CITROEN DS3 CABRIO DAG 2017 Handbook (in English)

Manufacturer: CITROEN, Model Year: 2017, Model line: DS3 CABRIO DAG, Model: CITROEN DS3 CABRIO DAG 2017Pages: 444, PDF Size: 14.09 MB

Page 201 of 444

199

DS3_en_Chap08_info-pratiques_ed02-2015

The speed limit st icker mu st be se cured to t

he interior of the vehicle in the

driver's

f

ield

o

f

v

ision,

t

o

r

emind

y

ou

th

at

a w

heel

i

s

i

n

t

emporary

u

se.

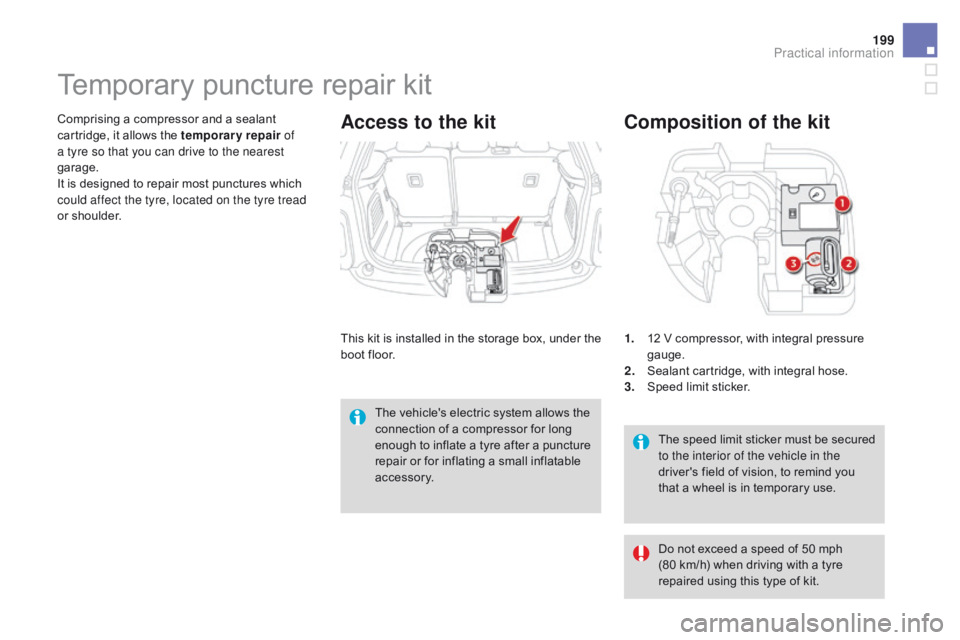

Composition of the kit

1. 12 V compressor, with i ntegral p ressure gaug

e.

2.

Se

alant

c

artridge,

w

ith

i

ntegral

h

ose.

3.

Sp

eed

l

imit

s

ticker.

Temporary puncture re pair kit

Comprising a compressor and a sealant ca

rtridge, i t a llows t he t emporary repair of

a tyre so that you can drive to the nearest

garage.

It

i

s

d

esigned

t

o

r

epair

m

ost

p

unctures

w

hich

co

uld affect the tyre, located on the tyre tread

or

s

houlder.Access to the kit

This kit is installed in th e st orage bo x, un der th e bo

ot f loor.

The

v

ehicle's

e

lectric

s

ystem

a

llows

t

he

co

nnection

o

f

a c

ompressor

f

or

l

ong

en

ough

t

o

i

nflate

a t

yre

a

fter

a p

uncture

re

pair

o

r

f

or

i

nflating

a s

mall

i

nflatable

ac

cessory. Do

n

ot

e

xceed

a s

peed

o

f

5

0

m

ph

(

80

k

m/h)

w

hen

d

riving

w

ith

a t

yre

re

paired

u

sing

t

his

t

ype

o

f

k

it.

