integrated electronic ignition system with a single connector E.C.U., it is neces-

sary to proceed as follows:

- connect the I.E.I. control unit to the black connector of OUT 105 029.T

- set the switch of the apparatus to the “1 connector” position

- I.E.I. with 1 or 2 sensors can be checked with this device.

a) Testing the ignition coil primary winding:

- The warning lamps, one at each coil, blink rythmically with the impulses transmitted to their primary win-

ding. Steady blinks indicate that there is enough current to generate a spark in the secondary winding.

- The switch situated under the warning lamps makes it possible for the primary windings of both coils to

be insulated, by pushing, in the “out of circuit“ position, any interference coming from the HT circuit when

the frequency of illumination for sensor warning lamps is checked.

- If the warning lamps blinking is correct, the failure may be caused by:

- the ignition information to the fuel injection control unit, (paragraph c),

- the secondary winding (coil wires, coils),

- any other item required for a correct operation of the engine such as injection, valve gear, rockers etc.) -

If the warning lamps blinking is not correct, examine the control unit warning lamps, (paragraph b),

b) Testing the sensors: -

The warning lamp connected with the “datum” sensor blinks rythmically with the impulses transmitted by

the peg, i.e. one blink per engine revolution, (2 sensors fitted).

- The warning lamp connected with the “flywheel pick up” sensor, blinks rythmically with the impulses sent ’

by the flywheel teeth.

The frequency of the flashes is such as they can hardly be seen.

Apparently, the lamp stays on, (1 or 2 sensors fitted).

On the CX 2400 I.E. and 2500 I.E. with normally aspirated engine, the vacuum pressure warning lamp lights

up momentarily after a sharp acceleration: this warning lamp is no longer usable on the CX 2500 I.E. with

turbocharger.

c) Tests related with the I.E.I. control unit:

E.C.U. functions: -

The rev. counter warning lamp blinks rythmically with the impulses transmitted to the rev. counter.

- The injection warning lamp blinks rythmically with the impulses sent to the fuel injection control unit

+k 8531

Page 385 of 648

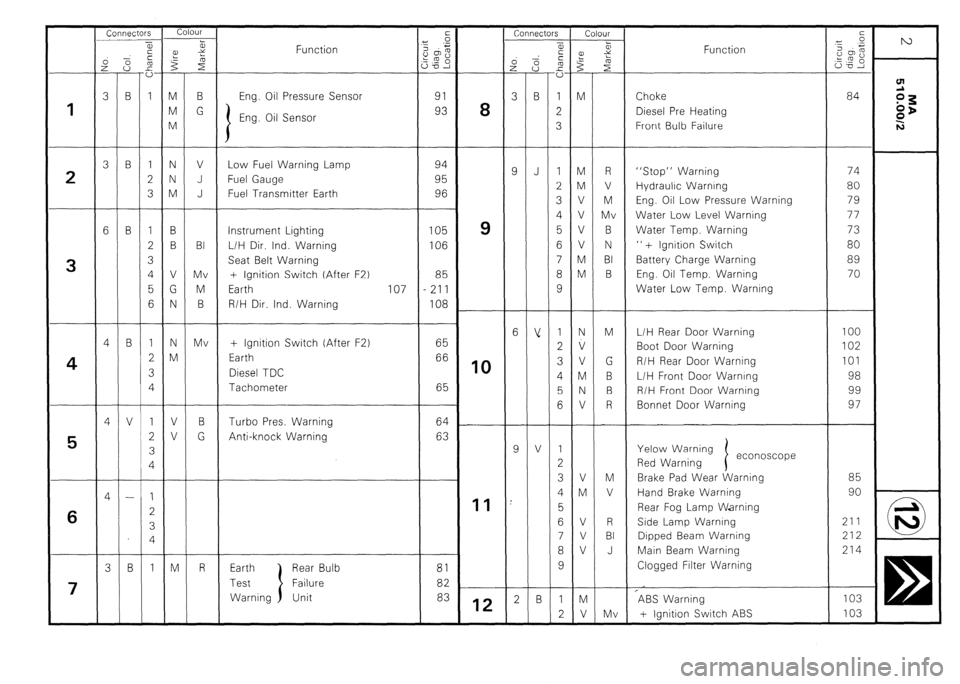

Connectors

l.-~l

a,

- Connectors

,”

