bulb CITROEN CX 1988 Service Manual

[x] Cancel search | Manufacturer: CITROEN, Model Year: 1988, Model line: CX, Model: CITROEN CX 1988Pages: 648, PDF Size: 95.8 MB

Page 17 of 648

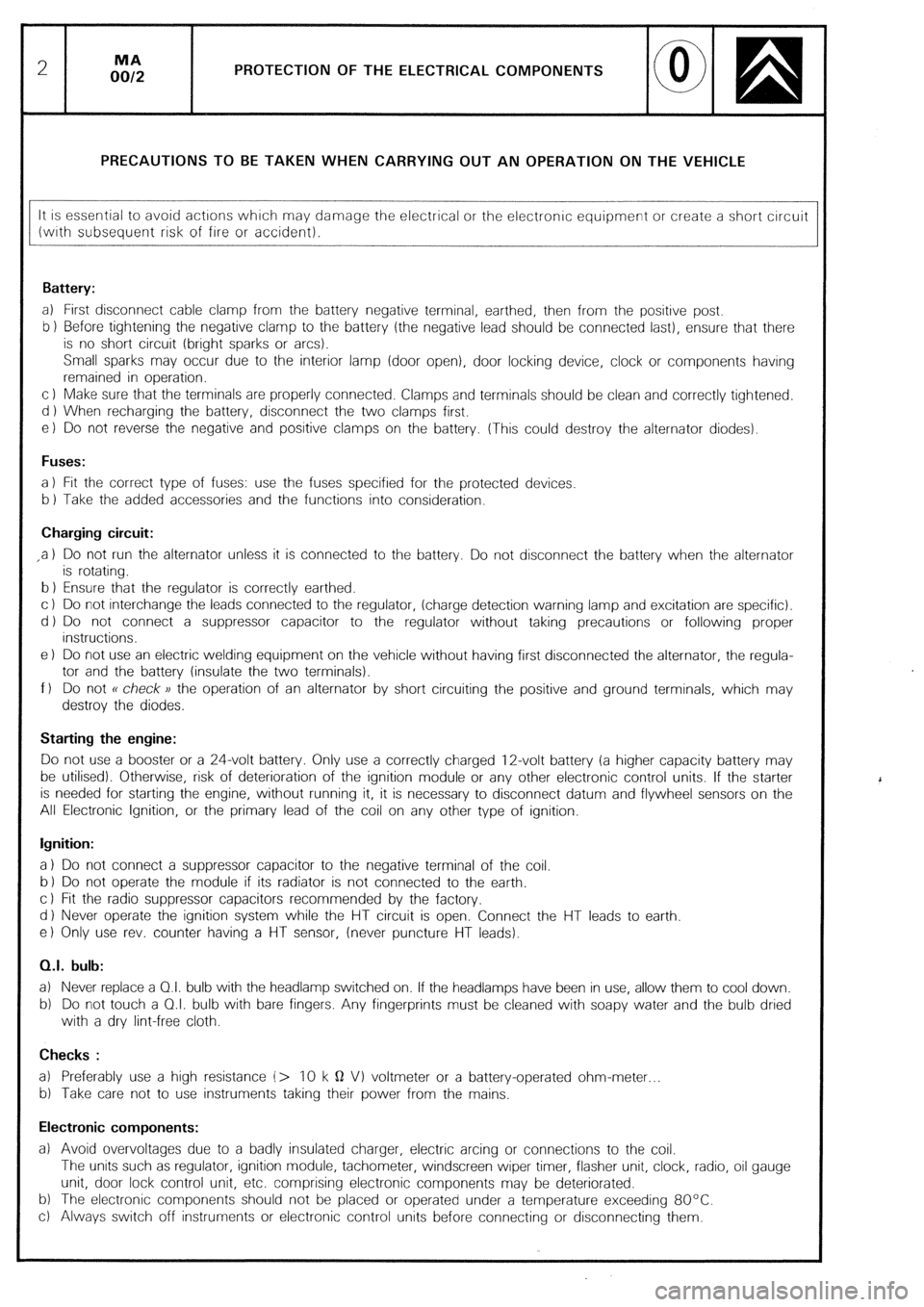

PROTECTION OF THE ELECTRICAL COMPONENTS

PRECAUTIONS TO BE TAKEN WHEN CARRYING OUT AN OPERATION ON THE VEHICLE

It is essential to avoid actrons which may damage the electrical or the electronic equipment or create a short circuit

(wrth subsequent risk of fire or accident).