Practical information

Page 202 of 444

DS3_en_Chap08_info-pratiques_ed02-2015

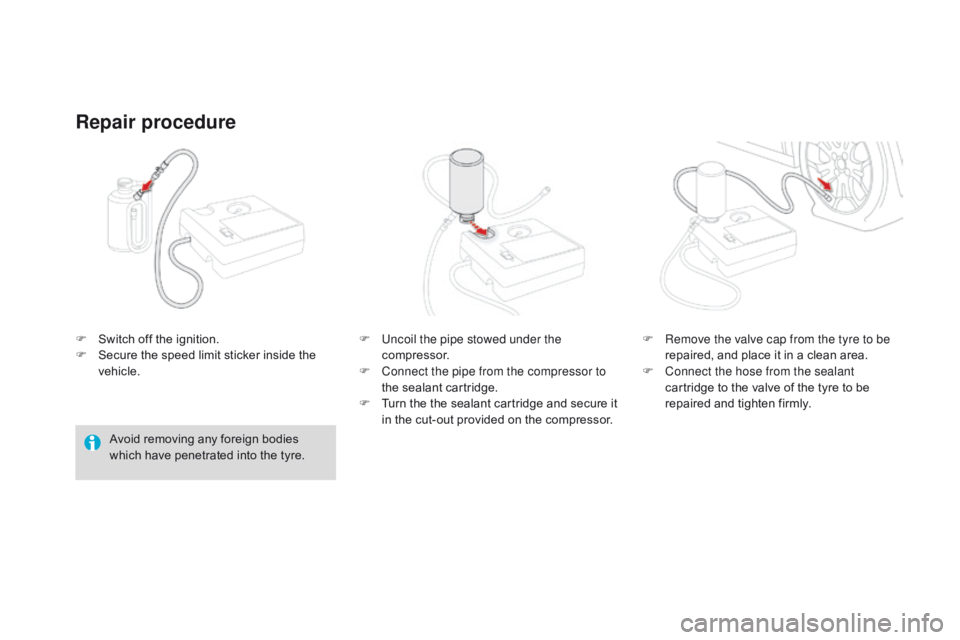

F Switch off t he i gnition.

F Se cure t he s peed l imit s ticker i nside t he ve

hicle.

Repair procedure

Avoid removing any foreign bodies which h ave p enetrated i nto t he t yre.F

Un

coil the pipe stowed under the

compressor.

F

Co

nnect the pipe from the compressor to

the

s

ealant

c

artridge.

F

Tu

rn

t

he

t

he

s

ealant

c

artridge

a

nd

s

ecure

i

t

in t

he

c

ut-out

p

rovided

o

n

t

he

c

ompressor.F

Re

move the valve cap from the tyre to be

repaired,

a

nd

p

lace

i

t

i

n

a c

lean

a

rea.

F

Co

nnect the hose from the sealant

cartridge

t

o

t

he

v

alve

o

f

t

he

t

yre

t

o

b

e

re

paired

a

nd

t

ighten

f

irmly.

Page 203 of 444

201

DS3_en_Chap08_info-pratiques_ed02-2015

If after around 5 to 7 minutes the

pressure is not attained, this indicates

that

t

he

t

yre

i

s

n

ot

r

epairable;

c

ontact

a CI

TROËN dealer or a qualified

workshop

f

or

a

ssistance.