9 r, 75 Colour

FiY

E

vl

-

M

M

V

V

V

V

M

M

-

N

v

V

M

N

V

-

V

M

V

V

V

-

M

V

2

$

R

V

M

Mv

B

N

BI

B

Mv . -

z

Y

i

r”

B

G Function Function

:

m

.e-

1

-

1

2

3

-

1

2

3

4

1

2

3

4

I

2

3

4

-

1 .-

f

-

M

M

M

-

N

N

M

-

B

B

V

G

N

-

N

M

-

V

V

-

-

M 1

2

3

-

-

-

-

1

2 -

3 -

6 -

4 -

4 -

4 -

3

1

3

-

9

-

6

-

9

-

2

L.

B

-

J

-

v

-

V

-

B

m

sg

ZD

‘N

B

-

B

-

B

-

B

-

V

-

-

-

B Eng. Oil Pressure Sensor

94

95

96 Choke

Diesel Pre Heating

Front Bulb Failure 84

I 8

1

Eng. Oil Sensor

V

J

J Low Fuel Warning Lamp

Fuel Gauge

Fuel Transmitter Earth “Stop” Warning

Hydraulic Warning

Eng. Oil Low Pressure Warning

Water Low Level Warning

Water Temp. Warning

” + Ignition Switch

Battery Charge Warning

Eng. Oil Temp. Warning

Water Low Temp. Warning

2 74

80

79

77

73

80

89

70

100

102

101

98

99

97

85

90

211

212

214

103

103

9

10

11 Instrument Lighting

L/H Dir. Ind. Warning

Seat Belt Warning

+ Ignition Switch (After F2)

Earth 107

R/H Dir. Ind. Warning 105

106

85

211

108

65

66

65 BI

Mv

M

B

Mv

3

L/H Rear Door Warning

Boot Door Warning

R/H Rear Door Warning

L/H Front Door Warning

R/H Front Door Warning

Bonnet Door Warning + Ignition Switch (After F.2)