Battery:

a) First disconnect cable clamp from the battery negative terminal, earthed, then from the positive post.

b 1 Before tightening the negative clamp to the battery (the negative lead should be connected last), ensure that there

is no short circuit (bright sparks or arcs).

Small sparks may occur due to the interior lamp (door open), door locking device, clock or components having

remained in operation.

c 1 Make sure that the terminals are properly connected. Clamps and terminals should be clean and correctly tightened.

d ) When recharging the battery, disconnect the two clamps first.

e) Do not reverse the negative and positive clamps on the battery. (This could destroy the alternator diodes).

Fuses:

a 1 Fit the correct type of fuses: use the fuses specified for the protected devices

b 1 Take the added accessories and the functions into consideration.

Charging circuit:

,a 1 Do not run the alternator unless it is connected to the battery. Do not disconnect the battery when the alternator

is rotating.

b 1 Ensure that the regulator is correctly earthed.

c ) Do not interchange the leads connected to the regulator, (charge detection warning lamp and excitation are specific).

d ) Do not connect a suppressor capacitor to the regulator without taking precautions or following proper

instructions.

e 1 Do not use an electric welding equipment on the vehicle without having first disconnected the alternator, the regula-

tor and the battery (insulate the two terminals).

f 1 Do not R check )) the operation of an alternator by short circuiting the positive and ground terminals, which may

destroy the diodes.

Starting the engine:

Do not use a booster or a 24-volt battery. Only use a correctly charged 12-volt battery (a higher capacity battery may

be utilised). Otherwise, risk of deterioration of the ignition module or any other electronic control units. If the starter

is needed for starting the engine, without running it, it is necessary to disconnect datum and flywheel sensors on the

All Electronic Ignition, or the primary lead of the coil on any other type of ignition.

Ignition:

a 1 Do not connect a suppressor capacitor to the negative terminal of the coil.

b 1 Do not operate the module if its radiator is not connected to the earth.

c 1 Fit the radio suppressor capacitors recommended by the factory.

d 1 Never operate the ignition system while the HT circuit is open. Connect the HT leads to earth

e) Only use rev. counter having a HT sensor, (never puncture HT leads).

0.1. bulb:

a) Never replace a 01. bulb with the headlamp switched on. If the headlamps have been in use, allow them to cool down.

b) Do not touch a 0.1. bulb with bare fingers. Any fingerprints must be cleaned with soapy water and the bulb dried

with a dry lint-free cloth.

Checks :

a) Preferably use a high resistance (> 10 k Q VI voltmeter or a battery-operated ohm-meter

b) Take care not to use instruments taking their power from the mains.

Electronic components:

a) Avoid overvoltages due to a badly insulated charger, electric arcing or connections to the coil.

The units such as regulator, ignition module, tachometer, windscreen wiper timer, flasher unit, clock, radio, oil gauge

unit, door lock control unit, etc. comprising electronic components may be deteriorated.

b) The electronic components should not be placed or operated under a temperature exceeding 80°C.

c) Always switch off instruments or electronic control units before connecting or disconnecting them.