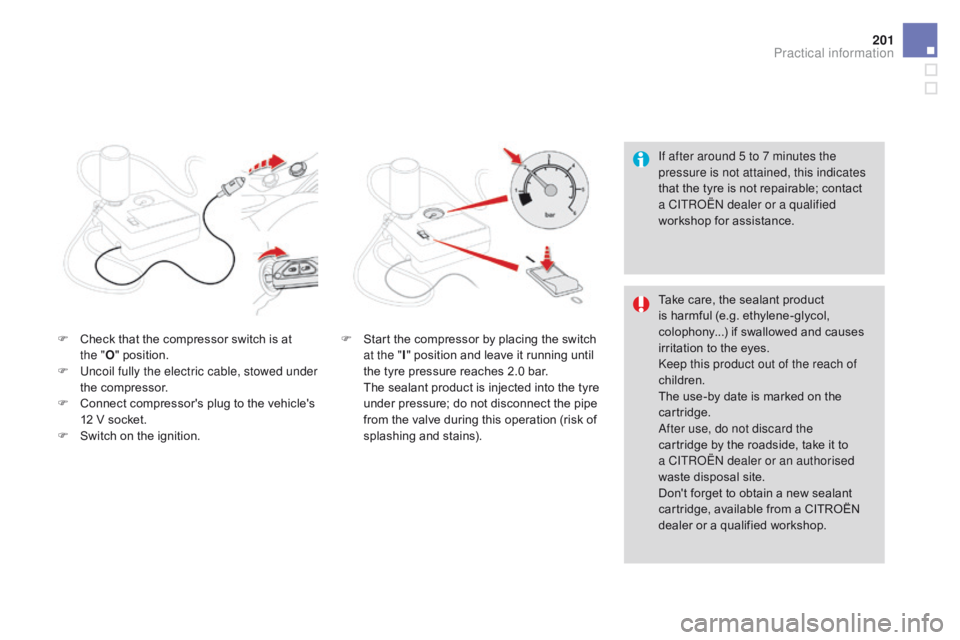

F

Ch

eck

t

hat

t

he

c

ompressor

s

witch

i

s

a

t

th

e

" O " p

osition.

F

Un

coil fully the electric cable, stowed under

the

c

ompressor.

F

Co

nnect

c

ompressor's

p

lug

t

o

t

he

v

ehicle's

12 V s

ocket.

F

Sw

itch

o

n

t

he

i

gnition. F

St

art

t

he

c

ompressor

b

y

p

lacing

t

he

s

witch

at t

he " I"

p

osition

a

nd

l

eave

i

t

r

unning

u

ntil

th

e

t

yre

p

ressure

r

eaches

2

.0

b

ar.

Th

e

s

ealant

p

roduct

i

s

i

njected

i

nto

t

he

t

yre

un

der

p

ressure;

d

o

n

ot

d

isconnect

t

he

p

ipe

fr

om

t

he

v

alve

d

uring

t

his

o

peration

(

risk

o

f

spla

shing

and st

ains). Take

c

are,

t

he

s

ealant

p

roduct

is h

armful

(

e.g.

e

thylene-glycol,

co

lophony...)

i

f

s

wallowed

a

nd

c

auses

ir

ritation

t

o

t

he

e

yes.

Keep this product out of the reach of

children.

The

u

se-by

d

ate

i

s

m

arked

o

n

t

he

ca

rtridge.

After use, do not discard the

cartridge

b

y

t

he

r

oadside,

t

ake

i

t

t

o

a CI

TROËN

d

ealer or an authorised

waste

d

isposal

s

ite.

Don't

f

orget

t

o

o

btain

a n

ew

s

ealant

ca

rtridge,

a

vailable

f

rom

a C

ITROËN

de

aler

o

r

a q

ualified

w

orkshop.

Practical information

Page 204 of 444

DS3_en_Chap08_info-pratiques_ed02-2015

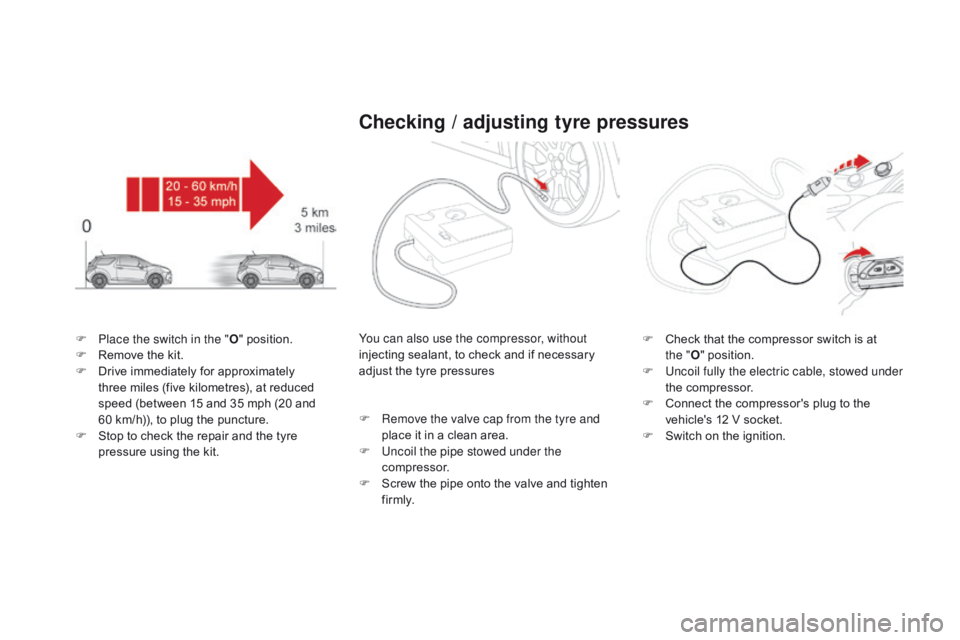

F Place the switch in the "O" p osition.