Earth

Diesel TDC

Tachometer

4

B

G Turbo Pres. Warning

Anti-knock Warning 64

63

Yelow Warning

Red Warning econoscope

5

Brake Pad Wear Warning

Hand Brake Warning

Rear Fog Lamp Warning

Side Lamp Warning

Dipped Beam Warning

Main Beam Warning

Clogged Filter Warning

0 ic 6

R Earth

Test

Warning Rear Bulb

Failure

Unit 81

82

83

7

12 ?ABS Warning

+ Ignition Switch ABS

Page 388 of 648

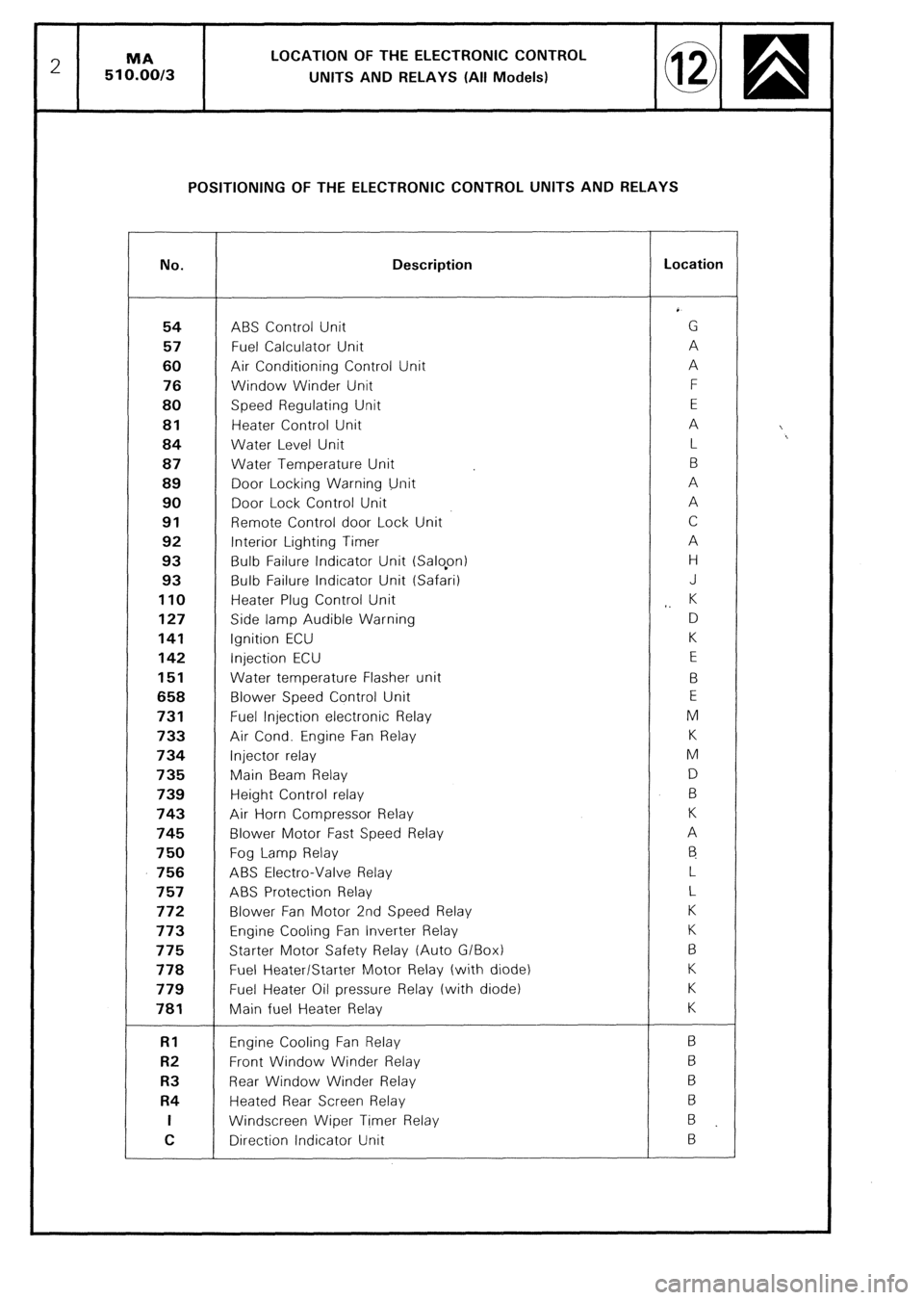

2 MA LOCATION OF THE ELECTRONIC CONTROL

510.00/3

UNITS AND RELAYS (All Models)