‘

Page 385 of 648

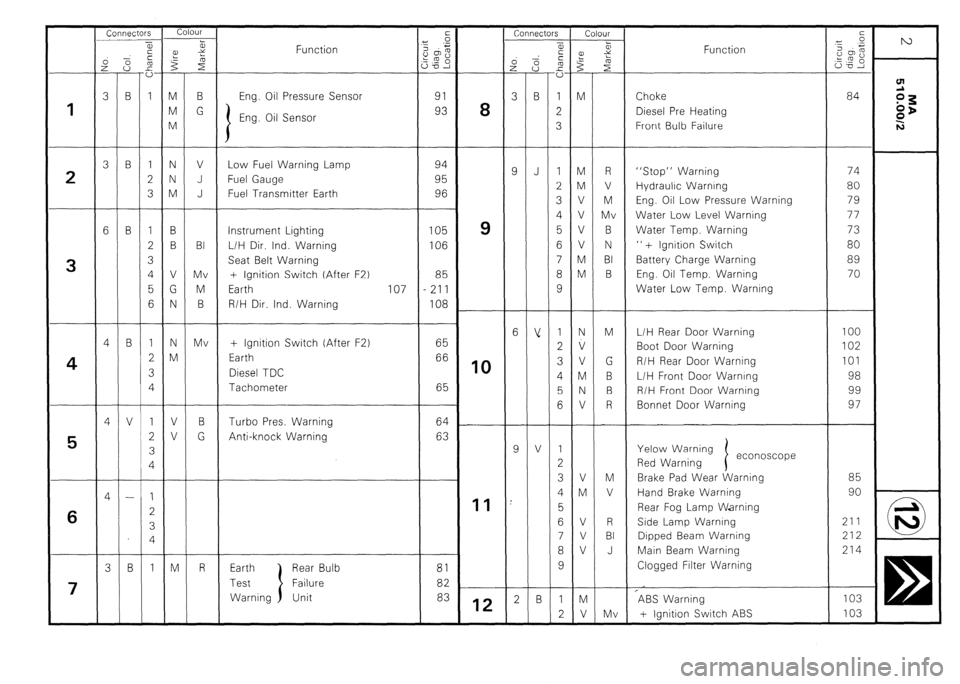

Connectors

l.-~l

a,

- Connectors

,”

9 r, 75 Colour

FiY

E

vl

-

M

M

V

V

V

V

M

M

-

N

v

V

M

N

V

-

V

M

V

V

V

-

M

V

2

$

R

V

M

Mv

B

N

BI

B

Mv . -

z

Y

i

r”

B

G Function Function

:

m

.e-

1

-

1

2

3

-

1

2

3

4

1

2

3

4

I

2

3

4

-

1 .-

f

-

M

M

M

-

N

N

M

-

B

B

V

G

N

-

N

M

-

V

V

-

-

M 1

2

3

-

-

-

-

1

2 -

3 -

6 -

4 -

4 -

4 -

3

1

3

-

9

-

6

-

9

-

2

L.

B

-

J

-

v

-

V

-

B

m

sg

ZD

‘N

B

-

B

-

B

-

B

-

V

-

-

-

B Eng. Oil Pressure Sensor

94

95

96 Choke

Diesel Pre Heating

Front Bulb Failure 84

I 8

1

Eng. Oil Sensor

V

J

J Low Fuel Warning Lamp

Fuel Gauge

Fuel Transmitter Earth “Stop” Warning

Hydraulic Warning

Eng. Oil Low Pressure Warning

Water Low Level Warning

Water Temp. Warning

” + Ignition Switch

Battery Charge Warning

Eng. Oil Temp. Warning

Water Low Temp. Warning

2 74

80

79

77

73

80

89

70

100

102

101

98

99

97

85

90

211

212

214

103

103

9

10

11 Instrument Lighting

L/H Dir. Ind. Warning

Seat Belt Warning

+ Ignition Switch (After F2)

Earth 107

R/H Dir. Ind. Warning 105

106

85

211

108

65

66

65 BI

Mv

M

B

Mv

3

L/H Rear Door Warning

Boot Door Warning

R/H Rear Door Warning

L/H Front Door Warning

R/H Front Door Warning

Bonnet Door Warning + Ignition Switch (After F.2)

