tow CITROEN DISPATCH SPACETOURER 2017 Handbook (in English)

[x] Cancel search | Manufacturer: CITROEN, Model Year: 2017, Model line: DISPATCH SPACETOURER, Model: CITROEN DISPATCH SPACETOURER 2017Pages: 774, PDF Size: 48.25 MB

Page 285 of 774

283

Stowing

F Press the latches A and slide them inwards to release the box.

F

L

ift the box slightly then pull it as far as it

will go to take it past bar 1 .

F

T

hen, lift the box upwards to take it past

bar 2 . F

U nclip the fixings B on the cover, then

open it for access to the tools.

OpeningRemoving

Pull on the box to check that it is secure

in its housing.

F

O

ffer up the box with the front inclined

upwards.

F

T

o take it past bar 2 , push the box in and

down. F

T

o take it past bar 1

, raise the box slightly

then push it fully in.

F

R

efit the cover on the box and clip the

fixings B. F

O

nce the box is fully home

in its housing,

push it against the floor carpet then slide

the latches A outwards to secure it.

8

In the event of a breakdown

Page 287 of 774

285

This kit is stowed in the tool box. This kit consists of a compressor and a sealant

cartridge.

It allows the temporary repair of a tyre.

You are then able to go to the nearest garage.

It is designed to repair most punctures which

could affect the tyre, located on the tyre tread

or shoulder.

Its compressor can be used to check and

adjust the pressure of the tyre.

Temporary puncture repair kit

Access to the kit

1. 12 V compressor. T o temporarily repair a tyre using an

integral sealant cartridge and adjust the

tyre pressure.

2.

T

owing eye. The tyre inflation pressures are given on this

label.

The vehicle's electric system allows the

connection of a compressor for long

enough to inflate a tyre after a puncture

repair or for inflating a small inflatable

accessory.

For more information on To w i n g

, refer

to the corresponding section.

List of tools

These tools are specific to your vehicle and can

vary according to equipment. Do not use them

for other purposes.

For more information on the Tool box ,

refer to the corresponding section.

8

In the event of a breakdown

Page 291 of 774

289

F Connect the compressor's electric plug to the vehicle's 12 V socket.

F

S

tart the vehicle again and leave the

engine running. F

A djust the pressure using the compressor

(to inflate: switch B in position "I" ;

to

deflate: switch B in position "O" and

press button C ), in accordance with the

vehicle's tyre pressure label (located on the

left-hand door aperture).

A l

oss of pressure indicates that the

puncture has not been fully plugged;

contact a CITROËN dealer or qualified

workshop for assistance.

F

R

emove and stow the kit.

F

D

rive at reduced speed (50 mph

[80

km/h] max) limiting the distance

travelled to approximately 120 miles

(200

km).

As soon as possible, go to a CITROËN

dealer or a qualified workshop.

You must inform the technician that you

have used this kit. After inspection, the

technician will advise you on whether

the tyre can be repaired or if it must be

replaced.

Removing the cartridge

F Stow the black pipe.

F

D etach the angled base from the white pipe.

F

S

upport the compressor vertically.

Beware of discharges of fluid.

The expiry date of the fluid is indicated

on the cartridge.

The sealant cartridge is designed for

single use; even if only partly used, it

must be replaced.

After use, do not discard the cartridge

into the environment, take it to an

authorised waste disposal site or a

CITROËN dealer.

Do not forget to obtain a new sealant

cartridge, available from CITROËN

dealers or from a qualified workshop.

F

U

nscrew the cartridge from the bottom.

8

In the event of a breakdown

Page 292 of 774

290

Checking / adjusting tyre

pressures

You can also use the compressor without

injecting any product, to check and if necessary

adjust your tyre pressures.F

T

urn the selector A to the

"Air"

position. F

C

onnect the compressor's electrical

connector to the vehicle's 12 V socket.

F

S

tart the vehicle and let the engine run.

F

A

djust the pressure using the compressor

(to inflate: switch B in position "I" ;

to

deflate: switch B in position "O" and

press button C ), according to the vehicle's

tyre pressure label.

F

R

emove the kit then stow it.Should the pressure of one or more

tyres be adjusted, it is necessary to

reinitialise the under-inflation detection

system.