POSITIONING OF THE ELECTRONIC CONTROL UNITS AND RELAYS

No. Description Location

54 ABS Control Unit G

57 Fuel Calculator Unit A

60 Air Conditioning Control Unit A

76 Window Winder Unit F

80 Speed Regulating Unit E 81

Heater Control Unit A

84 Water Level Unit L

87 Water Temperature Unit B

89 Door Locking Warning Unit A

90 Door Lock Control Unit A 91

Remote Control door Lock Unit C

92 Interior Lighting Timer A

93 Bulb Failure Indicator Unit (Salopn) H

93 Bulb Failure Indicator Unit (Safari) J 110

Heater Plug Control Unit

,. K 127

Side lamp Audible Warning D 141

Ignition ECU K 142

Injection ECU E 151

Water temperature Flasher unit B 658

Blower Speed Control Unit E 731

Fuel Injection electronic Relay M 733

Air Cond. Engine Fan Relay K 734

Injector relay M 735

Main Beam Relay D

739 Height Control relay B 743

Air Horn Compressor Relay K 745

Blower Motor Fast Speed Relay A 750

Fog Lamp Relay

6 756

ABS Electra-Valve Relay L 757

ABS Protection Relay L 772

Blower Fan Motor 2nd Speed Relay K 773

Engine Cooling Fan lnverter Relay K 775

Starter Motor Safety Relay (Auto G/Box) B 778

Fuel Heater/Starter Motor Relay (with diode) K

779 Fuel Heater Oil pressure Relay (with diode) K 781

Main fuel Heater Relay K RI

Engine Cooling Fan Relay B R2

Front Window Winder Relay 6 R3

Rear Window Winder Relay B R4

Heated Rear Screen Relay 6 I

Windscreen Wiper Timer Relay

B

C Direction Indicator Unit B

Page 393 of 648

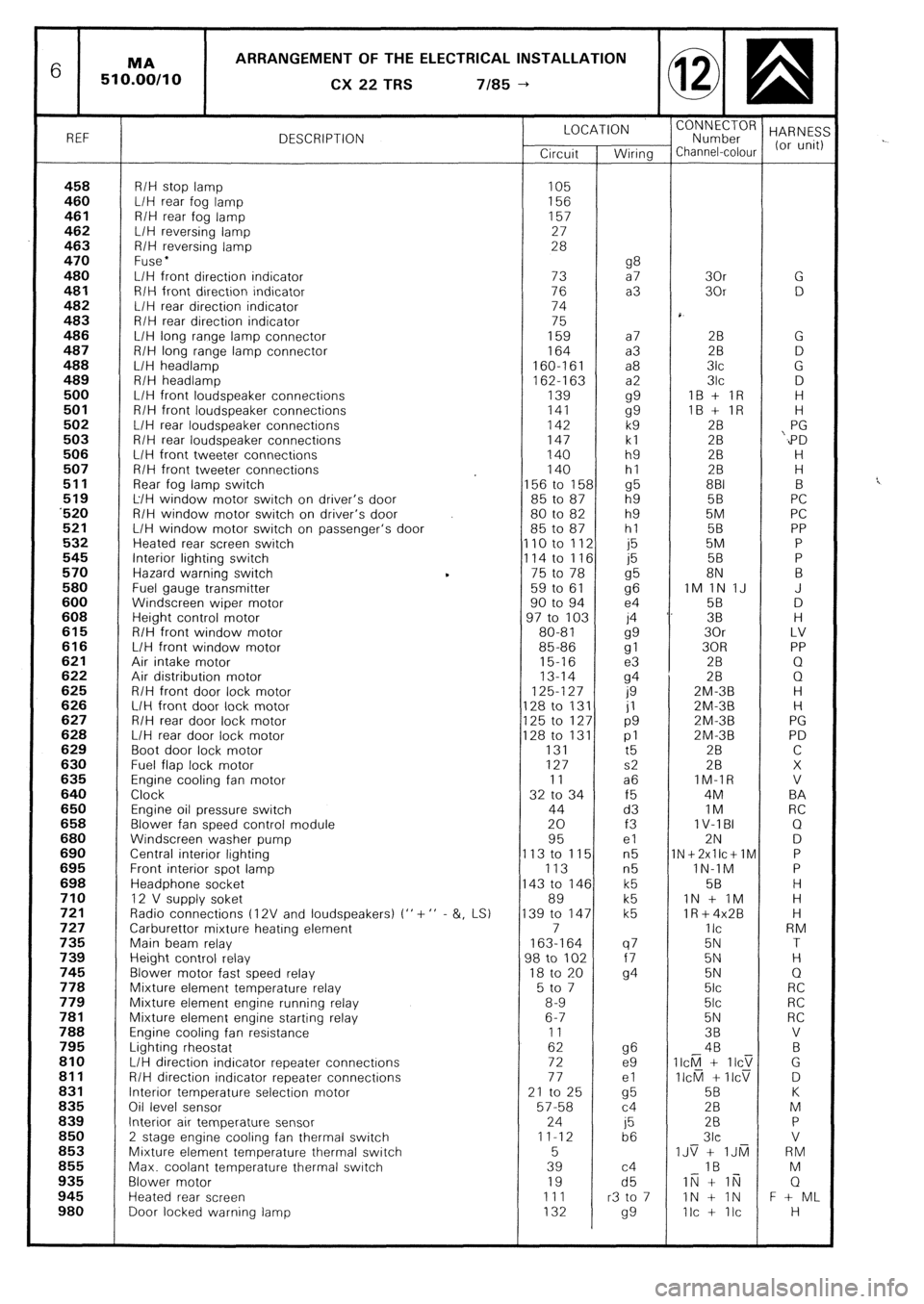

6 ARRANGEMENT OF THE ELECTRICAL INSTALLATION

CX

22 TRS 7185 --)

REF DESCRIPTION LOCATION

“;;;;;roR HARNES:

Circuit Wiring Channel-colour (or unit)

458 R/H stop lamp 105 460 L/H rear fog lamp 156 461 R/H rear fog lamp 157

462 L/H reversing lamp 27

463 R/H reversing lamp 28

470 Fuse l 480 g8 L/H front direction indicator 73 a7 30r G 481 R/H front direction indicator 76 a3 30r D 482 L/H rear direction indicator 74

483 R/H rear direction indicator 75