Earth

Diesel TDC

Tachometer

4

B

G Turbo Pres. Warning

Anti-knock Warning 64

63

Yelow Warning

Red Warning econoscope

5

Brake Pad Wear Warning

Hand Brake Warning

Rear Fog Lamp Warning

Side Lamp Warning

Dipped Beam Warning

Main Beam Warning

Clogged Filter Warning

0 ic 6

R Earth

Test

Warning Rear Bulb

Failure

Unit 81

82

83

7

12 ?ABS Warning

+ Ignition Switch ABS

Page 388 of 648

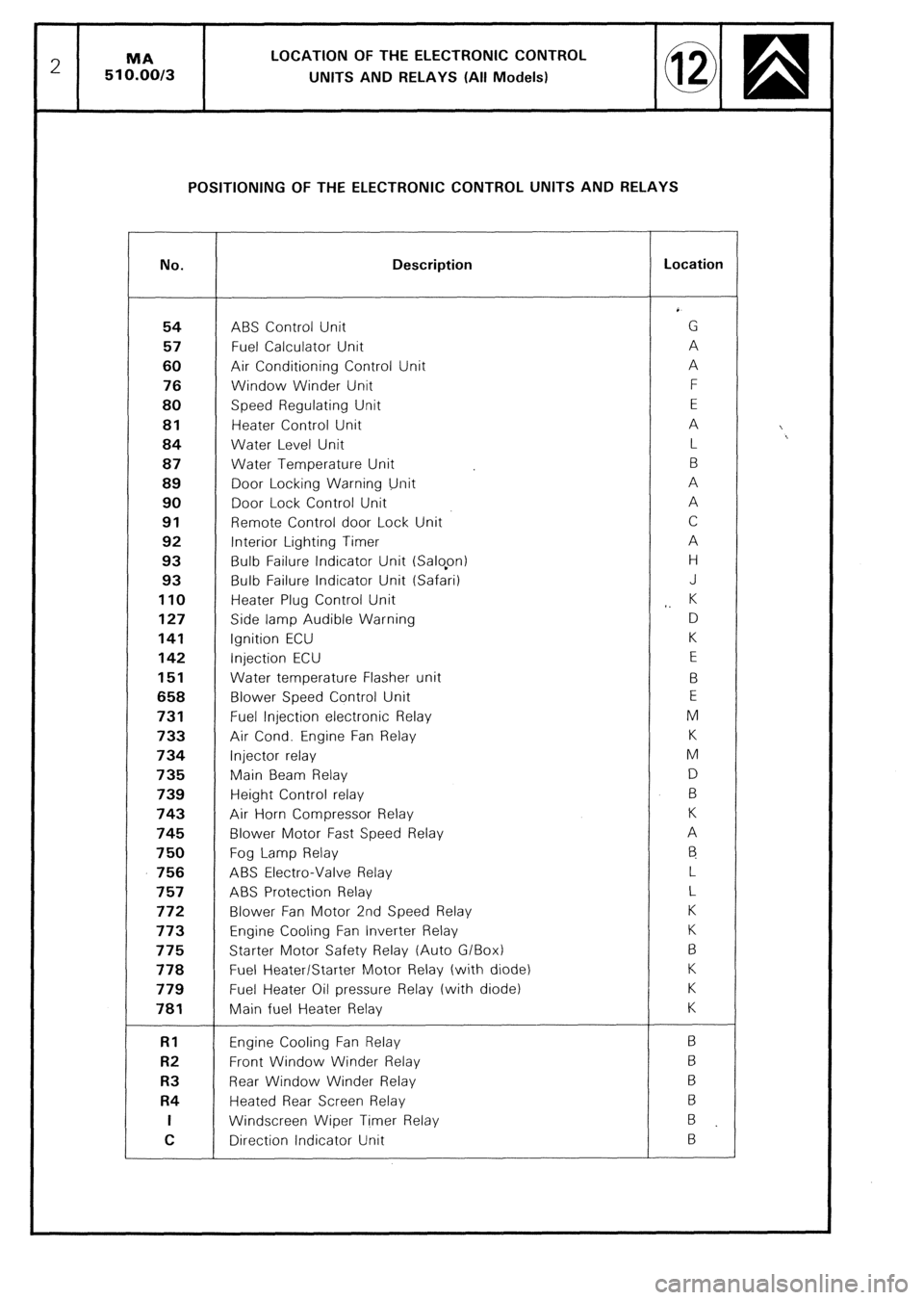

2 MA LOCATION OF THE ELECTRONIC CONTROL

510.00/3

UNITS AND RELAYS (All Models)