F Re move t he k it.

F

Dr

ive

i

mmediately

f

or

a

pproximately

th

ree

m

iles

(

five

k

ilometres),

a

t

r

educed

sp

eed

(

between

1

5

a

nd

3

5

m

ph

(

20

a

nd

60 k

m/h)),

t

o

p

lug

t

he

p

uncture.

F

St

op

t

o

c

heck

t

he

r

epair

a

nd

t

he

t

yre

pr

essure

u

sing

t

he

k

it.

Checking / adjusting tyre pressures

You can also use the compressor, without

injecting sealant, t o c heck a nd i f n ecessary ad

just

t

he

t

yre

p

ressures

F

Re

move the valve cap from the tyre and

place

i

t

i

n

a c

lean

a

rea.

F

Un

coil the pipe stowed under the

compressor.

F

Sc

rew

t

he

p

ipe

o

nto

t

he

v

alve

a

nd

t

ighten

f i

r m l y. F Ch

eck t hat t he c ompressor s witch i s a t th

e

"O " p

osition.

F

Un

coil fully the electric cable, stowed under

the

c

ompressor.

F

Co

nnect

t

he

c

ompressor's

p

lug

t

o

t

he

ve

hicle's

1

2

V s

ocket.

F

Sw

itch

o

n

t

he

i

gnition.

Page 205 of 444

203

DS3_en_Chap08_info-pratiques_ed02-2015

F Start the compressor b y p lacing t he s witch at t

he "I" p

osition a nd a djust t he p ressure to t

he

v

alue

s

hown

o

n

t

he

v

ehicle's

t

yre

pr

essure

l

abel.

To d

eflate:

p

ress

t

he

b

lack

b

utton

o

n

t

he

co

mpressor

p

ipe,

a

t

t

he

v

alve

c

onnector.

F

On

ce the correct pressure is reached, put

the switch to the " O"

p

osition.

F

Re

move

t

he

k

it

t

hen

s

tow

i

t.

Tyre under-inflation

detection

After repair of the tyre, the warning lamp will remain on until the system is

reinitialised.

For more information on under-inflation

detection,

r

efer

t

o

t

he

c

orresponding

sec

tion.

Should the pressure of one or more

tyres

b

e

a

djusted,

i

t

i

s

n

ecessary

t

o

rei

nitialise the under-inflation detection

system.

For more information on under-inflation

detection,

r

efer

t

o

t

he

c

orresponding

sec

tion.

Practical information

Page 206 of 444

DS3_en_Chap08_info-pratiques_ed02-2015

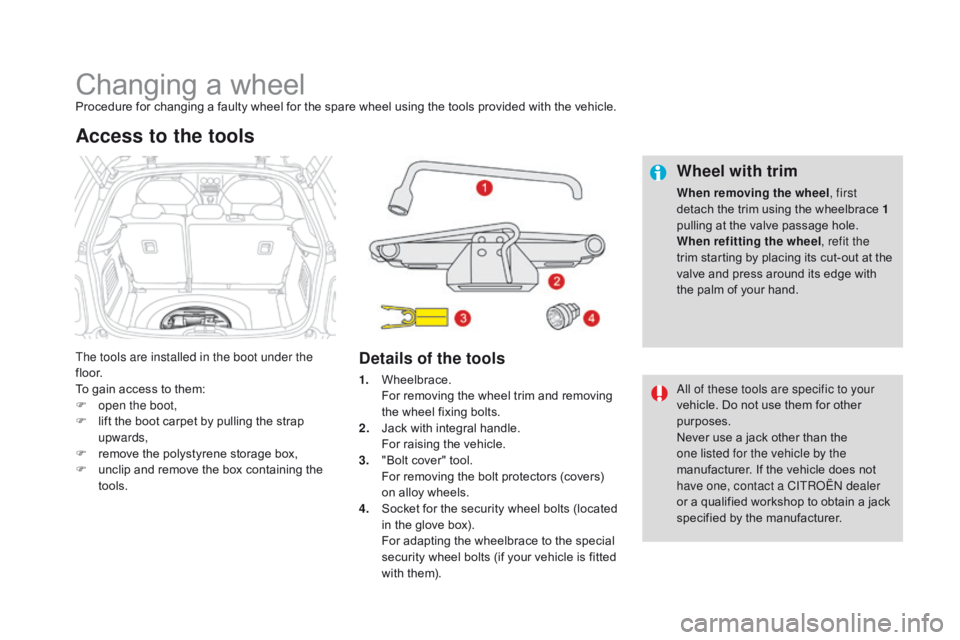

Changing a wheelProcedure for changing a faulty wheel for the spare wheel using the tools provided with the vehicle.