486 L/H long range lamp connector 159 a7 28 G 487 R/H long range lamp connector 164 a3 2B D 488 L/H headlamp 160-161 a8 3lc G

489 R/H headlamp

162-l 63 a2 3lc D 500 L/H front loudspeaker connections 139

gg IB + IR H 501 R/H front loudspeaker connections 141

gg IB + IR H 502 L/H rear loudspeaker connections 142 k9 28 PG 503 R/H rear loudspeaker connections 147 kl 28 ‘,PD 506 L/H front tweeter connections 140 h9 2B H 507 R/H front tweeter connections 140 hl 28 H

511 Rear fog lamp switch 156 to 158 g5 881 B 519 L/H window motor switch on driver’s door 85 to 87 h9 5B PC ‘520 R/H window motor switch on driver’s door 80 to 82 h9 5M PC 521 L/H window motor switch on passenger’s door 85 to 87 hl 58 PP 532 Heated rear screen switch 110 to 112 j5 5M P 545 Interior lighting switch

114 to 116 j5 58 P 570 Hazard warning switch 75 to 78

g5 8N B 580 Fuel gauge transmitter 59 to 61

96 IM 1N IJ J 600 Windscreen wiper motor 90 to 94 e4 58 D 608 Height control motor 97 to 103 j4 ‘. 38 H 615 R/H front window motor 80-81

gg 30r LV 616 L/H front window motor 85-86

gl 30R PP 621 Air intake motor 15-16 e3 2B Q 622 Air distribution motor 13-14

94 28 0 625 R/H front door lock motor 125-127

0 ZM-3B H 626 L/H front door lock motor 128 to 131 jl ZM-3B H 627 R/H rear door lock motor 125 to 127 p9 2M-3B PG 628 L/H rear door lock motor 128 to 131 pl 2M-3B PD 629 Boot door lock motor 131

t5 2B C 630 Fuel flap lock motor 127 s2 28 X 635 Engine cooling fan motor 11 a6 IM-IR V 640 Clock 32 to 34 f5 4M BA 650 Engine oil pressure switch 44 d3 IM RC 658 Blower fan speed control module 20 f3 1 V-l BI Q 680 Windscreen washer pump 95 el 2N D 690 Central interior lighting 113 to 115 n5 1N+2xllc+lM P 695 Front interior spot lamp 113 n5 lN-1M P 698 Headphone socket 143 to 146 k5 58 H 710 12 V supply soket 89 k5 IN + IM H 721 Radio connections t 12V and loudspeakers) I” + ” - &, LS) 139 to 147 k5 lR+4x2B H 727 Carburettor mixture heating element 7 IIC RM 735 Main beam relay 163-164 q7 5N T 739 Height control relay 98 to 102 f7 5N H 745 Blower motor fast speed relay 18 to 20