POSITIONING OF THE ELECTRONIC CONTROL UNITS AND RELAYS

No. Description Location

54 ABS Control Unit G

57 Fuel Calculator Unit A

60 Air Conditioning Control Unit A

76 Window Winder Unit F

80 Speed Regulating Unit E 81

Heater Control Unit A

84 Water Level Unit L

87 Water Temperature Unit B

89 Door Locking Warning Unit A

90 Door Lock Control Unit A 91

Remote Control door Lock Unit C

92 Interior Lighting Timer A

93 Bulb Failure Indicator Unit (Salopn) H

93 Bulb Failure Indicator Unit (Safari) J 110

Heater Plug Control Unit

,. K 127

Side lamp Audible Warning D 141

Ignition ECU K 142

Injection ECU E 151

Water temperature Flasher unit B 658

Blower Speed Control Unit E 731

Fuel Injection electronic Relay M 733

Air Cond. Engine Fan Relay K 734

Injector relay M 735

Main Beam Relay D

739 Height Control relay B 743

Air Horn Compressor Relay K 745

Blower Motor Fast Speed Relay A 750

Fog Lamp Relay

6 756

ABS Electra-Valve Relay L 757

ABS Protection Relay L 772

Blower Fan Motor 2nd Speed Relay K 773

Engine Cooling Fan lnverter Relay K 775

Starter Motor Safety Relay (Auto G/Box) B 778

Fuel Heater/Starter Motor Relay (with diode) K