For more information on Under-

inflation detection

, refer to the

corresponding section.

F

U

ncoil the black pipe H fully.

F

C

onnect the black pipe to the tyre valve.

In the event of a breakdown

Page 293 of 774

291

Changing a wheel

The tools are stowed in the tool box.

Access to the tooling

1. Wheelbrace. For removing the wheel bolts and raising/

lowering the jack.

2.

J

ack.

F

or raising the vehicle.

3.

W

heel bolt cap/wheel trim removal tool.

I

f your vehicle is so equipped, for removing

the wheel bolt head covers on alloy wheels

or the central wheel trim on steel wheels.

4.

S

ocket for the security bolts.

F

or adapting the wheelbrace to the special

"security" bolts.

5.

T

owing eye. For more information on To w i n g

, refer

to the corresponding section.

The jack must only be used to change a

wheel with a damaged tyre.

The jack does not require any

maintenance.

The jack conforms to European

legislation, such as defined in the

Machinery Directive 2006/42/CE.

List of tools

These tools are specific to your vehicle and can

vary according to the level of equipment. Do

not use them for other purposes.

For more information on the Tool box ,

refer to the corresponding section.

8

In the event of a breakdown

Page 294 of 774

292

F Access to the spare wheel is from the rear.

F O pen the side-hinged rear doors or the

tailgate, according to the configuration of

your vehicle. F

A

ccess the carrier bolt, located on the rear

door sill.

F

T

urn the bolt anti-clockwise using the

wheelbrace (about 14 turns) until the

carrier is low enough to allow the carrier

hook to be disengaged.

Access to the spare wheel

F If your vehicle is fitted with a towbar, raise the rear of the vehicle using the jack (must

be at jacking point B ) to allow sufficient

space to remove the spare wheel.

Removing

To avoid any unwanted opening of the

electric side door(s), deactivate the

" Hands-Free Access " function in the

vehicle configuration menu.

For more information on the Hands-

free sliding side door , refer to the

corresponding section.

In the event of a breakdown

Page 299 of 774

297

F If your vehicle is so equipped, tighten the security bolt using the wheelbrace 1 fitted

with the security socket 4 .

F

T

ighten the other bolts using the

wheelbrace 1 o n l y.

F

S

tow the tools in the tool box. The tyre inflation pressures are given on this

label.

After changing a wheel

Stow the punctured wheel in the carrier.

Have the tightening of the bolts and the

pressure of the spare wheel checked

by a CITROËN dealer or a qualified

workshop without delay.

Have the punctured wheel repaired

and refitted to the vehicle as soon as

possible.

If your vehicle has tyre under-inflation

detection, check the tyre pressures and

reinitialise the system.

Tyre under-inflation detection

The steel spare wheel does not have a

sensor.

Wheel with large wheel

trim

When refitting the wheel

, refit the

wheel trim by placing its cut-out at the

valve, and press round its edge with the

palm of your hand.

For more information on Under-

inflation detection

, refer to the

corresponding section.