Th e tools are installed in the boot under the

f l o o r.

To

g

ain

a

ccess

t

o

t

hem:

F

op

en the boot,

F

li

ft

t

he

b

oot

c

arpet

b

y

p

ulling

t

he

s

trap

upw

ards,

F

re

move

t

he

p

olystyrene

s

torage

b

ox,

F

un

clip

a

nd

r

emove

t

he

b

ox

c

ontaining

t

he

too

ls.

Access to the tools

Details of the tools Wheel with trim

When removing the wheel

, first

detach t he t rim u sing t he w heelbrace 1

pulling

a

t

t

he

v

alve

p

assage

h

ole.

When refitting the wheel , refit the

trim

s

tarting

b

y

p

lacing

i

ts

c

ut-out

a

t

t

he

va

lve

a

nd

p

ress

a

round

i

ts

e

dge

w

ith

th

e

p

alm

o

f

y

our

h

and.

1.

Wh

eelbrace.

Fo

r

r

emoving

t

he

w

heel

t

rim

a

nd

r

emoving

th

e

w

heel

f

ixing

b

olts.

2.

Ja

ck

w

ith

i

ntegral

h

andle.

Fo

r

r

aising

t

he

v

ehicle.

3.

"B

olt

c

over"

t

ool.

Fo

r

r

emoving

t

he

b

olt

p

rotectors

(

covers)

on a

lloy

w

heels.

4.

So

cket

f

or

t

he

s

ecurity

w

heel

b

olts

(

located

in t

he

g

love

b

ox).

Fo

r

a

dapting

t

he

w

heelbrace

t

o

t

he

s

pecial

se

curity

w

heel

b

olts

(

if

y

our

v

ehicle

i

s

f

itted

wi

th

t

hem). All of these tools are specific to your

vehicle.

D

o

n

ot

u

se

t

hem

f

or

o

ther

pu

rposes.

Never

u

se

a j

ack

o

ther

t

han

t

he

on

e listed for the vehicle by the

manufacturer.

I

f

t

he

v

ehicle

d

oes

n

ot

ha

ve one, contact a CITROËN dealer

or

a q

ualified

w

orkshop

t

o

o

btain

a j

ack

sp

ecified

b

y

t

he

m

anufacturer.

Page 207 of 444

205

DS3_en_Chap08_info-pratiques_ed02-2015

The spare wheel is installed in the boot under

the floor.

Depending

o

n

t

he

c

ountry

o

f

s

ale,

y

ou

w

ill

ha

ve either a "space saver" spare wheel or a

temporary

p

uncture

r

epair

k

it.

For access to it, refer to the "Access to the

tools"

se

ction.

Access to the spare wheel

Fitting the "space-saver"

type spare wheel

If your vehicle is fitted with alloy

wheels, it is normal to notice, when

tightening

t

he

b

olts

o

n

f

itting,

t

hat

t

he

wa

shers do not come into contact with

the

"

space-saver"

t

ype

s

pare

w

heel.

Th

e wheel is secured by the conical

contact

s

ur face

o

f

e

ach

b

olt.

Taking out the wheel

F Unscrew the ye llow c entral b olt.

F Ra ise the spare wheel towards you from

the

r

ear.

F

Ta

ke

t

he

w

heel

o

ut

o

f

t

he

b

oot.