779 Fuel Heater Oil pressure Relay (with diode) K 781

Main fuel Heater Relay K RI

Engine Cooling Fan Relay B R2

Front Window Winder Relay 6 R3

Rear Window Winder Relay B R4

Heated Rear Screen Relay 6 I

Windscreen Wiper Timer Relay

B

C Direction Indicator Unit B

Page 392 of 648

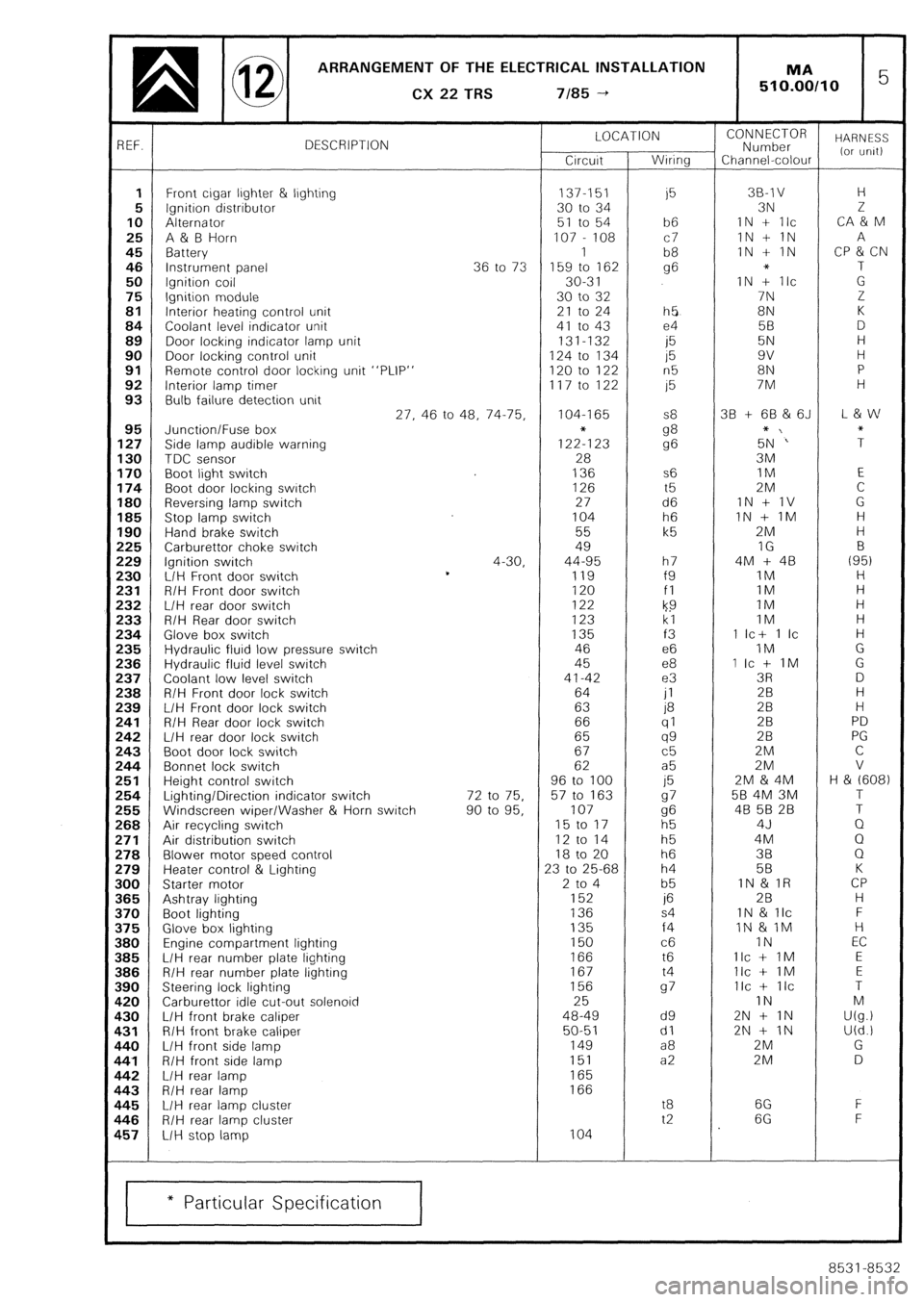

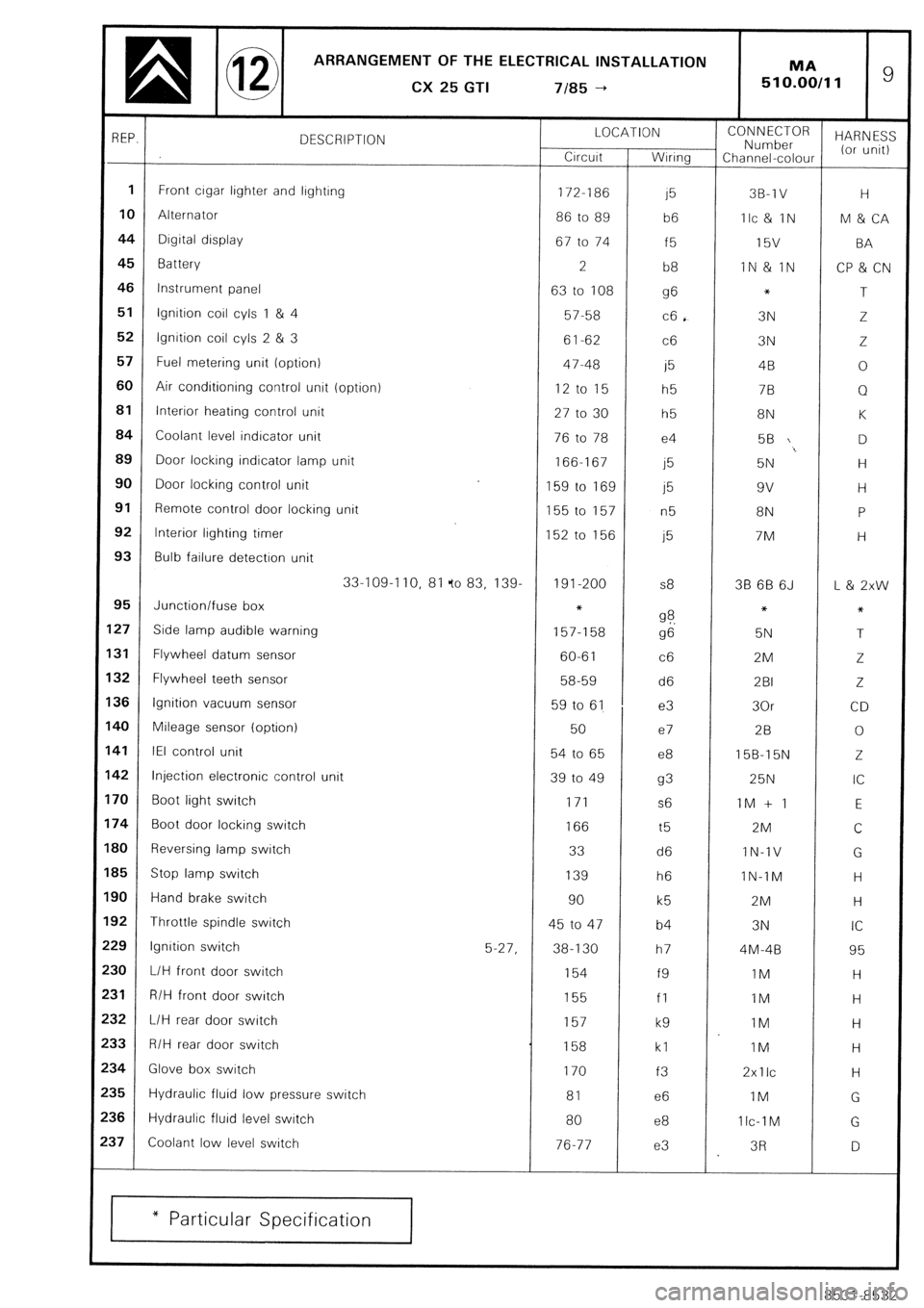

ARRANGEMENT OF THE ELECTRICAL INSTALLATION

q @ CX22TRS 7/85-t 1 MA 5 510.00110

3EF. DESCRIPTION LOCATION

Circuit Wiring CONNECTOR

Number HARNESS

Channel-colour (or urilt)

1 Front cigar ljghter & lighting 137-151

i5 38-l v H

5 Ignition distributor 30 to 34 3N 2

10 Alternator 51 to 54 b6 IN + Ilc CA & M

25 A & B Horn 107 - 108 c7 1N + 1N A

45 Battery 1

b8 IN + IN CP & CN

46 Instrument panel 36 to 73 159 to 162 g6 * T

50 Ignition coil 30-3 1 IN + Ilc G

75 Ignition module 30 to 32 7N Z

81 Interior heating control unit 21 to 24 h5 8N K

84 Coolant level indicator unit 41 to 43 e4 5B D

89 Door locking indicator lamp unit 131-132

i5 5N H

90 Door locking control unit 124 to 134 15 9v H

91 Remote control door locking unit “PLIP” 120 to 122 n5 8N P

92 Interior lamp timer 117 to 122 15 7M H