94 5N Q 778 Mixture element temperature relay 5 to 7 5lc RC 779 Mixture element engine running relay 8-9 5lc RC 781 Mixture element engine starting relay 6-7 5N RC 788 Engine cooling fan resistance 11 38 V 795 Lighting rheostat 62 g6 4B B 810 L/H direction indicator repeater connectrons 72 e9 II&l + IICT G 811 R/H direction indicator repeater connections 77 el II&l + IICV D 831 Interior temperature selection motor 21 to 25

cl5 5B K 836 Oil level sensor 57-58 c4 28 M 839 Interior air temperature sensor 24

j5 28 P 850

2 stage engine cooling fan thermal switch 11-12

b6 3lc V 853 Mixture element temperature thermal switch 5 IJS + IJti RM 855 Max. coolant temperature thermal switch 39 c4 IB M 935 Blower motor 19 d5 IN + li;j Q 945 Heated rear screen 111 r3 to 7 IN + IN F + ML 980 Door locked warning lamp 132

99 Ilc + Ilc H

Page 399 of 648

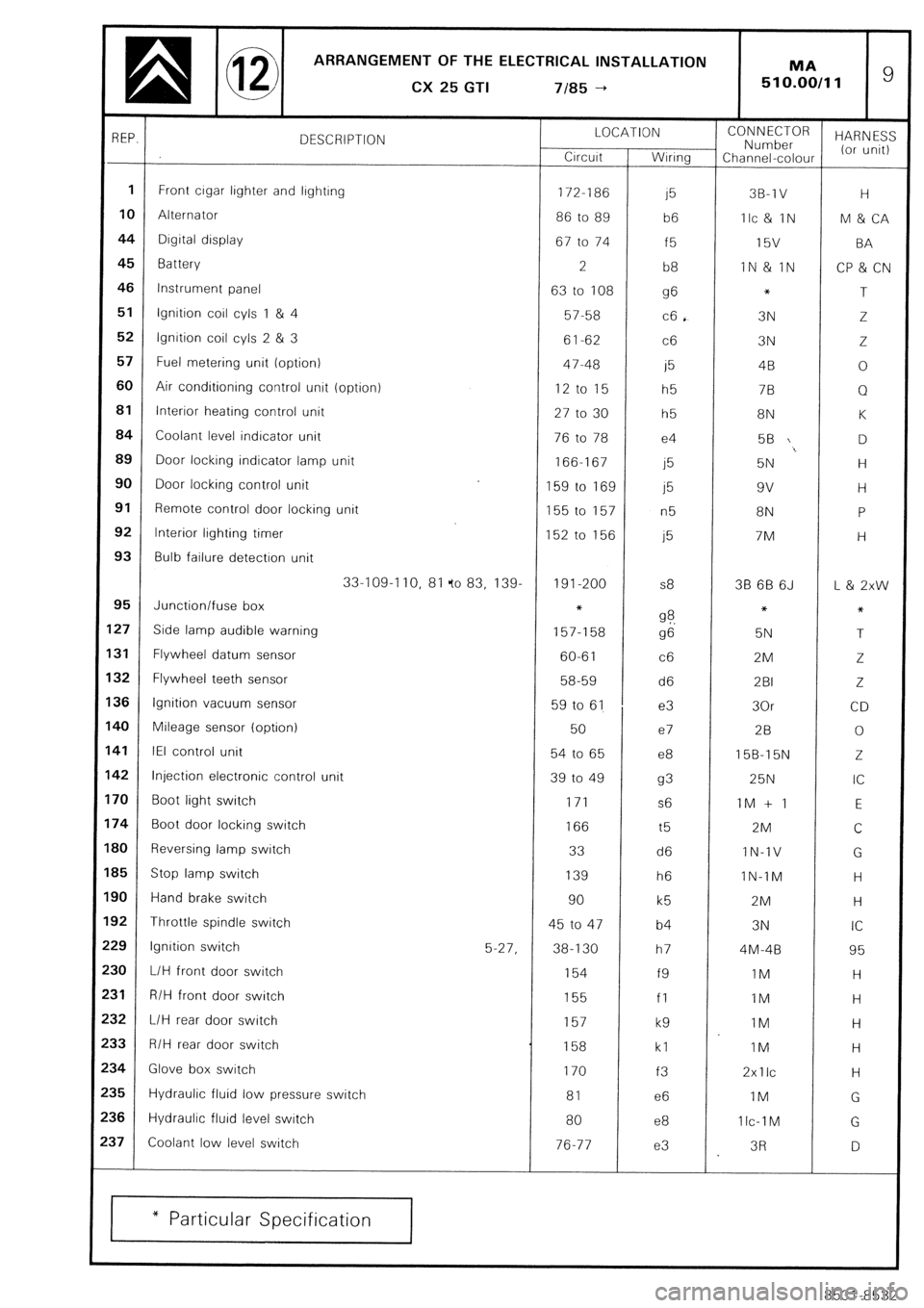

ARRANGEMENT OF THE ELECTRICAL INSTALLATION

a @ CX25GTI 7185-t MA ’ 510.00/11

REP.

DESCRIPTION LOCATION

Crrcurt Wrnng CONNECTOR

Number HARN ES:

Channel-colour (or unit)

1 Front lighter and lrghtrng

crgar 172-186 15 3B-1 V H

10 Alternator

86 to 89

b6 Ilc & IN M & CA

44 Dtgital display

67 to 74 f5 l5V BA

45

Battery

2

b8 IN & IN

CP & CN

46 Instrument panel

63 to 108 g6 *

T

51 Ignition coil cyls 1 & 4

57-58 c6 . 3N Z

52 lgnrtion coil cyls 2 & 3

61-62 c6 3N Z

57 Fuel metering unit (option)

47-48 i5 4B 0

60 Air conditioning control unit (option)