Practical information

Page 208 of 444

DS3_en_Chap08_info-pratiques_ed02-2015

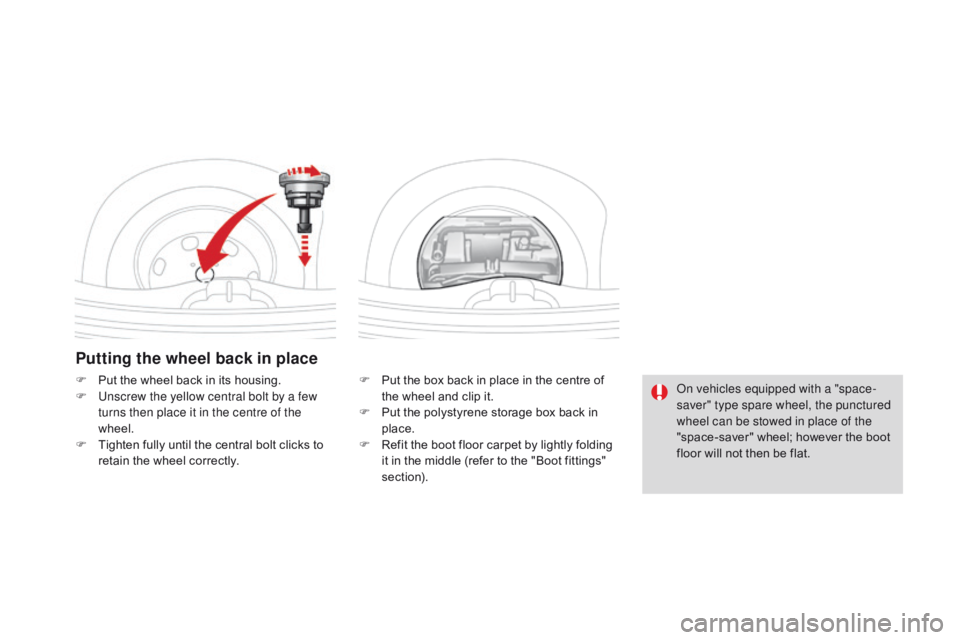

Putting the wheel back in place

F Put the box b ack i n p lace i n t he c entre o f th

e w heel a nd c lip i t.

F

Pu

t

t

he

p

olystyrene

s

torage

b

ox

b

ack

i

n

pl

ace.

F

Re

fit

t

he

b

oot

f

loor

c

arpet

b

y

l

ightly

f

olding

it i

n

t

he

m

iddle

(

refer

t

o

t

he

"

Boot

f

ittings"

sec

tion).

F Pu

t t

he w

heel b

ack i

n i

ts h

ousing.

F Un

screw the yellow central bolt by a few

turns then place it in the centre of the

wheel.

F

Ti

ghten

f

ully

u

ntil

t

he

c

entral

b

olt

c

licks

t

o

re

tain

t

he

w

heel

c

orrectly. On vehicles equipped with a "space-

saver" type spare wheel, the punctured

wheel can be stowed in place of the

"space-saver"

w

heel;

h

owever

t

he

b

oot

fl

oor

w

ill

n

ot

t

hen

b

e

f

lat.