93 Bulb failure detection unit

27, 46 to 48, 74-75, 104-I 65 S8 38 + 68 & 6J L & w

95 Junction/Fuse box

127 Side lamp audible warning 1222123 g8

g6 5+N‘” ;

130 TDC sensor 28 3M

170 Boot light switch 136 s6 IM E

174 Boot door locking switch 126 t5 2M C

180 Reversing lamp switch 27 d6 1N + 1V G

185 Stop lamp switch 104 h6 IN + IM H

190 Hand brake switch 55 k5 2M H

!25 Carburettor choke switch 49 IG B

!29 Ignition switch 4-30, 44-95 h7 4M + 48 (95)

!30 L/H Front door switch *

119 f9 IM H

!31 R/H Front door switch 120 fl 1M H

!32 L/H rear door switch 122

k9 IM H

!33 R/H Rear door switch 123 kl IM H

!34 Glove box switch 135 f3 1 Ic+ 1 Ic H

!35 Hydraulic fluid low pressure switch 46 e6 IM G

!36 Hydraulic fluid level switch 45 e8 1 Ic + IM G

!37 Coolant low level switch 41-42 e3 3R D

!38 R/H Front door lock switch 64

jl 28 H

!39 L/H Front door lock switch 63 P

28 H

!41 R/H Rear door lock switch 66 (71 28 PD !42 L/H rear door lock switch 65 qg 28 PG

!43 Boot door lock switch 67 c5 2M C

!44 Bonnet lock switch 62 a5 2M V

!51 Height control switch 96 to 100

j5 2M & 4M H & (608) !54 Lighting/Direction indicator switch 72 to 75. 57 to 163 97 58 4M 3M T