12 to 15

h5 7B Q

81 Interior heating control unit

27 to 30 h5 8N K

84 Coolant level indicator unit

76 to 78 e4 56 D

89

Door locking indicator lamp unit

166-167

j5 5N H

90 Door locking control unit

159 to 169 j5 9v H

91

Remote control door locking unit

155 to 157

n5 8N P

92 Interior lighting timer

152 to 156 j5 7M H

93 Bulb failure detectron unit

33-109-I 10, 81 fo 83, 139. 191-200 s8 38 6B 6J L & 2xw

95 Junction/fuse box *

27 Side lamp audible warning 9 ?. *

*

157-l 58

g6 5N T

31

Flywheel datum sensor

60-61 c6 2M

Z

32 Flywheel teeth sensor

58-59 d6 2BI 2.

36 Ignition vacuum sensor

59 to 61 e3 30r CD

40 Mileage sensor (option)

50 e7 28 0

41 IEI control unit

54 to 65 e8 15B-15N Z

42 Injection electronic control unit

39 to 49 93 25N IC

70 Boot light switch

171 s6 1M + 1 E

74

Boot door locking switch

166 t5 2M

C

BO

Reversing lamp switch 33

d6 IN-1V

G

B5 Stop lamp switch

139 h6 IN-TM H

90 Hand brake switch

90

k5 2M H

92 Throttle spindle switch

45 to 47 b4 3N IC

29 lgnrtion switch

5-27, 38-130 h7 4M-48 95

30

L/H front door switch 154

f9 IM H

31 R/H front door switch

155

fl IM H

32 L/H rear door switch

157

k9 IM H

33 R/H rear door switch

158 kl 1M H

34

Glove box switch

170

f3 2xllc

H

35 Hydraulic fluid low pressure switch

81 e6 IM

G

$6

Hydraulic fluid level swatch

80 e8 1 Ic-1 M

G

$7

Coolant low level switch

76-77 e3 3R

D

* Particular Specification

8531-8532