Page 209 of 444

207

DS3_en_Chap08_info-pratiques_ed02-2015

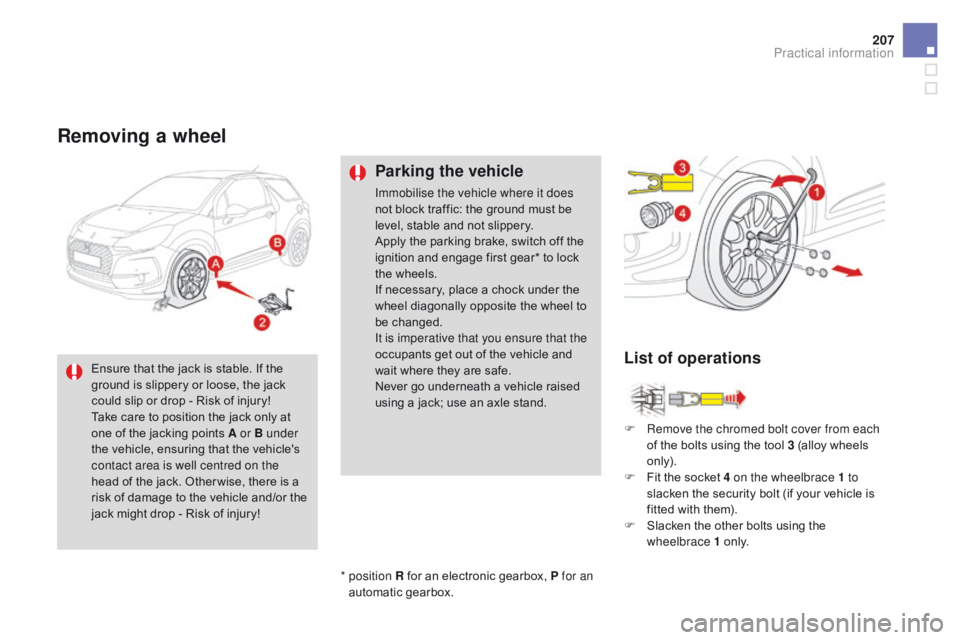

Removing a wheel

Parking the vehicle

Immobilise the vehicle where it does

not block t raffic: t he g round m ust b e le

vel,

s

table

a

nd

n

ot

s

lippery.

Apply

t

he

p

arking

b

rake,

s

witch

o

ff

t

he

ig

nition

a

nd

e

ngage

f

irst

g

ear*

t

o

l

ock

th

e

w

heels.

If

n

ecessary,

p

lace

a c

hock

u

nder

t

he

wh

eel

d

iagonally

o

pposite

t

he

w

heel

t

o

be ch

anged.

It is imperative that you ensure that the

occupants

g

et

o

ut

o

f

t

he

v

ehicle

a

nd

wa

it

w

here

t

hey

a

re

s

afe.

Never

g

o

u

nderneath

a v

ehicle

r

aised

us

ing

a j

ack;

u

se

a

n

a

xle

s

tand.F

Re

move the chromed bolt cover from each

of

t

he

b

olts

u

sing

t

he

t

ool

3 (

alloy

w

heels

on

ly).

F

Fi

t

t

he

s

ocket

4

on the wheelbrace 1 to

slacken

t

he

s

ecurity

b

olt

(

if

y

our

v

ehicle

i

s

fi

tted

w

ith

t

hem).

F

Sl

acken

t

he

o

ther

b

olts

u

sing

t

he

wh

eelbrace 1

o n

l y.

*

p

osition R

f

or

a

n

e

lectronic

g

earbox,

P

for an

automatic

g

earbox.

Ensure

t

hat

t

he

j

ack

i

s

s

table.

I

f

t

he

gr

ound

i

s

s

lippery

o

r

l

oose,

t

he

j

ack

co

uld

s

lip

o

r

d

rop

- R

isk

o

f

i

njury!

Take

c

are

t

o

p

osition

t

he

j

ack

o

nly

a

t

on

e

o

f

t

he

j

acking

p

oints

A

or B

u

nder

the

v

ehicle,

e

nsuring

t

hat

t

he

v

ehicle's

co

ntact area is well centred on the

head

o

f

t

he

j

ack.

O

ther wise,

t

here

i

s

a ri

sk

o

f

d

amage

t

o

t

he

v

ehicle

a

nd/or

t

he

ja

ck

m

ight

d

rop

- R

isk

o

f

i

njury!

List of operations

Practical information

Page 210 of 444

DS3_en_Chap08_info-pratiques_ed02-2015

F Position the f oot o f t he j ack 2 o n t he g round an

d ensure that it is directly below the

front

A

or rear B

j

acking

p

oint

p

rovided

o

n

the

underbody, whichever is closest to the

wheel

t

o

b

e

c

hanged.

On v

ehicles fitted with sill finishers, the

jacking

l

ocation

i

s

i

ndicated

b

y

a m

arking

on t

he

f

inisher.

T

he

j

ack

m

ust

b

e

p

laced

ce

ntrally

i

n

l

ine

w

ith

t

his

m

arking,

a

t

t

he

ja

cking

p

oint

l

ocated

b

ehind

t

he

f

inisher

an

d

n

ot

o

n

t

he

p

lastic

f

inisher

i

tself. F Re

move the bolts and store them in a clean

place.

F

Re

move

t

he

w

heel.

F Ex

tend t he j ack 2 until its head comes into

contact w ith t he j acking p oint A or B u sed. Th

e contact area A or B on the vehicle

must

b

e

e

ngaged

w

ith

t

he

c

entral

p

art

o

f

th

e

h

ead

o

f

t

he

j

ack.

F

Rai

se the vehicle until there is sufficient

space

b

etween

t

he

w

heel

a

nd

t

he

g

round

so t

hat

t

he

s

pare

(

not

p

unctured)

w

heel

c

an

th

en

b

e

f

itted

w

ithout

d

ifficulty.