8

In the event of a breakdown

Page 302 of 774

300

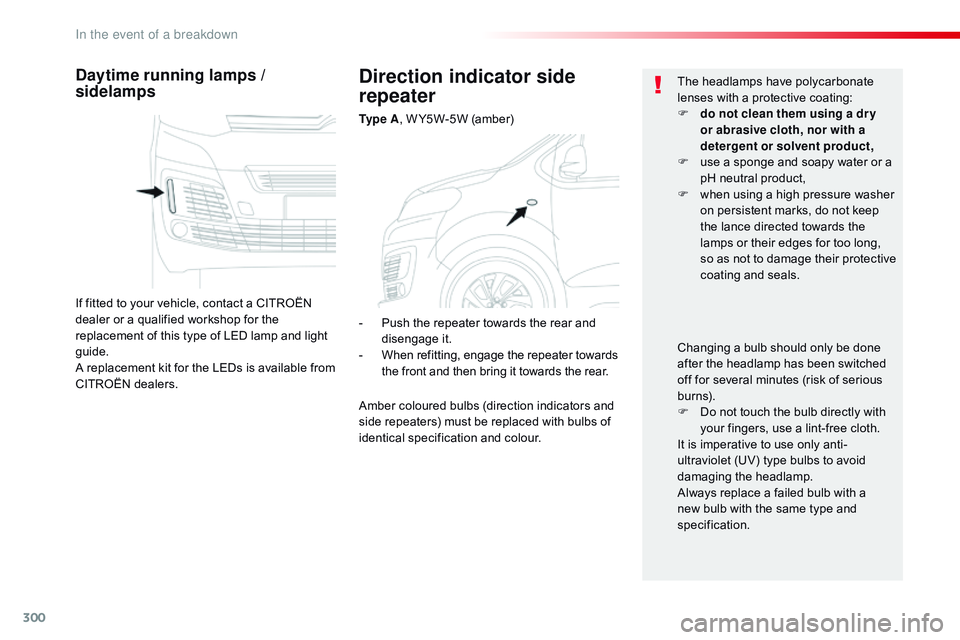

Direction indicator side

repeater

Ty p e A, W Y5W-5W (amber)

Daytime running lamps /

sidelamps

If fitted to your vehicle, contact a CITROËN

dealer or a qualified workshop for the

replacement of this type of LED lamp and light

guide.

A replacement kit for the LEDs is available from

CITROËN dealers. The headlamps have polycarbonate

lenses with a protective coating:

F

d

o not clean them using a dr y

or abrasive cloth, nor with a

detergent or solvent product,

F

u

se a sponge and soapy water or a

pH neutral product,

F

w

hen using a high pressure washer

on persistent marks, do not keep

the lance directed towards the

lamps or their edges for too long,

so as not to damage their protective

coating and seals.

Changing a bulb should only be done

after the headlamp has been switched

off for several minutes (risk of serious

burns).

F

D

o not touch the bulb directly with

your fingers, use a lint-free cloth.

It is imperative to use only anti-

ultraviolet (UV) type bulbs to avoid

damaging the headlamp.

Always replace a failed bulb with a

new bulb with the same type and

specification.

-

P

ush the repeater towards the rear and

disengage it.

-

W

hen refitting, engage the repeater towards

the front and then bring it towards the rear.

Amber coloured bulbs (direction indicators and

side repeaters) must be replaced with bulbs of

identical specification and colour.

In the event of a breakdown

Page 308 of 774

306

Number plate lamps

(side-hinged doors)

Ty p e A, W5W-5W

F

R

emove the plastic cover using a small

screwdriver.

F

U

sing a screwdriver through the aperture,

push the lamp towards the outside.

F

D

isconnect the electrical connector.

F

R

emove the lamp.

F

T

urn the bulb holder a quarter turn anti-

clockwise.

F

C

hange the failed bulb.

To refit, press on the lamp to clip it in place.

Third brake lamp

(side-hinged doors)

Ty p e A , W5W-5W

To refit, press on the lens to clip it in place.

F

O

pen the left-hand rear door. F

I

nsert a thin screwdriver into one of the

cut-outs in the lens.

F

P

ush it outwards to unclip it.

F

R

emove the lens.

F

C

hange the failed bulb.

In the event of a breakdown

Page 310 of 774

308

Rear lamps

(tailgate)

For more information on Changing a bulb and

in particular, the types of bulbs, refer to the

corresponding section.

F

W

hile holding the lamp in place, press the

clip on the inside then carefully remove the

lamp.

F

D

isconnect the electrical connector.

F

I

dentify the failed bulb then open the boot.

For vehicles with interior trim, contact

a CITROËN dealer or a qualified

workshop to have the work done.

1.

B

rake lamps / sidelamps.

Ty

p e B, P21/5W-21/5W.

2.

D

irection indicators.

Ty

p e B, PY21W-21W (amber)

3.

R

eversing lamps.

Ty

p e B, P21W-21W

4.

F

oglamps / sidelamps.

Ty

p e B, P21/4W-21/4W. F

F

rom inside, remove the cover, if your

vehicle has one.

F

F

rom the outside, press on the inner clips

on the plastic finisher then tip it towards the

outside to remove it.

F

U

nscrew the two lamp fixing screws.F

S

pread the three lugs slightly, then extract

the bulb holder.

F

R

emove the failed bulb by pressing

lightly on it, then turning it a quarter turn

clockwise.

F

C

hange the bulb.

To reassemble, carry out these operations in

reverse order.

In the event of a breakdown