!55 Windscreen wiper/Washer & Horn switch 90 to 95, 107 g6 48 5B 28 T

!68 Air recycling switch 15 to 17

h5 4J Q

!71 Air distribution switch 12 to 14 h5 4M Q !78 Blower motor speed control 18 to 20 h6 38 Q

!79 Heater control & Lighting 23 to 25-68 h4 58 K

100 Starter motor 2 to 4 b5 IN & IR CP 165 Ashtray lighting 152 if5 2B H

I70 Boot lighting 136 s4 1N & llc F

I75 Glove box lighting 135 f4 IN & 1M H I80 Engine compartment lighting 150 c6 IN EC

I85 L/H rear number plate lighting 166 t6 Ilc + IM E 186 R/H rear number plate lighting 167 t4 Ilc + IM E

190 Steering lock lighting 156 97 Ilc + IIC T

L20 Carburettor idle cut-out solenoid 25 IN M L30 L/H front brake caliper 48-49 d9 2N + IN U(g.) I31 R/H front brake caliper 50-51 dl 2N + IN U(d.!

L40 L/H front side lamp 149 a8 2M G

141 R/H front side lamp 151 a2 2M D 142 L/H rear lamp 165 L43 R/H rear lamp 166 I45 L/H rear lamp cluster t8 6G F

146 R/H rear lamp cluster t2 6G F

157 L/H stop lamp 104

* Particular Specification

8531-8532

Page 399 of 648

ARRANGEMENT OF THE ELECTRICAL INSTALLATION

a @ CX25GTI 7185-t MA ’ 510.00/11

REP.

DESCRIPTION LOCATION

Crrcurt Wrnng CONNECTOR

Number HARN ES:

Channel-colour (or unit)

1 Front lighter and lrghtrng

crgar 172-186 15 3B-1 V H

10 Alternator

86 to 89

b6 Ilc & IN M & CA

44 Dtgital display

67 to 74 f5 l5V BA

45

Battery

2

b8 IN & IN

CP & CN

46 Instrument panel

63 to 108 g6 *

T

51 Ignition coil cyls 1 & 4

57-58 c6 . 3N Z

52 lgnrtion coil cyls 2 & 3

61-62 c6 3N Z

57 Fuel metering unit (option)

47-48 i5 4B 0

60 Air conditioning control unit (option)

12 to 15

h5 7B Q

81 Interior heating control unit

27 to 30 h5 8N K

84 Coolant level indicator unit

76 to 78 e4 56 D

89

Door locking indicator lamp unit

166-167

j5 5N H

90 Door locking control unit

159 to 169 j5 9v H

91

Remote control door locking unit

155 to 157

n5 8N P

92 Interior lighting timer

152 to 156 j5 7M H

93 Bulb failure detectron unit

33-109-I 10, 81 fo 83, 139. 191-200 s8 38 6B 6J L & 2xw

95 Junction/fuse box *

27 Side lamp audible warning 9 ?. *

*

157-l 58

g6 5N T

31

Flywheel datum sensor

60-61 c6 2M

Z

32 Flywheel teeth sensor

58-59 d6 2BI 2.

36 Ignition vacuum sensor

59 to 61 e3 30r CD

40 Mileage sensor (option)

50 e7 28 0

41 IEI control unit

54 to 65 e8 15B-15N Z

42 Injection electronic control unit

39 to 49 93 25N IC

70 Boot light switch

171 s6 1M + 1 E

74

Boot door locking switch

166 t5 2M

C

BO

Reversing lamp switch 33

d6 IN-1V

G

B5 Stop lamp switch

139 h6 IN-TM H

90 Hand brake switch

90

k5 2M H

92 Throttle spindle switch

45 to 47 b4 3N IC

29 lgnrtion switch

5-27, 38-130 h7 4M-48 95

30

L/H front door switch 154

f9 IM H

31 R/H front door switch

155

fl IM H

32 L/H rear door switch

157

k9 IM H

33 R/H rear door switch

158 kl 1M H

34

Glove box switch

170

f3 2xllc

H

35 Hydraulic fluid low pressure switch

81 e6 IM

G

$6

Hydraulic fluid level swatch

80 e8 1 Ic-1 M

G

$7

Coolant low level switch

76-77 e3 3R

D

* Particular Specification

8531-8532